Bark Side Down Argument

Bark Side Down Argument

Why Should Wood Boards Be Placed Bark Side Down?

- POST a QUESTION or COMMENT about wood deck & porch construction: board cupping cause and prevention

Wood expert arguments support the bark side down advice for deck and stair construction.

These experts explain the three types of wood shrinkage and movement, define the most significant type of wood shrinkage pattern and direction, and explain why all else being equal a wood board will often curl with its edges towards the bark side as it dries.

This article series explains the causes of cupping in wood boards & wood board right side up advice for steps, decks, ramps, concluding which side of boards should face up or down (bark side down or bark side up in some cases) when building a deck or exterior wood stairs.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Wood Experts Arguments for Bark Side Down

When the bark side up or down, pith side up or down argument seemed closed, or at least were sick of it, our friend Barry Lam lent us a wood joinery text by a Terrie Noll, a wood expert whose wood joinery advice reiterated the argument supporting placing deck boards bark side down..

When the bark side up or down, pith side up or down argument seemed closed, or at least were sick of it, our friend Barry Lam lent us a wood joinery text by a Terrie Noll, a wood expert whose wood joinery advice reiterated the argument supporting placing deck boards bark side down..

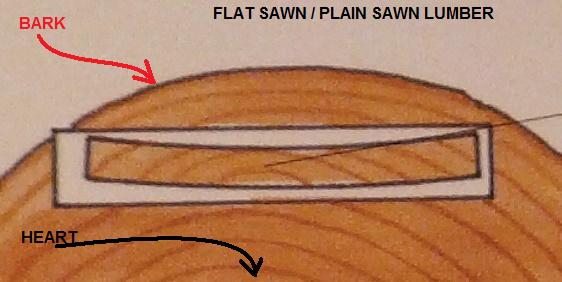

Illustration at left adapted from The Joint Book Terrie Noll cited below.[4]

[Click to enlarge any image]

Cabinet makers and other wood joinery experts pay great attention to the properties of wood, particularly its shrinkage, or wood's cyclic shrinkage and expansion in response to variations in ambient humidity.

These details become critical in fine joinery such as furniture that might otherwise become damaged or even not usable if wood joints open up, separate, warp or jam.

The amount and direction of wood shrinkage as well as any tendency of a board to cup or bend depends significantly on the wood species and more, on how the board was cut and from what portion of the original tree or log it was cut. But most framing lumber such as shown in our photos above is plain sawn or flat sawn - the illustration shown here.

As we cite from Mr. Noll's excellent wood joint techniques book, he argues that a flat sawn or plainsawn board tends to cup such that the bark side of the board will be concave - that is, if we want our wood deck or step boards to best shed water and we want the cup side down then we'd place the bark side down - opposite of my experience and that of Bernie.

As we cite from Mr. Noll's excellent wood joint techniques book, he argues that a flat sawn or plainsawn board tends to cup such that the bark side of the board will be concave - that is, if we want our wood deck or step boards to best shed water and we want the cup side down then we'd place the bark side down - opposite of my experience and that of Bernie.

Here is Noll's description of the directions of wood shrinkage.

In relation to the growth rings of the tree, wood moves more tangentially than radially, or more along the rings than across them.

As wet wood dries, tangential shrinkage distorts the board consistent with its original position in the log. That position is easy to determine by the pattern of growth rings in a board's end grain.

Flatsawn boards are usually cut so the growth rings on the end run more parallel to he width than the thickness of the board. Quartersawn boards [see our photo just above] are cut so growth rings are more perpendicular to the width of the board.

The rule of thumb is that a flatsawn board will shrink twice as much across its width as a quartersawn board, and have twice the potential for expansion and dimensional instability.[4]

While this text explains why flatsawn boards shrink more across their width than quatersawn boards it does not itself explain the direction of board cupping as shown in Noll's illustration presented earlier. To explain wood cupping as a feature of wood shrinkage we need to look for reasons that a board experiences different amounts of shrinkage on one of its flat sides than the other.

Individual board growth ring differences viewed from the end grain across the board's width

Notice that in our photos except for a rare "perfect quartersawn" board, looking at end grain reveals that the cross grains in the board are by no means uniform across the board's width.

