Knob & Tube Electrical Wiring Safety

Knob & Tube Electrical Wiring Safety

Inspection, Evaluation, & Repair Suggestions

- POST a QUESTION or COMMENT about knob and tube wiring: inspection, detection, & repair advice

Guide to knob and tube electrical wiring:

This article explains the properties, safety concerns and wiring rules for Knob and Tube electrical wiring.

We define knob and tube wiring, we include photographs that aid in recognition of this generation of electrical wiring, and we describe both proper and improper K&T (knob and tube) wiring installations, repairs, or circuit extensions.

Photo at page top: ceramic knobs and tubes readily identify knob-and tube wiring. Photo courtesy of Tim Hemm.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Knob-and-tube wiring in older homes: description, inspection, repair

Knob and tube electrical wiring has been installed in homes from the 1920s right up into the 1970s in some jurisdictions.

Knob and tube electrical wiring has been installed in homes from the 1920s right up into the 1970s in some jurisdictions.

Article Contents

- KNOB & TUBE WIRING PROPERTIES

- KNOB & TUBE WIRING ILLUSTRATIONS - examples of good & bad

- DAMAGED KNOB & TUBE WIRING

- REPLACE KNOB & TUBE WIRING?

- EFFECTS of INSULATION on KNOB & TUBE CIRCUIT SAFETY

- KNOB & TUBE WIRING EXTENSIONS ELECRICAL CODE CONCERNS

- ADVICE on IMPROVING KNOB & TUBE WIRING SAFETY

Knob and tube wiring, if it has not been physically damaged nor modified, is legal and acceptably safe in most conditions, though not as safe as newer grounded electrical circuits.

The photos in this article will assist homeowners and inspectors in recognizing the knob & tube electrical wiring method as well as common safety defects for which an inspector should be alert.

Characteristics & Safety Considerations of a Knob and Tube Electrical Circuit

- No grounding conductor:

Only a hot and neutral wire are provided.

Watch out: A knob and tube electrical circuit has no electrical ground path. - Wire insulation:

The individual electrical wires are wrapped in a rubberized cloth. That was fine when the wires remained suspended in air and had not been chewed by a squirrel.

Look for wires that have been overheated such that the insulation is dry and cracked or crumbling.

Our photo shows a home inspection client pointing out knob and tube electrical wiring in an older home along with an improper extension of the circuit using modern NMC wire.

We say more about that mistake at KNOB & TUBE WIRING EXTENSIONS ELECRICAL CODE CONCERNS

- Knob and tube wiring connections or splices

were made outside of electrical junction boxes. In normal practice, knob and tube wiring splices are soldered and also taped.

We describe these splices at "Taps"

in ELECTRICAL SPLICES, HOW TO MAKE.

- Ceramic tubes (shown above) route knob and tube electrical wires through building framing members:

Wherever the knob and tube circuit wires pass through building framing lumber a ceramic tube is used to insulate the wire from the wood.

These thick ceramic tubes are a good insulator separating electrical wire from wood - if both are undamaged. Our photos just above and just below show knob and tube electrical wiring in the Justin Morrill Smith historic home in Strafford VT.

- Ceramic knobs (shown above) support knob and tube electrical wires passing over building framing surfaces:

Where the knob and tube wiring is surface mounted in a building, it is attached using a ceramic "knob".

These ceramic knobs are a good insulator provided they have not been damaged or modified.

Our photo above at left shows knob and tube electrical wiring in the Justin Morrill Smith historic home in Strafford VT. Also see ceramic tubes supporting knob and tube circuits in other photos and sketches on this page.

Our photo above, adapted from reader Lucas' photo of K&T wire, illustrates previously concealed knob and tube electrical wiring, now exposed as the wall has been opened.

- Concealed knob and tube wiring:

for example, where knob and tube wiring was run inside of building wall or ceiling cavities. Its condition is unknown and it might be unsafe.

Examples of events reducing the safety of knob and tube wiring and increasing the risk of an electrical fire include:- insulation may have been added to the building cavity: the wiring is no longer suspended in open air and is at greater risk of overheating.

- rodents may have gnawed or damaged the knob and tube wire insulation leaving exposed conductors

Even in jurisdictions where K&T wiring remained "legal" up to recent years , concealed knob and tube wiring may be prohibited or, as seen in New York City's 2011 electrical code technical provisions, the installation of concealed knob and tube wiring is not permitted.

NEW YORK CITY 2011 ELECTRICAL CODE TECHNICAL PROVISIONS: ARTICLE 394, CONCEALED KNOB-AND-TUBE WIRING [PDF] (2011) - retrieved 2023/05/06, original source: nyc.gov/html/dob/downloads/bldgs_code/electrical_code_local_law_39of2011.pdf

Illustrations of Proper and Improper Knob and Tube Wiring Details

The sketch above, courtesy of Carson Dunlop Associates, shows the usual ways that knob and tube electrical wiring is connected in homes. Below: knob and tube electrical wiring, including the ceramic components, fasteners, and the electrical conductors themselves may look as if they're in great shape.

That's what I think of the K&T photo just below. But beware: the electrical wiring you see at first glance may be in terrible condition somewhere else in the building. Here are some things you need to know about knob and tube electrical wiring.

Knob and tube electrical wiring:

-

Knob and tube electrical circuits are not "illegal":

There is not a code requirement that they be replaced. However this wiring method is considered obsolete. - No electrical ground is provided:

The circuit is less safe than a modern grounded electrical circuit. Appliances and devices that use a grounded plug should not be connected on an ungrounded circuit. - The knob and tube wiring may have become damaged:

Age, exposure to leaks, or chewing rodents can cause damage. In attics, for example, we often see that this wiring has been damaged by having been stepped on or by chewing rodents. - The safety of the knob and tube circuit may have been affected by building changes:

Adding insulation (discussed below) and modifications to the original circuit (discussed after that) can affect safety.

