Manufactured Home & Mobile Home Tie-Downs & Stabilizing Systems

Manufactured Home & Mobile Home Tie-Downs & Stabilizing Systems

Tie-Down Specifications & HUD Wind Zone Maps, Wind Design Pressures, Roof Live Load Specifications

- POST a QUESTION or COMMENT about wind & storm protection for mobile homes & multiwides using tie downs or anchors.

Mobile home stabilizing systems & tie down requirements for doublewides, mobile homes, multiwides, & trailer.

Here we describe defects commonly found in the stabilizing systems, cables, & tie downs for wind & storm damage resistance of mobile homes, doublewides, multiwides, trailers, risking lack of resistance to wind or storm damage.

We include HUD Specifications for wind zone data, design loads, roof loads & tie-down specifications to protect manufactured homes and mobile homes or trailers in high wind areas.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Tie Downs & Stabilizing Systems for Mobile Homes

Mobile home, trailer, singlewide, or doublewide stabilizing systems are required to prevent these homes from being flipped over or simply blown away during hurricanes and other severe storms.

Mobile home, trailer, singlewide, or doublewide stabilizing systems are required to prevent these homes from being flipped over or simply blown away during hurricanes and other severe storms.

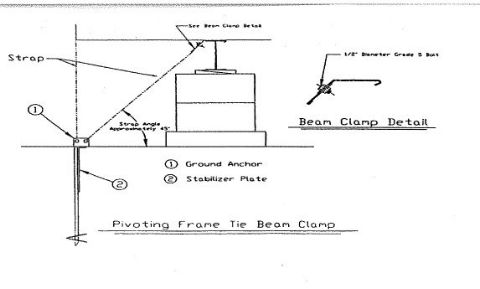

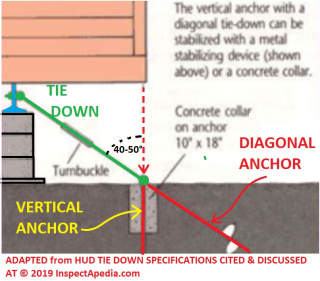

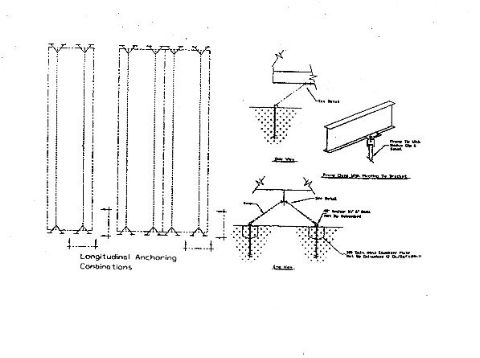

A stabilizing system consists of strapping that secures the mobile home's frame to anchors set into the ground as shown in this HUD illustration of a diagonal tie-down using a vertical anchor. Adding to HUD's confusing terminology the same illustration shows a second anchor installed diagonally. [colored annotations are ours.]

You will see that the tie down in this installation connects between the top of the pier under the mobile home, through a cable-strap and to a pair of anchors to secure the tie-down system. Other under-home tie down designs are illustrated below.

Not all mobile home tie-downs connect the pier or frame to earth-set anchors.

For certain homes, as we will explain here, the strapping or anchoring system may instead have to extend over the home's roof and then connect to anchors on each side of the home rather than connecting between the home's floor frame and anchors.

[Click to enlarge any image]

Source: HUD TIE DOWN REQUIREMENTS for MOBILE HOMES [PDF] retrieved 2019/11/24, original source: http://wchapa.org/wp-content/uploads/2013/02/Tie-Downs.pdf

Definitions of Tie-Downs or Stabilizing Systems for Manufactured / Mobile HOmes

- Stabilizing Devices: all components of the anchoring & support systems

- Support System: combination of footings, piers, caps, shims that support the home

- Anchoring System: system to resist overturning and lateral movement

- Anchoring Equipment: combination of straps, cables, turnbuckles, chains and tensioning devices.

- Anchor: device secured in the ground (Screw or other)

After the very extensive damage and flooding caused by Hurricane Irma in Florida in 2017, the New York Times reported that a number of Florida mobile homes had survived the Category 4 hurricane, most likely due to both the rapid decline in the storm's strength as it moved across the state but

also due to "... toughened construction and installation regulations for mobile homes ...". - Treaster, Joseph B., Henry Fountain, "Stricter Regulations, and Depleted Storm, May Have Helped Save Mobile Homes", The New York Times, 15 September 2017 p. A14.

Above, illustrating

The New York Times reporters noted that increased building standards put in place in Florida after Hurricane Andrew (August 1992) and mobile homes built to those new standards meant that homes had a significantly improved survival rate.

While carports and awnings blew to smithereens and some building siding and roof shingles were lost, fewer homes in Key Largo Florida, about ten percent, suffered significant roof damage. (Those homes suffered significant water damage though.)

It appears likely that the requirement for multiple anchor cables including over-roof cabling added after Hurricane Andrew protected many mobile or manufactured homes in the area.

Illustration: a simpler vertical anchor and diagonal tie down connected to an anchor set below the perimeter of the mobile home. Source: HUD Op. Cit.

Illustration above: six types of anchors used with mobile home tie-down or anchoring systems, illustrated in the HUD document cited above and again at the end of this article.

The concrete deadman anchor at left or anchors in concrete slab are installed at time of slab or tie-down construction; the auger anchor is turned into the earth like a giant screw; the drive anchor and hard-pack anchor are driven into the earth. Just which type of tie-down anchor is suitable for a specific mobile home or doublewide depends chiefly on soil conditions.

Inspection Points for Mobile Home Anchoring Systems

Watch out: when working under a mobile home, manufactured home, or any tight crawl space, there may be serious health and safety hazards. More than one reader have reported getting an electrical shock while working under a mobile or manufactured home.

