Sticking A/C or Heat Pump Thermostatic Expansion Valve TEV

Sticking A/C or Heat Pump Thermostatic Expansion Valve TEV

- POST a QUESTION or COMMENT about how to diagnose and repair air conditioning and heat pump systems.

Sticking or jammed thermostatic expansion valves:

In addition to debris, dirt, or icing problems that occur in TEVs or thermostatic expansion valves, sometimes the thermostatic expansion valve on brand new air conditioners may need an extra jolt to get it working, as we explain here.

Page top image provided courtesy of the Toronto engineering, education & home inspection firm Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Sticking Air Conditioner or Heat Pump Thermostatic Expansion Valves at New Installation

At THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR where we list various troubles with thermostatic expansion valves and suggest diagnostic and repair procedures we noted the following:

At THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR where we list various troubles with thermostatic expansion valves and suggest diagnostic and repair procedures we noted the following:

Sticking TEV valves: The TEV and also AEVs depend on a little oil or oil mist flowing along with refrigerant to lubricate the interior of the valve.

Occasionally debris in the refigerant system can cause the TEV to jam, chatter, or fail to perform properly.

But we suspect that a more common cause of TEV valve sticking is the freezing of a droplet of water at the needle valve, holding it stuck. The valve stops working properly.

But as we learned from Ontario reader E.T. and her HVACR installation and service company, TEVs may be "sticky" right out of the box from the manufacturer. At left: a KeepRite™ air conditioner compressor / condensing unit, newly installed.

The installer used a simple "overcharge" procedure to free the TEV as we describe in this reader report.

[Click to enlarge any image]

Reader Question: new KeepRite® air conditioner not working well: does not cool the house

I placed a comment on the InspectApedia website last night about my new air conditioner not working well. Here are the photos you asked for. Our house is 980 square feet with a finished basement. I have closed all the vents in the basement.

We live in Ontario and are having fluctuating temperatures. Today it is 72F outside with an expected high of 85. I turned the air conditioner on yesterday when the outside temp was 65F and the temp inside my house was 78 because it had been a hot day and the air conditioner was not able to bring the temperature down.

I set the thermostat for 72F. It took 5.5 hours to bring the temp down to 76F, which is when we went to bed. Thorough the night it managed to bring the temp down to 72. In the morning I turned the thermostat up to 73 and the air conditioner has not stopped running, even momentarily, since I got up this morning. The couple of times I woke through the night it was running as well (I have a young baby).

I was not given a manual, only an invoice for the unit and the work done. It was installed 4 weeks ago. We had the ducts cleaned 3 years ago and they do need cleaning again - I have an appointment booked for Friday. If you would like to see the emails that were exchanged with the installer I can forward them to you. Thank you very much for getting back to me so quickly. I appreciate that I am able to ask questions this way. - E.T. 7/21/2014

Reply: why doesn't the installer fix their installation SNAFU?

I see in your photos a newly installed air conditioning system that by your description certainly is not cooling. Your additional photo (left) shows that a refrigerant-drier was installed, though I can't tell from the image if it's in the right direction or not. The flow direction is marked plainly on the canister label.

See REFRIGERANT DRIERS & FILTERS.

Something as simple as failure to adequately clean (pull a vacuum) and filter the refrigerant system could cause the system not to cool even if the compressor and air handler themselves seem to be working.

It's usually easy to diagnose a new system by checking refrigerant charge, pressures, temperatures, and current draw. Why didn't the installing company return to fix it? Enlarging your third photograph of the data tag on the KeepRite condenser / compressor unit (shown at below left) gives us more information about this unit.

The Product model number begins with N4A318K ... which is the same as found on Tempstar® R-410A refrigerant air conditioning compressor / condenser units in the N4A3 series. These units use a Copeland® compressor and are factory-charged with R-410A refrigerant.

It's possible that your KeepRite® air conditioner is using the same equipment components, re-branded with the KeepRite® name.

