Type B-Vent Chimney FAQs

Type B-Vent Chimney FAQs

Type B gas vents

- POST a QUESTION or COMMENT about B-vents chimneys & flues: installation specifications

Metal B-Vent flue installation requirements & inspection questions & answers:

This article answers frequently-asked questions about B-vent metal chimneys used for gas-fired appliances.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Q&A on B-Vents for Gas Fired Appliances

These questions & answers about B-vent chimneys & vents were posted originally at the topic home page: TYPE B-VENT CHIMNEYS. Please be sure to see the advice and fire clearances discussed there.

These questions & answers about B-vent chimneys & vents were posted originally at the topic home page: TYPE B-VENT CHIMNEYS. Please be sure to see the advice and fire clearances discussed there.

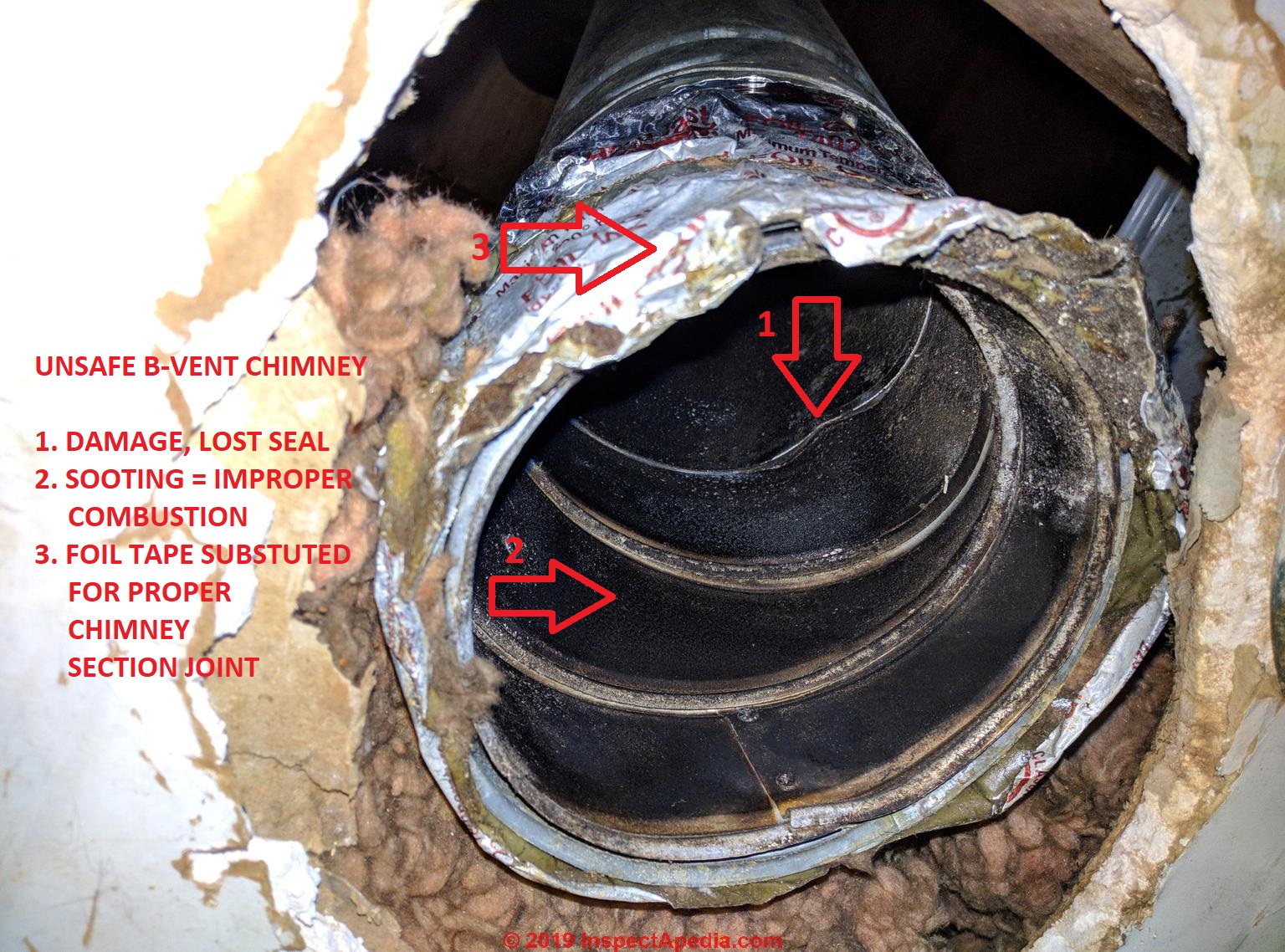

Photo: Chris's damaged B-Vent chinmney with multiple safety concerns.

[Click to enlarge any image]

On 2019-12-08 by (mod) -

So perhaps someone was retro-fitting new-to-existing chimney sections and the lengths didn't match up sufficiently to make a proper and safe joint.

