Do Not Use CU-Only, COALR or CU-AL Breakers, Electrical Outlets, Switches

Do Not Use CU-Only, COALR or CU-AL Breakers, Electrical Outlets, Switches

as a Repair for Aluminum Wire

- POST a QUESTION or COMMENT about using CO/ALR or CU-AL devices (electrical receptacles, "outlets", or switches) with aluminum electrical wiring

Safety advice about using COALR type devices with aluminum electrical wiring: this article explains why COALR, CO/ALR, AL-CU or CU-AL marked devices are not recommended for use with aluminum wiring as a "repair" for aluminum wiring.

We explain the differences between COALR, CO/ALR devices and AL-CU or CU-AL devices - they are not equivalent!

Aluminum wire connections can overheat enough to start a fire without ever drawing enough current to trip a circuit breaker. Making proper repairs to aluminum electrical wiring, using the proper electrical wire connectors and methods, can bring the level of electrical wiring safety in building to about the same as a copper-wired building.

Making improper repairs to aluminum wiring might actually increase the level of risk. The history, differences in performance, and significance of COALR, CO/ALR, CU-AL and AL-CU marked electrical devices in aluminum-wired homes. What are the concerns with COALR or CO/ALR -marked electrical devices when used with aluminum wiring.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Use of COALR, CO/ALR, AL-CU or CU-AL or CU-Only Marked Electrical Devices, Switches or Receptacles with Aluminum Wiring

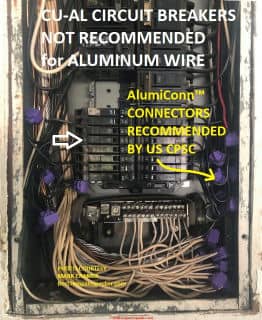

Independent tests support the US US CPSC recommendations for repairing aluminum electrical wiring: only the AMP TYCO COPALUM or the King Innovations AlumiConn connector repair - or re-wiring with copper

[Click to enlarge any image]

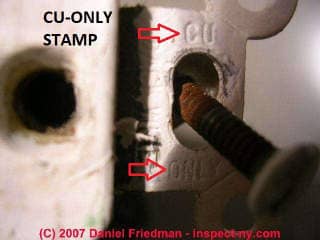

Electrical Receptacles and switches marked COALR, CO/ALR, AL-CU or CU-AL or CU-Only (photo above right) have not been recommended by the US CPSC for aluminum wiring repairs.

However COALR or CO/ALR - marked devices are not and should not be treated identically with electrical devices marked CU-AL or AL-CU.

Also, devices marked CU-only are intended for use only with copper wire.

Article Contents

Article Contents

Prior to the introduction of the "CO/ALR" wiring devices in about the 1973 timeframe, UL did not have any standard or standard tests for wiring device terminals for aluminum wire. The markings prior to that time regarding type of wire were optional for the manufacturer to apply as they wished.

At that time, UL considered all wiring devices with screw terminals as suitable for aluminum wire, even if the devices also had push-in backwired terminals.

The photograph at page top shows back-wired electrical receptacle with an aluminum-wired branch circuit.

The photo just above shows an electrical receptacle whose wires are connected to the (badly corroded and overheated) screw terminals.

In the case in those photos the electrical receptacle shown was marked as "AL-CU" but was further marked as Backwire CU-ONLY by its manufacturer. That stamping is visible on the metal strap of the electrical receptacle shown earlier on this page.

[Click to enlarge any image].

["Electrical receptacle" as used in our articles is a synonym for "electrical outlet" or what some people inaccurately call a "wall plug" or "wall socket".

"Electrical devices" include receptacles, switches, and possibly other electrical components which are connected to the electrical wiring in a building.

Electrical devices marked CU-AL or AL-CU

The CU-AL and AL-CU markings were applied by the wiring device manufacturers at their option, without any special testing for

compatibility with Aluminum Wire.

The CU-AL and AL-CU markings were applied by the wiring device manufacturers at their option, without any special testing for

compatibility with Aluminum Wire.

This was allowed (by UL) until about 1972.

Most of the devices marked this way are identical to those (of the same model # "family" from the same manufacturer) that are not marked AL-CU or CU-AL.

- The AL-CU or CU-AL marking was a manufacturer's option.

Within a brand and model line - Leviton 5320 receptacle, for instance

- there was no difference in design or construction (other than the stamped marking) between the devices that were marked "AL-Cu" and those that were not. - If the electrician and/or jurisdictional electrical or building inspector required the wiring devices to have the markings,

t

hey were available with the markings. - Since the markings were optional with the manufacturer,

there was a wide variety, but most commonly either none or "Al-Cu",

and, either way, the wiring devices were considered to be, promoted as, and sold as suitable for use with aluminum wire. - In about 1974 or so UL published a pamphlet on aluminum wiring which warned that the wiring devices with the "Al-Cu"

marking should not be used with aluminum wire.

[We are looking for a copy of this document - DJF]

Electrical devices marked COALR or CO/ALR

In about 1972, UL and the wiring device manufacturers agreed on a test standard for receptacles for use with Aluminum Wire. The devices that passed the standard were marked CO/ALR.

Five manufacturers initially manufactured "CO/ALR" wiring devices (receptacles and switches), and we believe that one or two continue to manufacture them today.

Since devices marked COALR or CO/ALR conform to the UL standard for compatibility with aluminum wire, the devices with CO/ALR markings must be considered differently - they are not the same as the AL-CU or CU-AL devices.

Summary of Test Results Comparing COALR and CU-AL Electrical Devices

Wright-Malta Corporation conducted long-term tests of "old technology" (including "CU-AL") wiring devices and CO/ALR devices for CPSC.

A total of 1000 receptacles (4000 wire terminations), were tested, including 500 of the CO/ALR (100 of each brand. All of the testing was done within the ratings for the wire size and receptacle application.[Aronstein reports in summary that there were] "... many failures and burnouts of the "old technology" receptacles, and one failure (burnout) of a CO/ALR device."

