Gravelless Septic System Design Specifications

Gravelless Septic System Design Specifications

Septic Leaching Chamber Site Requirements, Design Criteria, & Construction Details

- POST a QUESTION or COMMENT about gravelless or no-rock or chamber type septic absorption field site requirements

Gravelless septic drainfield site requirements:

This article explains the site requirements, design criteria, and construction details of a gravelless or "no gravel" or "no rock" septic drainfield systems, offering installation specifications.

Citation of this article by reference to this website and brief quotation for the sole purpose of review are permitted. Use of this information at other websites, in books or pamphlets for sale is reserved to the author. Technical review by industry experts has been performed and comments from readers are welcomed. Contributors are listed at the end of each article.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Site Requirements & Design Criteria for Gravelless Septic Absorption Systems

Drainfields, also called leach fields, absorption beds, soil absorption systems, and leaching beds, perform the functions of septic effluent treatment and disposal in onsite wastewater treatment systems, conventionally called "septic systems".

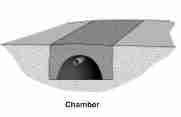

Typical gravelless septic systems use a plastic chamber, a geotextile-wrapped pipe, or a polystyrene-wrapped pipe to distribute effluent into the soil.

The necessary soil absorption area is provided by the perforated surface of the gravelless septic system components (or by soil at the bottom of a chamber) themselves rather than by the gravel and trench walls of a conventional septic drainfield.

Site Requirements for no-rock chamber or textile wrapped septic effluent disposal systems: These systems shall be used on sites that have been classified as having a design percolation rate of one to 45 minutes per inch, and meet the vertical and horizontal separation distances in Table 2 (of the New York State Standard - for example) shown in 75-A.4 Soil and site appraisal for Septic Systems.(2)

Chamber systems provided by Infiltrator Inc. (links below) have been approved for use in some states, including New York, at perc rates up to 60 minutes/inch, and in some other states, at percs up to 120 minutes/inch. Approval letters are available from that company.

Design criteria for no-rock chamber or textile wrapped septic effluent disposal systems: : The local health department having jurisdiction shall be contacted prior to construction regarding the acceptability of specific products for use as a gravelless distribution system. (3)

As we described above when discussing Geotextile-Wrapped Perforated Pipe systems for onsite wastewater treatment and disposal, the total lot area in square feet which is required for a given alternative treatment system will vary not only depending on the anticipated daily flow, flow rates, soil and site conditions, but also on what spacing requirements the local or state code officials will require.

So although a number of alternative treatment systems including these gravelless methods are capable of working in a smaller total square foot area than a conventional drain field, depending on what the local authorities require in spacing, more area may be required than the minimum.

For example, many states require that space be set aside to allow for future absorption line replacement in between the planned lines.

Construction Specifications for gravelless septic absorption systems

Gravelless distribution systems shall be installed in conformance with the manufacturer's instructions because of the proprietary design of some products.(4) The length, width, and depth of the required excavation will vary by individual product.

The essential difference between a gravelless wastewater treatment system and a conventional perforated-pipe and gravel-trench drainfield is the use of a special product to distribute and release effluent (sketches above) and the absence of gravel in the trench where the distribution system is buried.

The special gravelless products used are designed to avoid soil-clogging right at their surface or they would have a short life.

This concern is addressed by use of special materials (such as geotextiles) which resist soil clogging, and by a design that provides an adequate total area in square feet for soil contact.

Each product manufacturer should be expected to provide an installation manual for the product that you are going to use. The list below is generic and incomplete as site specific and product specific details can't be provided here.

- Perform a site survey to determine the size, layout, and materials needed. The manufacturer indicate the disposal area provided by the product (per linear foot, for example) but your engineer and installer need to evaluate your soils and daily wastewater usage to determine the amount of leaching area needed for your site.

- Tables of field sizing and soil percolation test

procedures are provided

at THE SEPTIC SYSTEMS WEBSITE. - Obtain local building code or board of health requirements

- As with any wastewater disposal field, never drive equipment in or over the trenches. Compacting

the soil (or after installation, damaging the drainage components) will reduce the absorption

system capacity or may destroy it completely.

Some systems such as Infiltrator Inc. chambers, have been tested to meet an H-10 engineering rating (16,000 lbs / axle), so occasionally if a system built using some chamber products are driven over it won't necessarily be an issue. But Infiltrator Inc. 's technical experts do not recommend constant vehicle traffic over anything but their heavier duty H-20 chambers.

These disclaimers notwithstanding, it remains a better practice to keep all traffic off of septic fields. And even where septic equipment has been described as rated for vehicle traffic, heavy equipment traffic can cause some surprising collapses that can be costly to repair as shown in THIS PHOTO. - Some sites may need a curtain drain or other special measures to redirect surface or subsurface runoff away from the effluent/wastewater absorption area.