Damaged Knob & Tube Electrical Wiring

As with any older electrical wiring, but particularly where wiring is exposed such as in an attic floor, the wiring may have been mechanically damaged by foot traffic, building leaks, building movement (earthquakes, for example) or by inattentive electrical or other contracting work.

Beyond the obvious snafus like broken wires or broken, lost ceramic knob and tube supports and insulation, look more carefully at wiring for cracking or damaged insulation.

Look also at the wiring support wherever there is visual access to do so. That may tell you to be more or less worried about the wiring sections that you cannot see.

Watch out: Above you can see that someone has run an old electrical conductor over a nail to "hang" an attic light fixture - a practice that's likely to damage the conductor over time - it is unsafe.

Look to the right of the "light pendant" at the plugs and sockets used to connect additional knob and tube circuits running along the roof: someone who's not an electrician has been at work here, raising a red flag suggesting more thorough inspection of the electrical wiring is needed.

Below, some had a similar attic lighting idea but worse: the light is suspended by hanging it from a knob and tube wire itself.

The second knob and tube wiring damage photograph below shows some of the cracks in the light wire insulation.

But more, knob and tube conductors are not intended to be used to hang the laundry, towels, nor other light fixtures.

Below: the original electrical fuse panel that powered a knob and tube wired Poughkeepsie, New York home is shown before and after we opened its panel door to have a look inside.

and now the mouse hotel:

When / Where Should K&T Wiring be Replaced?

OPINION:

K&T wire probably should be replaced with grounded circuit conductors when you're doing other electrical work if the wiring is easily accessible such as in an attic or basement, or if the walls or ceilings are opened for other reasons.

But in some cases that replacement may be more urgent.

It is highly recommended and K&T wire should be replaced if:

- any of the circuits are behaving erratically or intermittently lose power or cause flickering lights

- the K&T wires or joints were ever over heated

- the K&T wires were ever stepped on or otherwise impacted or damaged

- the K&T rubberized fabric covering is brittle and fractured with age

- the K&T wire was ever submerged or extensively soaked

- the K&T wire is already covered by insulation or if it is going to be surrounded by insulation. Any insulation completely changes the fire rating and safety of the K&T wiring.

Ignoring these recommendations is not [a violation of the national electrical code], nor is it illegal, but is risky, unsafe, and potentially dangerous.

K&T (knob and tube) wiring has several major inherent disadvantages compared to modern wiring.

First, it has no third wire ground conductor to protect the user in case of an internal fault within an appliance that a user may plug into a receptacle.

Second, the wires and receptacles are not polarized. This means that the larger shell of an incandescent lamp or the chassis of a hifi system or computer could be at the 120 volts potential of the hot wire instead of the near zero volts of the neutral conductor.

Both of these conditions could lead to a user being shocked or electrocuted which would not happen with normal more modern polarized and grounded electrical system.

With age, the rubberized cloth insulation on K&T may decay with mold, may dry out and fracture, and sometimes even falls off, potentially exposing people to hot electrified wires.

Old K&T is legal in the sense that it has been grandfathered in. Codes do not mandate retroactive replacement. However, it is absolutely not permitted or legal to install new knob and tube circuits today, and in many or most locations, it cannot be extended or modified.

K&T wiring is probably okay if:

- the K&T wire is fully contained within a wall or joist cavity where it is fully protected from being stepped on, being accidentally pulled or displaced, or otherwise damaged

- the K&T wire insulation is still intact

- the K&T wire has not been overheated

- the K&T wiring has not been subjected to flooding or soaking

See details at WET SUBMERGED K&T WIRING

- also opinion of reader Ozzie at sonic.net, by private email 2017/03/31

Effect of Building Insulation on Knob and Tube Electrical Circuit Safety

Adding building Insulation changes the knob and tube wiring game:

Watch out: The fire safety of knob and tube wiring relied on the fact that the wires were generally routed through the air, suspended by knobs and protected by a heavy ceramic tube where passing through wood.

Later, if building insulation is added in walls or ceilings such that it covers the original knob and tube wiring, that wiring is at risk of overheating, is unsafe, and could lead to a building fire.

The two photos above, courtesy of Tim Hemm, show a knob and tube circuit that has not been covered with insulation (though we wonder about the significance of those leak stains on the ceiling joist forming the attic floor), while the knob and tube circuit in the next photo has been partly buried in blown-in cellulose insulation.

We pose that the same insulation project may have filled wall cavities with insulation too, possibly leading to overheating of knob and tube circuits that run in the building's exterior walls. We're also concerned that where knob and tube wires have been run in an attic floor and later covered

by insulation, there's a good chance that someone walking in the attic has stepped-on and damaged the wires - a condition we've found often.

The contractor who blew cellulose loose-fill into the attic shown above wanted to make the home warmer. You can see that covering the knob and tube electrical wiring makes it easy to step on it while clambering around in a dim attic:

damaging the wiring, causing a fire, an event that will certainly warm the home. Consider also what two-word expletive you'll grunt while falling through the ceiling after you trip over a "hidden" electrical wire.

Where knob and tube electrical wires were routed in walls or in attic floors, and where later those building cavities have been insulated, the knob and tube wires are no longer suspended in air, can become hotter than intended, and may be a fire hazard for that reason.

Safety & Electrical Code Concerns with Knob & Tube Electrical Circuits that have been

Extended, Spliced-into, Modified or Disturbed

Model electrical codes do not prohibit the presence or use of knob and tube wiring circuits in buildings, but you will want to be sure that the specific knob and tube wired circuits in your building are in good condition, safe to use, and that the circuit has not been improperly modified.