Electrical devices marked CU-Only

Electrical devices that are stamped CU-Only are intended only for use with copper wiring and should not be used with aluminum electrical wiring.

Should COALR or CO/ALR or CU-AL or AL-CU -Marked Devices Be Used With or as a "Repair" for Aluminum Wiring?

- No. Make the proper aluminum wiring repair instead:

experts including the US CPSC, Aronstein and others recommend that aluminum-wired homes be repaired using only one of the approved, recommended measures described

at HOW TO REDUCE THE RISK of aluminum electrical wiring in buildings - CU-AL or AL-CU marked electrical outlets,

switches, or other devices should not be used as a repair for aluminum electrical wiring. - COALR or CO/ALR marked electrical devices

as tested by Wright Malta Corporation performed better than CU-AL devices when used with aluminum branch circuit wiring provided that the connections and wiring were installed properly.

Aronstein has not [yet] commented, for example, on aluminum wiring and back-wired receptacles with COALR devices nor on field reports of aluminum wiring failures with either type of marked electrical device.

[Other research by Aronstein found poor performance at back-wired electrical devices, most likely because of the very limited contact surface between the spring end and the wire surface. - Ed.]

The replacement of receptacles with CO/ALR devices is treated to some extent in the report "Reducing The Fire Hazard in Aluminum-Wired Homes" a document available atReferences or Citations .

One might reasonably infer that it may be the case that an aluminum-wired home which has properly installed, not-backwired COALR or CO/ALR electrical outlets and switches might be at a lower risk level of an incident than homes without these devices, and such a home is probably at lower risk of an electrical incident than homes wired with CU-AL or AL-CU marked devices.

But risk assessment of the condition of aluminum wiring in any individual building is more complex than just this. Relying on the observation of the presence of COALR devices alone to assess risk is questionable at best. - Don't guess about aluminum wire safety:

We recommend against guessing about the condition of aluminum wiring in a building or making any assumption about its safety if the wiring has not been repaired using an approved method.

We also recommend against relying on superficial and possibly technically un-sound safety surveys using test instruments in buildings as a way to assess the risk of aluminum electrical wiring and as a way to decide whether or not to repair it. - The level of risk in an aluminum-wired building:

Assessing the actual level of risk associated with aluminum wiring at any individual building is difficult, highly technical, requires special equipment and procedures, and should not simply be "guessed" based on casual observations like "no problems have been reported" or " we have COALR devices already installed" or "the workmanship here was good".

The risk of an overheating connection in an aluminum-wired building varies with many factors which are difficult to assess because many of the variables are simply not visible, and because any individual risk assessment, even using special equipment, cannot predict future changes in building conditions, changes that could occur moments after the assessor left these building.

Some of these variables include changes in use of an electrical circuit by a new occupant, changes in the condition of an electrical connection, say at a receptacle, as the device is used, increased deterioration of an individual electrical connection in a building with age or time, variations in electrical installation workmanship from one part of a building to another.

We have received mail from readers reporting that a home inspector or electrician has "looked at the wiring" and has proclaimed it "safe". Such assessments are nonsense, irresponsible, and are potentially dangerous. - The US CPSC has recommended only re-wiring or use of the AMP TYCO COPALUM connector and the "copper pigtailing" repair approach using the AlumiConn™ for

aluminum wiring,

The AlumiConn™ is a more-recent aluminum repair product which appears to perform well in this application and is now also recommended by the US CPSC.

Readers should note that no authority has recommended use of electrical switches or outlets themselves of any kind as a "repair" method for aluminum wiring

Examples of Improperly-Wired COALR or AL-CU Devices with Aluminum Wiring

...

...

These photographs from a large condominium complex wired with aluminum show aluminum wiring connected to an electrical outlet marked CU-ONLY.

- This aluminum-wired device was not installed according to the manufacturer's specifications and is a safety hazard.

Some of the clients at this property wanted to simply replace the electrical outlets and switches with COALR or AL-CU devices. As we've explained above, that is not a recommended repair.

Beyond the concerns with use of COALR devices with aluminum wiring in a building we note two additional worries: - What about all of the other electrical connections and splices in the building?

Even if these devices worked, which has not been demonstrated, I am concerned that any incomplete "repair" of aluminum wiring also risks creating a false sense of security among the building's occupants, possibly leading them to ignore dangerous warning signs of a problem or leading them to fail to complete the proper repair using approved, recommended methods and devices -- OPINION DJF. - Back-wiring any electrical receptacle that uses a simple spring-clip to contact the wire internally gives

a poor and unreliable connection.

In this case the receptacle was (1) back-wired which is a less reliable connection, and (2) was back-wired with aluminum wire specifically in contradiction to the instructions of the manufacturer.

This is an improper and unsafe electrical connection. Some newer electrical receptacles that permit back-wiring use a connector that pinches the wire in a screw-tightened contact and may perform better when used with copper wire or a copper pigtail connected to aluminum wire by an approved connector. -- OPINION DJF

COALR & CU-AL Devices & Aluminum Wiring Repair Resources

Photo of an electrical panel containing aluminum branch circuit wires and CU-AL-marked circuit breakers in which copper pigtailing and AlumiConn™ connectors were installed. - Courtesy home inspector Mark Cramer.

- [1]AlumiConn [Website: AlCopStore.com ] ™ AlCopStore.com

223 Salt Lick Road, #279,

St. Peters, MO 63376

Tel: 866-826-2256, Fax: 636-754-0500, Email Sales: pking@AlCopStore.com, Email General Inquiry: info@AlCopStore.com - Campbell, Richard, HOME ELECTRICAL FIRES [PDF] (2019) NFPA, National Fire Protectyion Association, original source: https://www.nfpa.org/-/media/Files/News-and-Research/Fire-statistics-and-reports/US-Fire-Problem/Fire-causes/osHomeElectricalFires.pdf

Excerpt:

Aluminum wire connections have been found to be prone to deterioration that results in increased resistance to electric current, with the cumulative damage capable of producing hazardous overheating, leading the Consumer Product Safety Commission (CPSC) to recommend that home aluminum wiring be replaced or repaired by a qualified electrician to reduce the potential for fire. - [2] US CPSC REPAIRING ALUMINUM WIRING [As updated 2011] [Web Page Providing Original Document] U.S. Consumer Product Safety Commission Publication REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 available online

Excerpts:

CO/ALR” Switches and Receptacles The other repair recommended by the industry is to use switches and receptacles labeled “CO/ALR.”