Chamber Septic - No-Rock Septic Design Critera, Guides, Specifications

- Also see more product specifications and design guides

at GRAVELLESS NO-ROCK SEPTIC SUPPLIERS - ADS ON SITE SEPTIC SYSTEMS PRODUCT DESCRIPTIONS [PDF] retrieved 2019/02/11 original source: http://www.pmstp.com/img/pdf/en/10265_On-Site_Septic.pdf

ADS - ARC 18-24 LEACHFIELD INSTALLATION GUIDE [PDF] for ADS ARC 24 leach field Chambers - CPP’S No-Rock ™ Fabric Wrapped Septic Pipe [PDF] (2019) Crumpler Plastic Pipe, .O. Box 2068, Highway 24 West, Roseboro, NC 28382 USA, Tel: 1-800-334-5071

Email: cppsales@cpp-pipe.com retrieved 2019/02/11 original source: www.cpp-pipe.com/no_rock.html - Hancor Technology, INSTALLATION GUIDELINES FOR GRAVELLESS PIPE

FOR SEPTIC TANK LEACH FIELDS [PDF] (20056), Hancor Technology, Website: http://www.hancor.com/product/Gravelless_Septic_Design.html Tel: 888-FOR-PIPE

retrieved 2019/02/11 original source: https://www.lawsupply.net/storm_drains/Hancor/gravelless_pipe_install.pdf

Excerpt: As an alternative to gravel filled soil absorption trenches for septic tanks, the Hancor Gravelless Pipe system is recommended.

Corrugated high density polyethylene pipe is factory inserted in a synthetic filter material of Cerex® Type 25 protective wrap. It is available in both 8” and 10” diameters (inside) and in standard 20’ lengths. - Hanson, Adrian, Ph.D., P.E., Craig Runyan, Bruce Lesikar, A HOMEOWNERS GUIDE:

INSTALLING A SEPTIC TANK AND DRAINFIELD [PDF] (2006), New Mexico Environment Department, Tel: 1-800-219-6157, retrieved 2019/02/11 original source: https://www.env.nm.gov/wp-content/uploads/2017/08/Homeowner-Notebook-final-2006.pdf

This guidance is restricted to the Homeowner installing a conventional septic tank and drainfield system for their primary residence. It is also restricted to system receiving less than 2000 gallons/day and no more than 500 gallon/day/acre of liquid waste. Includes details on installing or constructing a gravelless septic system.

Includes construction details for gravelless septic systems. - Hygnstrom, Jan R., Sharon O. Skipton, Wayne E. Woldt, RESIDENTIAL ONSITE WASTEWATER TREATMENT:

GRAVELLESS DRAINFIELDS FOR EFFLUENT TREATMENT [PDF] (2008) University of Nebraska Extension,

Excerpt:

This publication explains how gravelless drainfields work and gives drainfield sizing and installation information for a home. It is not intended to provide all information needed to design a gravelless drainfield for a particular site or situation or to guarantee compliance with Nebraska regulations.

Includes formula to convert required conventional drainfield size in square feet of trench area to length of trenches required when using a gravelless pipe.

Basic formula:

Liner Feet of Gravelless Drainfield Trench = [Sq.Ft. Required Standard Drainfield Area] / (0.75 x pipe diameter in ft x 3.14]

- Infiltrator Systems, Inc. provides chamber products and geotextile septic products: Tel: 800-718-2754 Old Saybrook CT USA.

Website: http://www.infiltratorsystems.com/ or 4 Business Park Road P.O. Box 768 Old Saybrook, CT 06475

860-577-7000 - 1-800-221-4436

Infiltrator Systems ARC 18, ARC 24 GRAVELLESS CHAMBER SYSTEM INSTALLATION GUIDE [PDF] Op. Cit.

Infiltrator Systems ARC 36, ARC 36LP, ARC 36 GRAVELLESS CHAMBER SEPTIC SYSTEM INSTALLATION GUIDE [PDF] Op. Cit. - Oregon, DESIGN AND INSTALLATION MANUAL FOR INFILTRATOR QUICK4 CHAMBERS IN

OREGON [PDF] (2016), retrieved 2019/02/11 original source: https://www.oregon.gov/deq/FilterDocs/infiltrator.pdf

For more detailed design information, please contact Infiltrator Water Technologies at 1-800-221-4436 - NESC: GRAVELLESS SEPTIC DESIGN [PDF] Pipeline, NESC, National Envirobnmental Services Center,Box 6893, West Virginia University Morgantown, WV 26506-6893 USA, Email: info@mail.nesc.wvu.edu Tel: (304) 293-4191 retrieved 2019/02/11 original source: http://www.nesc.wvu.edu/pdf/WW/publications/pipline/PL_SU01.pdf copy on file as Gravelless-septic-deisign-NESC.pdf

- US EPA, DECENTRALIZED SYSTEMS

TECHNOLOGY FACT SHEET

SEPTIC TANK LEACHING CHAMBER [PDF] (2000) Municipal Technology Branch

U.S. EPA

Mail Code 4204

1200 Pennsylvania Avenue, NW

Washington, D.C. 20460 USA retrieved 2019/02/11 original source: https://www.epa.gov/sites/production/files/2015-06/documents/septic_tank_leaching_chamber.pdf

Excerpt: A leaching chamber is a wastewater treatment system consisting of trenches or beds, together with one or more distribution pipes or open-bottomed plastic chambers, installed in appropriate soils.