Watch out: when working under a mobile home, manufactured home, or any tight crawl space, there may be serious health and safety hazards. More than one reader have reported getting an electrical shock while working under a mobile or manufactured home.

Hazards in these crawl areas are outlined

at MOBILE HOME CRAWL SPACES and also

- Inadequate piers, incomplete tie-downs:

This mobile home frame (photo at left) has been set on dry-laid concrete blocks, with plywood shims. But the blocks rest directly on soil. This is not a reliable support system and may not be permitted by local building codes.

The tie-down cables are in place but we could not find that their free end was connected to anything. - Tie down materials

for mobile homes, trailers, double-wides: cable, chain, strap and tensioning device. - Diagonal

tie downs for mobile homes,

or frame straps, at 45 deg. angle attach to main frame at one end and to ground at other to resist lateral movement; Ground anchor should be about at same angle as the strap.

Our photo shows that although this trailer has been placed on a concrete slab foundation, it still rests on its wheels and on temporary jack stands. No piers, no tie-downs, no permanent support was provided.

Our photo shows that although this trailer has been placed on a concrete slab foundation, it still rests on its wheels and on temporary jack stands. No piers, no tie-downs, no permanent support was provided.

- Tie downs for mobile homes may be vertical.

- Diagonal tie downs for

double-wide units

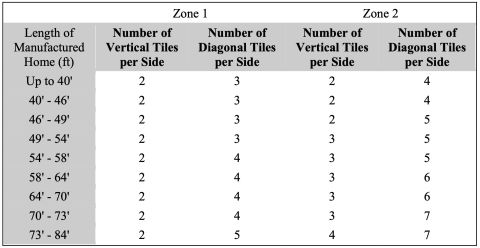

are required only at outside rails of each unit; Vertical straps or ground straps resist uplift and overturn, required only for hurricane or wind zones. - The number and placement of tie downs f

or mobile homes and trailers depends on the wind zone in which the home is located and the length of the structure. For example, a 65' trailer would need 2 to 3 vertical tie downs per side, or 4 to 6 tie downs per side if diagonal tie downs are used, depending on which wind zone it's in. - Connection requirements

for mobile home and trailer tie downs: the mobile home tie down is connected to the steel I-beam at specific locations provided by the manufacturer; typically strap wraps around the I-beam. - Tie downs for mobile homes, trailers, double-wides

are usually expected to be placed and connected according to details provided in the mobile home installation manual (have you ever seen one?). If you know your mobile home or trailer model name and perhaps serial number, you may be able to contact the mobile home manufacturer to ask for an installation manual.

Watch out: HUD-7584 prohibits dependence on screw-in type tie-down anchors commonly used in manufactured home anchorage systems.

HUD Codes on Manufactured & Mobile Home Tiedown Systems for Wind & Earthquake Damage Protection

- CFR Title 24, Vol 5 Subtitle B, CHAPTER X—OFFICE OF ASSISTANT SECRETARY FOR HOUSING—FEDERAL HOUSING COMMISSIONER, DEPARTMENT OF HOUSING AND URBAN DEVELOPMENT (INTERSTATE LAND SALES REGISTRATION PROGRAM) Subtitle B—Regulations Relating to Housing and Urban Development (Continued) parts 1710, 1715, 1720, retrieved 2019/11/24 original source: www.gpo.gov/fdsys/pkg/CFR-2001-title24-vol5/pdf/CFR-2001-title24-vol5-subtitleB.pdf

- HUD TIE DOWN REQUIREMENTS for MOBILE HOMES [PDF] retrieved 2019/11/24, original source: http://wchapa.org/wp-content/uploads/2013/02/Tie-Downs.pdf

- HUD 4150.2, CHG-1 on MANUFACTURED HOMES [PDF] U.S. HUD, retrieved 2022/04/07

Excerpt: The appraiser must receive a copy of the design engineer's inspection of the foundation from the mortgagee. - ILGA, TITLE 77: PUBLIC HEALTH CHAPTER I: DEPARTMENT OF PUBLIC HEALTH SUBCHAPTER q: MOBILE HOMES PART 870 MANUFACTURED HOME INSTALLATION CODE SECTION 870.220 TIEDOWN INSTALLATION REQUIREMENTS [PDF] Illinois General Assembly, - retrieved 2022/054/07 original source https://www.ilga.gov/commission/jcar/admincode/077/077008700E02200R.html

- Tie Down Eng. Co., MANUFACTURED HOOUSING ANCHOR INSTALLATION INFORMATION [PDF] (2009),TIE DOWN ENGINEERING 255 Villanova Drive SW Atlanta, GA 30336 USA,

www.tiedown.com (404) 344-0000 Fax (404) 349-0401 , retrieved 2022/04/07 original source: https://mobilehomepartspro.com/images/categories/TieDowns/installation.pdf - Tie Down Mfg., Co., TIE DOWN MANUFACTURED HOUSING INSTALLATION MANUAL [PDF] Tie Down, Manufactured Housing Products Division, 605 Stonehill Drive SW, Atlanta, Georgia 30336 USA Tel: 800-241-1806 • 404-344-0000 Web: www.tiedown.com ISO 9001:2015 Certification retrieved 2022/04/07, original source: https://www.tiedown.com/wp-content/uploads/pdf/d12.pdf

- MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARDS, Part 3280 contains 10 subparts pertaining to General (data plate and certification contents and locations), Plans (dimensions, exits, etc), Fire Safety, Body and Frame, Testing, Thermal Protection, Heating/Cooling and venting systems, Electrical, and Transportation (axles, springs, drawbar).

