Electric Meters

Electric Meters

Inspect electric meters & meter bases for damage; estimate the electrical service size

- POST a QUESTION or COMMENT about inspecting, installing, replacing residential electric meters

Electric meter inspection & repair:

This article discusses the visual inspection of electrical meters & meter bases & explains how to estimate the electrical service size, (or "electrical power" or "service amps") at a building by visual examination of the service entry cables, electric meter and meter base, electrical service panel, main switch, & other details.

We describe types of electric meters, meter inspection points, and how to read an electric meter. We also discuss electrical arc burns at the meter base and we include case reports of electric meter base overheat and arcing damage, failures, and repairs.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Electric Meters & Meter Bases

Visual inspection of the electric meter and use of digital multimeters (DMMs), Volt-ohm meters (VOMs), neon testers, and electrical inspection safety are discussed here along with tips on how to read an electric meter and how to read a smart meter or digital electric meter.

Visual inspection of the electric meter and use of digital multimeters (DMMs), Volt-ohm meters (VOMs), neon testers, and electrical inspection safety are discussed here along with tips on how to read an electric meter and how to read a smart meter or digital electric meter.

Photo: a free-standing electric meter and base panel outdoors in Port Angeles WA, USA. [Click to enlarge any image]

We discuss common electric meter defects, inspection points, and also meter readings, as we include photographs and sketches illustrate electrical panels, meter bases, and electric meters of various types in several countries.

One of the most frequently asked questions at home inspection conferences and education seminars is "How do I determine the service amperage?"

This question is no surprise, as even a casual inspection of the components of a building electrical service can turn up inconsistencies among service entry cable size, electrical meter rating, electrical panel rating and the main power disconnect ampacity.

Watch out: building inspectors learn quickly enough that just reading off the amperage number on the main power disconnect or5 "main breaker" is not an assurance that we have correctly named the building electrical service ampacity.

And discussion among various experts and one of the original reviewers (Douglas Hansen) quite aptly raised questions about the accuracy of estimating service size in volts or amps by inspecting modern electrical meters.

While some of the cases illustrated here remain accurate, these methods may be unreliable when examining modern electrical meters and meter bases.

Article Contents

- ELECTRIC METER BASE vs SERVICE AMPS

- ELECTRIC METER RATING vs SERVICE AMPS

- HOW TO INSPECT ELECTRIC METERS & BASES

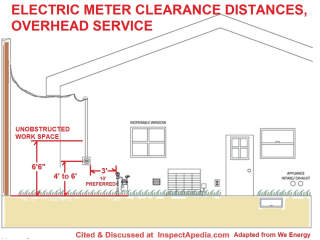

- ELECTRIC METER CLEARANCE DISTANCES & WORKING SPACE

- ELECTRIC METER ARC BURN POWER LOSS

- ELECTRIC METER OVERHEAT AL to CU WIRING

- ELECTRIC METER RUNS BACKWARDS

- SMART or DIGITAL ELECTRIC METER READINGS

It's not as difficult as one may think to get a reasonable handle on the electrical service capacity at a building without sophisticated analysis. But there are some pitfalls, and the process itself is dangerous.

The photos and text below will assist in identifying a variety of electrical meters and service panels of various ages and capacities.

Below: a bank of electric meters in Oxaca and in the second photo a pair of 120VAC electric meters in La Huerta, Mexico illustrate a broad range of meter size and installation.

An article in the Winter, in 1992 an ASHI Technical Journal produce & edited b DF discussed the procedure and considerations for inspectors to determine the service ampacity of an electrical system.

That article indicated that the safe and proper service amperage available at a property is set by the smallest of the service entrance conductor, the main disconnect fuse or circuit breaker, and the rated capacity of the panel itself.

These are also issues of concern for the electrical contractor installing the service. ASHI Technical Journal, Vol. 3. No. 1, Spring, 1993, "Determining Service Ampacity - Another Consideration," Robert L. Klewitz, P.E. Here information has been updated through March 2014. .

Electric Meter Bases as Indicators of Electrical Service Ampacity

A broad view of service ampacity determination must also consider electric meters & meter bases.

A broad view of service ampacity determination must also consider electric meters & meter bases.

