Plumbing Vent Definitions & Codes

Plumbing Vent Definitions & Codes

- POST a QUESTION or COMMENT about plumbing vent piping and systems: code, installation, distances, sizes

This article series defines plumbing vent system terms, distances, and functions, and other specifications and code requirements.

Here we include definitions of plumbing vent terms, types of plumbing vents, plumbing vent size requirements,and in a companion article we give plumbing vent clearance distances to building roof, vertical walls, nearby windows, or plumbing vent distance to chimneys.

We explain how plumbing vents work on buildings, why plumbing vent piping is needed, and what happens to the building drains when the vent piping is not working.

We define the soil stack, waste stack, wet vents and dry vents, and we summarize the distances permitted between plumbing fixtures and their vent piping. We also explain how sewer gas odors may be traced to plumbing vent problems. Contact Us by email if you are having trouble finding the information you need.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Plumbing Vent System Terms, Definitions, & Types

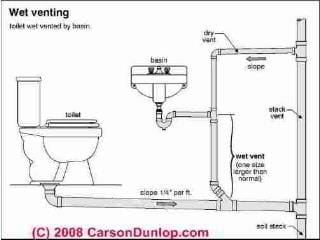

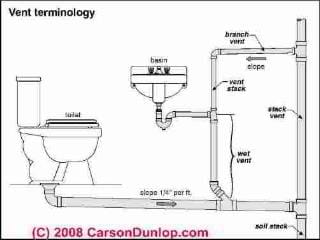

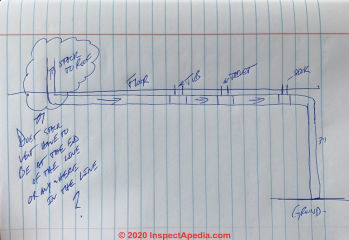

The basic plumbing vent terms are shown in the sketch at above/left. In these notes, the plumbing stack vents and other sketches included below are provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ]. [Click to enlarge any image]

The basic plumbing vent terms are shown in the sketch at above/left. In these notes, the plumbing stack vents and other sketches included below are provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ]. [Click to enlarge any image]

Take a look at the complete index to this article series found just below, or go immediately to PLUMBING VENT DISTANCES & ROUTING.

Article Contents

- HOW PLUMBING VENTS WORK

- DEFINITION of AIR ADMITTANCE VALVES / STUDOR VENTS

- DEFINITION of BACKFLOW & BACKFLOW PREVENTERS

- DEFINITION of BACKWATER VALVE

- DEFINITION of BRANCH INTERVAL & BRANCH VENT

- DEFINITION of CIRCUIT VENT

- DEFINITION of DIRECT VENTED PLUMBING FIXTURES

- DEFINITION of DRAIN LOOP VENTS or ISLAND SINK VENTS

- DEFINITION of DRAIN RE-VENTS vs RELIEF VENTS

- DEFINITION of a PLUMBING STACK VENT

- DEFINITION of WET VENTED PLUMBING FIXTURES

- DEFINITION of YOKE VENT

- DEFINITION of LOOP VENT

- PLUMBING VENT ROUTING SPECIFICATIONS

- PLUMBING VENT TEE POSITION

- PLUMBING VENT CODES - PDF downloads

How & Why Building Plumbing Vent Piping Works

The plumbing vent system is part of the building plumbing drain system and serves two basic functions:

1. Allow building drains to flow freely

by allowing air into the drain system, avoiding the vacuum and slow drainage that would otherwise occur at fixtures.

Imagine a full soda bottle with its cap off, turned upside down: the soda does not flow nicely out of the bottle. As some soda spills out, the spillage has to nearly stop to let some air into the bottle to fill the vacuum created by the soda leaving.

Now perform the same experiment, but punch a hole in the bottom of your soda bottle just before you turn it upside down. Because air can easily enter the bottle the soda flows nicely out of the bottle mouth.

2. Allow sewer gases to be vented safely outdoors.

Because sewer gases may flow back up into the building drain piping from a public sewer or private septic system, and because some sewer gases are included in building waste flowing through the piping, the plumbing vent system needs to carry these gases outside, usually above the building roof, where they are disposed-of safely and without leaving unpleasant, or possibly dangerous smells and gases inside the building.

Definition of Air Admittance Valve (AAV)

[Click to enlarge any image]

UPC Definition of Air Admittance Valve

One-way valve designed to allow air to enter the plumbing drainage system when negative pressures develop in the piping system.

The device shall close by gravity and seal the vent terminal at zero differential pressure (no flow conditions) and under positive internal pressures.

The purpose of an air admittance valve is to provide a method of allowing air to enter the plumbing drainage system without the use ofa vent extended to open air and to preventsewer gases from escaping into a building. - UPC 2006

Above, a Studor® Redi-Vent Air Admittance Valve from IPC Corporation. Where a conventional plumbing vent system is not available or not feasible the local plumbing inspector may permit an air admittance valve to be installed.

An AAV is basically a one-way valve that allows air to enter the drain to satisfy the vacuum caused by water passing down the drainage system, but that prevents sewer gases from backing up through the vent into the building.