- MFO, MANFACTURED HOME INSTALLATION MANUAL [PDF] (2008) The Manufactured Housing Research Alliance, 1655 Fort Myer Dr, Arlington, VA 22209 | 703-558-0400 | info@mfghome.org retrieved 2022/04/07 original source: http://www.manufacturedhousing.org/wp-content/uploads/2016/12/Model-Mfg-Installation-Manual_APR_15_09.pdf

- NEW YORK STATE MANUFACTURED HOUSING LAW [PDF] New York State Department of Licensing,

Excerpts below describe wind zone specifications & requirements for manufactured homes.

HUD Wind Zone Map for Manufactured Housing

[Click to enlarge any image]

Part 3280 (the document link just above) discusses preemption of state laws, among other things, and requires a new unit to be delivered with a "consumer manual" containing required information about the unit.

Thanks to NHFireBear for this update, April 2015. Retrieved 9 April 2015, original source: www.gpo.gov/fdsys/pkg/CFR-2001-title24-vol5/pdf/CFR-2001-title24-vol5-subtitleB.pdf [note this is a very large PDF that contains other sections.

Our live link above has excerpted the Manufactured Home standards section from the HUD document Ed.]

Excerpting from the above:

§3280.305 Structural design requirements [for Manufactured Housing]

(a) General.

Each manufactured home shall be designed and constructed as a completely integrated structure capable of sustaining the design load requirements of this standard, and shall be capable of transmitting these loads to stabilizing devices without exceeding the allowable stresses or deflections.

Roof framing shall be securely fastened to wall framing, walls to floor structure, and floor structure to chassis to secure and maintain continuity between the floor and chassis, so as to resist wind overturning, uplift, and sliding as imposed by design loads in this part.

Uncompressed finished flooring greater than 1/8 inch in thickness shall not extend beneath load-bearing walls that are fastened to the floor structure.

(b) Design loads for Mobile Home Tie Downs & Anchoring Systems

(1) Design dead loads.

Design dead loads shall be the actual dead load supported by the structural assembly under consideration.

(2) Design live loads.

The design live loads and wind and snow loads shall be as specified in this section and shall be considered to be uniformly distributed.

The roof live load or snow load shall not be considered as acting simultaneously with the wind load and the roof live or snow load and floor live loads shall not be considered as resisting the overturning moment due to wind.

(3) When engineering calculations are performed,

allowable unit stresses may be increased as provided in the documents referenced in §3280.304 except as otherwise indicated in §§3280.304(b)(1) and 3280.306(a).

(4) Whenever the roof slope does not exceed 20 degrees,

the design horizontal wind loads required by §3280.305(c)(1) may be determined without including the vertical roof projection of the manufactured home.

However, regardless of the roof slope of the manufactured home, the vertical roof projection shall be included when determining the wind loading for split level or clerestory type roof systems.

(c) Wind, snow, and roof loads—(1) Wind loads—design requirements for Mobile Home Anchors

(i) Standard wind loads (Zone I).

When a manufactured home is not designed to resist the wind loads for high wind areas (Zone II or Zone III) specified in paragraph (c)(1)(ii) of this section, the manufactured home and each of its wind resisting parts and portions shall be designed for horizontal wind loads of not less than 15 psf and net uplift load of not less than 9 psf.

(ii) Wind loads for high wind areas (Zone II and Zone III).

When designed for high wind areas (Zone II and Zone III), the manufactured home, each of its wind resisting parts (including, but not limited to, shear walls, diaphragms, ridge beams, and their fastening and anchoring systems), and its components and cladding materials (including, but not limited to, roof trusses, wall studs, exterior sheathing, roofing and siding materials, exterior glazing, and their connections and fasteners) shall be designed by a Professional Engineer or Architect to resist:

(A) The design wind loads for Exposure C specified in ANSI/ASCE 7–88, ‘‘Minimum Design Loads for Buildings and Other Structures,’’ for a fifty-year recurrence interval, and a design wind speed of 100 mph, as specified for Wind Zone II, or 110 mph, as specified for Wind Zone III (Basic Wind Zone Map); or

(B) The wind pressures specified in the following table:

HUD Table of Design Wind Pressures for Manufactured Housing § 3280.305

[Click to enlarge any image]

(2) Wind loads—zone designations.

The Wind Zone and specific wind design load requirements are determined by the fastest basic wind speed (mph) within each Zone and the intended location, based on the Basic Wind Zone Map, as follows:

(i) Wind Zone I.

Wind Zone I consists of those areas on the Basic Wind Zone Map that are not identified in paragraphs (c)(2)(ii) or (iii) of this section as being within Wind Zone II or III, respectively.

(ii) Wind Zone II.....100 mph - list of Wind Zone II cities, counties, parishes by U.S. State

The following areas are deemed to be within Wind Zone II of the Basic Wind Zone Map:

Local governments: The following local governments listed by State (counties, unless specified otherwise):

Alabama: Baldwin and Mobile.

Florida: All counties except those identified in paragraph (c)(1)(i)(C) of this section as within Wind Zone III.

Georgia: Bryan, Camden, Chatham, Glynn, Liberty, McIntosh.

Louisiana: Parishes of Acadia, Allen, Ascension, Assumption, Calcasieu, Cameron, East Baton Rouge, East Feliciana, Evangeline, Iberia, Iberville, Jefferson Davis, LaFayette, Livingston, Pointe Coupee, St. Helena, St. James, St. John the Baptist, St. Landry, St. Martin, St. Tammany, Tangipahoa, Vermillion, Washington, West Baton Rouge, and West Feliciana.

Maine: Hancock and Washington.

Massachusetts: Barnstable, Bristol, Dukes, Nantucket, and Plymouth.