Decoding the Model Data on a KeepRite® Air Conditioning Compressor / Condenser Unit

Since you were given no information whatsoever about your equipment, not even an installation/operation manual we're providing some data here.

Decoding the KeepRite® product number, N4A318KC100, based on TempStar's data (cited below)

- N = "Tempstar Entry" brand ( KeepRite®-branded equipment, according to the manufacturer cited below, uses a product nomenclature beginning with a K, such as KMHA050 H2- HT4A-A)

- 4 = Refrigerant is R-410A

- A = Air Conditioner (H would indicate a heat pump)

- 3 = SEER = 13

- 18 = 18,000 BTUH or 1 1/2 tons of cooling capacity

- K = Voltage code 208/230V - 1- 60 (single phase 60 cycle)

Reader Follow-up: sticking thermostatic expansion valve on new AC installations

I had the oven on for approximately 20 minutes at lunch time. The inside temp has risen and is staying at 76F although it is 72F outside and I have the thermostat set for 73. The air conditioner still has not stopped running. We have two dogs, our ducts do need cleaning as I mentioned before. But we did have it done 3 years ago.

Can this affect the air conditioner functioning to this extent? The unit is obviously working because it did finally bring the temp down through the night and maintained it this morning - but why it's struggling so hard is unclear to me.

The A/C installer did identify the problem and he came back to fix it.

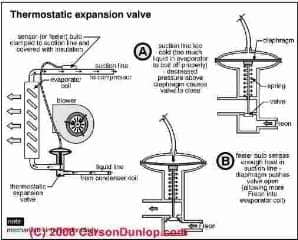

I'm relaying the information that I recall from what he told us so it may not be perfectly clear, but he said the diaphragm on the TY [TEV or Thermostatic Expansion Valve- Editor] valve (??i think) was sticking on the new installs and causing it to not be seated properly.

When he contacted the manufacturer they advised to overcharge the system and force it open further, which would cause it to then close properly and seat the valve. I hope I got the information right, as this seems to be an innate problem with these units and I would hope that this information could be useful to someone else down the road.

I also want to say that I found this website just through a Google search when we were having the issues with the A/C and I was feeling desperate that something had to be wrong and was being told that it probably wasn't.

You provide an invaluable service allowing yourself to be contacted with questions and providing service to others the way you do.

It's a very generous thing to do and do and I, for one, am grateful that you took the time to respond. Thank you very much!

I was very glad that our install person kept coming back and looking into the issue and finally got it fixed.

Reply: Expansion Valve SNAFUs

Indeed even a small amount of dirt or debris in a new refrigeration system can foul up the thermostatic expansion valve causing it to fail to operate properly. If the installer is making an error in cleanliness during initial installation, or if s/he forgets to install the proper refrigerant filter/dryer on the refrigerant lines, or if the refrigerant charge is incorrect the TEV may jam or fail to open and close properly.

Of course it's true that the TEV itself could be defective or water, ice, or debris can prevent it from opening or closing when it should.

The result is failure to release refrigerant at the proper rate into the cooling coil in the air handler. In turn that would allow the air handler to run without adequately cooling the building.

Reader Follow-up: using a refrigerant "overcharge" to clear a stuck TEV

Our air conditioner installer installed an identical unit to ours (a Keeprite) at another customer's house this week and was having the same issues as us. He contacted the manufacturer and was told that there is an issue in that model with a valve not closing properly on installation.

The unit needs to be overcharged which forces the valve open so that it snaps shut. He came tonight to do just that and it seems to be cooling.

I will be able to send more information about the specific valve etc when my husband gets home as he understands it better than I do, but I wanted to send an update to let you know that the problem has been found and in a case anyone writes in with a similar issue.

Reply: watch out for refrigerant overcharging

Watch out: The overcharge needs to be removed lest the compressor motor be destroyed.

See OVER CHARGED of REFRIGERANT, EFFECTS for details.