These devices are intended for direct connection to aluminum wire, although they can be used with copper or copper-clad wire. CO/ALR devices perform better with aluminum wire than non-CO/ALR devices when installed carefully and according to best electrical practices.

However, CO/ALR wiring devices have failed in laboratory tests when connected to aluminum wire typical of that installed in existing homes.

The test conditions simulated actual use conditions; no “overstress” type of testing was used.

Further, CO/ALR connectors are not available for all parts of the wiring system (e.g., for the permanently wired appliances and ceiling mounted light fixtures).

In the opinion of CPSC staff, CO/ALR devices must be considered, at best, an incomplete repair.

Based on these standards, as of the date of this publication, CPSC approves of only three methods for a permanent repair.

1) Complete Replacement of [ Aluminum Conductor Wire with ] Copper Cable

2) COPALUM Method of Repair

3) Acceptable Alternative Repair Method/AlumiConn Connector

... No other crimp connectors have been evaluated for connecting copper and aluminum conductors. CPSC staff strongly recommends against their use as a repair method.

... Twist-on Connectors ... In CPSC-sponsored laboratory testing and life tests, substantial numbers of these connectors overheated severely. ... this method of repair does not solve the problem of overheating present in

aluminum-wired branch circuits.

... - [3] US CPSC RECORD of COMMISSION ACTION, Commissioners Voting by Ballot [PDF] cover letter, US CPSC Publication No. 516, Repairing Aluminum Wiring (original version op.cit.), (Briefing package dated March 15, 2011, ballot vote due 21 March 2011), Quoting:

The Commission voted unanimously (5-0)·to approve republication of CPSC Publication No. 516, Repairing Aluminum Wiring, with the explicit recognition that the COPALUM and AlumiConn connectors currently are the only products that meet the agency's standards to prevent aluminum wire fire hazards

- US FEMA RESIDENTIAL BUILDING ELECTRICAL FIRES (2014-2016) [PDF] FEMA, original source: https://www.usfa.fema.gov/downloads/pdf/statistics/v19i8.pdf

- [4] Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards.

See ALUMINUM WIRING BIBLIOGRAPHY and

see FPE HAZARD ARTICLES, STUDIES for additional examples. - [5] "The Influence of Corrosion Inhibitor and Surface Abrasion on the Failure of Aluminum-Wired Twist-on Connections", Aronstein, J.; Campbell, W., Components, Hybrids, and Manufacturing Technology, IEEE Transactions on Volume 7, Issue 1, Mar 1984 Page(s): 20 - 24

- Denver CO, & cited in Florida Building Code, ALUMINUM ELECTRICAL WIRING, [PDF] Fire Prevention & Investigation Division, Denver Fire Department, Department of Safety (2001) - retrieved 2019/04/26 original source http://www.floridabuilding.org/fbc/commission/fbc_0411/electrical_tac/aluminum_wiring.pdf

Watch out: the advice in this document that CO/ALR or AL/CU connectors as acceptable is NOT recommended by the US CPSC and risks fire or injury

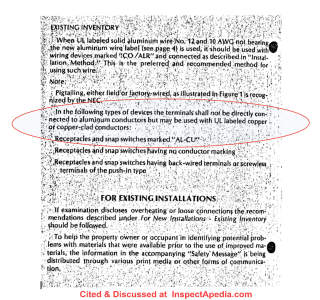

Excerpt from the UL Committee statement provided in PDF form below:

In the following types of devices the terminals shall not be directly connected to aluminum conductors but may be used with UL Listed copper or copper-clad conductors:

Receptacles and snap switches marked "AL-CU"

Receptacles and snap switches having no conductor marking

Receptacles and snap switches having back-wired terminals or screwless terminals of the push-in type.

- UL, THE USE of ALUMINUM CONDUCTORS with WIRING DEVICES in ELECTRICAL WIRING SYSTEMS [PDF] (03/1973) Statement prepared under the auspices of an Ad Hoc committee sponsored by Underwriters Laboratories, Inc., Public Information Office, Underwriters Laboratories Inc., 207 East Ohio Street, Chicago Illinois 60611, Issued March, 1973.

- REDUCING the FIRE HAZARDS in ALUMINUM-WIRED HOMES, [PDF], Jess Aronstein, Ph.D., (2011) updated version.

This document answers most technical questions about the hazards and remedies of aluminum electrical wiring and includes a report on independent test results of alternative products and methods for repairing aluminum wiring.

Some of the sections of this very thorough document are listed below: - HOW TO REDUCE THE RISK of aluminum electrical wiring in buildings [Web article]

- ALUMINUM WIRING REPAIR ELECTRICIANS specializing in aluminum wiring repairs< [Web article]/li>

- ALUMINUM WIRING REPAIR, Other Products for aluminum wiring, ones that work, or don't [Web article]

- DETAILED EXPLANATION of the aluminum electrical wiring hazard [Web article]

- Reducing the Fire Hazards in Aluminum-Wired Homes, [web page] Jess Aronstein, Ph.D., This document answers most technical questions about the hazards and remedies of aluminum electrical wiring. Some of the sections of this very thorough document are listed below:

- Fire Hazards With Aluminum to Copper Twist-on Connectors & Acceptable Aluminum Wiring Repair Practices Color Photos, Current Issues. 9/28/95 CPSC Meeting Minutes [web page]

- "Is YOUR Aluminum Wiring Safe?" article discussing safety claims made by some people without looking at the wiring, J. Aronstein, 11/21/95 [web page]

- REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 U.S. Consumer Product Safety Commission Publication REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 available online [web page]

Contributors & Technical Reviewers

Photographs courtesy Roger Hankey & Mark Cramer and the website author D Friedman.