These chambers receive wastewater flow from a septic tank or other treatment device and transmit it into soil for final treatment and disposal. - WA DOH GRAVELLESS EFFLUENT DISTRIBUTION PRODUCTS [PDF] (2013) Recommended Standards and Guidance for Performance, Application, Design, and Operation & Maintenance, Washington State DOH, Wastewater Management Section, Post Office Box 47824 Olympia, Washington 98504-7824 USA, Tel: 360.236.3330 FAX: 360.236.2257 Email: wastewatermgmt@doh.wa.gov retrieved 2019/02/11 original source: https://www.doh.wa.gov/Portals/1/Documents/Pubs/337-005.pdf

Consultants or suppliers in this field can be listed at our alternative septic designers page at no charge by contacting me.

Gravelless Septic Design using Poly-Wrapped Pipe

While polyethylene wrapped or peforated-plastic-wrapped plastic pipe is discussed in older no-rock septic system design manuals, the use of poly-wrapped pipe for gravel-less septic effluent disposal has, in our OPINION, been eclipsed by the use of geotextile-wrapped pipe instead.

As of May 2020 it was difficult to even find a vendor selling this product type.

Please see NO-ROCK SEPTIC GEOTEXTILE-WRAPPED PIPE

InspectApedia.com has no financial or other relationship with any suppliers listed at our website and we do not endorse specific products. No fees or costs are involved in product source listings. CONTACT us to add information.

...

Continue reading at NO ROCK SEPTIC SYSTEM LIFE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SEPTIC CONSULTANTS, DESIGNERS, ENGINEERS

- GRAVELLESS SEPTIC SYSTEMS

- SEPTIC EFFLUENT DISTRIBUTION Products Directory List

- SEPTIC FILTER / GRAYWATER FILTER SOURCES & Wastewater Treatment Systems Using Filtration Methods Products Directory

- SEPTIC SYSTEM DESIGN ALTERNATIVES

- SEPTIC SYSTEM DESIGN BASICS - home

- TYPES OF SEPTIC SYSTEMS - master list

Suggested citation for this web page

GRAVELESS SEPTIC DESIGN CRITERIA at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about gravelless or no-rock or chamber type septic absorption field site requirements.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- New York State Department of Health, APPENDIX 75-A WASTEWATER TREATMENT STANDARDS - INDIVIDUAL HOUSEHOLD SYSTEMS , [PDF] New York State Department of Health, 3 February 2010, retrieved 3/1/2010, original source: https://www.health.ny.gov/regulations/nycrr/title_10/part_75/appendix_75-a.htm

- Crumpler Plastic Pipe, Inc. Crumpler provides fabric-wrapped drainage piping 800-334-5071 Roseboro NC USA - "No-Rock TM Septic-Leachate drainpipe systems" are available in 8" and 10" systems.

- Jeff Pildis, Technical Service & Support, Infiltrator Systems, Inc. 800-718-2754

- Pennsylvania State Wastewater Treatment Fact Sheet SW-161, Septic System Failure: Diagnosis and Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-162, The Soil Media and the Percolation Test

- Pennsylvania State Wastewater Treatment Fact Sheet SW-l64, Mound Systems for Wastewater Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-165, Septic Tank-Soil Absorption Systems

- Document Sources used for this web page include but are not limited to: Agricultural Fact Sheet #SW-161 "Septic Tank Pumping," by Paul D. Robillard and Kelli S. Martin. Penn State College of Agriculture - Cooperative Extension, edited and annotated by Dan Friedman (Thanks: to Bob Mackey for proofreading the original source material.)

- Advanced Onsite Wastewater Systems Technologies, Anish R. Jantrania, Mark A. Gross. Anish Jantrania, Ph.D., P.E., M.B.A., is a Consulting Engineer, in Mechanicsville VA, 804-550-0389 (2006). Outstanding technical reference especially on alternative septic system design alternatives. Written for designers and engineers, this book is not at all easy going for homeowners but is a text I recommend for professionals--DF.

Design Manuals for Septic Systems

- US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL [online copy, free] Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm Onsite wastewater treatment and disposal systems, Richard J Otis, published by the US EPA. Although it's more than 20 years old, this book remains a useful reference for septic system designers. U.S. Environmental Protection Agency, Office of Water Program Operations; Office of Research and Development, Municipal Environmental Research Laboratory; (1980)

- Eco John® Innovative Toilet Solutions, Global Inventive Industries, Fountain Valley CA, PDF, product brochure

- "International Private Sewage Disposal Code," 1995, BOCA-708-799-2300, ICBO-310-699-0541, SBCCI 205-591-1853, available from those code associations.

- "Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems," Ontario Reg. 374/81, Part VII of the Environmental Protection Act (Canada), ISBN 0-7743-7303-2, Ministry of the Environment,135 St. Clair Ave. West, Toronto Ontario M4V 1P5 Canada $24. CDN.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.