Watch out: warranty coverage: You should register your product to assure proper warranty protection, and you should obtain the owners or installation manual for your air conditioner from the installer or if that contractor cannot help you, use the contact information we provide above to contact the company.

Our search of the KeepRite websites we found did not provide links to manuals or installation guides for equipment matching your product number.

Reader Follow-up:

You had told me that the overcharge needs to be removed, so I checked and he did remove it at the time.

Company Contact Information for KeepRit®e & TempStar® air conditioning & heat pump product types & series

- KeepRite® Heating & Cooling Products, Website: http://www.keeprite.com/ (At this website the company does not provide an address, company information, nor contact information). The KeepRite website does cite HVAC contractors in West Chester OH, USA, and Toronto, Ontario, Canada. Other contact information for KeepRite® Refrigeration is at http://k-rp.com/node/149, Factory telephone: 1-800-463-9517 Email for Warranty claims: warranty@k-r0pcom Customer Support Email: cs@k-rp.com

The KeepRite® compressor/condenser unit features a two-stage scroll-type compressor motor and the company cites a 10-year warranty. - Tempstar® AC & Heat Pump Systems, International Comfort Products, Lewisburg TN 37091 USA, Website www.tempstardir.com, TempStar® N4A3 Series Product Specifications

Reader Question: how to keep an old TEV Working on a house that was flipped and has many problems

I live in Quincy, IL. Be fore my mother passed away she bought me a small, cheap house that needs some repair I’m on SSI so I have a very limited income. I’m on a 2 year waiting list for the state to weatherize my house. I should have about 18 months left to go!

This house was totally redone 15 years ago by a house flipper and everything they used was, at the very best just low quality contractor type materials and they hid a lot of the problems and just made the house look pretty.

It worked because a lady fell for it and bought it and it just went downhill from then.

I’ve fixed what I can since I got the house and I’m trying to hold out for that 18 months to pass to get the other repairs done but Summer is coming and I’m on three meds that make heat unbearable for me so I need my central air to be working before it gets too hot.

My outside unit needs the capacitor replaced (it’s exploded at the top) but that’s a repair I can do and the cost is low.

The problem I’m having is the previous owner said that the entire AC system would run but not cool so she’d had a service tech in at some point and he found what he said was the problem and showed her husband.

There’s type of thermometer type device inside the lower part of the inside unit that had corrosion on it and he told them it would be over an $80 part or he could pull it out and lightly sand it and put it back for much cheaper. So that’s what they did and the system cooled as it should again until the next year.

They did this themselves for a few years and then just stopped doing it and got window units.

This device looks like a temperature probe and it’s held in with one screw. and a bracket that holds it so the probe looking part can point downward. I’d like to find out what this device is called so I can find out if I can afford to replace it.

It’s obvious I can replace it but myself but not sure I can afford to buy it and I can’t find out a price without knowing what it’s called.

It’s probably something very simple and I sound like an idiot by not having a clue but there’s no number or anything on it that I can find. If you can help me figure this out, I’d greatly appreciate it

I looked through all the photos on your website but I couldn’t find and pics or articles that seemed to even come close.

My laptop has a very small screen and I can’t see too well so I may have just missed it. When the previous owner pointed this thing out to me they said they’d never known what it was called.

Reply: fixing a non-responsive thermostatic expansion valve - the perils of house-flipping in real estate sales

I'm sorry but not surprised to read of the problems left behind when house-flippers get on to a property and perform only cosmetic skin-deep improvements.

Unfortunately in real estate such problems are so widely known and, regrettably, accepted, that the burden is on the house buyer to hire the inspectors needed to have an accurate understanding of the home.

More trouble comes because a home inspection is not invasive: so if a house flipper simply laminates drywall over a horrible mold contamination problem, only an astute inspector who understands subtle clues will come to even suspect such a problem, for example by noticing that trim has been built-out or that wall thicknesses vary.

About your A/C: unfortunately I doubt that you can do the part replacement you are asking about.