While the term "studor vent" is widely applied to describe an air admittance valve, Studor Mini-Vents as well as Redi-Vents are products of Studor Inc. & the IPS Corporation and are a brand name.

Details about Studor Vents® / AAVs (Air Admittance Valves) are found

Definition of Air Break & Air Gap in Drain Waste Vent Piping

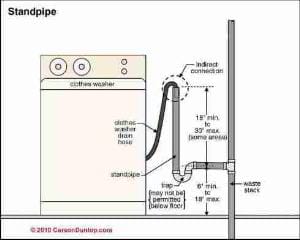

Carson Dunlop Associates' sketch above illustrates an air gap at a clothes washer drain hose connection. [Click to enlarge any image]

UPC Definition of Air Break in a drainage system

A piping arrangement in which a drain from a fixture, appliance or device discharges indirectly into another fixture, receptacle or interceptor at a point below the flood level rim and above the trap seal. - UPC 2006

UPC Definition of Air Gap in a drainage system

The unobstructed vertical distance through the free atmosphere between the outlet of the waste pipe and the flood level rim of the receptacle into which the waste pipe is discharging. - UPC 2006

Definition of an Air Gap in a water distribution system

The unobstructed vertical distance through the free atmosphere between the lowest opening from any pipe or faucet supplying water to a tank, plumbing fixture or other device and the flood level rim ofthe receptacle. - UPC 2006

A common example of an air gap in a drainage system is found at the connection of a clothes washing machine to a vertical standpipe connecting the washer to a drain line. Air conditioning condensate pump drains and water softener regeneration/backwash drains also often connect using an air gap or air break.

To understand why an air break or gap is essential to avoid contaminating a building water supply see CROSS CONNECTIONS, PLUMBING

Also see TUNDISH used in PLUMBING

Definition of Backflow & Backflow Preventers

Backflow is defined as

Pressure created by any means in the water distribution

system, which by being in excess of the pressure in the

water supply mains causes a potential backflow condition.

A backflow preventer is a device or means to prevent

backflow.

A backflow connection is any arrangement whereby backflow is possible. - UPC 2006

Let's convert these circular-sounding definitions into plain talk.

We don't want water in the water supply system to ever flow backwards out of the building into the water supply source such as back into a drinking water well or back into the municipal water supply system because we can't guarantee our neighbors that water in our building piping, fixtures, toilet cisterns, etc. has remained sanitary and safe to drink.

How might this happen? Suppose the building water supply system pressure is sitting at 70 psi on the building-side of a water pressure regulator at the incoming water supply line. And suppose the municipal water supply system temporarily loses its pressure.

Unless a backflow preventer or check valve has been installed, building water may flow backwards into the supply system.

Similarly we don't want wastewater in the drain system to ever flow backwards from the sewer or septic system back into the builiding because a sewage backup is unsanitary, nasty, gross, and a mess to clean-up.

Backflow can occur due to

- Backpressure,

defined in the 2006 UPC as A pressure less than or equal to 4.33 psi (29.88 kPa) or the pressure exerted by a 10-foot 3048 mm) column of water. - Backsiphonage.

The backflow of potentially contaminated water into the potable water system as a result of the pressure in the potable water system falling below atmospheric pressure of the plumbing fixtures, pools, tanks or vats connected to the potable water distribution piping.

We prevent these backwards flowing water or wastewater problems by installing the proper type of check valve at the proper locations in the building water supply or drain system piping.

Definition of CRITICAL LEVEL (C-L) in Backflow Preventers

An elevation (height) reference point that determines the minimum height at which a backflow preventer or vacuum breaker is installed above the flood level rim of the fixture or receptor served by the device.

The critical level is the elevation level below which there is a potential for backflow to occur. Ifthe critical level marking is not indicated on the device, the bottom ofthe device shall constitute the critical level. - UPC 2006

Details are at CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS

and

Definition of Backwater Valve in Drain Systems

A device or valve installed in the building drain or sewer pipe where a sewer is subject to backflow, and which prevents drainage or waste from backing up into a low level or fixtures and causing a flooding condition. - UPC 2006

A backwater valve is found on a drain pipe so it's technically not part of the building vent piping system but we included it here in response to reader questions.

Also see backflow preventers and check valves used both drain systems, water supply systems, and mechanical systems such as heating boilers. - Ed.

Also see CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS

Definition of Branch Interval and Branch Vent in Drain Systems

Define Branch Interval

A vertical measurement of distance, 8 feet (2438 mm) or more in developed length, between the connections of horizontal branches to a drainage stack.

