What are lightning protection systems ?

What are lightning protection systems ?

- POST a QUESTION or COMMENT about lightning protection systems

Definition of & components of a lightning protection system.

This article series describes common lightning protection systems, certification, installation, and lightning protection system inspection. We provide information about lightning strikes, lightning hazards, related equipment, sources of lightning protection system installers, and lightning strike risk assessment

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What Are Lightning Protection Systems?

A lightning protection system provides a safe pathway for energy from a lightning strike to find its way to earth, encouraging the bolt

to bypass building components that might otherwise be damaged.

A lightning protection system provides a safe pathway for energy from a lightning strike to find its way to earth, encouraging the bolt

to bypass building components that might otherwise be damaged.

[Click to enlarge any image]

So it's job is both to provide a path for the lightning strike to reach ground (instead of reaching the ground through the building or its components), and to avoid damaging the building as the electrical current of the lightning bolt flows through the protection system components.

In other words, a lightning rod and its components do not prevent a lightning strike, rather they give it a safer pathway to earth than would occur if the energy passed through building components on the way down.

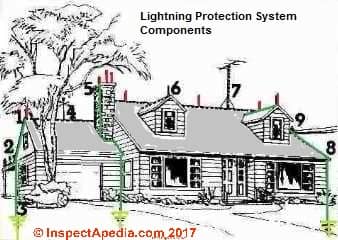

The basic components of a lightning protection system include the following

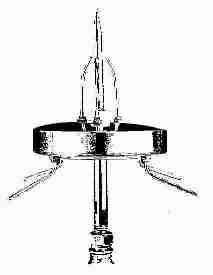

- Air terminals or "lightning rods" are metal rods which form the initial contact point for lightning strikes that are reaching towards ground in the immediate area. Modern lightning rods are placed vertically, typically extending about 10 above the building component they are intended to protect. Lightning rods are made of 1/2" diameter aluminum or 3/8" diameter copper; older components may be made of iron or steel.

- Main Conductor Cables, heavy twisted or braided 14-gauge aluminum or 16-gauge copper cable (or thicker) which is connected to the air terminal and/or run near the ridge or other building high points, routed to the ground.

- Grounds Ground rods, usually of a corrosion resistant alloy of copper and steel, 1/2" in diameter and 9' long. The ground rod is driven 10' into the earth [LPI specification] and connected to the cables.

- Bonding & Mounting hardware are used to splice or connect between air terminals, cables, ground rods, and possibly other devices, and to support the air terminals, cables, or other devices in place. These components too must be corrosion resistant and strong enough to keep their components secure.

- Lightning arrestors / surge protection are electrical devices installed in or on a building's electrical components and designed to protect electrical equipment from the electrical surge that occurs when lighting strikes a nearby power line. Common components receiving extra protection include computer equipment, televisions, telephones, sump pumps, and wells or well pumps.

As we mentioned above, a lightning protection system does not prevent lightning from striking; it provides a means for controlling it and preventing damage by providing a low resistance path for the discharge of lightning energy. This means that the energy from a lightning strike is directed along a heavy metal cable from an air terminal or other protection device down to a rod driven into the earth.

If an easier path is not provided for the energy (or current) to flow to earth, the energy from the lightning strike will find its own, often remarkably odd, pathway to earth anyway, perhaps moving on building water piping, electrical wiring, or even through damp timbers.

When the tremendous energy of a lightning strike moves through these building components instead of through a desired and safest cable designed for that purpose, damage to the building is likely, including explosion, fire, or electrical damage.

But lightning protection systems have a confusing history. The earliest lightning rod design, by Ben Franklin in 1752, ended in a sharp pointed trident which may have actually created an electrical field around the tip which invited strikes.

You'll notice that modern lightning rods have a short blunt tip and that they are connected to earth by heavy metal cables, often using braided copper. Having a properly-designed lightning protection system is very important if you're going to have one at all, since an improperly designed or installed system might actually increase the chances of a building being damaged by a lightning hit.