** Send me some sharp photos of your AC system and of the part you describe and I can comment further, but I think that

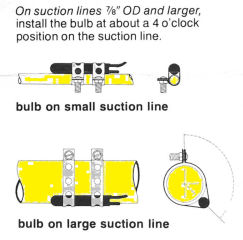

the "thermometer" device you describe is the temperature-sensing end of the TEV or thermostatic expansion valve that monitors the cooling coil temperature and according to the temperature there, opens or closes a valve that meters refrigerant into the coil. This is an essential part of the system. If the TEV has failed the system won't cool.

To read about this device

see EXPANSION VALVES, REFRIGERANT - home

You will find a series of articles about installation and repair of thermostatic expansion valves starting with that one and continuing

with THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR.

If cleaning the sensing bulb and clamping it back in place doesn't get it working, sometimes a service tech will try adjusting the TEV itself - SOME (not all) models have an adjustment screw in the unit base. But watch out: one cannot make an accurate adjustment without using some monitoring equipment that looks at temperature and at refrigerant pressures.

To replace the valve requires opening up refrigerant lines, and to do that requires removing the refrigerant from the system using a refrigerant-recovery machine (we don't just dump those gases into the air), followed by the valve replacement, followed by installing a new refrigerant charge in the system.

All of that work will cost probably hundreds of dollars: the $80. part is probably for the TEV itself but doesn't include the labor nor the refrigerant.

Try cleaning the sensor. If the system won't cool, ask your local air conditioning service company if they can perform a low-cost diagnostic inspection to tell you what the system needs to operate.

If all of the repair costs are significantly more than the cost of a window air conditioner, you may want to consider installing a window A/C as a temporary measure.

Keep me posted.

Question: After about ten minutes the heat pump switches to aux and won't go back to normal unless I reset power

First off my equipment is two York heat pumps. Downstairs unit works fine and the systems are only two years old. Unfortunately the company that installed the units are unwilling to figure out what the issue is so I'm taking it upon myself. I turned AC off and switched to heat at the end of November and almost immediately the system shut off.

I discovered one of the relays in the air handler and the ECP and both fusable links and nest thermostat base fried.

I ordered the parts ordering doubles of each just incase I was only fixing the symptoms. Installed everything and turned the system on. Fan kicks on fine the outdoor unit fires up and the big copper pipe gets warm.

After about ten minutes of run time the system switches to aux and won't go back to normal unless I reset power.

After the outside unit shuts off the big line does cool off and even though I'm reading 118 VAC on the heat strips point to ground it still gets very cold at night. I usually wake up to 58 degrees when requesting 71.

The outside unit does seem to have a bit of a hard start to it and the lights dim inside so I'm thinking I may have a bad starter cap but the fact that it does start up tells me that its not the main problem.

I did also notice that on my downstairs air handler the two 24volt wires are twisted together and the thicker gauge white wire is twisted with an 18 gauge brown wire that goes to the outside unit but my upstairs air handler has all three white wires twisted together.

When I get home this evening I'm going to check to see if maybe they just used a spare wire for the downstairs but it doesn't appear to be that way. Both air handlers appear to be identical in setup with that exception and the outdoor unit for the downstairs is about 2/3 the size as the upstairs unit.

Other then that they appear identical. I'm an aircraft technician by trade so I have some knowledge and have researched my heart out online to try to figure this out.

I put my civilian email address in the CC box. Thank you again for any assistance provided! - Anonymous by private email 2017/12/18

Reply: check for a failing compressor motor, bad capacitor, or a sticking TEV

If your compressor is dimming lights and hard starting the motor is probably failing; I'd agree that it would make sense to try using a new hard-start capacitor to see if you can get a bit more life out if it.

If your compressor is dimming lights and hard starting the motor is probably failing; I'd agree that it would make sense to try using a new hard-start capacitor to see if you can get a bit more life out if it.