In the flatsawn board to which our black arrow points the wood closer to the board's edges, especially its right hand edge, is more vertical - closer to the quartersawn pattern, extending vertically across the thickness of the board.

In contrast, towards the same board's center the growth rings are more flat or longitudinal - that is, tending to extend horizontally across the width of the board.

Individual board growth ring differences viewed from the end grain across the board's thickness

But it is more likely to be variations in growth ring patterns across the board's thickness that will ultimately explain the direction of board cupping. In our photos of cupped boards, ask your self why one side of the board expanded (as it got wet or more moist) more than the other side of the same board. These variations continue through a board's thickness, but most likely you'll see one of two conditions that explain the direction of board cupping:

- Uneven wetting and wood board cupping: as a wet board dries unevenly, the more dry side will tend to become concave (as the wood dries and shrinks) while the more wet side of the same board shrinks less and so remains more expanded (or more convex).

We see this phenomenon very clearly when an interior wood floor has been subject to uneven moisture: say due to flooding of its upper surface or conversely due to floor installation over a damp or wet basement or crawl space.

We illustrate this problem

at FLOOR WOOD, DAMAGE DIAGNOSIS and we discuss it further

at WOOD CUPPING vs WET SIDE - Longitudinal, Tangential & Radial movement & shrinkage vs wood board cupping.

Terrie Noll pointed out, tangential movement or shrinkage is movement across the wood grain, where "grain" is visible at the board's end-cut by noticing the pattern of growth rings.

Glen Huey and Terrie Noll and lots of other other experts describe three kinds of movement in wood: [3][4][5][6]- Longitudinal movement in wood:

movement along the wood grain or as I think of it, in the direction from the tree roots towards the tree top - not across the thickness of the tree trunk but along its length. Longitudinal shrinkage in wood is around 1/10th of one percent - negligible.

Longitudinal wood shrinkage movement in boards is across the length of the board not its width and not its thickness, and not much. [3] - Radial movement in wood:

this is movement out from the tree's center to its bark side, or as I prefer, movement that is orthogonal (right angles) to the lines formed by the growth rings, is always significantly less than tangential shrinkage or movement.

Radial wood shrinkage movement in most boards results in shrinkage that is mostly across the thickness of the board. Typically radial shrinkage in flatsawn boards is 4-6% - maybe 1/8" in 2" thick hardwood. [3] - Tangential movement in wood:

this is movement that across the wood grain (where "across the wood grain" = across wood fibers) and is the most significant in woods, with movement from 6 to 12 % across the board.

Tangential wood shrinkage movement across the wood grain affects the board in amounts that vary according to the grain pattern in the board which in turn depends on how the board was cut from the tree. In a quartersawn board tangential movement will be small and affects the board width. In a flatsawn board tangential movement tends to cause cupping or warping and cupping.

- Longitudinal movement in wood:

Ok so we've got three kinds of movement in wood, of which tangential movement is the most significant. But none of these explains cupping. Rather cupping occurs when one face of a board shrinks (or expands) more than the other. Just above we looked at direct variations in moisture content to explain cupping in wood floor boards.

But cupping may also occur due to variations in the wood grain pattern, the position and shape and location in the board of the growth rings, and the presence or absence of large areas of homogenous wood cells or summer wood that are present in the width of the board and that are not the same between the two board faces.

Or re-stating this point, a wet or damp (18% or above moisture content) board that is more or less uniform in moisture throughout its thickness will still tend to become concave as it dries due to differences in the wood grain pattern across the board's thickness and due to the location and position of the growth rings in the board's cross-sectional thickness.

Now, if the amount of tangential movement in a flatsawn board varies significantly across the thickness of the board (that is between its two faces, not its edges) you can figure that there are significant forces that will cause the board to cup.

Now again, if you look at the end grain photo of our flatsawn board you'll see that the pattern of growth rings is not uniform across the board's width, nor across its thickness.

Huey's rule of thumb for cupping is that a board "cups towards the bark side". Now what the heck does "cup towards" mean? I take it to mean becomes concave towards the bark side but then ... that's my field experience and is opposite of Noll's view. Here's what Huey says:

The rule of thumb is that boards cup toward the bark side. An easy way to visualize this is to imagine that the growth rings are trying to straighten. While this is most often the case, you will find boards that cup in the opposite direction. (Huey 2012, 2009) [3]

So picture trying to straighten out a growth ring. If I put the bark side is "up" when nailing a deck board, the "arch" formed by the growth rings points "up" - that is, the concave face of the arch is down and the convex side of the arch is "up".