Below is a photo of knob and tube wiring supporting a light fixture - well not exactly.

Watch out: This wiring makes me nervous:

First: running an old brittle electrical wire conductor over copper plumbing pipes, even with a bit of extra covering risks shorting the electrical circuit to the piping - risking a nasty or even fatal shock to any building occupant who has the bad luck to touch a metal pipe or even a metal faucet that's connected to the pipe.

You can see that someone else was nervous too, as they put a bit of tape over the pipe under the wire.

Second: that knob and tube connector was designed to hold electrical wire in its route to a destination. It was not designed to hold a suspended light fixture.

Third: the electric wire runs right into a lamp socket without the usual bushing or other protection against abrasion or notching or wire damage that would be provided in a proper light fixture.Extensions to knob and tube electrical wiring:

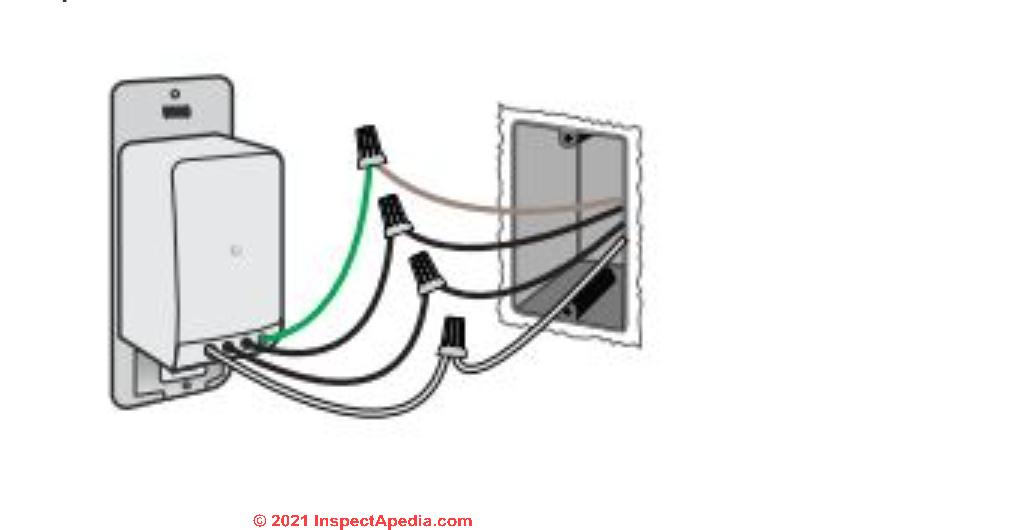

Often the original knob and tube wired electrical circuit has been modified or extended by subsequent building owners/occupants - an improper practice that may not be permitted depending on codes that apply where the building is located. Carson Dunlop's sketch, above illustrates how knob and tube circuits are often extended.

Image provided courtesy of Carson Dunlop Associates, a Toronto home inspection & education company.

Our photo below shows an inspection client pointing to a modern plastic NM electrical cable that has been used to extend an older knob and tube electrical circuit. You can see more of that modern plastic NMC as the white wire running horizontally below the client's arm.

In some jurisdictions, extending an existing knob and tube circuit is not recommended, and is even an illegal installation: adding load to the knob and tube circuit, risks increasing the temperature of the wiring and possibly causing a fire.

Watch out: for improperly abandoned knob and tube electrical wiring, knob and tube circuits that have been extended to include new circuits and devices, damaged knob and tube wire and wire insulation, knob and tube wire that has been insulated-over or around, changing its heat rating and perhaps creating a fire risk, and other K&T damage or defects that make the wiring system unsafe.