I also agree that the starter cap is probably a band-aid on a failing motor. Check the current draw during the startup and when it's running.

Also, if the expansion valve is sticking a compressor can have trouble starting not because of a bad motor but because it's starting against high head pressure.

Photo: a replacement 5-ton capacity TEV distributed by americanhvacparts.com and other vendors.

Reader follow-up: suspect the expansion valve

I wonder if it's not the expansion valve because it runs fine in Cooling mode?

I really appreciate you getting back to me. I did check the wiring at the outside units last night and they are wired identically so now I'm really wondering why they have the big white wire coming off of the ECP going to the small brown wire going to the ourside unit.

My main concern is why the outside unit doesn't keep cycling off and back on. It only cycles the one time and then goes to aux and the aux doesn't appear to be heating well at all because it's colder then my exwife in the morning lol.

I do have voltage sitting on the heat strips. This evening I will check from point to point instead of point to ground to make sure it's dropping the potential. If you have any input I appreciate it and I appreciate you getting back to me.

Reply: check for stuck TEV or stuck reversing valve

You might in fact want to call tech support at the manufacturer for the brand and model unit. I expect you understand as I do that the heat pump will switch to aux when it thinks the outdoor temp is too low or when some other sensor in the system detects that it's not able to produce heat.

That could be from a stuck reversing valve or simply a control or wire that's not switching the valve as it should. Try checking voltage to the reversing valve.

Reader follow-up: problem solved, refrigerant had been over-charged, TEV forced "open"

Thank you for all of you help. I did end up calling a technician out to the house and as it turns out my previous HVAC guy had 15 pounds of Freon in a ten pound system to apparently force the reversing valve open.

On 2020-02-19 - by (mod) - TXV is sticking - what to do

Rebecca

Thanks for a helpful question. To mince words a bit, it's not "normal" for a thermostatic expansion valve or "TXV" to freeze up in the sense that it should not happen in a heat pump or A/C system that is working properly.

But it is the case that that's a common problem.

I suspect that if the TXV jammed and froze once, it's going to do it again... and again ... until someone adds one or more filters onto the refrigerant piping and/or changes out the valve (possibly some can be opened and cleaned).

But IMO your tech was looking out for you by recommending that you try using the system. Even adding a filter can be costly as the refrigerant has to be removed, the system vacuumed, and fittings brazed in place to provide the new filters. So it is reasonable to wait to see how often this problem is occurring,

and to engage in the fantasy - it is a fantasy - that the existing system filter(s) might catch and reduce debris enough that you don't see the same problem again soon.

Keep me posted.

On 2020-02-19 by Rebecca

So I have a hvac system, that was freezing up outside. I called my hvac provider and they asked me to turn it to emergency heat and they would have someone out the next day. When the technician came he switched into heat and he said " the refrigerant pressures and motor amperages are normal.

Ran a couple defrost cycles and no problems. system is operating correctly. the txv could have stuck and caused heat pump to freeze sometimes they do stick for no apparent reason and then operate with no further issues. Bulb was properly placed and refrigerant charge is to factory specifications."

My question is; is this a normal thing to have happen? For reference the temperature on Sunday was mid 50's and the temperature on Monday when he came out was high 60's.

On 2019-11-02 - by (mod) - adjust the refrigerant charge so that the frost line on the cooling coil stops at the end of the coil

Rich:

Typically the installer adjusts the refrigerant charge so that the frost line on the cooling coil stops at the end of the coil ; if you see actual frost outside the coil or on the line outside the air handler then either the refrigerant charge is a bit low (really, low, not high), OR the expansion valve may need adjustment.

But beyond the frost itself, it's not uncommon to see condensation on the suction line along much of its length, particularly when the system is running for the first time or after having been off and where the cold piping is running through very humid air.

To avoid drips and water damage along the suction line's length it's usually covered with insulation.

I'd like to see a photo of the line near the air handler.