Technical content & review, Jess Aronstein.

- Dr. Jess Aronstein, Poughkeepsie, NY, - principal technical consultant. Dr. Aronstein is a Consulting Engineer, Mechanical amp; Materials Engineering, BME, MSME, Ph.D., N.Y. S. P.E. LIC. NO. 39860 845-462-6452 Email: protune@aol.com. Dr. Aronstein has conducted and continues to conduct extensive testing of electrical devices and connections and works as a forensic engineering consultant.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a home inspector in Tampa Florida, and home inspection educator.

Mr. Cramer served ASHI and the profession in many capacitines including on the ASHI Home Inspection Standards and other committees. He is a contributor to and occasional reviewer of articles at InspectApedia.com. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com - Roger Hankey, Hankey and Brown home inspectors, Eden Prairie, MN, technical review by Roger Hankey, prior chairman, Standards Committee, American Society of Home Inspectors - ASHI. 952 829-0044 - hankeyandbrown.com

Contributions of photos of CU-AL and COALR receptacles are sought by the author.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-12-29 by InspectApedia Publisher (mod) - only 3 methods of approved aluminum wire repair

@Adam,

First thank you for your careful reading and editing and for taking the time to write to help us out with accuracy and precision on this topic. I was quoting directly from the US CPSC so this is a pretty old mistake.

We have edited the lines to read:

Based on these standards, as of the date of this publication, CPSC approves of only three methods for a permanent repair.

1) Complete Replacement of [ Aluminum Conductor Wire with ] Copper Cable

2) COPALUM Method of Repair

3) Acceptable Alternative Repair Method/AlumiConn Connector

About using CO/ALR devices,

You'll read both in the article above, in other articles in this series, and in independent research that we cited, that the CO/ALR devices are

1. Not recommended by the US CPSC

2. Have not been shown to perform reliably nor safely in independent research

CO/ALR devices were permitted to be so-named by their manufacturers when the manufacturer deemed the devices suitable for use with copper or aluminum wiring, but there is not one document of any supporting research. You should not use these devices for aluminum wiring, "legal" or not.

And of course once you've pigtailed the original conductor. to a copper wire segment, you would then use the copper to connect to any electrical wiring device such as a lamp or receptacle or switch. CO/ALR offers no advantage.

Yes the "Twister" remains "listed" but ample independent research shows very poor field performance of those connectors, even when installed by the manufacturer's own engineers to the absolute best-recommended practices.

See details at

ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

Finally, "hard-wired" devices fed by aluminum conductors, such as a light fixture or bathroom fan must also be copper-pigtailed.

Those connections, left as aluminum to the fixture wire, are also at risk of overheating and fire.

Your risk assessment is reasonable - you note that more current = higher risk at aluminum wiring connections - but perhaps incomplete in that even at low current micro-fretting, a form of microscopic electrical arcing described by Aronstein, is what's actually happening at these problematic aluminum electrical connections. Micro-fretting causes, in turn deposits of oxides that increase electrical resistance across the connection leading, ultimately to overheating and a fire risk.

Also, in my OPINION, part of the reason that it is absolutely essential that EVERY aluminum wire connection be properly-repaired is that in my experience, once people think that a safety hazard has been addressed they may be inclined to ignore a future warning sign, thus ending in a disaster.

On 2022-12-28 by Adam

The article lists "1) Complete Replacement of Copper Cable" as one of the recommended repair options. I believe you meant either (Complete Replacement with Copper Cable) or (Complete Replacement of Aluminum Cable)

Also, I have a maintenance company recommending repair of one of my properties using "Ideal Twister Al/Cu Wire Connectors" to attach a pigtail and replacing all receptacles and switches with CO/ALR rated devices.

Is there a value to using CO/ALR devices if you already are installing a pigtail?

Is the Ideal Twister recommended for connecting the pigtails?

It does not seem to me to be as secure of a connection as other methods listed in this article. Product literature states "The Twister Al/Cu is the only UL listed aluminum-to-copper twist-on connector that prevents aluminum oxidation while providing a secure connection."

Is there also a concern at connections at light fixtures and other "hard-wired" connections such as bathroom fans/heater?

I imagine the amount of risk is relative to the current drawn from the appliance, making the concerns at a light fixtures less of a concern than that of a bathroom fixture.

On 2022-12-12 by Anonymous - "listed for use" on electrical devices is not always the same as "performs safely or performs well"

@Hai -Peter- Minh Au,

Used-for, even "listed for use"

is not the same as

safe

or

Performs well

Take a look at the research data.

Watch out for "ok to use" articles that may be published by industries or individual with a vested legal or financial interest.

InspectApedia.com tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

On 2022-12-11 by Hai -Peter- Minh Au

Base on other site, Co/Alr is used for aluminum and copper.

On 2022-07-08 by InspectApedia-911 (mod)

@Anonymous,

And other readers,

BEWARE: the advice from the Anonymous reader below (who touts CO/ALR devices for aluminum wiring repair) - that reader's advice is UNSAFE, is not recommended by the US CPSC, and could put your home at risk for fire.

Independent experts do

not recommend using CO/ALR devices as a repair for aluminum wiring.

The only recommended devices are the Amp Tyco COPALUM crimp connector and the Alumicon connector to install copper pigtails to make the final connections at every aluminum wiring connection in branch circuits in the building.

The readers comments do not reflect the inconsistent performance of the devices that he touts and nor the actual failure mechanism at aluminum wiring connections.

Specifically that mechanism is microfretting, a microscopic form of electrical arcing that causes oxidation, increased electrical resistance, and overheating at aluminum wiring connectors other than the two that are recommended.

While a number of experts have worked on this topic and support the two recommended connectors,

over the long history of aluminum wiring other confused or obsolete reports, some from competing interests of the aluminum industry, others from device manufacturers who were permitted to stamp their devices as permitted for use with aluminum wiring without actual testing to support that use nor publication for public review of such work,

can be misleading.

The seminal work on this topic was performed by several unbiased, expert electrical engineers including Dr Jess Aronstein who's a widely recognized and respected independent expert and the identifier of the microfretting phenomenon.