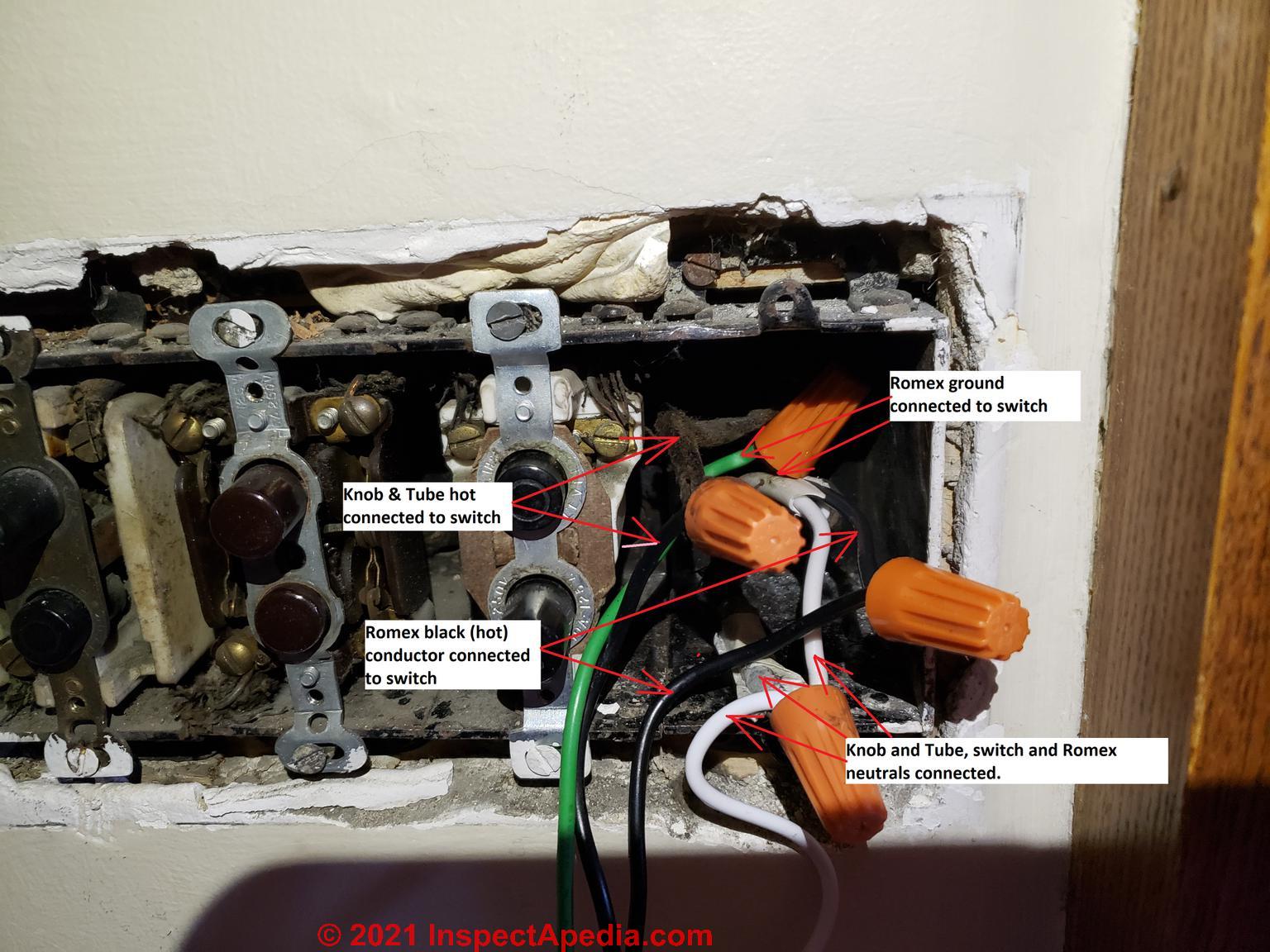

Our photos below show a combination of errors, extending a knob and tube electrical circuit and a twist on connector electrical splice outside of an electrical junction box. Immediately below is a DIY extension of an existing knob and tube electrical circuit.

Extending an existing K&T circuit to add more circuits, wires, devices, switches, lights, receptacles is not permitted. The concern is that you're going to overload an old electrical conductor, causing overheating and a fire: a risk that is increased if the wiring has been insulated-over or has been gnawed bare by rodents.

Below: this knob and tube circuit has been extended by running it into an electrical box.

Above and below: the knob and tube wiring circuit has been run to an electrical box where it is used to extend to additional circuits in the building.

Then there's more: the DIY wiring, missing box cover, overcrowded electrical box, unprotected knob and tube conductor run through the electrical box opening, damaged wiring conductors, exposed bare wires at splices, possible evidence of wire overheating, and more. [Click to enlarge any image]

The photo below also shows three types of electrical circuit wiring: knob-and-tube, armored "BX" cable, and plastic cable wires. The photo shows therefore three generations of electrical wiring (and probably other modifications) in this building.

Below: take a close look at this photograph and note the blackening of an old sill plate and ceramic knob. I think this electrical circuit may have been exposed to fire. If so the wire itself is likely to have suffered damage and may thus be unsafe.

Advice about improving the safety and reliability of knob and tube electrical wiring

[Click to enlarge any image]

Above: new knob and tube electrical wiring applied to a lighting circuit in Japan.

- Inspect the whole electrical system: An expert should inspect the condition of the building electrical wiring, including the wires, connections, devices like receptacles, switches, and overcurrent protection by fuses or circuit breakers.

- Replace bad circuits: Knob and tube circuits that have been modified, damaged, or covered with insulation should be replaced with a modern grounded electrical circuit.

- Ground fault protection GFCI CIRCUIT PROTECTION

and possibly ARC FAULT CIRCUIT PROTECTION can be added on two-wire ungrounded electrical circuits to reduce the chances of electrical shock or fire - steps that we recommend.

See details at AFCIs ARC FAULT CIRCUIT INTERRUPTERS.

(A homeowner cannot safely test a GFCI while it is in place, installed on an electrical circuit that has no ground but the GFCI can still be expected to work correctly if it is wired properly.)

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

What type of clamps/connectors are recommended for when K&T wires need to enter into a modern metal box?

Photo above: original ceramic wiring bushings used on knob and tube circuits where wires entered the electrical panel.

Hi, I wanted to ask what type of clamps/connectors you recommend for when K&T wires need to enter into a modern metal box?

My initial thought was the NMSC connectors on Raco boxes would be preferable as they provide 2 separate small knockouts (i.e., the wires would remain separated), but I've seen info that this would need to a “slot” cut between them to keep magnetic fields from surround the two conductors.

Would having the two wires go through 1 single connector be preferable? And/or would plastic connectors be better than metal?

Thanks so much - On 2023-05-15 by Robert -

Reply by InspectApedia DF (mod) - plastic wiring knockout wiring opening protector

@Robert,

Bottom line: Re-routing old knob and tube wiring into a new electrical box or panel the electrician typically uses BX type clamp connectors. The installations I've seen included additional friction tape wrapped around the wires for added protection.

Details:

Illustration from Code Check by Robert - discussed below - summarizes handling knob and tube wiring in existing buildings.

1. Best: Wrapping the K&T wire with friction tape where it passes through a steel BX connector without its clamp,

or a Raco plastic connector might be what one of the old timers would have done. In my opinion and from what I can find elsewhere, this is the best solution.