Mississippi: George, Hancock, Harrison, Jackson, Pearl River, and Stone. North Carolina: Beaufort, Brunswick, Camden, Chowan, Columbus, Craven, Currituck, Jones, New Hanover, Onslow, Pamlico, Pasquotank, Pender, Perquimans, Tyrrell, and Washington. South Carolina: Beaufort, Berkeley, Charleston, Colleton, Dorchester, Georgetown, Horry, Jasper, and Williamsburg.

Texas: Aransas, Brazoria, Calhoun, Cameron, Chambers, Galveston, Jefferson, Kenedy, Kleberg, Matagorda, Nueces, Orange, Refugio, San Patricio, and Willacy.

Virginia: Cities of Chesapeake, Norfolk, Portsmouth, Princess Anne, and Virginia Beach.

(iii) Wind Zone III.....110 mph - list of Wind Zone III cities, counties, parishes by U.S. State

The following areas are considered to be within Wind Zone III of the Basic Wind Zone Map:

(A) States and Territories:

The entire State of Hawaii, the

coastal regions of Alaska (as determined by the 90 mph isotach on the ANSI/ASCE 7–88 map), and

all of the U.S. Territories of American Samoa, Guam, Northern Mariana Islands, Puerto Rico, Trust Territory of the Pacific Islands, and the United States Virgin Islands.

(B) Local governments: The following local governments listed by State (counties, unless specified otherwise):

Florida: Broward, Charlotte, Collier, Dade, Franklin, Gulf, Hendry, Lee, Martin, Manatee, Monroe, Palm Beach, Pinellas, and Sarasota.

Louisiana: Parishes of Jefferson, La Fourche, Orleans, Plaquemines, St. Bernard, St. Charles, St. Mary, and Terrabonne.

North Carolina: Carteret, Dare, and Hyde counties..

(iv) Consideration of local requirements.

For areas where local building code requirements exceed the design wind speed requirements of these standards,

§ 3280.305 the Department will consider the adoption through rulemaking of the more stringent requirements of the State or local building authority.

Manufactured & Mobile Home Wind Protection Standards & Codes

Full details are at PART 3280—MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARDS [PDF] newer copy retrieved 2017/07/13 - faster-loading

Excerpts are below.

§3280.306 Windstorm protection.

(a) Provisions for support and anchoring systems.

Each manufactured home shall have provisions for support/anchoring or foundation systems that, when properly designed and installed, will resist overturning and lateral movement (sliding) of the manufactured home as imposed by the respective design loads.

For Wind Zone I, the design wind loads to be used for calculating resistance to overturning and lateral movement shall be the simultaneous application of the wind loads indicated in §3280.305(c)(1)(i), increased by a factor of 1.5.

The 1.5 factor of safety for Wind Zone I is also to be applied simultaneously to both the vertical building projection, as horizontal wind load, and across the surface of the full roof structure, as uplift loading.

For Wind Zones II and III, the resistance shall be determined by the simultaneous application of the horizontal drag and uplift wind loads, in accordance with §3280.305(c)(1)(ii).

The basic allowable stresses of materials required to resist overturning and lateral movement shall not be increased in the design and proportioning of these members. No additional shape or location factors need to be applied in the design of the tiedown system. The dead load of the structure may be used to resist these wind loading effects in all Wind Zones.

(1) The provisions of this section shall be followed and the support and anchoring systems shall be designed by a

Registered Professional Engineer or Architect.

(2) The manufacturer of each manufactured home is required to make provision for the support and anchoring systems but is not required to provide the anchoring equipment or stabilizing devices.

When the manufacturer's installation

instructions provide for the main frame structure to be used as the points for connection of diagonal ties, no specific

connecting devices need be provided on the main frame structure.

(b) Contents of instructions [for mobile home stabilizing devices]

(1) The manufacturer must provide printed instructions

with each manufactured home

that specify the location and required capacity of stabilizing devices on which the home's design is based.

The manufacturer must identify by paint, label, decal stencil, or other means: the location of each column support pier location required along the marriage line(s) of multisection manufactured homes; each pier location required along the perimeter of the home;

each required shear wall pier support; and any other special pier support locations specified in the manufacturer's printed instructions. Such identifications must be visible after the home is installed.

The manufacturer must provide drawings and specifications, certified by a registered professional engineer or architect, that indicate at least one acceptable system of anchoring, including the details or required straps or cables, their end connections, and all other devices needed to transfer the wind loads from the manufactured home to an anchoring or foundation system.

(2) For anchoring systems, the instructions shall indicate:

(i) The minimum anchor capacity required;

(ii) That anchors should be certified by a professional engineer,

architect, or a nationally recognized testing laboratory

as to their resistance, based on the maximum angle of diagonal tie and/or vertical tie loading (see paragraph (c)(3) of this

section) and angle of anchor installation, and type of soil in which the anchor is to be installed;

(iii) That ground anchors are to be embedded

below the frost line, unless the foundation system is frostprotected in

accordance with §§3285.312(b) and 3285.404 of the Model Manufactured Home Installation Standards in this chapter.

(iv) That ground anchors must be installed to their full depth,

and stabilizer plates must be installed in accordance with

the ground anchor listing or certification to provide required resistance to overturning and sliding.

(v) That anchoring equipment should be certified

by a registered professional engineer or architect to resist these

specified forces in accordance with testing procedures in ASTM D395397, Standard Specification for Strapping, Flat Steel

and Seals (incorporated by reference, see §3280.4).

(c) Design criteria for mobile home tie downs or stabilizers

The provisions made for anchoring systems shall be based on the following design criteria for

manufactured homes.

(1) The minimum number of ties

provided per side of each home shall resist design wind loads required in

§3280.305(c)(1).

(2) Ties shall be as evenly spaced

as practicable along the length of the manufactured home, with not more than two

(2) feet openend spacing on each end.