Lightning strikes at buildings and other sudden electrical currents (such as a tree touching a high tension power line) produce very high voltages which can take surprising routes at a property such as following underground tree roots, metal porch railings, and copper or steel building water pipes.

Lightning protection is also needed for trees

Lightning protection may be needed for tall trees on a property, either to protect the trees themselves from damage, or to

avoid subsequent tree damage to nearby buildings if the tree is stuck.

Lightning protection may be needed for tall trees on a property, either to protect the trees themselves from damage, or to

avoid subsequent tree damage to nearby buildings if the tree is stuck.

As a child on the Rappahannock river in Virginia I watched storms come up the river as a solid front of rain and lightning. Our house (photo at left), had been built in the 1930's and sat high on a hill overlooking the Rappahannock river.

Built originally as a farmhouse, the building had a standing seam metal roof and had been protected with a lightning rod system.

[Click to enlarge any image] Photo: Lindan, near the Fairfield filling station in Dunnsville, Virginia ca 1955.

But we regularly saw nearby trees take a strike. The energy from the lightning strike appeared to vaporize the sap within the tree, causing it to literally explode outwards.

I have also inspected a home damaged by an indirect electrical strike which originated below an electrical power transmission line at a nearby tree. The electrical energy from the power transmission line traveled down the tree, followed the tree roots under the garage concrete slab, exploded the garage floor slab (there was perhaps water below the slab), and finished by blowing the car up through the garage roof.

The electrical energy from this strike continued, following other roots of the tree across the property, up a metal entry stair railing, and into metal siding on the home and into the home's metal water supply piping system.

Aluminum rivets holding corner trim onto the aluminum-sided home melted and the siding corner trim fell to the ground. The water main melted, leaving a burst and leaking water entry line which then flooded the home's basement.

See LIGHTNING PROTECTION for TREES for more details of protecting trees from lightning strikes.

...

Continue reading at LIGHTNING PROTECTION, HOW IT WORKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BURMA SHAVE - life along the Rappahannock

- LIGHTNING PROTECTION SYSTEMS

Suggested citation for this web page

LIGHTNING PROTECTION SYSTEMS, DEFINITIONS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to LIGHTNING PROTECTION SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Portions of this information are based on UL publication 200-81 11/87 and other local service company information about lightning protection systems and lightning strike hazards.

- Special thanks to Associated Lightning Rod Company, Cooper Road Box 329A, Millerton NY who has been contributing technical content in presentations to NY ASHI home inspectors since 1996. Some of that information [on lightning system material and installation details] was edited for clarity. ALRCi can be reached at 518-789-4603, 845-373-8309, 860-364-1498 and will inspect your lightning protection system at no charge. [We have no financial nor any other business relationship with any company or product discussed at this website--DF]

- For more details on how lightning protection systems work, see Lightning Protection from Pacific Electric and Gas Company, and Electrical System Grounding and Lightning Protection, Engineering Technical Letter 90-6, Department of the Air Force, HQ USAF.

- Lightning strike risk assessment: for the full body of this excellent article which summarizes recent opinions about lightning strike risk assessment and safe practices for individuals or groups needing to avoid being struck by lightning, see Updated Recommendations for Lightning Safety - 1998 Ronald L. Holle and Raul E. Lopez from National Severe Storms Laboratory, NOAA and Norman, Oklahoma, Christoph Zimmermann Global Atmospherics, Inc. Tucson, Arizona

- As we indicated in an original version of this article, a lightning strike risk assessment guide can be found in Appendix I of the National Fire Protection Association's Lightning Protection Code, NFPA #780. The guide considers type of structure, type of construction, structure location, topography, occupancy, contents and lightning frequency. Contact NFPA, Batterymarch Park, Quincy, MA 02269 617-770-3000.