2. Plastic opening protector

First, for other readers, here's an example of the plastic wiring knockout wiring opening protector mentioned by Robert. Like the antique ceramic knob and tube connectors, it only passes the electrical wire through an opening; it doesn't grasp it.

But as you can see, the designers also think you're passing NMC wire not antique, less-insulated knob and tube wire.In original installation, where knob and tube electrical wiring entered/exited from the electrical panel, round ceramic strain reliefs were employed, such as those shown above, at the start of this question, in my photo taken in a Poughkeepsie New York home a decade or so ago.,

This knob and tube electrical panel was no longer in use, so you won't see any wires, just the steel panel enclosure and ceramic strain reliefs.

These ceramic knob and tube strain reliefs were manufactured in two parts that simply screwed together through the electrical panel knock-out opening - a make and female half. Thus we have a smooth ceramic - lined opening through which one or two knob and tube wires passed into and out of the electrical box itself.

Similar strain reliefs would have been used at an electrical junction box for knob and tube, though those were more rare as more-often splices were in open air, wrapped with friction tape.

At a modern installation I suspect that we'll have trouble finding a strain relief that is problem-free and completely compliant with modern electrical codes.

A steel clamp type strain relief will pinch the wires in a way never intended in original knob and tube wiring design. The wire insulation may be too thin and fragile to pinch safely.

3. The Raco NMSC plastic strain reliefis closer to the original ceramic ones in concept but is designed to pass modern electrical wiring that has more-durable insulation in more layers.

3. Unprotected steel box knockout openingsI'm sure you'll agree that we would not just pass K&T wires through an unprotected knockout opening - risking abrasion, wire damage, a short circuit.

4. Antique ceramic knockout opening protectorI'm concerned that a technically attentive electrical inspector could not even approve (except as "grandfathered") an open ceramic strain relief originally intended for knob and tube wiring when added to a modern electrical panel because the ceramic knob and tube wire strain relief does not close off openings completely enough to protect against the escape of sparks.

5. The electromagnetic fielditself isn't a concern any more that it is in modern NMC electrical wiring that places the hot and neutral and ground just mm apart. But the insulation properties are a concern. K&T wiring insulation presumed that wires ran in open air to allow heat dissipation.

I would be very grateful if you'd ask your local electrical inspector what she or he will accept for this knob and tube wire-to-panel strain relief installation, noting that option 1 above is preferred.Reader follow-up: Code Check Electrical book answers knob and tube question

@InspectApedia DF, First off, thank you for all your info. On a side note, I personally wanted to avoid the plastic button clamps: These are very, very tight and difficult to pull wire through...fine for romex, but (to me), too much stress on knob & tube insulation.

But...I'm a dumb-butt: I have a copy of the Code Check Electrical book, and didn't realize it actually had a section devoted to this exact question.As you can see...both wires enter through one knockout in a metal box (using standard romex-style clamps), but separate holes in plastic boxes. So...mystery solved, thank you so much again for all your time and help.

Question: my knob and tube wiring is buried in insulation - is that OK?

Re-posting from private email:

[I] thought I put picture and question in comment but don't see a response.

I am trying to identify this type of insulation- looks like a rope that is spun.

- Anonymous by private email 2020/10/12

Moderator reply:

Your photos look like mineral wool insulation.

Watch out: burying knob and tube wiring in insulation is common but unsafe as the wiring was originally designed to be cooled by running in free air.

Reader follow-up: I was told there can't be insulation in floor because your not suppose to be next to knob and tube. Mine is buried in the insulation. I am so thankful for this website.

Thank you for the clarification. I am so thankful for this website. The house built it 1904, has knob and tube. Was told there can't be insulation in floor because your not suppose to be next to knob and tube. Mine is buried in the insulation. Looks like it has been there a long time.

Moderator reply:

Whoever told you about not insulating around K&T was, more or less, correct. That knob and tube wiring, quite safe in its original concept, expected to be suspended in air in building cavities; when you insulate it you raise its potential temperature and could make the wiring unsafe.

However adding insulation was very common and zillions of homes were so-modified.

If you're not going to face the cost of re-wiring, at the very least, be sure that none of the circuits is over-fused, and take care to keep the load on those circuits to a minimum - no electric heaters for example.

Reader question: How to identify extended, modified Knob & Tube Wiring in a 100 year old House

Kind of an emergency question. I’m 500 miles from home, assisting my 70 year-old brother, who’s now quite immobile. His house is 100 years old, and four stories tall, and features a hodgepodge of wiring, including ACTIVE knob and tube.

He has all the risk factors in your very helpful article: past rodent activity, blown in cellulose insulation, past water damage, and extensive use of resistance heaters in multiple rooms.

My question is: assuming that some original K&T circuits have been spliced into, how do I identify which circuits those are, given that the splicing can have been made at either end? For example, there are no K&T runs that enter the updated panel. 2023-04-16 by jackofallthumbs Emergency

Reply by InspectApedia Editor - You can not, in my opinion, identify original knob and tube circuits that have been extended or "spliced onto" by electrical tests of any sort

@jackofallthumbs,

You can not, in my opinion, identify original knob and tube circuits that have been extended or "spliced onto" by electrical tests of any sort,

but you can inspect the most-likely areas where such splices occur. I'll list those that occur to me.

1. Look in the basement or crawl space for knob and tube circuits and follow the wiring; Look for newer BX (armored cable) or Romex or plastic or NMC cable as well and follow it to its termination - by eye.

2. Look in the attic with the same object in mind as in step 1

3. In finished areas of the home, look at electrical receptacles to see if you are finding a mix of older two-prong with no ground - type receptacles and newer electrical receptacles that sport a ground plug opening.