Measurements are taken down the stack from the highest horizontal branch connection. - UPC 2006

Define Branch Vent

A vent connecting one or more individual vents with a vent stack or stack vent. - UPC 2006

Definition of Circuit Vent in Plumbing Vent Systems

A vent that connects to a horizontal drainage branch and vents two traps to a maximum of eight traps or trapped fixtures connected into a battery. - UPC 2006

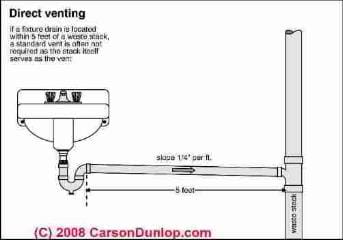

Definition of Direct Venting of Plumbing Fixtures

Basically,larger piping diameter allows longer distances between a plumbing fixture and its vent stack. If a plumbing fixture is located too far from the main building vent stack, then its own drain pipe must have its own vent stack connection piping.

But if a plumbing fixture is close enough (five feet or less) to the main waste stack pipe (vent), the fixture does not usually require its own plumbing vent piping, and it is considered a direct-vented plumbing fixture.

Of course this rule presumes that the drain piping between the fixture trap and the waste stack is properly installed and properly sloped.

The usual slope on the fixture drain piping is 1/4" of slope per 12" (foot) of horizontal distance or "run" of piping.

Definition of Drain Fixture Units or DFUs

Drain Fixture Units or DFUs used in sizing air admittance valves or drain waste or vent piping are calculated using a table or formula that assigns a number or weight to each type of fixture on a drain system.

The total number of DFUs determines the required drain or vent size necessary for proper drain and waste disposal and venting.

See DRAIN FIXTURE UNITS DFUs for details.

Definition of Plumbing Re-Vents vs. Relief Vents

Question: difference between a re-vent and a relief vent

(Feb 1, 2016) wgpaganelli@yahoo.com said:

Explain the difference between a re-vent and a relief vent please. Thank you

Reply:

WG

Definition of a plumbing re-vent or revent

A re-vent or revent pipe in a plumbing drain-waste-vent or DWV system is an auxiliary vent that is attached to the drain pipe close to an individual plumbing fixture. The re-vent or revent pipe is routed upwards above the fixture and then horizontally over to a tee that attaches it to the main stack vent pipe.

At the fixture the revent pipe can connect immediately behind the plumbing fixture or it may be connected close to the fixture along a horizontal drain line that serves that fixture.

Definition of a plumbing relief vent.

Relief vents are defined in the model plumbing codes as follows:

917.3.2 Relief vent. Where the horizontal branch is located more than four branch intervals from the top of the stack, the horizontal branch shall be provided with a relief vent that shall connect to a vent stack or stack vent, or extend outdoors to the open air.

The relief vent shall connect to the horizontal branch drain between the stack and the most downstream fixture drain connected to the horizontal branch drain. The relief vent shall be sized in accordance with Section 916.2 and installed in accordance with Section 905. The relief vent shall be permitted to serve as the vent for other fixtures.

Also see AIR ADMITTANCE VALVES AAVs.

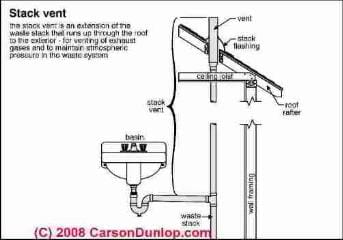

What is the Plumbing Stack Vent?

Here we show the main building vent pipe, the plumbing stack vent, connecting inside plumbing drains to a vent pipe that extends above the building roof in order to let needed air into the drains and to vent sewer gases harmlessly above the building.

[Click to enlarge any image]

Below we explain how building plumbing vent systems work and why plumbing vents are needed for drain function and plumbing drain safety.

Above the roof plumbing vent height: vent pipes should extend to outdoors above the building roof and should terminate vertically not less than 6" above the roof surface (nor more than 24") and must be at least 12" from any vertical surface (such as a nearby sidewall).

(UPC (i) 906.1 and 906.2). Note that there are other restrictions: for a roof that is also used as an occupied space, for example, the vent has to extend at least seven feet above the surface and be secured with stays.

Above roof plumbing vent diameter: in areas exposed to snow or freezing or temperatures below 0 degF., that can block a plumbing vent, the vent pipe should be at least 2" in diameter beginning at least one foot inside the building in an insulated space before the vent passes through the roof.

Where there is a snow-cover risk (snow can block the plumbing vent) the vent should extend 24" above the roof surface.

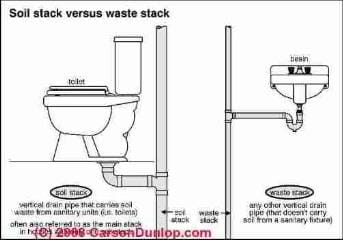

What is the Difference Between a Soil Stack & a Waste Stack?

The soil stack pipe, as shown in Carson Dunlop Associates' sketch, carries waste from toilets to the house trap (if one is installed) and there connects to the sewer line extending outside the building and on to a public sewer or private septic system.

The soil stack is the large-diameter main vertical waste pipe or building drain, or vertical portion of the "main drain" in the building.

The soil stack pipe is normally extended outdoors above the building roof, as shown in the page top sketch.

Other main building drain piping sections that slope closer to horizontal are connected to the soil stack but move waste horizontally where needed in a building.