We've worked with Dr. Aronstein on this topic for nearly 50 years and completely support his findings and conclusions as they are reported both at this website and at his own independent and widely published research.

It is particularly dangerous to select and base life safety decisions about proper and safe aluminim wiring repair on other, often older aluminum wiring studies and reports that were completed before the problem was fully understood,

And dangerous as well to base them on a vehement opinion expressed by an anonymous and unaccountable reader postingon internet pages.

Continuing, and noting that we appreciate the discussion by the anonymous reader

I should add for clarity that this discussion applies to both devices marked

CU/AL

and

CO/ALR

Who's performance with inconsistent across manufacturers, time, and wiring methods.

We also should add that there's a significant hazard increase if these devices are back wired using the push-in connector provided on some models.

Does "Listed" status for an electrical product really assure its safety and performance?

Regarding the reader's comment

Additionally, all of the CO/ALR receptacles that I have seen are UL listed and CSA listed.

To an engineer this actually means something; as opposed to "CPSC recommended," which I have no clue what that means (more on that below).

In our OPINION that could be a fair criticism if only UL Listings were themselves always reliable across all products. That's not the case.

- Self-testing & self-listing:

Some UL standards such as UL 486 permit the manufacturer to perform their own testing - self-certification, and in some cases without providing one iota of test results to the public. You'd think if the tests supported the conclusion the manufacturer would be pleased to make them public. - Some "Listing" standards may be written to serve the manufacturer:

While it's natural that the staffing of the committee who write an electrical standard such as UL 486 should come from industry (that's where the experts-are), there is an innate conflict of interest if the committee, made up of or dominated by engineers from the electrical device manufacturers themselves, write a performance standard that "passes" for listing products that in fact do not perform adequately in the field. - Some listed products fail badly:

Some "Listed" products including those used for repair of aluminum wiring have been unequivocally shown to fail at unacceptable rates in both careful and in more-typical "normal" installation and use. - Conflict of interest when listing agency is supported by its industry:

In the U.S. (unlike some other countries), safety and performance listing agencies including UL and others, are paid and supported by fees paid by the very manufacturers whose products they are supposed to be putting through qualifying tests to obtain a listed-status. That's an innate conflict of interest.

The difficulty in manufacturing and testing electrical devices for safe performance is not a new one. Aronstein describes this issue in detail in his book:

HOT CONNECTIONS, The Beverly Hills Supper Club Fire, Aluminum Wiring and the Myth of the Self-Regulating Industry [Website] Jesse Aronstein, Ph.D., P.E., available at Amazon or by a web-search for book "hot connections aluminum wire"

Introduction excerpt:

The catastrophic fire at the Beverly Hills Supper Club in Southgate, Kentucky in 1977 resulted in 165 fatalities. More than 2,000 people were there, many to hear John Davidson sing, some just for dinner, and others for a variety of functions including meetings and a wedding reception. This fire ranks high among the major civilian fire losses of the 20th century.

Six years before the deadly fire, at about the same time that some aluminum wiring was being installed in the club, a Vice President of Southwire, one of the aluminum wire manufacturers, wrote:

A genuine crisis exists in our industry, of a magnitude that jeopardizes the entire aluminum conductor market and the life and property of consumers.

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided to the public at no cost - we have no business nor financial connection with any manufacturer or service provider discussed at our website. We very much welcome critique, questions, or content suggestions for our web articles.

On 2022-07-08 by Anonymous - disagrees with the conclusion that CO/ALR devices are unsafe

[Ed. note: BEWARE: the advice from the Anonymous reader below (who touts CO/ALR devices for aluminum wiring repair) - that reader's advice is UNSAFE, is not recommended by the US CPSC, and could put your home at risk for fire. See our full response above.]

@InspectApedia-911,

Thank you for your response. I took some time to read through most of your references and found some of my own. Here is what I found:

1.) Dr. Aronstein’s discussion of his testing of CO/ALR receptacles can be found here: http://aluminumwire.info/COALR_Receptacle_Failures_-_Letter_to_UL.pdf

1.a) If you read this test report, you'll see that he tested 500 aluminum-wired CO/ALR receptacles, 100 of each of the five brands available at the time. In his testing, he experienced two failures of CO/ALR receptacles; however, both of these receptacles were from the same brand.

He stated that statistically, there is less than a 1% chance that two random failures would show up in the same sample group, so he concluded the problem is likely a design feature of that particular brand of CO/ALR receptacle. The other brands passed his testing (one brand had an issue not relating to the aluminum joint.)

1.b) In this test report, he comments that the new UL testing standard for aluminum wire receptacles UL 1567, which was not yet issued and was out for comment, "should not be issued until it is modified to deal effectively with the problems now known to exist in older CO/ALR standard."

Dr. Aronstein then continues that "he would be glad to contribute specific recommendations." This test report was written in 1983, UL 1567 was originally issued in 1984 and it is currently on its 5th revision.

Dr. Aronstein does not say what his recommendation were, but it is likely that they have been incorporated if they were valuable. (UL is a top rate organization and instrumental in ensuring safety in this country, I have no reason to doubt them).

2.) Dr. Aronstein’s “Reducing the Fire Hazard in Aluminum-Wired Homes” (2011) discusses using CO/ALR devices as an alternative corrective action “with less certainty of safe, permanent, and complete correction relative to pigtailing of all connections.”

Dr. Aronstein does not say anywhere that these device are not safe or good for use, but rather that there is lower certainty than the pigtailing methods. I feel this page of your website mis-characterizes Dr. Aronstein report in this regard.

He ABSOLUTELY does not say to “not use CO/ALR devices” nor that they are unsafe. His reservation about CO/ALR appear to resolve around workmanship sensitivity and condition of the indium plating.

3.) By far the most complete discussion of this topic that I’ve found is the National Bureau of Standards (NBS) report NBSIR 75-723 prepared for the U.S. Consumer Product Safety Commission from June 1975.