Now as the board shrinks and tries to straighten the arch, it never will reach perfect straightness but it'll get straighter;

The convex side remains arched "up". For a board with bark side "up" to straighten its growth ring arches enough to become concave side up the arches would have to pass through dead flat and continue to bend in the opposite direction. That just does not happen. So I'm not sure what "boards cup in the opposite direction" means in the quotation above.

If you take a look at our photos of flatsawn board end grain growth ring patterns throughout this article you'll see that the bark side of the board of the board has more growth rings intact while the pith side or heart side of the board has larger open areas of summer wood that is not divided by growth rings; this is especially true for flatsawn boards on which the center of the board is approximately in line with what was the center of the tree (our flatsawn board marked by the arrow in our photo).

It seems apparent that larger sections of wood that are made up of homogeneous summer wood, unmarked by growth rings, will experience more total shrinkage. That may explain another reason why some boards don't follow the science and instead cup with the concave side towards the tree pith . - Ed.

Bark Side Down Research & Footnotes

- The moisture content in wood varies depending on not only green un-dried lumber versus dried or kiln dried lumber, but also wood species, the ambient environment, and more.

Green lumber that has not been soaked by rain or floating down a river may still have moisture at 30% or above; and wet wood that has been soaked may have 2 1/2 times as much moisture as that same wood species when it has been dried or kiln dried.

Free water on or in wood dries quickly but bound water within wood cells takes much longer to dry or requires kiln drying or other measures for its removal. - The fiber saturation point of wood or wood's FSP is defined as the moisture content of that wood when all of the free water has been removed.

Picture the clothes in your clothes washer at the end of a spin cycle. The wet clothing has been squeezed until you couldn't get more water out of it - that clothing is at its fiber saturation point.

And just as FSP varies among wood species, if you've ever done laundry you've noticed that some fabrics retain less water at the end of the washer's spin cycle than others. - Glen D. Huey, "Why Wood Warps", Popular Woodworking Magazine, 12 July 2012, retrieved 7/17/2013 original source http://www.popularwoodworking.com/article/why-wood-warps, reprinting from Woodworking Magazine, Summer 2009.

- Terrie Noll, The Joint Book, Popular Woodworking Books, Cincinnati OH, www.popularwoodworking.com Quarto Publishing, , Inc., 2002, ISBN 1-55870-633-x

- R. Bruce Hoadley, Understanding Wood, Taunton Press

- U.S. D.A. Forest Products Laboratory, "The Wood Handbook",

- Cloutier, Alain, and Yves Fortin. "A model of moisture movement in wood based on water potential and the determination of the effective water conductivity." Wood Science and Technology 27, no. 2 (1993): 95-114.

Abstract:

A model of isothermal moisture movement in wood during drying using the gradient in water potential as the driving force is proposed. The moisture transport coefficient used in this model is the effective water conductivity.

It is a function of moisture content, temperature, and direction of flow. The boundary desorption curve of the effective water conductivity function is established in the radial and tangential directions of aspen sapwood from nearly saturated to dry conditions at 20, 35, and 50 °C using the instantaneous profile method. The results show that the effective water conductivity increases exponentially with moisture content and temperature.

The effect of temperature cannot be solely explained by the variation of the viscosity of water. The variation of the moisture content-water potential relationship with temperature would explain a large part of this effect. The effective water conductivity was generally higher in the radial direction than in the tangential direction in a ratio varying from 1/1 to 25/1 depending on moisture content and temperature.

The flux-gradient relationship obtained at given moisture contents were found to be linear, confirming the validity of the model for the experimental conditions considered in the present work. - Clarke, S. H. "The differential shrinkage of wood." Forestry 4, no. 2 (1930): 93-104. .oxfordjournals.org

- Boyd, J. D. "Relationship between fibre morphology and shrinkage of wood." Wood Science and Technology 11, no. 1 (1977): 3-22.

