High Head Pressure Diagnostic FAQs

High Head Pressure Diagnostic FAQs

Q&A on causes of high refrigerant pressure

- POST a QUESTION or COMMENT about refrigerant pressure readings in air conditioners, heat pumps, & other refrigeration equipment

Q&A on how to diagnose high head pressures at the air conditioning or heat pump compressor.

This article series explains the causes of high head pressure at an air conditioner or heat pump compressor motor? This article lists twelve causes of high head pressure and explains their causes, effects, and diagnosis.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A/C or Heat Pump Compressor High Head Pressure Diagnostic FAQs

These questions and answers about causes of and cures for high head pressure in an air conditioner or heat pump compressor motor were posted originally

These questions and answers about causes of and cures for high head pressure in an air conditioner or heat pump compressor motor were posted originally

at REFRIGERANT HIGH HEAD PRESSURE DIAGNOSIS - be sure to review the high A/C or heat pump compressor head pressure causes there.

What's the cause of high head pressure reading after compressor is running for hours on a hot day

I have a 2 ton a/c compressor that had a high head pressure reading after running for hours on a hot day, will head pressure reading be lower when first turned on a cooler day? - On 2019-07-10 by Tom H

Reply by (mod) -

Perhaps, Tom; we'd need a bit more diagnosis; for example if an expansion valve (TEV or TXV) is sticking shut that will cause high head pressures;

that might happen sooner when the ambient temperature is lower. Or higher - depending on what's going on inside the TEV.

Can non-compressibles in the refrigerant system cause high head pressure?

Ambient outside air was about 80 while he was taking those measurements.

I have a 3 ton carrier system that is only 2 years old. It is at a rental property so I have not been observing it intensely since installation. While at the property recently, I noticed the system was short cycling and inadequately cooling. Found the drain line was clogged and cleared it.

Regrettably short cycling continued though not quite as often. Observed that float valve was dry at the moment it shut off multiple times. Called my tech.

Tech measured a high side fluctuation from about 410 psi to 550 psi when he first hooked up equipment. Air cooling while active was still 15-17 degrees drop. It must have bumped the high pressure cutoff mark because it cut off on one of those swings.

He drained some coolant and the pressure swing just changed to be 350-490 psi on the high side and about a 10 psi range on the low side centered around 132 or so. The really weird thing was that the low and high side rose and dropped together rather than opposite each other. I would think a TXV closing would cause high side to raise and low side to drop.

When compressor turns on, high side immediately shoots to the max reading, drops over about 40 seconds to the minimum, than quickly shoots to the max again, repeats the slower drop to minimum, ad infinitum.

Condenser coils are clean though long strips of the black paint carrier coated them with did flush out with the foam on one side. Odd. Outside fan working fine. Air circulation through condenser seems good.

Technician who has been in the business many years (at least a couple of decades we've known him) says he's never seen this before where it was not overcharge or a blocked condensor or evaporator. He is talking about just starting to replace things starting with the lines (on the possibility of blockage).

My reading says possible non-compressibles in system? Why does high and low side rise and fall together instead of opposite of each other? Would think any form of blockage would be opposite. - On 2019-07-09 by Rhett

Comment by (mod) - You wouldn't know if you had abnormally High head pressure unless ...

Thanks for the important question, Rhett, that gives me a chance to clear this up.

You wouldn't know if you had abnormally High head pressure unless that problem cause the compressor motor or other components to actually fail.

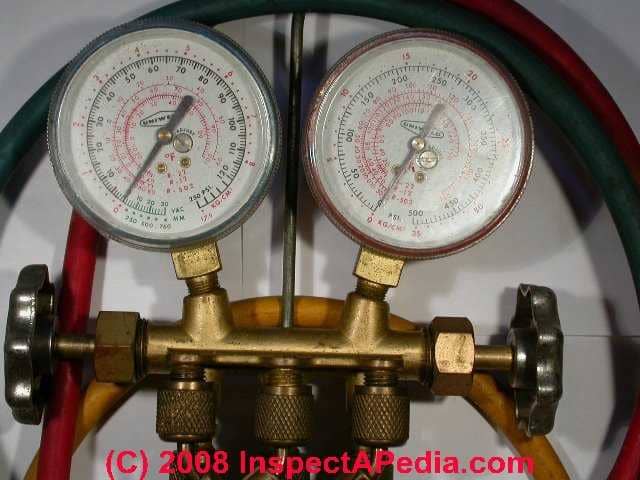

The service technician however can measure the high side refrigerant pressure and note if it's at an abnormal level.

To do that requires a special gauge set and some training on how to make the connections without either injuring yourself or damaging the system.

How do I know if my air conditioner or heat pump system head pressure is too high?

What is the rule of thumb for head pressure

How can I know if my head pressure is excessively high - On 2019-06-24 by Bernard Bailey

Reply by (mod)

If the A/C or heat pump compressor system head pressure exceeds the normal range for your particular refrigerant then it's probably too high.