The waste stack pipe

shown in the sketch refers to any other vertical drain piping in the building that does not carry soil (sewage) from a sanitary fixture (toilet). Typically waste stack piping carries drainage away from sinks, tubs, and showers.

Definition of Wet Vent, What is a Wet-Vented Plumbing Fixture?

A standard plumbing vent pipe is always dry; water runs down the drain line but the vent portion of the piping is dry. NO water runs in it.

Definition of wet vent:

In contrast with a classic or standard "dry" plumbing vent pipe, a wet vent is a combination drain line and vent line. To work successfullly, the wet vent piping must be large-enough in diameter that it will never fill with water, thus allowing air to enter the drain system simultaneously with the passage of wastewater draining from fixtures connected to the wet vent system.

In many buildings we find that the toilet is located quite close (within 5 feet) of the main building waste stack. This makes sense because the toilet needs really effective venting. Our sketch above shows a toilet located close to the waste stack - an installation that should work fine.

When you flush a toilet it sends a sudden large volume of waste and wastewater into the building drain waste vent (DWV) piping. This surge of wastewater can certainly create a vacuum problem in the waste line if the vent piping system is inadequate, blocked, or missing entirely.

It is exactly this condition that produces the gurgling or even siphonage out and loss of water in nearby sink or tub traps when you flush a toilet in a building where the vent piping is inadequate.

See PLUMBING DRAIN NOISE DIAGNOSIS

A toilet that is located too far from the soil stack can be wet vented as shown in Carson Dunlop Associates' sketch. The drain piping for a sink (basin) or other fixture located closer to the soil stack than is the toilet can provide a pathway to let air into the horizontal waste piping used by the toilet to carry waste to the soil stack.

But a wet vented fixture requires a larger drain pipe diameter in its wet portion as we show in the sketch. This diameter increase helps assure adequate air flow into the drain system in the event that the sink basin (in this example) happens to be draining at the same moment that the toilet is flushed. (908.2.3.)

Also note that wet vented fixtures (toilet, bathtub, shower, or floor drain) are permitted for bathrooms on the same floor level, not between floors.

Definition of Plumbing Yoke Vents & Offset Relief Vents

On tall buildings (often considered 11 stories or higher), prevent drain venting problems that could occur due to pressure variations in the stack vent system. A yoke vent, basically an offset relief vent, may be installed on every 5th floor from the top floor downwards.

A pipe connecting upward from a soil or waste stack to a vent stack for the purpose of preventing pressure changes in the stacks. - UPC 2006

A yoke vent is any pipe that connects upwards from a soil stack or vertical waste stack to a higher location in order to prevent pressure changes in the stack pipe. Those pressure changes could prevent proper drain venting. In a typical arrangement, a yoke relief vent or yoke vent is constructed by using a 45 degree wye on a soil pipe or waste stack.

The wye points upwards and connects using a second 45-degee connecting wye to a separate vertical vent stack pipe at a point higher in the building and usually above any other branch vents that connect to the same vent stack.

The yoke vent pipe diameter is typically the same as (per code below) or one pipe size smaller (per local authority) than the drain and vent stacks to which it connects.

917.3 Offset Reliefs Such offsets may be vented by installing a relief vent as a vertical continuation of the lower section of the stack or as a side vent connected to the lower section between the offset and next lower fixture or horizontal branch.

The upper section of the offset shall be provided with a yoke vent. The diameter of the vents shall be not less than the diameter of the main vent, or of the soil and waste stack, whichever is the smaller. - 2000 UPC

See ISLAND SINK PLUMBING VENTS for an illustration of and a discussion of the application of yoke vents.

Definition of Plumbing Loop Vents

Loop vents may be used at island sinks or "free-standing sinks" where there is no direct route from above the sink's flood rim to a vertical vent stack.

To keep the loop vent dry, that is so that the vent can work without flooding, the loop vent has to connect at the top of the fixture's vertical drain line, and the horizontal portion of the revent pipe must be at least 6-inches above the flood rim of the sink or other plumbing fixture being vented.

The flood-rim is the highest possible point that water can rise in the fixture, or the actual horizontal rim of the sink if there is no sink overflow feature.

See ISLAND SINK PLUMBING VENTS for details.

Also see AIR ADMITTANCE VALVES AAVs or Studor vents.

Plumbing Vent Routing Specifications

Within the building the plumbing vent routing is generally unrestricted.

That is, dry vent piping carrying only air, sewer gas, or moisture to above the roof line is unrestricted. However the piping does need to be protected from nails - use nail plates to protect vent and drain piping both where where piping passes through studs, joists, or rafters.

Special routing and connections are required for proper venting of plumbing fixtures such as kitchen island or peninsula sinks or dishwashers - plumbing fixtures that are located where a direct vertical vent stack connection is not possible.

See ISLAND SINK PLUMBING VENTS for details.