The concerns of inspectors must be broad in scope. Inspectors must look at the entire system, some of which may be dictated by the electric utility, and may not be a concern of the wiring installer or National Electrical Code. [National Electrical Code, article 90-2(b)(5)]

Because of this, there is one additional item that must be considered when determining service ampacity. This item is the rating of the electrical meter base and the meter itself.

Often there will be no sure way of determining this rating on a visual inspection, since the rating sticker would typically be inside the meter base and would require pulling the meter off to see it.

However, there are some guidelines and "rules of thumb" that can be used. We will review those here.

Warning: Looking at meter bases and meters to guess at ampacity is questioned by some experts as too unreliable.

Systems that have been installed for the last 20 years or so will typically have a rectangular meter base of various sizes as shown in the rectangular-base meter at left. These are usually compatible with 200 Amp services, although undoubtedly there are exceptions to this.Watch out: Did you notice the measuring tape marking the 3" gap between the siding "J" channel and the top of the meter in our photo shown at above left?

This electric meter had been pulled downwards by backfill settlement which pushed down the horizontal portion of the buried conduit bringing the service laterals to the building. There is risk that electrical wires or connectors between the meter base and the electrical panel (not visible) have been stretched, or even damaged or broken, making the installation unsafe.

I [DF] considered this a reportable defect as it was possible that the buried conduit was broken and subject to water entry from this condition and since the wires entering the building panel from the meter box have were disturbed.

However Mark Cramer points out

that most conduit is not continuous, so breaking it is not really an issue aside from damage to conductors underground.

However Mark Cramer points out

that most conduit is not continuous, so breaking it is not really an issue aside from damage to conductors underground.

In 1976, an Underwriters Laboratory (UL) ruling required that all new meter bases be "continuous rated for 200 Amps," otherwise only 70% of the actual rating would be considered usable, (i.e., a 200 Amp meter base that was not "continuous rated" could only be used on a 160 Amp or smaller service).

Inspectors can probably assume that a rectangular meter base is compatible with the system it is serving, unless a major change or a new panel has been installed.

The meter in our photo at left is obsolete.

Square meter bases such as the unit being pointed to with great caution by an ASHI Headquarters staff member on a field trip in the photo at below-left were normally rated at 100 Amps. Later generations of them were sometimes rated at 125 Amps.

Older electrical systems that were installed 30 or more years ago may be served by a square meter base with a round meter mounted on top of the square base as seen in the next photo at below-center - often called an "A-base" meter.

Still older electrical metering systems used the round meter base shown at below right. Round meter bases originally were rated for 60 Amps when installed 50 or more years ago. (Later generations of round meter bases were rated at 100 Amps.)

These meters can have a NMC main service wire running to and from them, or the wire may be installed in conduit.

[Click any image for a larger, more detailed view.]

The photo just below is an exciting collection of main switch, meter base, round meter above the square base, and a four-fuse "main" panel.

What do you think the ampacity was of this electrical meter, main switch, and fuse panel system?

Electric Meters as Indicators of Service Ampacity

The meter itself is also a consideration when determining the service ampacity of an electrical system.

The meter itself is also a consideration when determining the service ampacity of an electrical system.

Most modern electrical meters for single family homes have the designation "CL200" somewhere on their face, which indicates they are rated for up to a 200 Amp service. The CL200 rating may not limit these to 200 amps. Cramer reports finding larger services with CL200 meter bases.

Inspectors will also occasionally find a "CL10" meter which is a transformer-rated meter for large houses with larger electrical systems or two separate main panels.

Some older meters have other designations such as "15 Amps" on their face. This was their test rating. These meters are only usable on systems up to 100 Amps.

Some older meters were also designated as "30 Amps" on their face and these are compatible with 200 Amp services.

For example, one may occasionally find an older house with an upgraded 200 Amp service that still has an old 15 Amp meter plugged into a new meter base.

This meter is not really compatible with the system and should be replaced. Since the responsibility for the meter varies throughout the country, inspectors should contact the local electric utility for their policies and procedures concerning meters.

How to Inspect Electric Meters & Electric Meter Bases

The antiquated electric meter installation shown here is at the Poughkeepsie NY railroad station.