Details of how to make this diagnosis are

at REFRIGERANT HIGH HEAD PRESSURE DIAGNOSIS

and

at REFRIGERANT PRESSURE READINGS & CHARTS - home you can see what are typical pressure readings for your system and the refrigerant it uses.

Trane packaged system goes out on high head pressure

I have a trane package unit that goes out on high head it did it once while I was at the unit the suction is 135 and the head is 375 when I’m there R410 freon the guy said it goes on and off about 3 times - On 2019-02-11 by Mike

Reply by (mod) -

Mike

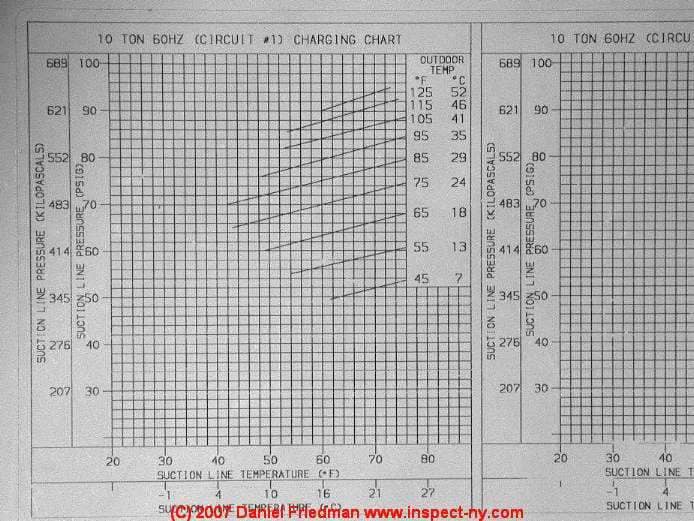

at REFRIGERANT PRESSURE READINGS & CHARTSwe note (and you probably know better than I) that making sense of any refrigerant pressure reading requires also a note of the ambient temperature.

If we take 75°F as an example point, R410 low side typical pressure would be about 120 psi and the high side between 410-420 psi.

Your high side is a little low.

I would start by checking the TXV / TEV adjustment.

Stumped about finding out why head pressure is over 400 psi

Working on a Trane 10 ton split R22.

Situation Head pressure starts out normal but slowly creeps up and up until breaker trips. Indoor coils are 4 rows thick. Yesterday I chemically cleaned indoor coil as this was performed last year as well.

Coils dont look dirty. Blower belt and direction of blower are good.

It is approx 45 degrees outside. Indoors 70. It just went off on high pressure when it reached 400 psig. Suction stays steady at 55 psig. Past history is Circuit breaker would trip occasionlly and once reset would stay on for long periods ( AC mode).

We have been handling this store for a long time but last year another contractor came out and no one knows what exactly he did. When I came out after them, Ihad to dump alot of refrigerant. It was grossly overcharged.

3 years ago the indoor TXV was replaced. - On 2019-02-08 by Howard Haraway

Reply by (mod) -

I note that the TXV was replaced but often that's the explanation for the head pressure creep you describe.

The TXV could also be freezing up. Did you try adjusting it at all?

Another less likely candidate might be a clogged filter-drier. Or ... one of the other shotgun causes listed in thearticle REFRIGERANT HIGH HEAD PRESSURE DIAGNOSIS.

Watch out: dumping refrigerant, that is releasing it to the atmosphere is worse than bad for the environment, it's also illegal. When refrigerant must be removed from a system it ought to be taken into a refrigerant recovery system.

Compressor unit pressures going to over 550 psi: What do I check?

My outside unit high pressure increases from about 325 psi to 550+ psi or so before the high pressure switch cuts the unit off.

Takes an hour and a half. I have cleaned the condensor coils good so that is not the problem. What is next check? - by Ron

Reply by (mod) -

Check for a sticking or malfunctioning thermostatic expansion valve

Troubleshooting an R-22 Lennox cooling system

I'm having an issue with an old Lennox package unit and was hoping I could get some feedback into a possible solution and/or to see if I'm diagnosing correctly.

So I work at a school district and get a call about leaving water through ceiling tiles, I find its a package unit on the roof and looks like it has a stopped up condenstation line.

Blew it out and everything started draining correctly, problem was there was a whole lot of water around the unit on the roof for just simple coil condensation, so I take the evaporator door off to check system.

Sure enough is got a frozen coil, so I let it thaw a few hours with the blower running.

Come back to check pressures while unit is running and initially everything looks ok, but then my suction pressure started lowering slowly.

I shoot a quick burst of R-22 in it and addiction gauge shows full for a good 30 seconds until the needle lists back to where it was before.

I went ahead and checked filters, not too bad but I remove them anyway. Seems to help the pressure minimally, but suction was not where I wanted it.

Keep in mind this whole time has pressure hasn't changed at all, maintaining about 275 psi (~125 degree saturation temp) which looked good to me since it was 95 degrees outside.

I went ahead and pulled TXV bulb off of the pipe to open up the valve and again seemed to help some, but not much. I'm wondering maybe if that's a sure sign of a bad TXV since it didn't change the suction pressure dramatically.