Abstract:

This is a study on the shrinkage of wood representing the wide range of morphology variation in leaning trees. It involved 13 trees of Eucalyptus regnans, one of Eucalyptus sieberi and four of Pinus radiata, and specimens taken at close intervals around the circumference of each.

Data indicated a systematic modulation, between extremes at upper and lower sides of each stem, in longitudinal growth strains, relative proportions of thin, medium and thick-walled fibres, microfibril angle in the S2 layer of these, and both Klason and acid-soluble lignin content.

Analyses indicated that the microfibril angle in S2 was a prime factor in influencing both longitudinal and volumetric shrinkage reactions; proportion of thick-walled fibres in the tissue, thickness of S2 relative to S1, and variations in lignification also were involved.

Unusually thick-walled fibres were associated with visco-elastic strain recovery effects, which could form a substantial part of dimensional changes apparently attributable to shrinkage.

- Gu, H., A. Zink-Sharp, and J. Sell. "Hypothesis on the role of cell wall structure in differential transverse shrinkage of wood." European Journal of Wood and Wood Products 59, no. 6 (2001): 436-442.

- Barkas, W. W. "Wood water relationships, VI. The influence of ray cells on the shrinkage of wood." Transactions of the Faraday Society 37 (1941): 535-547. Excerpting:

The shrinkage of wood is not the same in the three directions of the grain. It is greatest in the tangential (7) direction where the shrinkage per unit change in moisture content dr/dm lies for most woods between 0-2 and 0.4. In the radial (p) direction dp/dm is usually about half this value, while in the longitudinal direction ... [shrinkage] is much smaller, amounting to about 1/50th of the tangential.

...

Continue reading at WOOD CUPPING vs WET SIDE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BARK SIDE UP or DOWN on DECKS & STEPS?

- BUTT JOINT CURLING in FIBER CEMENT SIDING

- DECK & PORCH CONSTRUCTION - home

- FLOOR DAMAGE DIAGNOSIS

- SLIPPERY STAIRS, WALKS, ROOFS

- WOOD FLOOR DAMAGE

- WOOD FLOOR MOISTURE

Suggested citation for this web page

BARK SIDE DOWN ARGUMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] The moisture content in wood varies depending on not only green un-dried lumber versus dried or kiln dried lumber, but also wood species, the ambient environment, and more. Green lumber that has not been soaked by rain or floating down a river may still have moisture at 30% or above; and wet wood that has been soaked may have 2 1/2 times as much moisture as that same wood species when it has been dried or kiln dried. Free water on or in wood dries quickly but bound water within wood cells takes much longer to dry or requires kiln drying or other measures for its removal.

- [2] The fiber saturation point of wood or wood's FSP is defined as the moisture content of that wood when all of the free water has been removed. Picture the clothes in your clothes washer at the end of a spin cycle. The wet clothing has been squeezed until you couldn't get more water out of it - that clothing is at its fiber saturation point. And just as FSP varies among wood species, if you've ever done laundry you've noticed that some fabrics retain less water at the end of the washer's spin cycle than others.

- [3] Glen D. Huey, "Why Wood Warps", Popular Woodworking Magazine, 12 July 2012, retrieved 7/17/2013 original source http://www.popularwoodworking.com/article/why-wood-warps, reprinting from Woodworking Magazine, Summer 2009.

- [4] Terrie Noll, The Joint Book, Popular Woodworking Books, Cincinnati OH, www.popularwoodworking.com Quarto Publishing, , Inc., 2002, ISBN 1-55870-633-x

- [5] R. Bruce Hoadley, Understanding Wood, Taunton Press

- [6] U.S. d.a. Forest Products Laboratory, "The Wood Handbook",

- [7] Cloutier, Alain, and Yves Fortin. "A model of moisture movement in wood based on water potential and the determination of the effective water conductivity." Wood Science and Technology 27, no. 2 (1993): 95-114. - Abstract: A model of isothermal moisture movement in wood during drying using the gradient in water potential as the driving force is proposed. The moisture transport coefficient used in this model is the effective water conductivity. It is a function of moisture content, temperature, and direction of flow. The boundary desorption curve of the effective water conductivity function is established in the radial and tangential directions of aspen sapwood from nearly saturated to dry conditions at 20, 35, and 50 °C using the instantaneous profile method. The results show that the effective water conductivity increases exponentially with moisture content and temperature. The effect of temperature cannot be solely explained by the variation of the viscosity of water. The variation of the moisture content-water potential relationship with temperature would explain a large part of this effect. The effective water conductivity was generally higher in the radial direction than in the tangential direction in a ratio varying from 1/1 to 25/1 depending on moisture content and temperature. The flux-gradient relationship obtained at given moisture contents were found to be linear, confirming the validity of the model for the experimental conditions considered in the present work.