In a K&T wired home I am suspicious that

- grounded electrical receptacles may have been installed as a repair or an "update" simply by replacing older ungrounded models, but in fact there may be no ground present.

That's not an immediate disaster, but I want to be double sure that no one installed a bootleg ground such as to a nearby water pipe or to metallic-sheathed wire - using those as a ground path is unsafe;

4. Since you are seeing NO knob and tube runs connected right into the main electrical panel, follow the wires again, looking for a sub panel or even one or more larger junction boxes that feed knob and tube circuits from wires in the main panel.

5. For high-risk areas, you can install GFCI or AFCI or both types of electrical receptacles (kitchen, bathrooms, garage, basement) to reduce the shock hazard. Those devices can work to reduce risk even where no ground is present, though they can't be tested using their built-in test buttons (as those rely on a local ground).

6. I'm concerned about changes to the K&T wire that increase the risk of a fire, such as

- rodents chewing off insulation from the wiring

- addition of blown-in insulation in wall or ceiling spaces where K&T was run - changing the heat properties of the wire that was intended to be suspended in open air

If you find a K&T circuit that's obviously damaged, safest is to shut it off entirely, pending re-wiring.

Post some photos (one per comment) of what you're finding and we can comment further. - DF

Reader question - How to repair break in knob and tube wire in attic?

Thanks for taking questions and taking the time to run an independent free advice site.

How to repair break in knob and tube wire in attic? Discovered that the installer of a whole house attic fan had cut and spliced unrelated live knob and tube wires to reroute them around the fan. The K&T wires were simply wire nutted to single conductor THHN at each end, no junction boxes used.

We suggest removing the spliced section, installing a plastic junction box at each end, and replacing the THHN with Romex. Bring each K&T wire into its JB through the built-in plastic pinch connector, wire nut it to the Romex. Route and fasten the Romex per code.

Is this the best way to do it? Thanks for taking questions and taking the time to run an independent free advice site. I'll keep your site bookmarked and your advertisers in mind. On 2022-04-12 by Mad Monty

Reply by Inspectapedia Com Moderator

@Mad Monty,

Thank you for your kind comment - we work hard on this material so we're really grateful when readers notice what we're up-to.

About that K&T wiring, as you probably know, current electrical codes permit K&T to remain in use (*provided it's undamaged) but it's not supposed to be extended.

That puts us in a tricky spot when a case like yours comes-up: the K&T circuit needs to be interrupted and re-routed around something else being installed.

While original knob and tube splices were often left exposed, wrapped in cloth friction tape, for a modification such as you describe, I would put the splices in a modern electrical junction box and use approved twist-on connectors. Then cap off the boxes with simple blind cover.