It can be found here: https://www.govinfo.gov/content/pkg/GOVPUB-C13-de20a775eeb82a774b61e2984ca27d9e/pdf/GOVPUB-C13-de20a775eeb82a774b61e2984ca27d9e.pdf

Please read all 94 pages of it. I did…and I learned a lot. It contains summaries of testing performed at the following facilities: NBS Measurement Engineering Division, The Center for Building Technology, Underwriters Laboratories, and the Battelle Institute. You asked for published test results, here you go.

A big take aways from this report:

(a). Aluminum wiring is more sensitive to installation workmanship than copper.

Especially installation torque. Almost all of the observed failures in the report were cases with intentional low installation torques.

(b). The device terminal screw material has one of the largest impacts on device performance.

Due to the same copper shortage in the mid-60s that caused builders to switch to aluminum wiring, device manufacturers changed the terminal screws from brass to steel. Steel has a much smaller coefficient of thermal expansion compared to aluminum or brass.

This greatly increases the relative movement over a thermal cycle, increasing the fretting corrosion that you mentioned, and increasing the likelihood of yielding the aluminum, which will cause loose joints and eventual thermal runaway.

(c). Indium plating of contacts reduces the electrical resistance and improves the mechanical stability of the terminations with aluminum conductor. Indium is soft and ductile.

It adheres to other surfaces, flows into cracks in oxide layers, and forms gas-tight seals around asperities. (there is some concern with copper diffusion within indium that makes the metal harder – this could be resolved by plating the terminals with nickel before plating the indium. Unclear if the nickel is actually necessary since there was no observed issued relating to this copper diffusion concern)

(d). It is important to design the electrical joint to have some pre-load or spring tension on the aluminum conductor such that it can maintain contact pressure over the life of the joint while the aluminum creeps or anneals (stress relief).

(e). The different test houses all showed that they had viable CO/ALR devices as far back as 1975.

For example, look at the UL testing. They were testing 15A receptacles with 40A test current (which is 7x the heat input due to I^2R) cycling for 3.5 hours on, .5 hours off for a minimum of 500 cycles with vibration and disturbances.

This is a severe and conservative test with current levels that would trip breakers quickly - there were no failures at below 500 cycles. They continued the testing to more cycles and eventually began to see weaknesses with certain manufacture’s designs, which were addressed. Again…this was 1975, we have had 47 years since to refine designs.

SO AFTER A FAIR BIT OF RESEARCH, I STAND BY MY ASSESSMENT THAT CO/ALR DEVICES CAN BE DESIGNED AND INSTALLED TO BE SAFE.

I FOUND NO REASON TO SUGGEST THAT MODERN CO/ALR RECEPTACLES DESIGNED BY REPUTABLE MANUFACTUERS, SUCH AS EATON AND LEVITON, AND CERTIFIED BY REPUTABLE TEST HOUSES, SUCH AS UL AND CSA, AREN’T ACCEPTABLE FOR USE AS FIRE MITIGATION FOR ALUMINUM WIRING.

THERE IS NO SUCH THING AS NO RISK.

A poorly made copper termination will start fires just like a poorly made aluminum termination. A properly designed aluminum termination will work perfectly. If you don’t believe me, just look at the electric grid where nearly all of the overhead conductors are aluminum.

Properly installed CO/ALR devices should move the aluminum wiring risk much further down the risk register, well into the negligible category.

On 2022-06-08 by InspectApedia-911 (mod) - use only COPALUM or AlumiConn for Aluminum wire repair, do not use CO/ALR or CU-AL devices.

@Professional Engineer - Power,

Thank you for taking the time to write about your opinion on CO ALR devices. It provides an opportunity to make clear two points:

1. Some commenters may be unfamiliar with the safety issues at hand or may not be a truly dis-interested professional

2. Only two connectors have been recommended as safe for use with aluminum wiring repairs, and CO/ALR and CU-AL are not among those recommended.

Details:

I suspect that either you be you're not a neutral professional or you are unfamiliar with the history of CO/ALR and CU/AL devices for which there is a complete lack of industry-provided test data that would actually support their use.

Although manufacturers were permitted to use those product apellations and to market them (cfL UL Standard 1567, Underwriters Laboratories, Inc., Northbrook IL (CO/ALR Wiring Device Terminals for Aluminum Wire) there has never been a single release of any supporting test data showing that they perform acceptably. Yet there has been research and field performance showing that they do not.

You may also be unfamiliar with the actual failure mechanism in aluminum electrical wiring connections, including micro-fretting, resulting in arc burns that lead to an insulating effect at the connection that leads to overheating and in the worst cases fatal building fires. Nothing, not one iota of the design, of a CO/ALR or CU/AL device addresses that failure mechanism.

If I am mistaken, please provide us with at least a reference to supporting research by independent experts or even from a manufacturer of these device and who has in fact released any test data supporting a claim of successful performance. We would be pleased to review such material and to ask for comment by industry experts.

WATCH OUT: we must insert a severe CONSUMER PROTECTION SAFETY NOTICE here:

The devices that this engineer discusses have not proven safe for use in homes and are NOT RECOMMENDED by the United States Consumer Protection Commission CPSC, for use with aluminum wiring in buildings.

The ONLY devices recommended for use with aluminum wiring are those outlined by the CPSC and in this article series, namely the AMP Tyco crimp connector or the King Innovation AlumiConn terminal connector.

The CPSC issued a letter making that clear, in an effort to state by inclusion those connectors that work with aluminum wiring and, by omisssion, to deliberately exclude connectos that do not work, while avoiding the cost associated with more-explicit finger-pointing.

In our OPINION that was a generous move by the Commission.

I am concerned when I see a long diatribe like that by the unnamed engineer that the writer is expressing an opinion that could put human life and property at risk and yet doesn't sign his name, leaving himself completely unaccountable.

Consumers should be aware that sometimes a posting like the one we have just read from "professional engineer - power" may not be from a dis-interested party, or may be from someone who is simply unfamiliar with the mechanism of the failure and overheating and fires associated with aluminum electrial wiring.

While InspectApedia does not require that a reader identify him/herself when posting a comment, when such a reader remains anonymous they can claim virtually anything without being accountable or liable for the possible injury or damages that could ensue.