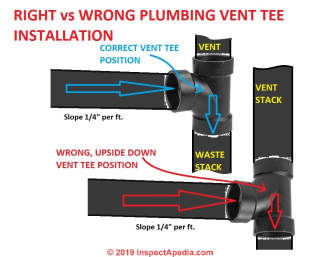

Plumbing Vent Tee Position

Question: plumbing inspector says our vent tees are installed backwards

Question: plumbing inspector says our vent tees are installed backwards

Megan said:

We had a plumbing inspection where he stated: Plumbing Venting tees - installed backwards..

He gave no indication where or how many.. or will answer calls for questions.

We are a homeowner doing our own work, so just trying to narrow it down. From this can you help identify if at least..

1. it is going to be on a vent stack

2. it is going to be associated with an inline vent installation

3. what does "backwards" mean?? upside down, using wrong piece..?

Any help would be appreciated!

Reply: Upside down plumbing vent tee connections:

Megan,

I cannot give an accurate guess at exactly what's wrong where from your question.

A plumbing "tee" is a drain pipe connection that joins a horizontal (well sloped 1/4" per foot but roughly horizontal) drain or vent pipe to the vertical vent or wet vent drain pipe.

But I think that your inspector says that plumbing vent tee connections like those I show in our illustration are installed upside down so that water down a wet vent won't fully drain into the vertical drain line and vent stack.

Follow the vent piping in your building, locate all joints, connections, tees, photograph them, and post photos here or ask the inspector to be more specific if some but not all connections were improper.

Our illustration shows the proper as well as an "upside down" position of a plumbing vent tee.

Note that if the tee, seen at the vertical plumbing vent riser, were upside down, water would be trapped in the horizontal piping, ultimately inviting clogs.

Use the "add Image" button (one per comment) and post photos of your plumbing drain and vent piping tee connections and we can comment further.

Watch out: if plumbing tees are installed backwards or more-accurately, upside down, that's a sign of an inexperienced plumber doing the work. You need to be alert for other drain-waste-vent plumbing mistakes and problems.

Fix those now, before the walls and ceilings are enclosed or you'll face greater costs later.

Plumbing Codes, Citations, Fulltext Codes, & Plumbing Code References

Watch out: while the 2015 IPC is the most-recent version of the International Plumbing Code, while the 2018 IPC is under development. To understand which generation of the model building code or plumbing code applies to your specific project you will need to check with your local building official. For example many jurisdictions are on the 2012 IPC or still older versions.

- International Code Council, 500 New Jersey Avenue, NW, 6th Floor, Washington, DC 20001

Tel: 1-888-ICC-SAFE (422-7233); Fax: (202) 783-2348

International: (202) 370-1800, Email: webmaster@iccsafe.org, Website: iccsafe.org

Excerpt describing the IPC - International Plumbing Code

The International Plumbing Code (IPC) is a proven, comprehensive model plumbing code that works seamlessly with ICC's family of building codes. It sets minimum regulations for plumbing systems and components to protect life, health and safety of building occupants and the public.

The IPC is available for adoption by jurisdictions ranging from states to towns, and is currently adopted on the state or local level in 35 states in the U.S. The IPC is built on the proven legacy of the BOCA National Plumbing Code, SBCCI Standard Plumbing Code, and ICBO Plumbing Code.

The IPC sets minimum regulations for plumbing systems using both prescriptive and performance-related provisions ...

Purchase the 2015 International Plumbing Code at this ICC page: http://shop.iccsafe.org/codes/2015-international-codes-and-references/2015-international-plumbing-coder.html - 2012 IPC International Plumbing CODE, complete text, [OFFLINE - at demand of ICC, previously MARYLAND-Plumbing_Code_2012_ICC_IPC_Full_Text.php ]] as adopted, incorporated by Maryland - download not available free from ICC - find at UpCodes.] retrieved 2016/08/11, original source: https://law.resource.org/pub/us/code/ibr/icc.ipc.2012.pdf, as adopted by the U.S. State of Code Maryland Administrative Regulations section 05.02.01.02

This public document is the entire 2012 Plumbing Code - 2009 IPC ICC International Plumbing CODE, [PDF] full text, retrieved 2016/08/11, original source: https://law.resource.org/pub/us/code/ibr/icc.ipc.2009.pdf as adopted and incorporated by various U.S. states including Alabama, Colorado, Delaware, Florida, Michigan, New Hampshire, North Carolina, Ohio, Oklahoma, Pennsylvania, Rhode Island, Utah, Vermont, Virginia, West Virginia, and others.

- 2006 IPC ICC International Plumbing CODE, [PDF] full text, retrieved 2016/08/11, original source: https://law.resource.org/pub/us/code/ibr/icc.ipc.2006.pdf as adopted by various U.S. states and municipalities including Arizona, Arkansas, District of Columbia, Georgia, New York, South Carolina, and others.

- 2006 IPC Chapter 9, Vents, 2006 Uniform Plumbing CODE, [PDF] complete text as adopted by the Virgina 2006 Plumbing Code

- 2000 IPC Chapter 9, Vents, 2000 Uniform Plumbing CODE, [PDF] fulltext on plumbing vents, as adopted by the state of Louisiana

- International Residential Code (IRC), for One and Two Family Dwellings, 2012 (First Printing)

Home Page: publicecodes.citation.com/icod/irc/index.htm

Citation Page:

publicecodes.citation.com/icod/irc/2012/icod_irc_2012_31_sec003.htm - International Mechanical Code (IMC), International Code Council [888] 422-7233, Op. Cit.