(3) Vertical ties or straps shall be positioned at studs.

Where a vertical tie and a diagonal tie are located at the same

place, both ties may be connected to a single anchor, provided that the anchor used is capable of carrying both loadings,

simultaneously.

(4) Addon sections of expandable manufactured homes

shall have provisions for vertical ties at the exposed ends.

(d) Requirements for tie downs & anchors varies by wind zone

HUD Table of Number of Tie Downs Required for Mobile Homes

Above: this table, excerpted from the HUD TIE DOWN REQUIREMENTS for MOBILE HOMES document cited in this article explains that the number of vertical or diagonal tie downs reqired per side of a mobile home depend on the wind zone in which the home is located and the length of the home in feet.

Manufactured homes in Wind Zone I require only diagonal ties.

These ties shall be placed along the main frame and below the outer side walls.

All manufactured homes designed to be located in Wind Zones II

and III shall have a vertical tie installed at each diagonal tie location.

(e) Protection requirements for anchoring systems

Protection shall be provided at sharp corners where the anchoring system requires the

use of external straps or cables. Protection shall also be provided to minimize damage to siding by the cable or strap.

(f) Anchoring equipment—load resistance.

Anchoring equipment shall be capable of resisting an allowable working load equal to or exceeding 3,150 pounds and shall be capable of withstanding a 50 percent overload (4,725 pounds total) without failure of either the anchoring equipment or the attachment point on the manufactured home.

(g) Anchoring equipment—weatherization.

Anchoring equipment exposed to weathering shall have a resistance to

weather deterioration at least equivalent to that provided by a coating of zinc on steel of not less than 0.30 ounces per

square foot of surface coated, and in accordance with the following:

(1) Slit or cut edges of zinccoated steel strapping do not need to be zinc coated.

(2) Type 1, Finish B, Grade 1 steel strapping, 1 1 ∕4 inches wide and 0.035 inches in thickness, certified by a registered professional engineer or architect as conforming with ASTM D395397, Standard Specification for Strapping, Flat Steel and Seals (incorporated by reference, see §3280.4).

§3280.307 Resistance to elements and use.

(a) Exterior coverings

shall be of moisture and weather resistive materials attached with corrosion resistant fasteners

to resist wind, snow and rain. Metal coverings and exposed metal structural members shall be of corrosion resistant

materials or shall be protected to resist corrosion.

All joints between portions of the exterior covering shall be designed,

and assembled to protect against the infiltration of air and water, except for any designed ventilation of wall or roof cavity.

(b) Joints between dissimilar materials

and joints between exterior coverings and frames of openings shall be

protected with a compatible sealant suitable to resist infiltration of air or water.

(c) Where adjoining materials or assemblies of materials are of such nature that separation can occur

due to

expansion, contraction, wind loads or other loads induced by erection or transportation, sealants shall be of a type that

maintains protection against infiltration or penetration by air, moisture or vermin.

(d) Exterior surfaces shall be sealed

to resist the entrance of rodents

Hurricane Tie Down or Strapping Fastener Requirements

Question: Can I use screws to install the straps instead of nails

Question: Can I use screws to install the straps instead of nails

2019/02/01 dave said:

I have to install new hurricane straps to tie the rafters to the top plate and the wall in zone 3 (port orange FL 32129).

Can I use screws to install the straps instead of nails

Reply: generally no

Dave

Your local building inspector might approve construction screws rather than nails to attach hurricane strapping to tie down rafters to a top plate PROVIDED that the screws are properly-selected construction screws of the right size and length. But probably not - as I will explain below.

As a more-general point, never conventional generic hardware screws and do not use drywalls screws where structural connectors specify nails or other special fasteners. .

Why not use screws? After all, in my OPINION, because screws have a greater withdrawal resistance than nails they can be superior in some applications.

However, the risk if construction screws are used in steel connectors such as hurricane tie-downs is that such screws might break under load across the screw diameter even though their screw design resists pulling out of the wood.

Most construction screws are smaller in cross-sectional diameter than the galvanized joist hanger nails designed for use with joist handers and similar structural steel strapping and tie-downs.

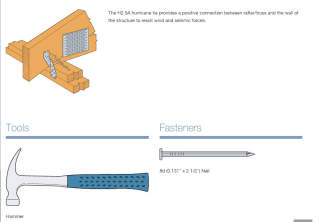

My photo (below) illustrates the use of joist hanger nails as specified by Simpson at a job requiring that we strap roof I-joists to the building's structural frame.

Simpson’s instructions for which nail is used for nailing the strapping or tie-down to the framing lumber vary a bit by connector and its application but the most-common is the 8d (0.131" x 2 1/2") Nail.

Simpson’s instructions for which nail is used for nailing the strapping or tie-down to the framing lumber vary a bit by connector and its application but the most-common is the 8d (0.131" x 2 1/2") Nail.

Here is a table of the fasteners speciried for the most-commonly-used Simpson Strong Tie Tie Down Connectors, cource as cited below.

H2.5A Hurrricane Tie: 8d (0.131" x 2 1/2") Nail

H2.5T Hurricane Tie: 8d (0.131" x 2 1/2") Nail

H10A Hurricane Tie: Blocking Condition connecting truss/rafter and wall: 8d (0.131" x 2 1/2") Nail

H10A Hurricane Tie: Rafter Condition, connecting rafter to wall top plate: 10d (0.148" x 1 1/2") Nail

LS Utility Clip/Skewable Angle: 10d x 1 1/2" (0.148" x 1 1/2") Nail

LSTA Strap Tie used over a ridge-board to strap I-Joists as ridge ties: 10d (0.148" x 3") Nail OR 10d x 1 1/2" (0.148" x 1 1/2") Nail

For I-joist installation only.