The antiquated electric meter installation shown here is at the Poughkeepsie NY railroad station.

Electrical inspectors need to examine the meter and meter base and should take them into account when determining service ampacity. The elements to consider are:

- The size/rating of the service entrance conductors.

- The rating of the panel.

- The rating of the main breaker, if any.

- The rating of the meter base.

- The rating of the meter.

The weakest or smallest of these five items will determine the service ampacity of the system.

This inspection will also determine whether or not all parts of the system are compatible with each other and proper for the installation.

The electric meter below shows visual clues that should make the inspector consider water damage and meter safety, an example of another good reason to look at the meter base and meter during your inspection.

Occasionally one may discover these other meter defects or concerns:

- Moisture or water inside the meter face and/or rust on the meter base, such as leaks at the service entry cable or other meter base components. Note the rust at the bottom corners of the electrical meter box in our photo (left).

- Missing knockouts on the meter base - openings into the electrical meter base.

- Broken or cracked conduit at the electrical meter or meter hubs

- Loose connections of the meter base, including meter pulling away from the building wall and loose mounting screws -

Watch out: this is extremely dangerous. You shouldn't even touch an electric meter or panel if you see that it is loose or falling off of the building. Call the electric company to have them drop power to permit proper repair.

Besides the risk of a fatal electric shock is a fire hazard.

We've seen a house fire that originated when a screw from a loose electric meter box fell into the meter and caused a dead short. - Inadequate fastening of the meter base and/or mast to the building.

- Evidence of tampering at the electrical meter, such as a locking ring seal that has been cut and not replaced by the electrical utility company.

- Evidence of burning or arcing at the electric meter connection mounts -

see ELECTRIC METER MOUNTING BASE ARCING CORROSION & OVERHEATING discussed just below.

This condition is unlikely to be visible unless the meter is actually removed from its mounting base.

Watch out: the step of pulling an electric meter or opening the meter base should be performed by a licensed electrician. It is not within the scope of a visual home inspection nor that of a homeowner.

Doing so risks shock or death by electrocution.

Photo: in San Miguel de Allende, Mexico, a CFE electric utility employee is removing the electric meter to inspect the cause of a burn-up and loss of electrical power.

Photo: in San Miguel de Allende, Mexico, a CFE electric utility employee is removing the electric meter to inspect the cause of a burn-up and loss of electrical power.

Notice that the worker's arm is blocked by a tree branch.

Not shown in the photo was the difficulty faced by the worker in removing a security cover over the electric meters (preventing theft of the whole meter itself).

The scope of a building inspector's responsibility is similar to but may even go beyond that of the electrical contractor and the local electric utility in that she must observe and report visual evidence of unsafe or expensive defects and conditions as part of a public trust.

Because of this, the visual inspection of the meter and meter base is an important part of your electrical system inspection, and must be done carefully.

This will help to protect your client's interests and will help fully inform them about electrical system defects and the proper service ampacity of the house they occupy or that they are planning to buy.

Electric Meter Clearance Distances & Working Space

This topic is now found at

ELECTRIC METER CLEARANCE DISTANCES & WORKING SPACE

Electric Meters that Run Backwards

Reader Question: Duncan and General Electric 3 phase meters running sometimes forward and sometimes backwards

8/21/14 Anonymous said:

I have a Duncan and General Electric 3 phase meters running sometimes forward and sometimes backwards. These are not smart meters. I've checked voltages, neutrals and connections. Can anyone help answer or have a remedy for these two meters. The other meters fed from the same source are running fine.

Reply: US DOI document on electric meter testing gives details about meter creep and backwards-running electric meters

If you are not sending electrical power backwards into the grid - say from a local energy source - then I suspect the meter is defective OR more likely your meter is experiencing what I quote below:

8.1.2.3. 3-phase, 3-wire, 2-element Meters.(Figure 11)

An inherent characteristic of this metering circuit lends itself to checking by means of shifting connections. On loads having a lagging power factor greater than 50-percent, both elements rotate forward, whereas on less than 50-percent power factor, one element tends to rotate backward, and will do so if the potential circuit of the other element is disconnected.

A power factor of 50-percent or less is not normally encountered in loaded power circuits. Loads such as an induction motor running with no load or a very light load, or a synchronous motor partly loaded and under excited, will draw current at less than 50-percent power factor.