In contrast, the aluminum electrical wiring safety articles published here are supported by technical research by recognized industry experts such as Dr. Jess Aronstein (and others cited in various references), experienced electrical engineers and inspectors including, for example, and in contrast to the "anonymous" engineer posting below on this page" we have the following named experts whose comments and research appear in our citations on aluminum wiring hazards and repairs.

- J. Aronstein

- H. Dupre,

- N.T. Bond,

- R. Schubert,

- C.W. Zimmerer,

- Braunovic, Milenko,

- Nikolai K. Myshkin, and

- Valery V. Konchits,

- F.Neumer,

- Babrauskas,

- Vytenis,

- Schoft,

- Stephan,

- Josef Kindersberger,

- Helmut Löbl.,

- Shea, John J.,

- Tom D'Agostino)

and also US CPSC experts such as

- R. Newman

- W.H. King, Jr., P.E. EE, US (now retired) who directed the CPSC electrical engineering department,

- and many other experts cited in the references section on various pages in the article series where the names, identity, credentials of the researchers are given.

The article above on this page includes more than twenty reference citations and some of those provide, in turn, list dozens more research articles on this topic. See, for example,

the ALUMINUM WIRING BIBLIOGRAPHY

In addition the ABOUT US page for this website lists the names and credentials of its Publishers and Technical reviewers.

About the writer’s complaint that we don’t address his claim that it might be possible to design another aluminum wire connector that works successfully (two have been so-made and are cited above), nowhere in our article series do we make any claim about what type of electrical connectior might be designed or invented.

Rather we discuss the actual electrical products that have been designed and marketed to consumers, unfortunately in the case of CU/AL - CO/ALR, without a shred of supporting public data, and worse the engineer omits the US CPSC has recommended ONLY the two devices that have been proven to work are in fact available.

Daniel Friedman, Editor, publisher, inspectapedia.com

InspectAPedia.com® is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information for the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website.

We are dedicated to making our information as accurate, complete, useful, and unbiased as possible: we very much welcome critique, questions, or content suggestions for our web articles. Contributors, even if it's just a small correction, are cited, quoted, and linked-to from the appropriate additional web pages and articles - which benefits us both. Working together and exchanging information makes us better informed than any individual can be working alone.

On 2022-06-08 by Professional Engineer - Power

[Ed. note: WATCH OUT: we must insert a severe CONSUMER PROTECTION SAFETY NOTICE here: The devices that this reader discusses below have not proven safe for use in homes and are NOT RECOMMENDED by the United States Consumer Protection Commission CPSC, for use with aluminum wiring in buildings. See our full response above.]

This articles treatment of CO/ALR receptacles and switches is uninformed and frankly...ignorant.

As an electrical power engineer, I have designed may high powered bolted and crimped electrical joints for the Nuclear and Hydro power industry. Designing a connection for aluminum wire is not impossible or even hard.

It is mainly a problem of matching the thermal expansion of material such that you maintain strong contact pressure without exceeding the yield stress of any of the materials anywhere in the joint design - over the complete range of possible temperatures.

(Resistance decreases non-linearly with contact pressure, so you get some negative feedback=>thermal stability). Of course you also have to account for dissimilar metals, oxidation, heat dissipation... and all of the other general engineer considerations.

For this reason, I find the assumption that all CO/ALR receptacles or switches are not or cannot be designed correctly is absurd.

Further, the CPSC is not the key authority on this matter. The key authority is the National Electric Code, which clearly allows the use of CO/ALR receptacles and switches in sections NEC 406.3(c) and 404.14(C).

Additionally, all of the CO/ALR receptacles that I have seen are UL listed and CSA listed.

To an engineer this actually means something; as opposed to "CPSC recommended," which I have no clue what that means (more on that below).

Finally, the CPSC is not suppose to be in the business or recommending products. Look at their website and read their charter. They issue recalls for unsafe items. If CO/ALR devices are unsafe, the CPSC would have recalled them.

The CPSC Publication that is cited in this article states that the "CPSC can recommend repair methods or products only where there is a satisfactory documented evidence that the methods or products meet the following criteria: Safe...Effective...and Permanent" (CPSC Pub. 516, pg. 5). The CPSC does not define any testing standard (like a UL test) that is required to meet their criteria. The CPSC publication continues to explain in the fine print that manufacturers have to recommend their products and submit documentation of compliance with such standards to the CPSC.

And further, the "burden of cost of establishing compliance with such standards is the responsibility of the requestor." (id.)

So the referenced CPSC publication basically says that there is no defined standard that the CPSC tests to, the evaluation is self selected by the manufactuer, the manufacturer gets to choose what data to submit for certification, and the testing is performed (or funded) by the manufactuer not the CPSC.

This is not what I would consider to be the gold standard.

I'm not arguing that the Alumiconns aren't great. I am also not saying that there isn't the possibility of some manufacturers designs being poorly designed or faulty.

But in general, if the current CO/ALR devices were unsafe, wouldn't somebody have already designed receptacles and switches with integrated Alumiconn style setscrew terminals with anti-ox (since fitting alumiconns in a junction box can be challenging)? My intuition is that these don't exist because they are not needed.

Inspectapedia, please stop spreading misinformation.

If you disagree, please publish testing data that shows the failure rates of CO/ALR receptacles. Reading your citations, all I could find is that there was one observed failure back in the 1980s and there was no discussion on the root cause of the failure (i.e. design, installation, quality control...ect).

On 2021-12-09 by Inspectapedia Com Moderator (mod)

@Anthony,

I can definitely tell you at least one thing meant by your description of the home's electrical wiring.

If there is a solid conductor aluminum branch circuit wiring in the electrical panel that is connected directly to circuit breakers without proper copper pigtailing, then even if you see Copper at devices elsewhere in the building you know that a proper and correct aluminum wiring repair has not been done at this home.

You also need to be alert for incomplete or in expert electrical work if there has been partial aluminum repair because that tells you that the repair person did not know or follow proper and safe procedures.