LTP4/LTP5 Framing Angle Connector - connecting top plate to rim board or blocking, 8d (0.131" x 2 1/2") Nail and 8d x 1 1/2" (0.131" x 1 1/2") Nail

MST Strap TIe (can be installed with either nails or bolts): 16d (0.162" x 3 1/2") Nail [bolt not specified]

RBC Roof Boundary Clip: 10d x 1 1/2" (0.148" x 1 1/2") Nail

RSP Stud Plate Tie: 8d x 1 1/2" (0.131" x 1 1/2") Nail

SP Stud Plate Tie: (provides uplift resistance): 10d (0.148" x 3") Nail

SSP Stud Plate Tie: 10d (0.148" x 3") Nail

TSP Stud Plate Tie (truss to plate): 10d (0.148" x 3") Nail

Watch out: if you cannot show that the screws you use are specifically designed for and rated for steel structural connectors like hurricane tie-downs by the same manufacturer, then the inspector is likely to "fail" your job.

I have not yet found construction screws such as deck screws that were rated for use with steel connectors.

Bottom line: you must use fasteners that are approved for that use by the manufacturer of the connector you are using.

Ask your local building department - the final legal authority - and let me know their reply.

The illustration below, excerpted from Simpson StrongTie’s installation instructions for tie-downs, shows only nails, not screws.

Source: Simpson StrongTie, H2.5A Hurricane Tie Installation Instructions, retrieved 2019/02/01, original source: www.strongtie.com/resources/product-installers-guide/h25a-installation

Also see the research below

Research on Mobile Home Tie Downs & Storm Damage

- Ash, Kevin D. "A qualitative study of mobile home resident perspectives on tornadoes and tornado protective actions in South Carolina, USA." GeoJournal 82, no. 3 (2017): 533-552.

- Davis, Brett Maxwell. "Analysis of Manufactured Home Vulnerability in Extreme Winds." PhD diss., Auburn University, 2020.

- Hebert, Kirby, and Marc Levitan. PERFORMANCE OF MANUFACTURED HOUSING IN LOUISIANA DURING HURRICANES KATRINA AND RITA [PDF] In Proc., 11th American Conf. on Wind Engineering. San Juan, PR: American Association of Wind Engineering, Polytechnic Institute of Puerto Rico. 2009.

Abstract excerpt:

Results indicate that manufactured housing built and installed after implementation of the 1994 HUD rule on wind standards performed well structurally and in regard to anchorage.

Wind speeds in the study area did not reach design speeds for the post-1994 HUD wind zone rated units in either storm and few units that were poorly anchored or lacking any anchorage suffered significant damage related to anchorage failure. - HUD TIE DOWN REQUIREMENTS for MOBILE HOMES [PDF] retrieved 2019/11/24, original source: http://wchapa.org/wp-content/uploads/2013/02/Tie-Downs.pdf

Also cited / claimed at http://wchapa.org/wp-content/uploads/2013/02/Tie-Downs.pdf - Kim, Jae H., Mohammadtaghi Moravej, Elaina J. Sutley, Arindam Chowdhury, and Thang N. Dao. "Observations and analysis of wind pressures on the floor underside of elevated buildings." Engineering Structures 221 (2020): 111101.

Abstract

A popular method of building flood-proofing in coastal regions is the use of stilts or piers to elevate buildings.

These elevated building structures are generally well-designed to reduce or withstand the hydrodynamic loading resulting from flooding waters, storm surge and carried debris. However, design for wind loading on elevated buildings is not well-informed or codified, despite the changes in the elevated buildings’ aerodynamics.

In order to begin developing the body of knowledge regarding wind effects on elevated buildings, a field study on such structures in the coastal region of the Florida Panhandle was conducted following 2018 Hurricane Michael. In addition, wind tunnel testing on large-scale models of an elevated single-story residential home was performed at the NHERI Wall of Wind Experimental Facility at the Florida International University. The evidence of floor underside damage from the field study are consistent with trends of pressure patterns from the experimental program.

Measured pressure coefficients on the underside of wind tunnel models were significant and frequently of similar or greater magnitude to those on the roof, the latter for which estimation procedures have already been well-established. These findings show that deliberate design for floor underside pressures are necessary, and provide critical impetus for continued research in order to reduce damages observed in past hurricanes.

-

copy at inspectapedia.com/Manufactured_Homes/Wind-Pressure-Under-Floors-Kim.pdf

Excerpt: Skirting is commonly attached around the perimeter of manufactured homes to, amongst other purposes, reduce the wind

passage through the air gap. Unfortunately, skirting commonly becomes detached in high wind events.

- Marshall, Timothy P. WIND SPEED-DAMAGE CORRELATION IN HURRICANE KATRINA JP 1.36 Haag Engineering Co., Dallas, TX

Excerpt:

Unanchored homes are prone to being pushed off their supports especially if they are not anchored well to the ground and/or are broadsided by the wind (DOD 3). - Marshall, Tim, HURRICANE LAURA DAMAGE SURVEY [PDF] in 34th Conference on Hurricanes and Tropical Meteorology. AMS, 2021.

Excerpt:

Proper anchoring of manufactured homes proved they can survive major hurricanes. - PNCE MOBILE HOME CONSTRUCTION REQUIREMENTS [PDF]

- Rumbach, Andrew, Esther Sullivan, and Carrie Makarewicz. "Mobile home parks and disasters: Understanding risk to the third housing type in the United States." Natural hazards review 21, no. 2 (2020): 05020001.

- Shivers-Williams, Cassandra A., and Daphne S. LaDue. EXPLORING SOUTHEAST US MOBILE AND MANUFACTURED HOME RESIDENTS’ ANCHORING DECISIONS [PDF] International Journal of Disaster Risk Reduction 82 (2022): 103383.