On 2019-11-02 by Rich

Just had a new Amana ASXC16 AC installed. Overnight the liquid line got so cold it began to sweat the entire length. Pressures looked good and the unit cools but the liquid line gets cold later and continues to sweat. The inside humidity is steady at 60%.

The installed had me turn off he power to the outside unit as a diagnostic test but after several hours the line is still cold to the touch and sweating. Any help would be greatly appreciated

On 2017-08-14 - by (mod) -

Kehinde

If the TEV is an adjustable model it is possible that opening and closing it a bit might free up a stuck valve but most-likely it needs to be replaced.

On 2017-08-13 by KEHINDE GABRIEL ADEKUSIBE

How to repair stocked TXV

On 2017-07-10 by James Milich

I just had about 7 yrs ago my air conditioner replaced its a carrier 16 seer 3.5 ton ,have not had a problem with it until last week I live in phx AZ were it's very hot n called air condition co they came out a week later it's not cooling ,wen they came out they told my wife it was txv valve is there really a txv on residential unit

On 2017-06-04 - by (mod) -

Steve,

I can make up an answer that would be an example of a problem that would cause the symptom that you described.

Let us suppose that the refrigerant gas leak is actually at the valve that is used to connect test gauges or to insert refrigerant into the system.

In that case taking off the valve cap and connecting a gauge or a refrigerant supply to re charge the system might and fact leave the valve with a bit more debris on the valve.

The technician has not caused the defect but the service call may have Disturbed and existing problem such that the defect is more obvious and more extreme.

On 2017-06-03 by Steve Fox

I think the same thing happened last time. The system was cooling fine and it quit all at once.

The first time it quit two years ago, it stayed on longer and longer, it never completely quit cooling.

Yes, that was two years ago. System has worked fine since then.

He said they all start having issues around seven years old, intimating that working on it is a waste of time because it's worn out.

I guess my real question is how can it hold pressure and then lose it all three days later? The first charge lasted five years, the second two years and the third, three days, at most. I think it dumped it all in less than 10 minutes.

It didn't start staying on longer, like it was low on Freon. I was sitting on the porch reading and it was cycling normally for a couple of hours, then it came on and stayed on. The unit is close to the porch where I was sitting, so it is obvious when it is running. After it ran for half an hour, I came in to see what was wrong and it wasn't cooling.

Is there a pressure relief valve that dumps the Freon if the pressure gets too high?

Thanks for your help, it is appreciated.

On 2017-06-02 - by (mod) - "low on freon" is incomplete diagnosis

Unfortunately, "low on freon" is a sort-of incomplete diagnosis. Since refrigerant is not a consumable, if your system was "low" then there was a leak. That was two years ago?

What your tech did was reasonable in that it's a common practice to just add refrigerant, since the claim is that finding and fixing a small slow leak is quite expensive.

Any pure refrigerant charge would leak out again. That's why the tech tried a stop-leak product. Unfortunately some sources I've consulted warn that stop-leak can also clog or foul a TEV or clog a filter-drier on the system.

I cannot be as smart as your onsite tech. But I sure dislike seeing a leak used as an argument for a complete system replacement - unless there is another expensive problem like a damaged compressor motor. Barring that, I'd look again at whether or not a more-experienced tech can give a shot at finding the leak. Consider that if you replaced the whole compressor/condenser (outdoor) unit, and left the indoor unit alone, you'd still have to either find the leak then or replace all of the refrigerant tubing.

Keep me posted and we may be able to comment further.

On 2017-06-02 by Steve Fox

I have a 2 ton heat pump that is 7 years old. It quit working two years ago and the guy said it was low on Freon, so he put in a pound.

It quit working all at once last Friday. It was cooling and ten minutes later, it wasn't.

We called him out again. This time, he said they system was completely empty, with no Freon and no pressure. He checked it and it held pressure, so he added stop-leak and recharged it. He said next time, the entire system would need replacing. The whole service call took less than an hour.