- International Plumbing Code (IPC) (see NPC below), Op. Cit.

- National Standard Plumbing Code, (NPC), 2009

obtained From: National Assoc. of Plumbing-Heating-Cooling Contractors in New Jersey at [800] 652-7422 or NAPHCC [800] 533-7694, [Cited by New Jersey State Department of Community Affairs]

state.nj.us/dca/divisions/codes/codreg/pdf_misc_codes/2006_nspc.pdf - New Jersey State Department of Community Affairs, Website: state.nj.us/dca/divisions/codes/codreg/

- International Code Council, 500 New Jersey Avenue, NW, 6th Floor, Washington, DC 20001 Tel: 1-888-ICC-SAFE (422-7233); Fax: (202) 783-2348 International: (202) 370-1800, Email: webmaster@iccsafe.org, Website: www.iccsafe.org

- International Residential Code (IRC), for One and Two Family Dwellings, 2012 (First Printing)

Home Page: publicecodes.citation.com/icod/irc/index.htm

Citation Page:

publicecodes.citation.com/icod/irc/2012/icod_irc_2012_31_sec003.htm - International Mechanical Code (IMC), International Code Council [888] 422-7233, Op. Cit.

- International Plumbing Code (IPC) (see NPC below), Op. Cit.

- National Standard Plumbing Code, (NPC), 2009

obtained From: National Assoc. of Plumbing-Heating-Cooling Contractors in New Jersey at [800] 652-7422 or NAPHCC [800] 533-7694, [Cited by New Jersey State Department of Community Affairs]

state.nj.us/dca/divisions/codes/codreg/pdf_misc_codes/2006_nspc.pdf - New Jersey State Department of Community Affairs, Website: state.nj.us/dca/divisions/codes/codreg/

- PLUMBING VENT BOOT GUARD INSTRUCTIONS [PDF] Best Materials,

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-11-12 by (mod) - code requirement between a stove vent and a plumbing vent on the roof exterior?

Aaron

Are we discussing a woodstove chimney?

If so, https://inspectapedia.com/chimneys/Chimney_Height_Codes_Specifications.php CHIMNEY HEIGHT & CLEARANCE CODES

On 2020-11-12 by Aaron Hebert

In Louisiana is there a distance minimum code requirement between a stove vent and a plumbing vent on the roof exterior?

On 2020-10-22 by (mod)

Ken

The Florida Plumbing code, section 910.1 reads as follows:

Section 910 Individual Vent

Each trap and trapped fixture is permitted to be provided with an individual vent. The individual vent shall connect to the fixture drain of the trap or trapped fixture being vented

I'm not sure what the inspector meant by "dry base" - you need to ask for clarification lest you waste time and money fixing the "wrong thing" .

Possibly that floor drain is not properly trapped.

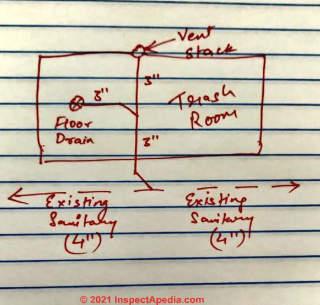

On 2020-10-22 1 by Ken - "Vent at trash room shows a dry base not permitted FPC sec. 910.1"

Can someone please clarify this comment I received from building department?

"Vent at trash room shows a dry base not permitted FPC sec. 910.1"

On 2020-10-15 9 - by (mod) -

PT

I agree that a dripping water sound can be very disturbing.

Take a look at https://inspectapedia.com/noise_diagnosis/Dripping_Water_Noise_Diagnosis.php

DRIPPING WATER SOUND SOURCES

for some suggestions. Let me know what you think by posting follow-up remarks there;

As it may prompt help from another reader I'll also copy your question to that page.

On 2020-10-15 by Pt

I have been unable to sleep in bedroom For 1 year due to intermittent drip noises (sounds sometimes like it’s hitting water but no leak) but especially loud waterfall noise in wall where stack is. You can hear the same noise in both bathrooms also which are side to side and there is a stack there also .

I am On first floor in 9 story building built in 1969. Cast iron in the vertical stacks. Plumbers are clueless and say the noise is not normal. Louder than it should be. I don’t know where to turn.

On 2020-09-21 - by (mod) - plumbing vent clearance to dryer vent

Anon:

Anon:

Both of these are exhaust devices;

We provide the major plumbing codes at PLUMBING VENT CODES - code sources https://inspectapedia.com/plumbing/Plumbing_Vent_Definitions.php#Codes

that's above on this page where you are welcome to download any of those PDF files to take a closer look for yourself.

You won't find an explicit building code statement about clearance between a plumbing vent and a clothes dryer vent on a roof.