Abstract:

Forensic engineering assessments of tornado damage have consistently shown that inadequate or absence of anchorage of mobile and manufactured homes (MMHs) has been the primary cause of structure failure, leading to high tornado fatality rates in the Southeast United States.

Therefore, it is important to determine whether these residents have anchored their homes and their underlying motivations.

This research quantitatively explored various factors influencing Southeast US MMH residents’ current anchorage decisions and qualitatively explored other contextual factors for these decisions, including general mitigation knowledge and financial means.

Results showed age, insurance, community shelter access, and self-efficacy perceptions reliably distinguished those who have already anchored their homes from those who have not and have no intentions to do so.

On the other hand, among those who have not already anchored their homes, only tornado risk perceptions marginally distinguished those with intentions to anchor from those without. Also, those not already anchored were least likely to believe in the five tested myths and were potentially willing to spend $500–$999 on general mitigation, though few had ever considered fortifying their MMH and cost was the most cited barrier to doing so.

The majority of participants knew nothing about the wind resistance of their home and only half of the sample knew the mitigation term, “manufactured home tie-down.” The knowledge gained here can help various public-facing communication entities design effective outreach materials to facilitate this population better protecting themselves from tornadoes by way of strengthening their vulnerable homes. - SIMPSON STRONGTIE®, H2.5A HURRICANE TIE INSTALLATION INSTRUCTIONS [PDF] (2022) Simpson Strong-Tie - retrieved 2022/04/06 original source: www.strongtie.com/resources/product-installers-guide/h25a-installation

- Sutley, Elaina J., Karen Vazquez, Jae H. Kim, Thang Dao, Blythe Johnston, and Josh Hunt. "Performance of manufactured housing during Hurricanes Irma and Michael." Journal of performance of constructed facilities 34, no. 4 (2020): 04020078.

Abstract

Manufactured homes historically have been some of the most vulnerable structures to earthquakes, tornadoes, and hurricanes. More than 20 million people reside in manufactured homes in the US, leaving many at considerable risk across the country. Approximately 10% of the nation’s manufactured home stock is in Florida, where they were subjected to 2 consecutive years of intense hurricanes, including 2017 Hurricane Irma and 2018 Hurricane Michael.

This paper presents post hurricane imagery and damage assessment of 279 manufactured homes assessed after each of these hurricanes in Florida. Predicted and mapped peak and sustained wind speed data were coupled with public database information of manufactured homes and parks in order to identify site locations with particular ranges of wind speeds in the impacted areas.

Damage observations at the component- and system-level were presented based on post-Michael reconnaissance imagery. It generally was observed that manufactured home performance was consistent with historical observations, including 20% of surveyed homes classified as completely destroyed. These findings are intended to highlight the physical vulnerabilities of manufactured housing and to provide impetus for further research and updated standards for safer, affordable housing.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2019-11-24 by (mod) - mobile home roof trusses broken by over-roof tie-downs?

On 2019-11-24 by (mod) - mobile home roof trusses broken by over-roof tie-downs?

Clara

I would need to see more to be entirely confident of an answer, but in general, as long as the tie-downs are connected only between the mobile home chassis or floor frame and the ground, I'd blame something else for the dramatic roof truss failure in your photos.

There are, however, some "tie down" add-on systems that I've seen that run a cable right over the roof of a mobile home and then down to anchors on either side.

Properly that's referred to as "Over-the-Top strapping" in HUD guidance on mobile home tie-downs. Here is what HUD says

Typically, homes manufactured prior to July 13, 1994, where factory installed roof ties are not evident and it cannot be determined that the mobile/manufactured home is “Hurricane Resistant” without such ties, then vertical roof ties are required.

A single-wide up to 60 ft. long would get 3 over-the-roof tie-downs; A single-wide 61 ft. or longer would get 4 over-roof tie-downs.

A double-wide home gets over-roof tie-downs only if they were installed by the manufacturer.

HUD Warns that over-roof tie-downs must be aligned with a rafter to avoid damage to the roof.

If over-roof tie-downs were installed at your home, and if they were not properly-installed, and/or if there has been a storm, an uplift movement of the home, or some aggressive tightening of the tie-downs during installation I could imagine breaking roof trusses such as your photos show.

Tell me

- the country and city where this home is installed

- the age of the home

- the location and type of tie-down system installed

and include some exterior and crawl space photos of the home and I may be able to say more.

On 2019-11-22 by Clara

Is it possible for tie downs to effect the gables in a mobile home? Please see image, I don't know how the gables broke, a new roof was installed in 2012.

Is it possible if mobile home tie downs are incorrectly installed, or too many are installed, to effect the roof structure. In this case a few of the roof gables are broken, and other than the tie downs I can't figure out how the gables broke?

On 2019-09-21 by (mod) mobile home skirting requirements including skirting tiedowns

Sorry. Those details area at MOBILE HOME SKIRTING

On 2019-09-21 by Anonymous

Thank you for that, but I am referring specifically to some new code that relates to the skirting only and how it must be installed with something other than those spikes they normally use in the bottom runner.

On 2019-09-21 - by (mod) - FEMA-sponsored analysis in 2005 reports on mobile home tie downs and is worth reading

For Pennsylvania readers and others, in PA the Washington County Housing Authority expands on HUD's limited specifications on mobile home tie downs,

- HUD-TIE-DOWN-ADDITIONAL-DETAILS [PDF] Washington County Housing Authority, Pennsylvania, original source: http://wchapa.org/wp-content/uploads/2013/02/Tie-Downs.pdf

Also a FEMA-sponsored analysis in 2005 reports on mobile home tie downs and is worth reading

- THIRD PARTY ANALYSIS of MANUFACTURED HOME RETROFIT TIE DOWNS [PDF] FEMA 2005, original source: https://www.fema.gov/media-library-data/20130726-1711-25045-6495/third_party_analysis_of_manfactured_home_retrofit_tie_downs.pdf

Available free online at InspectApedia.com

On 2019-09-21 - by (mod) - code for tying down mobile homes

Bill,

Skirting requirements including securing skirting are

at MOBILE HOME SKIRTING

I researched for updates to the Florida 2004 Code on Mobile / Manufactured Homes, Wind Resistance, and Tie Downs. (Homes meeting the previous code dated 1999 had an update program available to meet the 2004 Wind Resistance and Tie Down standards of 2004 that followed hurricanes Charlie and Katrina.