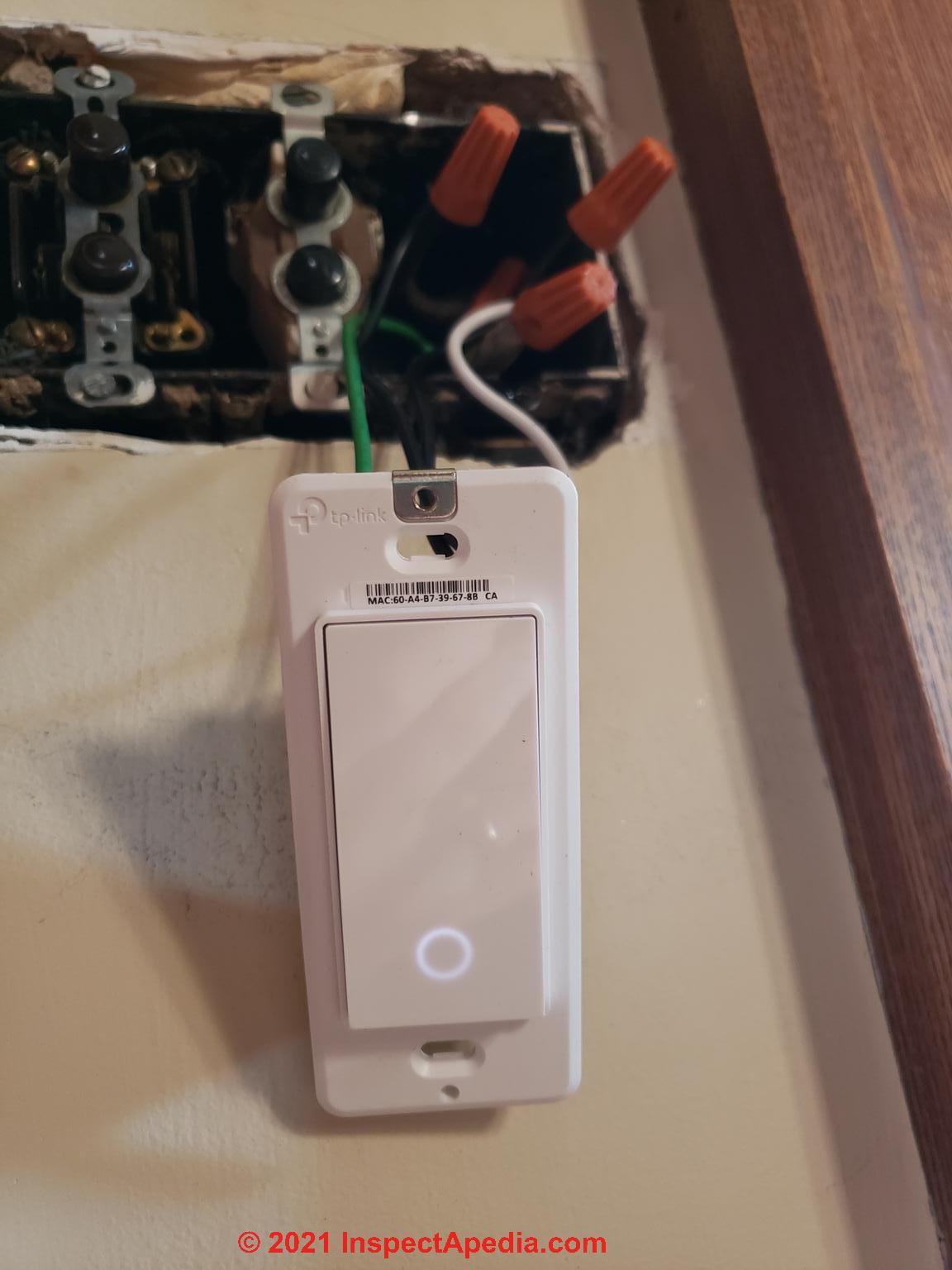

Reader question - How do I replace a manual switch with a Kasa smart switch on Knob and Tube electrial wiring?

I still have some knob and tube wiring in my circa 1910 house.

I want to replace a manual switch with a smart switch. I have identified the hot and neutral wires of the knob and tube at the switch.

I have run a two wire Romex type cable to the switch box as well. I hooked everything and the smart switch has power but it can't turn the light on.

Any suggestions?

Cheers -

Ken On 2022-04-12

by Mad Monty

Reply by Inspectapedia Com Moderator - I still have some knob and tube wiring in my circa 1910 house.

@Ken,

I'd like to be more-helpful but from just your note I don't know what wires are present nor to what they are connected - what terminals, etc.

In general an electrical switch has no business needing the presence of a ground wire to operate properly - if it does I suspect a wiring error.

In other words, a "smart switch" should work properly regardless of the presence or absence of a ground wire.

However you should consider adding circuit grounds for improved safety, and depending on where you live you might be required to use a licensed electrician.Reader follow-up:

@Inspectapedia Com Moderator,

The attached is basically the wiring schematic. Sorry, I should have taken a picture of what I had installed. I have removed it and replaced it with the old mechanical timer switch just using the knob and tube wiring.

In my case, one of the black (hot) wires is a knob and tube wire that goes to a front porch light fixture. The other black (hot) wire goes to the closest plug receptical where there is power. I installed that.So, it is a new 3 wire conductor. Since there is no ground in the knob and tube the ground wire in the new cable is not used, that is, there is no ground wire connection as shown in the diagram.

The neutral knob and tube is connected to the other white neutral that I installed. It boggles my mind why the smart switch gets power but it can't turn the porch light on. The smart switch is a Kasa HS200.

I'm in Toronto, Ontario, Canada. Cheers Ken

Reply by Inspectapedia Com Moderator - smart switch isn't working

@Ken,

I haven't seen the IO manual for your smart switch - we should both look at it and you might give the CO. a call, too.

I'm unclear on how power is fed into the switch and whether or not there'd be a problem if we feed power IN to the switch on two separate HOT lines that are in opposite phases vs. on the same phase (typically your panel supports two groups of 120V circuits, on two different phases).Review the grounding requirements for your switch.

Reader follow-up:

@Inspectapedia Com Moderator,

OK I haven't looked at the manual either. I will have a look at it. And, if nothing there, I will try to contact them.

Either way, I'll let you know what I find.

Two separate hot lines is an interesting idea. I did hook up one of these Kasa smart switches for a back porch light with an identical circuit where no knob and tube was involved and it worked!! Crazy eh!Reader follow-up: smart switch should work with knob and tube electrical wired circuits

@Inspectapedia Com Moderator,

So, I have been emailing back and forth with a tech. rep. from Kasa. They claim that the switch should work with the knob and tube.

To help, I rewired the Kasa HS200 switch so that I could take some pictures to send to them. I just sent them the pictures today.

I am sending them to you too so that you can see how I wired it. As you can see the switch is getting power but it still won't turn on the porch light.And here is a picture of the switch showing that it does have power.

Reply by Inspectapedia Com Moderator - look for a wiring error in your smart switch hook-up to a K&T circuit

@Ken,

With power to the switch and with confidence that you wired the switch correctly from power-in to power-out to the light fixture

if the light does not turn on

- are there any splice boxes in the circuit between switch and light fixture? If so check their connections

- is the light fixture itself defective: swap in a simple test bulb or use a neon tester or VOM/DMM to check for power at the light fixture wires

- are we going to be embarrassed to find that we had a bad fixture bulb? (It's not a fluorescent that might have a bad starter or ballast, right?)

Reader follow-up: - Kasa switch j not working on knob and tube circuit

I don't know if there are any splice boxes. I would have to open up walls and ceilings to to see and I'm not going to do that ... not worth it.

I swapped out the bulb (incandescent) and I tried another Kasa switch just in case the one that I first tried was defective. No luck with either.

Remember, when I reconnect the existing mechanical switch, it works.

From the picture that I sent, does it look properly connected to you?

I'll see what the Kasa rep. says, but I have this feeling that it baffles them too.Reply by Inspectapedia Com Moderator - smart switch not working on K&T circuit - diagnosis

@Ken,

Good to eliminate the possibility of a bad bulb.

Good to remember that the light works when wired to a conventional switch.

Good to affirm there are no splices or devices or junction boxes on the circuit between switch and light.

And this is a 2-way switch setup, right, not a 3-way switch - that is, only one switch operates the light fixture.

And you're not switching some type of light that wants more current than the switch can handle, right.

In this case either we've missed something, OR provided it's wired correctly, you've got a defective switch.Reply by Inspectapedia Com Moderator - Changing out manual switch for a Kasa HS200 smart switch with knob and tube wiring - SNAFU

@Ken,

Please do keep us posted as what you eventually find out as the cause of this light switch problem will certainly help other readers as well.