Today, three days later, same thing happened. It was cooling and ten minutes later it wasn't.

How does all the Freon leak out in such a short period of time, but the system hold pressure?

Did he cut corners on the service? It sounded like he only ran the vacuum pump for 10 minutes and didn't replace the dryer or any other parts.

My house is way up in the rural mountains and it is difficult to even get someone to come look at it.

Does it sound reasonable that I need a new unit without further testing?

Thanks,

Steve Fox

...

Continue reading at THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR - the air conditioning system seems to be "running" but not enough cool air, or no cool air at all is being delivered to the occupied space, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

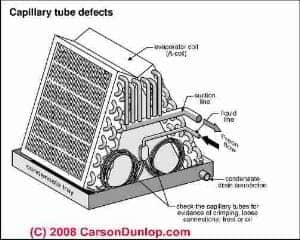

- CAPILLARY TUBES

- CONTROLS & SWITCHES, A/C - HEAT PUMP

- LOST COOLING CAPACITY - air conditioning "running" but not enough cool air, or no cool air

- PRESSURE CONTROLS & SAFETY SWITCHES - home

- REFRIGERANT FLOODBACK, LIQUID SLUGGING - possible result of a failed thermostatic expansion valve.

- REFRIGERANT LEAK DETECTION effects of dirt and moisture on TEVs and capillary tubes. .

- REFRIGERANT METERING CAPILLARY TUBES

- THERMOSTATIC EXPANSION VALVES - home

- THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR

- THERMOSTATIC EXPANSION VALVE TEV STICKING REPAIR

Suggested citation for this web page

TEV / TXV STICKING REPAIR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [2] Thanks to Mark Cramer, Tampa Florida, for assistance in technical review of the "Critical Defects" section and for the photograph of the deteriorating gray Owens Corning flex duct in a hot attic. Mr. Cramer is a Florida home inspector and home inspection educator.

- [3] Thanks to Jon Bolton, an ASHI, FABI, and otherwise certified Florida home inspector who provided photos of failing Goodman gray flex duct in a hot attic.

- [4] Thanks to Scott at SJM Inspect for suggesting this EPA document and for technical editing remarks regarding our air conditioning website, SJM Inspection Service LLC, serves the entire state of CT, sjminspect.com 203-543-0447 or 203-877-4774 5/16/07

- [5] Thanks to Joe Panimondo for technical editing, April 2011

- [15] Singer brand HVAC equipment brand history: Singer was bought by & became the climate control unit of Dallas-based Snyder General Corp. (founded by a former Singer HVAC manager) in 1982. The name Singer was dropped in 1984. In 1984 Snyder General operations included Arcoaire, Comfortmaker, and McQuay. In 1991 Snyder General sold Arcoaire & Comfortmaker to Inter-City Products. In 1994 Snyder General was acquired by Hong Leong Group Malaysia. Snyder General is at 2001 Ross Avenue Dallas, TX 75201

- [16] Lennox air conditioning and heat pump owners manuals for air conditioners, air handlers, furnaces, heat pumps, indoor air quality systems, packaged units, water heaters, zone controls and other controls such as thermostats, are provided by Lennox at http://www.lennox.com/support/manuals.asp

- [23] Air Diffusion Council, 1901 N. Roselle Road, Suite 800, Schaumburg, Illinois 60195, Tel: (847) 706-6750, Fax: (847) 706-6751 - Email: info@flexibleduct.org - www.flexibleduct.org/ -

"The ADC has produced the 4th Edition of the Flexible Duct Performance & Installation Standards (a 28-page manual) for use and reference by designers, architects, engineers, contractors, installers and users for evaluating, selecting, specifying and properly installing flexible duct in heating and air conditioning systems.

Features covered in depth include: descriptions of typical styles, characteristics and requirements, testing, listing, reporting, certifying, packaging and product marking.

Guidelines for proper installation are treated and illustrated in depth, featuring connections, splices and proper support methods for flexible duct. A single and uniform method of making end connections and splices is graphically presented for both non-metallic and metallic with plain ends."