- Lightning Protection Institute, 3365 N. Arlington Heights Rd., Suite J., Arlington Heights IL 60004

- Underwriters Laboratory Standard UL96A. These requirements cover the installation of lightning protection systems on all types of structures other than structures used for the production, handling, or storage of ammunition, explosives, flammable liquids or gases, and other explosive ingredients including dust. These requirements apply to lightning protection systems that are complete and cover all parts of a structure. Partial systems are not covered by this standard. These requirements do not cover the installation of lightning protection systems for electrical generating, distribution, or transmission systems. These requirements do not cover lightning protection components, which are covered by the Standard for Lightning Protection Components, UL 96.

- Underwriters Laboratory Standard UL96: These requirements cover lightning protection components for use in the installation of complete systems of lightning protection on buildings and structures. These requirements do not cover the installation of lightning protection components. Products of this type are covered by the Standard for Installation Requirements for Lightning Protection Systems, UL 96A.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Armor Lightning Protection Inc Manchester Center, VT, 802-375-0266 state-of-the-art lightning protection and surge protection for residential and commercial buildings in Vermont, New England, and throughout the Northeast

- Associated Lightning Rod Company, Inc., Box 329A, Cooper Road, Millerton, NY 12546 914/373-8309 518/789-4603

- A-C Lightning Security, Inc., 2100 East First St., PO Box 329, Maryville MO 64468 816-582-8115 800-821-5575 816-562-2932. In New York, Hudson Valley, contact Christensen Electrical Power Systems, Richard G. Christensen, 518-537-4128.

- Lightning Eliminators & Consultants6687 Arapahoe Road Boulder, CO 80303 (303) 447-2828. "Engineering Solutions For Lightning, Grounding and Surge Protection Worldwide Since 1971"

- Electrical EINET

- Lightning Protection for Facilities, Dr. Bruce Gabrielson, Robert B. Marcus, Published and presented: EMCEXPO92, Washington D.C.

- MIT's Electrical Safety Files

- Lightning Protection for Workers What to Do if You're Outside in a Lightning Storm - Center to Protect Workers' Rights (PDF)

- 1998 and Current Lightning Protection Conferences & Exhibitions

- Lightning Risk and Hazard Analysis Measurement from the National Lightning Safety Institute (NLSI).

- "Lightning Fatalities, Injuries, and Damage Reports in the United States from 1959-1994", E. Brian Curran, Ronald L. Holle, Raul E. Lopez, NOAA Technical Memorandum NWS SR-193 October 1997

- UL - Underwriters Labs Lightning equipment certification program. "Underwriters Laboratories Inc. (UL) has been testing and certifying lightning protection equipment since 1908. UL issues certificates of conformance for systems, inspecting system components and checking completed installations. Installations are required to comply with UL's internationally recognized Standards for lightning protection systems. Manufacturers, suppliers and installers demonstrate their commitment to safety by building, selling and installing only those lightning protection products that pass UL's rigorous testing." -- (Op.Cit.)

- * Safety Hazards and Safe Inspection Procedures for Electrical and Home Inspectors at Residential Electric Panels

- Aluminum Wiring Information WebsiteAluminum Electrical Wiring Hazards and Repairs: in-depth authoritative info, photos, documents including selection of proper vs. ineffective repair methods. E.g.: Ideal 65 "Twister" purple connector fails in field and lab testing with aluminum wire.

- Electrical Panels, How to Inspect in buildings, safety for electrical inspectors, electrical panel, fusing, wiring defects, defective products. Inspection Class Presentation

- Lightning Strike Risk Assessment, Protection Systems & Services

- Multi-wire branch circuit inspection and defects

- Rust and Corrosion in Electrical Panels, A Study and Report on Frequency and Cause for Electrical and Home Inspectors at Residential Electric Panels

- Directory of Home Inspectors accessible via internet

- Electrical System & Wiring Hazard Inspection, Detection, Cause, Remedy, Prevention - Main Electrical Page

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.