It's not something to panic about nor a reason not to buy a house, but the presence of unrepaired or improperly repaired aluminum electrical wiring needs to be addressed promptly.

In fact you may find that some insurance companies won't insure the home until you have that condition corrected.

On 2021-12-09 by Anthony

@Inspectapedia Com Moderator, Got it. Thank you for the reply!

I'm closing on a home soon with aluminum wiring in the breaker, but every receptacle I inspected had copper wiring and no evidence of pigtailing in the junction box. Do you have any idea what this could mean?

Thank you again for the help.

On 2021-12-08 by Inspectapedia Com Moderator

@Anthony,

No

COALR devices are NOT a safe, acceptable repair for aluminum electrical wiring IF the aluminum wire is connected directly to those devices, and those are NOT recommended by the US CPSC despite their being "listed".

If all of the device connections (receptacles and switches) are made with copper pigtails that in turn were pigtailed to the original aluminum suing the AlumiConn connector (as directed) the the fact that those copper-connected receptacles or switches are stamped COALR is fine.

On 2021-12-08 20:29:07.310877 by Anthony

Would using CO/ALR receptacles and switches (NOT backwired) in combination with AFCI+GFCI breakers in the panel and AlumiConns for everything else (e.g. light fixtures) be considered a complete repair?

On 2020-03-10 by Anonymous - CU with AL "crossed out" = not for use with aluminum wire

Anon

Post a photo using the "add image" button if you can.

Watch out: I suspect you're seeing an electrical device marked for use with copper wire only, explicitly prohibiting connection to aluminum electrical wire.

On 2020-03-09 by Anonymous

What is CU with AL crossed out

On 2015-05-09 - by (mod) - no need for CO/ALR devices if you've already copper-pigtailed aluminum wire ends.

COALR receptacles, as you will read above, are not in any case a solution for aluminum electrical wiring.

Using the AlumiConn allows copper pigtailing = that means you can connect the copper wires to modern devices such as switches or receptacles.

On 2015-05-08 by Jason

Hi, I own a rental property that has aluminum wiring. I just had some work done and anywhere electrical was touched we used the alumiconn connectors. I've looked in every outlet/switch in the unit now and see no evidence of overheating. There are some boxes that are somewhat loose in the wall though so I am replacing any that are in that condition.

If I use the alumiconn connectors with pigtails do I still need to use CO/ALR receptacles/switches or can I use standard ones since all of the connections to the receptacle/switch are now CO?

Thanks.

On 2015-03-25 - by (mod) -

Yes Ron, in fact that's what the manufacturer intended with the CO/AL label: where CO stood for copper. In that application, properly installled on copper wire, the performance and overheating issues associated with aluminum don't pertain.

On 2015-03-25 by ron

can co/alr switches and outlets be used in a home with copper wire?

On 2014-10-16 by Rosie

I am looking for independent research testing results on CO/ALR devices for a research project I'm doing. I'd like to understand and be able to report specific results as to how many times CO/ALR devices have failed in field or lab studies. I'd also like to be able to report (with testing results) just how much safer the recommended repairs are.

Thanks

On 2014-09-26 - by (mod) - house has aluminum wiring and recently I have experienced some arcing in the receptacles.

Anon

With all due respect, the problem is not this article unless we failed to make clear the following:

Watch out: CO/ALR dual receptacles that you are recommending are *NOT* recommended by the US CPSC for aluminum wiring repairs. That's because they are not safe.

The U.S. CPSC is the key authority in this matter - folks who have taken pains to specify which aluminum wiring repairs work and are safe when properly executed.

The "repair" you like (Cooper Devices CO/ALR dual receptacles) is not one of the acceptable nor recommended repairs.

Your second observation, that the old receptacles you removed "are still functioning" needs to be undertood in the context of how overheating occurs at connections and how that leads to fires. "Functioning" in the sense of passing along electricity through a duplex receptacle to the device plugged-in does not mean "safe".

A small change such as wiggling around a receptacle or switch by plugging devices in and out of it or by flipping a switch on and off add movement that can be a source of loose connections.

But even without *any* such movement, as Aronstein's research points out, a combination of oxidation and micro-fretting at the connection points of aluminum to copper receptacle or switch screws leads to a cycle of increased heat, increased oxidation and corrosion, until an overheat and possibly a fire occurs.

On homes where all of the devices have been removed and replaced as part of aluminum wiring repair, it is certainly the case that not every device shows signs of overheating.

But after several decades of independent research and receipt of field reports on aluminum wiring overheats and fires, we see that during an aluminum wire repair at a building, it is very very rare for the electrician to fail to find at least one dangerously overheated device, connector or receptacle or switch.

Happily not all overheats burn the building down. Many are contained within the junction box and some simply burn enough to shut off the circuit.

You should rely on COALR or CO/ALR devices if you want to follow the advice of those independent experts who have no conflicting interests.

On 2014-09-26 by Anonymous - I used Cooper Devices CO/ALR receptacles

This article is a problem. My house has aluminum wiring and recently I have experienced some arcing in the receptacles. The connections to the plug were very loose and there was difficulty sometimes in making a good connection.

I have replaced a portion of the receptacles with Cooper Devices CO/ALR dual receptacles. The difference is very noticeable. This is a quick fix anyone can do.

You seem to be discouraging people from reducing the risk with a fix that is approved. The receptacles that I removed were not marked with the CO/ALR and after 40 years of use are still functioning. This whole article is misleading and I would say dangerous.

...

Continue reading at ALUMINUM WIRING REPAIRS NOT-RECOMMENDED or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ALUMINUM WIRING REPAIR COALR & CU-AL FAQs - questions, answers, and comments posted originally at the end of this page

Or see these

Recommended Articles

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIR METHODS - CPSC Meeting 9/28/95

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

- ALUMINUM-WIRED HOMES, REDUCE THE HAZARD - PDF

Suggested citation for this web page

ALUMINUM WIRING REPAIR COALR & CU-AL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about using CO/ALR or CU-AL devices (electrical receptacles, "outlets", or switches) with aluminum electrical wiring

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.