I am also curious about the check valve possibility because the suction pressure would sort of flutter as ot was going down, would drop about 2 psi then back up 1, then drop 2 again and back up 1 again and would repeat that as it kept lowering. If that may be the problem, how do you check that?

Thanks ahead of time for any help you can give me. This one's kind of a learning project for me since school is out for summer and the room isn't a high priority. - by Joey V -

Reply by (mod) -

Joey,

I am not the smartest TEV in the box but to me it looks as if the TEV is sticking closed, perhaps from debris clogging or from icing.

If the TEV is an adjustable unit I might try turning the adjustment screw back and forth to see if that frees up a bit of crud that might then get caught downstream by a filter at the compressor, or I might just tap the TEV to see if it frees up. Else I suspect it needs to be replaced.The clue I'm keying off of is your observation that the suction pressure started lowering slowly.

A TEV that is sticking closed might lower pressure on the suction side - perhaps because it's icing up internally if not clogging from debris.

The iced coil could be from low refrigerant and the same icing might jam the TEV. I feel as if I"m shotgunning a bit here: if there is a refrigerant leak we'll see first coil icing and maybe TEV icing, but ultimately the icing problem will disappear because when we lose enough refrigerant there is no more cooling happening at the coil.

I've read that a constriction in the liquid refrigerant line would have the same effect as a TEV that's not metering enough refrigerant: mimicking a low refrigerant charge (probably a leak).An ACHR news article back in 2002 pointed out causes of a restriction in the liquid line including:

a clogged (dirty) filter drier,

dirt, debris clogging the TEV (TXV) inlet screen,

a kink in the liquid line,

or an excess-solder blob restricting the line.

Of these restrictions, some would have been present since "new" like the solder blob while others (debris clogging the TEV or a kink in refrigerant line or a clogged filter-drier occur later over the service life of the equipment.

- Tomczyk, "Diagnosing A Restricted Liquid Line Can Be Tricky", ACHR News 12/02/2002 http://www.achrnews.com/articles/90784-diagnosing-a-restricted-liquid-line-can-be-tricky

Symptoms of restrictions include (this isn't the whole list, you'll want to see the article)

- higher than normal discharge temperatures at the condenser (it's refrigerant starved)

- low pressure in the evaporator

- bubbles in the sight glass (maybe)

- low current draw - this is counter-intuitive to some but in fact when any pump (ac compressor or well pump) is starved for liquid its pumping mechanism encounters less physical resistance so its driving motor will draw lower current

- short cycling low pressure control

I would add oil slugging or a blob of oil that restricts a refrigerant line without blocking it entirely (probably a design problem)Followup by Joey V - TXV was first thing I was going to check,

Ok, ya TXV was first thing I was going to check, figure if I can't get it to work by adjusting our knocking it then I'll replace that and the liquid line filter at the same time.

While I've got you here, I've got another one I'm doing here. I have a split system heat pump that will run right for a while but then the head pressure shoots up dramatically and the cutoff switch kills the condenser unit.Our lead here says it looks like a blockage in the line (he suggests changing both TXVs and the liquid line drier), but I've heard that your pressures actually go down with a blockage as if you were pumping the system down.

Just wanted to get a second opinion before I start taking the system apart lol.

Actually that article you linked was very informative on the whole subject.

I'm thinking the split system problem isn't going to be a blockage, maybe non condensibles (haven't run across that yet as I'm only a year in but have heard about it in class) or something else?

Would overcharge be a possible cause for that as well? If so I need to take some superheat and subcooling readings on that... Again, any help is appreciated, and thanks for your first reply.

Question: short cycling A/C heat pump at 10 second interval

I have a 4yr old American Standerd a/c heat pump unit. cycles every 10sec. tech serviced 12/06/2014 had to shut unit down01/20/2015. live on a island only way to get here in winter is by plane. expensive! put gauge on high side,unit off temp out side 20deg f read 50#psi - Ed

Reply: starty by turning off the system

Ed you are right to shut off the system; it may be that at low outside temp the unit wants to switch to backup heat anyway.

Short cycling could be a shot or frozen compressor, a burned out compressor base heater, a failed start/run capacitor, a failed relay or control board, a frozen expansion valve that's causing a high pressure safety switch to shut off the system, or something else. With just your note I'm doubtful one could actually diagnose the system.

Is your backup heat running?

Start by checking the control relays and check for a clogged or frozen TEV

...

...

Continue reading at REFRIGERANT HIGH HEAD PRESSURE DIAGNOSIS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- LOST COOLING CAPACITY

- PRESSURE CONTROLS & SAFETY SWITCHES

- REFRIGERANT CHARGING PROCEDURE

- REFRIGERANT GASES & PIPING - home

Suggested citation for this web page

REFRIGERANT HIGH HEAD PRESSURE DIAGNOSTIC FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- Refrigeration and Air Conditioning Technology, 5th Ed., William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- Carson Dunlop, Associates, Toronto, have provided us with (and we recommend) Carson Dunlop Weldon & Associates'Technical Reference Guide to manufacturer's model and serial number information for heating and cooling equipment ($69.00 U.S.).

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.