I would consider that I don't want lint clogging the plumbing vent outlet.

Please see details at CLOTHES DRYER VENT CLEARANCES & TERMINATION https://inspectapedia.com/Appliances/Clothes_Dryer_Vent_Clearances.php

Here are example dryer vent specifications

An exhaust hood should cap the vent to keep rodents and insects from entering the home.

Do not use an exhaust hood with a magnetic latch.

Locate the vent such that there is no less than 12" (305mm) between the bottom of the exhaust vent hood and the ground surface

Locate the vent such that there is no less than 12" (305mm) between the nearest side of a dryer exhaust vent hood and an adjoining wall or building inside corner

No obstructions by snow, flowers, rocks, plants, fences, walls, air conditioner condenser/compressor units, etc.

For other readers, a "Dryer Jack" is a roof exhaust vent such as the model shown below, from DryerJack = https://dryerjack.com/

On 2020-09-21 by Anonymous

I am planning to install a Dryer Jack on my roof with 41" sheet aluminum vent pipe going from it to dryer. There is a 1 1/2" plumbing vent pipe exiting the roof about a foot from where I need the Dryer Jack installed. Is this within code?

On 2020-08-28 by francine lowe

By regulation, does every room of a residential home have to have a HVAC register? My powder room has an exhaust fan, but no register.

On 2020-08-28 by Anonymous

By regulation, does every room of a residential home have to have a HVAC register? My powder room has an exhaust fan, but no register.

On 2020-08-02 - by (mod) -

Larry you NEVER vent just into the attic, never ever. The vent must go outside. The risks are odor, moisture, and even a methane gas explosion hazard.

On 2020-08-02 by Larry Miller

New home construction, what is the code for venting all of the sewer pipes? Is is legal to vent only to the attic or does it has to vent through the roof of other means to the outside?

Email address is "larrymiller@email.com"

On 2020-07-04 - by (mod) -

You would either route a vent line around in the wall / ceiling from the new location or you might be permitted to use an AAV or air admittance valve or Studor vent.

On 2020-07-04 by Joemomma

I'm moving a bathroom sink to opposite wall across the bathroom. The current location is tied in with toilet to 3" sewer drain line and 2" vent pipe. What do I do about venting the sink 1.5" pipe once I move the sink across the bathroom to opposite wall and tie into the 3" drain/sewer line. Also this project is upstairs

On 2020-06-28 - by (mod) -

Sure, Tracy, but you may need to use an AAV or air admittance valve .

see DEFINITION of AIR ADMITTANCE VALVES / STUDOR VENTS https://inspectapedia.com/plumbing/Plumbing_Vent_Definitions.php#AAV

On 2020-06-28 by tracymayo57@gmail.com

Can you plumb a drain vent under the sink on a outdoor grill island?

On 2020-06-19 - by (mod) -

Shad

Ask your plumber if a vacuum breaker vent can be installed and will be approved by local code officials. If so it'd save a lot of trouble and expense caused by the idiot

On 2020-06-18 by Shad sellers

In this condo some idiot cut the stack at the roof so he could take out a wall and just capped it off. We need to hook it back up by code so we can sell the condo. It runs right through the kitchen. He wanted an open kitchen I guess.

Is it just a matter of connecting ABS from ceiling to floor? I can’t find a sketch of this issue. Any help would be great

On 2020-02-11 - by (mod) -

Final authority to answer that question is your local plumbing inspector.

On 2020-02-11 by loven

I’m in Minnesota. I tied a lav vent into a main stack vent and realized I put the tee so the sweep is facing downward. I know I should of put it the other way. But just wondering if it’s legal so I don’t have to cut everything out.

On 2020-01-04 - by (mod) -

Mickey

You might check with your local building department to see if they have copies of the 1992 Alabama residential plumbing code on file;

I also found some older alabama codes at the Internet Archive by searching for "History of Alabama Plumbing Code"

On 2020-01-04 by Mickey

What was the waste line size plumbing code in 1992 in a residential home in Alabama?

On 2019-12-16 - by (mod) -

Tyler

You can run a vent from other than one end of the drain but that will change fixture drain operation into "wet vents" for some fixtures

details are at DEFINITION of WET VENTED PLUMBING FIXTURES https://inspectapedia.com/plumbing/Plumbing_Vent_Definitions.php#VWet

On 2019-12-16 by Anonymous

What type of material is prohibited for a vent stack? Its on my Plumbing Inspector exam, and I cannot find the answer. I have been choosing Cast Iron pipe

On 2019-12-16 by Tyler

My question is does the vent have to come off the end of the header line or can it be placed in between any of the fixtures and just cap the end. Having issues with accessibility on the end of the line.

I have a sink with a 2” vent tieing in at the bottom of the riser already as shown in the picture.

This main vent acts as a vent for

2 toilets

2 showers

3 sinks

1 tub

Let me know what you think.

On 2019-11-21 by Estela

What is the requirement for a garbage disposal, air admittance valve and P-trap installation. Distance required between P-trap, garbage disposal and AAV

On 2019-09-08 by (mod) - ok for the vent pipe to be at an angle?