- [8] Clarke, S. H. "The differential shrinkage of wood." Forestry 4, no. 2 (1930): 93-104. .oxfordjournals.org

- [9] Boyd, J. D. "Relationship between fibre morphology and shrinkage of wood." Wood Science and Technology 11, no. 1 (1977): 3-22. Abstract: This is a study on the shrinkage of wood representing the wide range of morphology variation in leaning trees. It involved 13 trees of Eucalyptus regnans, one of Eucalyptus sieberi and four of Pinus radiata, and specimens taken at close intervals around the circumference of each. Data indicated a systematic modulation, between extremes at upper and lower sides of each stem, in longitudinal growth strains, relative proportions of thin, medium and thick-walled fibres, microfibril angle in the S2 layer of these, and both Klason and acid-soluble lignin content. Analyses indicated that the microfibril angle in S2 was a prime factor in influencing both longitudinal and volumetric shrinkage reactions; proportion of thick-walled fibres in the tissue, thickness of S2 relative to S1, and variations in lignification also were involved. Unusually thick-walled fibres were associated with visco-elastic strain recovery effects, which could form a substantial part of dimensional changes apparently attributable to shrinkage.

- [10] Gu, H., A. Zink-Sharp, and J. Sell. "Hypothesis on the role of cell wall structure in differential transverse shrinkage of wood." European Journal of Wood and Wood Products 59, no. 6 (2001): 436-442.

- [11] Barkas, W. W. "Wood water relationships, VI. The influence of ray cells on the shrinkage of wood." Transactions of the Faraday Society 37 (1941): 535-547. Excerpting: "The shrinkage of wood is not the same in the three directions of the grain. It is greatest in the tangential (7) direction where the shrinkage per unit change in moisture content dr/dm lies for most woods between 0-2 and 0.4. In the radial (p) direction dp/dm is usually about half this value, while in the longitudinal direction ... [shrinkage] is much smaller, amounting to about 1/50th of the tangential"

- [1]Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- [2] Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - [3] America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- [4] American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, www.apawood.org

- [30] A Simplified Guide to Custom Stair building, George R. Christina

- [31] Basic Stair building, Scott Schuttner

- [32] The Staircase (two volumes), John Templar, Cambridge: the MIT Press, 1992

- [33] The Staircase: History and Theories, John Templar, MIT Press 1995

- [34] Steps and Stairways, Cleo Baldon & Ib Melchior, Rizzoli, 1989.

- [35] "The Dimensions of Stairs", J. M. Fitch et al., Scientific American, October 1974.

- [36] Stephenson, Elliott O., THE ELIMINATION OF UNSAFE GUARDRAILS, A PROGRESS REPORT [PDF] Building Standards, March-April 1993

- [37] "Are Functional Handrails Within Our Grasp" Jake Pauls, Building Standards, January-February 1991

- [38] Sam Williams and Mark Knaebe, "The Bark-Side/Pith-Side Debate", The Finish Line, (A Forest Products Laboratory finishing factsheet), December 1995, U.S. Forest Products Laboratory, retrieved 9/13/12, original source http://www.fpl.fs.fed.us/documnts/finlines/willi95b.pdf [copy on file as Bark_Side_Wood_FPL.pdf] R. Sam Williams and Mark Knaebe are researchers in Wood Surface Chemistry at the USDA Forest Service, Forest Products Laboratory, One Gifford Pinchot Drive, Madison, WI 53705–2398

- [39] Sarah Lyall, "Bark Up or Down? Firewood Splits Norwegians", The New York Times, 20 February 2013, p. A4.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Paul Galow [Website galowconsulting.com ] - technical consultant on networking, LAN design, applications support. Galow Consulting Services [Website galowconsulting.com ] , 914-204-1749, email: paulgalow@galowconsulting.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.