The conversation demonstrates the difficulty of troubleshooting building problems based solely on text and self-reporting.

In over 50 years of building diagnosis I have found that virtually 100% of the time that I actually went to a building site I was able to find importance details that weren't previously obvious or reported.

It might be that an experienced electrician at your site would spot either one of the electrical problem causes that we've already suggested or something else that hadn't occurred to any of us.Reader follow-up: - still working on my K&T smart switch wiring

Thank you very much for all this. I'll go through it all. May take a while

I did use a VOM to determine which were the hot and neutral Knob and Tube wires in the switch box. I did this by measuring the voltage across each Knob and Tube wire and a totally separate wire that was grounded on the copper water pipes coming into the house.It is definitely not a three way switch nor have I switched to a type of light that requires more power.

And, I did try another Kasa HS200 switch that I have ... same thing ... its getting power but can't turn on the light. Very frustrating.

I have read through all this material that you provided, but still no clues as to why the Kasa smart switch can't turn the porch light on. Thank you again for providing the material.

Also, the Kasa tech. rep. says that it should work too.

So, the mystery will continue. I will keep searching.

Thank you very much again for all your help.Reply by Inspectapedia Com Moderator - smart switch not working on K&T circuit: Diagnostic Steps

@Ken,

Adding: the switch has to connect to your WiFi and probably has to be re-booted, right?

Are we sure it's set up and booted?

Have you got these two documents:

KASA HS 200 SMART SWITCH USER'S GUIDE [PDF] (2021)

KASA HS200 SMART SWITCH WIFI INSTRUCTIONS [PDF] (2020)

skimpy but might help - explains about downloading the app

TP Link offers: support and guides at www.tp-link.com/support

One last thing:

Watch out: on your original light switch wiring, I am not sure which wires were used. Sometimes the white wire is used NOT as a neutral wire but as the second power wire to the switch.

And watch out: switch wiring for a light can be confusing depending on the original source of power to be taken to the light fixture.

Case 1: power arrives in the electrical box where the switch will be mounted and runs through the switch and on to the light; the light has to have its neutral wire in its electrical box running back to the panel.

Case 2: power arrives in the electrical box where the light fixture itself will be mounted, is routed down to the switch then back up from the switch to the light fixture itself.

Let me describe this case in more detail:

If we start at the light fixture:

Power in to the fixture (K&T, no ground) provides 2 wires

TWO MORE wires (a pair) are run from the fixture's electrical box down to the switch. Often in older wiring these are a white and black pair.

- black (hot) (if properly wired)

- white (neutral) (ditto)

ONE of them, usually a black wire, is wired FROM the HOT in the electrical box where the fixture is mounted TO the switch, to one of its switch-terminals.

The second wire of the pair from fixture's electrical box down to the switch is often the white wire - it should have been black-taped to indicate it's not a neutral, it's being used to carry current.

In the electrical box for the fixture, that WHITE wire (end taped with black tape) is connected to the light fixture's BLACK or incoming power terminal. The other end of that WHITE (End taped with black) wire runs from the fixture down to the switch where it connects to the second switch terminals.

So that pair of wires is in essence interrupting power in the light fixture's electrical box, taking it down to and back from the switch and the onwards to the light fixture's black or incoming power wire or terminal.

Separately, a true neutral, WHITE wire, in the light fixture's electrical box is wired to the light fixture's white or neutral terminal.

Have you used a VOM or DMM to make absolutely sure your wires are correctly identified:

That white wire is supposed to be neutral.

The two black wires are the hot or switch wires that operate the light.

If you're unclear on which wire does what, check theKASA HS200 SMART SWITCH WIRING GUIDE [PDF] provided by the company - original source tp-link.com/us/support/faq/1128/

I infer that the smart switch itself needs a neutral wire as well as power in on one of those black wires (as it has to run its little computer chip and wifi chip) and it will sport a second “black” wire that sends power up to the light fixture.If you haven't seen it

LIGHT SWITCH WIRING DETAILShas what I think are very clear illustrations and text on light switch wiring.

Eventually we'll move this discussion to that page. Maybe after you've got the switch working.

...

Continue reading at OLD HOUSE ELECTRICAL SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see KNOB & TUBE WIRING FAQs - questions & answers posted originally at this page

Or see these

Recommended Articles

- ASBESTOS ELECTRICAL WIRE INSULATION

- ELECTRICAL PANEL FUSED NEUTRAL WIRE HAZARDS

- FALSE GROUND at RECEPTACLES

- FALSE GROUND, BOOTLEG & FLICKERING LIGHTS

- KNOB & TUBE WIRING of Proper and Improper Knob and Tube Wiring Details

- OLD ELECTRICAL WIRING HISTORY

- OLD ELECTRICAL WIRING TYPES

- OLD HOUSE ELECTRICAL SYSTEMS

- WET SUBMERGED K&T WIRING

Suggested citation for this web page

KNOB & TUBE WIRING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [2] Timothy Hemm, Yucala, CA, contributed various photographs of electrical equipment installed in California buildings. Mr. Hemm can be contacted at TimHemm@yahoo.com

- [3] Kosta Trivlidis Home Inspector (AIBQ) National Home Inspector (NHICC) CSI Inspections Inc. csiinspections.ca kosta@csiinspections.ca

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- "Electrical Systems," A Training Manual for Home Inspectors, Alfred L. Alk, American Society of Home Inspectors (ASHI), 1987, available from ASHI. [DF NOTE: I do NOT recommend this obsolete publication, though it was cited in the original Journal article as it contains unsafe inaccuracies]

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.