The printed manual is available in English only. Downloadable PDF is available in English and Spanish. - [24] Engineering toolbox properties of water - http://www.engineeringtoolbox.com/water-thermal-properties-d_162.html and email: editor.engineeringtoolbox@gmail.com web search 09/16/2010

- [25] Owens Corning Duct Solutions - www.owenscorning.com/ductsolutions/ - provides current HVAC ductwork and duct insulating product descriptions and a dealer locator. Owens Corning Insulating Systems, LLC, One Owens Corning Parkway, Toledo, OH 43659 1-800-GET-PINK™

- [26] "Flexible Duct Media Fiberglas™ Insulation, Product Data Sheet", Owens Corning - see owenscorning.com/quietzone/pdfs/QZFlexible_DataSheet.pdf

"Owens Corning Flexible Duct Media Insulation is a lightweight, flexible, resilient thermal and acoustical insulation made of inorganic glass fibers bonded with a thermosetting resin." - [27] Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- [28] Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- [29] Refrigeration and Air Conditioning Technology, 5th Ed., William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- [30] Carson Dunlop, Associates, Toronto, have provided us with (and we recommend) Carson Dunlop Weldon & Associates'Technical Reference Guide to manufacturer's model and serial number information for heating and cooling equipment ($69.00 U.S.).

- [33] Histoire de l'Académie royale des sciences avec les mémoires de mathématique et de physique tirés des registres de cette Académie: 363–376. Retrieved 2009-06-19.- Pitot Tubes, Henri Pitot (1732)

- [34] Wikipedia Web: https://www.wikipedia.org/ provided background information about some topics discussed at this website provided this citation is also found in the same article along with a " retrieved on" date. NOTE: because Wikipedia entries are fluid and can be amended in real time, we cite the retrieval date of Wikipedia citations and we do not assert that the information found there is necessarily authoritative.

"Pressure sensor", retrieved 7/16/2012 - [35] "GE Zoneline® Owners Manual and Installation Instructions, Heat/Cool Model 2900, Heat Pump Model 3900", General Electric Corporation, [copy on file].

- [36] "GE Zoneline® Owners Manual and Installation Instructions, Heat Pump Model 5800", General Electric Corporation, [copy on file].

- [37] "Whirlpool WGPH45 Packaged Heat Pump, Product Specifications", Whirlpool Corporation, [copy on file]. Website: www.whirlpoolcomfort.com

- [38] N Lu, YL Xie, Z Huang, "Air Conditioner Compressor Performance Model", U.S. Department of Energy, August 2008, [copy on file as PNNL-17796.pdf] Available to the public from the National Technical Information Service, U.S. Department of Commerce, 5285 Port Royal Rd., Springfield, VA 22161 ph: (800) 553-6847, fax: (703) 605-6900 email: orders@ntis.fedworld.gov online ordering: http://www.ntis.gov/ordering.htm

- [39] Yinger R, R Bravo, and D Martinez. 2006 Air Conditioner Stalling Effects Study/Air Conditioner Testing Procedures. Southern California Edison, Rosemead, California

- [40] Bravo, R, R Yinger, and L Gaillac. 2006. Conditioner Stalling Unit Level Solutions Test Report. Southern California Edison, Rosemead, California.

- [41] Lu N, B Yang and Z Huang. 2008a. Evaluation of Southern California Edison Air-Conditioner Stalling Solutions. PNNL-17686, Pacific Northwest National Laboratory, Richland, Washington.

- [42] Danny S. Parker, John R. Sherwin, Bart Hibbs, "Development of High Efficiency Air Conditioner Condenser Fans", ASHRAE Transactions June 2005, [copy on file as FSEC-CR-1674-05.pdf]

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Complete List of Air Conditioning & Heat Pump Design, Inspection, Repair Books at the InspectAPedia Bookstore.

- Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.