It's not, JR, but I can't know this something's wrong without more information.

On 2019-09-07 by JR

I have a roof pipe that is at a angle compare to the others which point straight up is this normal?

On 2019-08-05 by (mod) -

If it's truly only a plumbing vent then you can probably move it over a bit.

However if it's a sewer line clean-out access you may make cleaning the line more difficult in the future.

On 2019-08-04 by dave

In my back yard i have a vent pipe that runs straight down to the pipe that runs out to my alley. If i move this pipe does it have to straight up and down or can I elbow it to move it say 5 feet.

On 2019-06-21 by (mod) -

Sorry Ted I'm not clear on the question. If you mean to ask

Can an improperly-vented clothes dryer be dangerous?

The answer is absolutely, including the risk of a building fire.

You're on our plumbing vent page.

Use the on-page search box for CLOTHES DRYER VENTING and you'll find plenty of detail on that topic. Please take a look and let me know if you have furthter questions.

On 2019-06-20 by Ted

Any dangers in a improper dryer vent in stated incorrectly?

On 2019-05-19 by (mod) -

Marcia

Absence of venting on the drain line can interfere with good drainage, but more-likely, when flushing a toilet, if the vent were blocked the toilet would flush but you'd hear a glub-glub sound at smaller nearby sink, shower, or tub traps.

I'd start by checking the water level in the toilet bowl and the water level in the tank at the end of a toilet tank re-fill cycle after flushing.

More detailed help is at TOILET FLUSHES POORLY https://inspectapedia.com/plumbing/Repair_Slow_Toilet_Flush.php

On 2019-05-09 by Marcia

I have a lower level half bath where the toilet suddenly will not flush (water just swirls around). There is no blockage. We just had some chimney work done - is there ANY chance that the chimney worker screwed up something with the vent pipe that could be causing this?

If so, what are we looking for when we get up on the roof? I am grasping at straws here - I cannot for the life of me see what could suddenly be causing this issue. Thanks in advance for any help!

On 2019-04-28 by (mod) -

I think you just need to measure the pipe diameter, identify the pipe material, and pick up an appropriate length of extension and a union or coupling at your plumbing supplier

On 2019-04-27 by AStrawcutter

I want to extend a plumbing vent pipe. Right now the pipe rises only 10 inches or so. I need a pipe that fits (locks in? maybe) the existing pipe and adds another 6 feet of total height.

Plumbing Vent Clearance Distances to Building Features

The table has moved to VENT DISTANCE to BUILDING FEATURES - code citations

Codes for Plumbing Vent or Vent Stack Clearance Distances

Moved to VENT CLEARANCE DISTANCE CODES

How far can the plumbing vent piping be located from a plumbing fixture?

This discussion moved to DISTANCE: PLUMBING FIXTURE to VENT PIPE STACK

Table of Plumbing Drain Pipe & Vent Pipe Sizes & Critical Distances to Plumbing Fixtures

Moved to DRAIN & VENT SIZE & DISTANCES to FIXTURES

...

Continue reading at PLUMBING VENT DISTANCES & ROUTING - routing & clearance distances for plumbing vents, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see PLUMBING VENT CODES & DEFINITIONS FAQs - questions and answers posted originally on this page.

Or see these

Recommended Articles

- AIR ADMITTANCE VALVES AAVs - Studor Vents Explained

- DRAIN FIXTURE UNITS DFUs - calculate plumbing vent requirements

- PLUMBING DRAIN NOISES

- PLUMBING VENT DEFECTS & NOISES - home

- PLUMBING VENT CODES, DEFINITIONS, TYPES

- PLUMBING VENT DISTANCES & ROUTING - separate article

- PLUMBING VENT REPAIR

Suggested citation for this web page

PLUMBING VENT CODES, DEFINITIONS, TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- International Code Council, 500 New Jersey Avenue, NW, 6th Floor, Washington, DC 20001 Tel: 1-888-ICC-SAFE (422-7233); Fax: (202) 783-2348 International: (202) 370-1800, Email: webmaster@iccsafe.org, Website: www.iccsafe.org

- International Residential Code (IRC), for One and Two Family Dwellings, 2012 (First Printing)

Home Page: publicecodes.citation.com/icod/irc/index.htm

Citation Page:

publicecodes.citation.com/icod/irc/2012/icod_irc_2012_31_sec003.htm - International Mechanical Code (IMC), International Code Council [888] 422-7233, Op. Cit.

- International Plumbing Code (IPC) (see NPC below), Op. Cit.

- National Standard Plumbing Code, (NPC), 2009

obtained From: National Assoc. of Plumbing-Heating-Cooling Contractors in New Jersey at [800] 652-7422 or NAPHCC [800] 533-7694, [Cited by New Jersey State Department of Community Affairs]

state.nj.us/dca/divisions/codes/codreg/pdf_misc_codes/2006_nspc.pdf - New Jersey State Department of Community Affairs, Website: state.nj.us/dca/divisions/codes/codreg/

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.