The 2005 Standard added tie-downs and toughened their installation specs.

- 4ft anchors placed every 64-inches

- typically added using a 4 ft metal-helix screw-in type anchor strapped from the anchor to the home's frame

- a metal plate keeps the anchor from wobbling and thus loosening

Meanwhile take a look at section 15C-1.0104 Installation Standards for Anchors and Tie-Downs and 15C-1.0105 Testing Specifications for Straps,Piers, Anchors and All Components - and subsequent sections on strap testing etc. found in the

- FLORIDA ADMINISTRATIVE CODE CHAPTER 15C-1 [PDF] widely distributed and also found at

On 2019-09-2 by Bill Duke

In regard to Florida mobile homes. I have been told there is a new code for tying down the skirting. Does anyone have information on this?

On 2019-08-06 by (mod) - where to find an installer for mobile home tie downs

Jen

FInd a mobile home near yours that has tiedowns or anchors, then knock on the door and ask the owner who installed them.

Watch out: the HUD mobile home tie down guidelines cited in this article state

Who can install Mobile Home tie-downs?

Section 320.8249, Florida Statute, requires that anyone who will install a mobile/manufactured home must be licensed by the Manufactured Housing Section, Division of Motorist Services, Department of Highway Safety and Motor Vehicles.

The law further requires that licensed installers must place an installation decal on every home they install certifying that the home was installed in accordance with state regulations.

The label shall be located at the “tail light” end of each transportable section of the manufactured home approximately one foot up from the floor and one foot in from the road side.

Presently, there are 377 licensed installers in Florida. A list of approved installers can be found at www.flhsmv.gov.

On 2019-08-06 by jen

Trying to find someone to install anchors in a doublewide I am trying to buy with VA loan. The zip code is 12423. I am batting out.. but there are mobile homes all over the place.

On 2019-03-28 by (mod) - find an inspector to see if trailer was set properly

Don you might find an inspector using the page top EXPERTS DIRECTORY to look at the home inspectors directory for MD

On 2019-03-20 by Don

I have a double wide mobile home not even a year old I had manufacturers come in and repair ceiling crack and I said the trailer was not set properly I have a crack coming back in the same area and I have more cracks in the ceiling holes in my ceiling

I'm wondering if it is that the trailer is not set properly if you think that's true do you have any information on anybody in the Maryland area that does the inspections I would appreciate it thank you have a nice day

On 2019-02-01 by (mod) - install new hurricane straps to tie the rafters to the top plate and the wall in zone 3

Dave

To have space for an illustrated and authoritative answer to your question of whether or not it's ok to use screws instead of nails for hurricane strapping (generally the answer is no) I have repeated your question and give a detailed reply now found above on this page

Please take a look at that article and let me know what further questions you'd like to ask.

Thanks for the question.

On 2019-02-01 by dave

I have to install new hurricane straps to tie the rafters to the top plate and the wall in zone 3 (port orange FL 32129). can I use screws to install the straps instead of nails

On 2018-08-05 by (mod) - tie downs must meet the Zone II or Zone III requirements

Gregor

Your tie downs must meet the Zone II or Zone III requirements depending on where you live in Florida. See the map and specs above on this page.

Cheryl:

Not if the strapping is properly connected to an intact mobile home frame. But yes, improperly-installed tie downs to the floor or chassis or over-roof tie-downs can damage a home as well as causing it to be damaged or unsafe in the event of a storm.

On 2018-07-30 by Gregor - What are the specs for FHA/VA anchoring of single wide mobile homes ?

What are the specs for FHA/VA anchoring of single wide mobile homes in north central Florida

On 2018-07-01 - by (mod) -

Gregory

Please see MOBILE HOME STABILIZING SYSTEMS - [you are now on this page - Ed.]

for "straps" or tie-down requirements for mobile homes.

On 2018-06-29 by Gregory T Malarkey

How many straps must go completely over the trailer and how far apart.

How many anchor straps must anchor the chassis and how far apart

On 2018-05-29 by (mod)

Yes, but on the other hand, tie-down straps or cables should be snug, not loose and floppy.

On 2018-05-29 by Cheryl

Can tightening the strapping on a mobile home too tightly cause floor damage?

...

Continue reading at MOBILE HOME CRAWL SPACES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see

- CONNECTORS, FASTENERS, TIES

- FRAMING CONNECTORS & JOIST HANGERS

- FRAMING FASTENERS, NAILS, SCREWS

- HURRICANE TIE DOWN CONNECTORS & FASTENERS

- MOBILE HOMES, DOUBLEWIDES, TRAILERS - home

- MOBILE HOME WIND RATINGS

- MOBILE HOME SKIRTING

- MOBILE HOME STABILIZING SYSTEMS - tie-down requirements for mobile homes

- MOBILE HOME STRUCTURAL DEFECTS

- MOBILE HOME PIERS

- MOBILE HOME PIER INSPECTION

Suggested citation for this web page

MOBILE HOME STABILIZING SYSTEMS at InspectApedia.com online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

INDEX to RELATED ARTICLES: ARTICLE INDEX to MANUFACTURED & MOBILE HOMES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.