Also, a generator operated at part load with strong excitation (field) can be made to supply power at less than 50- percent power factor. – “Watt-Hour Meter Maintenance and Testing”, Vol. 3-10, Dec 2000, Facilities Engineering Branch, Denver Office, Denver CO, US Department of the Interior, Bureau of Reclamation, retrieved 8/21/14, original source: www.usbr.gov/power/data/fist/fist3_10/vol3-10.pdf

8.3 [Electric Meter] Creep.

The disk of a meter may move, either forward or backward when all load is disconnected. A meter in service is considered to creep when, with all load wires disconnected and test voltage applied, the moving element makes one revolution in 10 minutes or less. (ANSI Standards, C12-1965).

Meter disks usually have holes or slots punched in them to stop creep when the holes or slots reach a position directly under the potential coil pole. Observation of creep should, therefore be based on at least one complete revolution.

The document we cite lists eight reasons for this "backwards creep" in some electrical meters

(1) Light-load adjustment used to compensate for instead of removing friction. Examine for friction.

If the friction has since disappeared, or is found and eliminated, the meter will be found fast on light load under test, and the creep will disappear when the meter is adjusted at light load.

(2) Short-circuited turns in potential coil. In this case the meter will be found inaccurate e at low power factor. Replace coil or entire electromagnet.

(3) Vibration. Remove cause of vibration. Move meter.

(4) Stray fields either internal or external.

(5) Too high voltage which has the same effect as overcompensation of light-load adjustment.

(6) The potential circuit being connected on the load side of the meter.

(7) Short-circuited turns in current coils. Replace coil or entire electromagnet.

(8) Mechanical disarrangement of the electromagnetic circuit.

A high-resistance short or ground in the customer's circuit can cause a turning of the rotating element which may be mistaken for creeping; therefore, residence wiring should be isolated from the meter when checking for creep.

Although the definition of creep permits one revolution in 10 minutes or less, the serviceman should persevere in eliminating any tendency of a meter to creep. – “Watt-Hour Meter Maintenance and Testing”, Vol. 3-10, Dec 2000, Facilities Engineering Branch, Denver Office, Denver CO, US Department of the Interior, Bureau of Reclamation, retrieved 8/21/14, original source: www.usbr.gov/power/data/fist/fist3_10/vol3-10.pdf

Digital or Smart Meter Electric Meters

This discussion has moved to SMART or DIGITAL ELECTRIC METER READINGS

Overheating, Arcing, Corrosion at Electric Meter Mounting Bases

This topic moved to ELECTRIC METER ARC BURN POWER LOSS

Aluminum-to-Copper SEC Connection Leads to Electric Meter Burn-Up Failure

A case similar to the U.S. electric meter burn damage reported above by a California reader, is reviewed

at ELECTRIC METER OVERHEAT AL to CU WIRING where we illustrate a wiring connection overheat that resulted in melting electric meter parts and loss of electrical power in one side of the electrical panel.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-02-13 - by (mod) -

Jay

smartgridawareness and other sources such as some smart meter specifications sheets tell us that very low levels of electricity usage won't be registered by a smart meter.

" If the power consumption of the home is between 12 watts and 24 watts as one example, it would not be detected by an analog meter but would with the ACLARA meter."

On 2021-02-12 by Jay b

Zero use investigation to find out why no usage in months.. if it’s a smart meter it should recognize nothing wrong with the meter... people just not using it... seasonal vacant etc.?

How can an Ami send out zero use knowing the breaker is open or it’s not yet feeding anything?

On 2020-08-19 - by (mod) -

PJ

Not necessarilhy, no. But if the meter was damaged by the power surge, then yes.

On 2020-08-18 by Pj

Will the meter be able to show that my house was hit by a surge of power? Power company replaced transformer outside of my house, but they refused to accept any responsibility for the damages to my wires and circuit breaker. They also took meter with them, could I use the reading on it as a proof of higher voltage?

On 2020-02-04 - by (mod) -

Brandon

Depending on which meter base lug is damaged, your electrical company or electrician can either replace that lug or replace the entire meter base; it may be necessary to drop power temporarily at the service entry to make the repair.

Leaving the connection arcing and loose risks not just power loss and flickering lights but a catastrophic house fire.

On 2020-02-04 by Brandon

Had a tree fall across line ripping meter base from house. As I was putting it all back on the one of the screws on the lug was seized up got it turning enough to tighten wire back. Ever since then sometimes the lights flicker in house just some not all and the tv in living room goes off briefly but comes right back on. Never had electrical problems in house until I had the prob with the lug

On 2019-09-07 - by (mod) -

No. Older electric meters that are electromechanical do not store usage data.

For an update on electricity metering technology see this nice article by John Goodman

Collecting Billing Data at the Meter

Innovative metering technology that meets tomorrow’s business requirements today

by John R. Goodman, Senior Account Executive of Metering Systems, Elster Electricity, LLC.

https://electricenergyonline.com/energy/magazine/118/article/Collecting-Billing-Data-at-the-Meter.htm

On 2019-09-07 by Steven

Does a meter using dials store usage memory that can be retrieved if the meter is broken?

...

Continue reading at ELECTRIC METER OVERHEAT AL to CU WIRING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ELECTRIC METER & METER BASE FAQs - questions & answers posted originally at the end of this article.

Or see these

Recommended Articles

- AMPS VOLTS DETERMINATION - home

- AMPS MEASUREMENT AUTOMOTIVE DC

- AMPS MEASUREMENT METHODS

- ELECTRIC METER & SEC SAFETY - Watch out -

- ELECTRIC METERS & METER BASES

- ELECTRIC METER BASE vs SERVICE AMPS

- ELECTRIC METER RATING vs SERVICE AMPS

- HOW TO INSPECT ELECTRIC METERS & BASES

- ELECTRIC METER CLEARANCE DISTANCES & WORKING SPACE

- ELECTRIC METER ARC BURN POWER LOSS

- ELECTRIC METER OVERHEAT AL to CU WIRING

- ELECTRIC METER RUNS BACKWARDS

- FPE ELECTRIC METER BASE & BREAKERS

- SMART or DIGITAL ELECTRIC METER READINGS

- ELECTRIC POWER LOSS / FLICKERING LIGHTS

- ELECTRIC SERVICE ENTRY WIRING & AMPACITY

- ELECTRICAL SYSTEM DEFECTS LIST

- MAIN ELECTRICAL DISCONNECT

- VOLTS / AMPS MEASUREMENT EQUIP

Suggested citation for this web page

ELECTRIC METERS & METER BASES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Watt-Hour Meter Maintenance and Testing”, Vol. 3-10, Dec 2000, Facilities Engineering Branch, Denver Office, Denver CO, US Department of the Interior, Bureau of Reclamation, retrieved 8/21/14, original source: www.usbr.gov/power/data/fist/fist3_10/vol3-10.pdf

- Thanks to reader Kirk Schwoebel for discussing electric meter inspection and evidence of arcing and burns at the meter mounting base - January 2011

- Thanks to reader Robert McBride for providing photographs of arcing and burns at electrical meter bases - July 2011

- The Original Authors: Alan Carson is an ASHI Member, national home inspection educator, author and building failures researcher in Toronto, Ontario. Daniel Friedman, an original author of this article and the editor and producer of InspectAPedia where this article now appears is an ASHI Member, first ASHI Technical Committee chairman, editor and publisher of the ASHI Technical Journal, licensed home inspector, educator, and building failures researcher in Poughkeepsie, NY. Robert Klewitz is a licensed professional engineer, a professional home inspector, an ASHI Member, and has served on the ASHI Technical Committee as well as in other ASHI activities. His practice is in Issaquah, WA.

- Douglas Hansen, Robert Stead. Mark Cramer. Photographs: Daniel Friedman.

- N. Srinivasan, MSEE, is a senior member of IEEE with 30 years experience in the electrical industry. Mr. Srinivasan is in Vienna VA.

- Louis P. Babin generously contributed technical editing about the effects of doubling ampacity in an electrical circuit (September 2007)

- "How to Read Electric and Natural Gas Meters", U.S. DOE original source: www.energysavers.gov/your_home/water_heating/index.cfm/mytopic=13120?print

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.