That might happen, for example, when connecting a new furnace and chimney in the building up to a pre-existing metal chimney at the rooftop, if the new equipment were slightly shorter or lower (or taller would give the opposite problem).

Just taping a "not quite fits" joint with metal tape is in this case unsafe.

Proper would have been to

- adjust the rooftop chimney up or down or replace it

- adjust the in-building system up or down by lifting the entire heater the necessary fraction of an inch during installation

- use an adjustable-length or cut-to-length- or flexible B-vent

Watch out: in one of your photos (shown above) I see what looks like

- Damage: chimney interior bent inwards: a likely leak that may make that section unsafe.

- Also that sooting is not common in a gas-fired heating chimney and may indicate improper combustion - itself unsafe risking fatal carbon monoxide CO poisoing;

- And of course using foil tape to span gaps in B-vent chimney sections is improper and unsafe, risking fire or CO poisoning.

- Also there are signs of condensate or external leaks along the right side of your image

On 2019-12-08 by Chris

I'm not sure why it was taped. Perhaps roofers did a shoddy reinstallation at some point? I can't imagine that the furnace installer did this. This experience has been a real wake-up call for me - I will certainly be installing a dedicated detector near the furnace as well as a couple inside the home after this ordeal.

I think I was mistaken when I stated that they both seemed like female ends. I need to clean up the old tape but I think that it is likely these two sections will join together properly but I still have the issue of the gap. Do you have any idea if MTL-FAB has always used the same twist-lock securing mechanism?

Since my vents appear to have no model/part numbers beyond a generic '5M', I'm wondering if the existing vents will mate up properly to new vents made by MTL-FAB. They have a different pattern/color to the metal as compared with the new versions. I suspect these pipes date back to the early 1970's.

I came across this dual-walled flexible (accordian-styled) B vent named 'B-Flex' by the same company.

https://www.mtlfab.com/media/L1940.pdf

This seems like a better idea than trying to jimmy the large ceiling support "box" I posted earlier into place and hope that the height is perfect. I can use the thinner SureGrip support plate as well. It's quite tempting for a several reasons: Ease of assembly, lighter-weight (aluminum), rust-free, and less joints/bends.

The only downside I can think of (assuming this will mate to my existing vent) is that it likely less sturdy and robust than the original rigid steel vent.

What do you think?

On 2019-12-08 by (mod) -

OK right, thanks for clarifying; yes arrow up = correct.

So why were the sections taped? A mis-fit or a leak perhaps;

The danger is fatal CO poisoning from flue gas leaks or (less likely) a fire.

On 2019-12-08 by Chris

This is the interior of the furnace side

On 2019-12-08 by Chris

Yes, all the parts are B type double walled vents. I have inspected the roof sheeting and attic area and it doesn't appear to be leaking from outside.

I suspect the water damage was caused by the condensation in the exhaust itself when the pipes separated. These must've been separated for quite some time (venting into my house!) before I noticed it. Luckily, we rarely use heat at my location.

This is the interior of the attic section.

Both the section of venting in the attic and the lower section are stamped with UL 5M MTL-FAB Type B Gas Vent and 1" clearance ratings.

Both sections of pipe also have arrows pointing up which leads me to believe that they are in fact oriented properly. I'm enclosing a close-up photo of the inside of the two mating pipes.

On 2019-12-08 by (mod) -

No you didn't break it, Clark's server re-booted and left us off the air; Gas flue = B-Vent so we want to find embossing or labeling confirming that all of the chimney parts are so-rated. Links above at Continue reading give B-vent clearances (starting at inspectapedia.com/chimneys/B-Vent-Chimneys.php) as also will the manufacturer'sinstructions on any replacement parts you need. Typically that 1" clearance to combustibles is stamped right into the metal. Separate rooftop clearances are given in another of the links above.

Gas flue = B-Vent so we want to find embossing or labeling confirming that all of the chimney parts are so-rated. Links above at Continue reading give B-vent clearances (starting at inspectapedia.com/chimneys/B-Vent-Chimneys.php) as also will the manufacturer'sinstructions on any replacement parts you need. Typically that 1" clearance to combustibles is stamped right into the metal. Separate rooftop clearances are given in another of the links above.

There are ceiling support kits that connect to joists or rafters and clamp around the B-vent section. (Using foil tape as in the photo is not proper nor sufficient).

The leak stains in the ceiling make us want to look carefully at the rest of the installation from rooftop and chimney cap down, to find the leaks - it could have all been condensate but don't assume that.

I suspect you're going to want to remove and replace most or all of what's there. Fortunately B- vent sections are not the most-expensive.

It looks to me as if this vent is installed upside down, with the "male" end facing up towards the ceiling. That means that any condensate running down the flue interior wants to leak out at the joints. If that's the case then the whole installation is suspect (safety, correctness, etc) as it would have been installed by someone who didn't know the best procedures.

In the example of a B-vent from Hart & Cooley www.hartandcooley.com/chimney-and-vent/type-b-vent-gas shown below you can see the mating sections in proper orientation. Notice that INSIDE the flue the inner lip of the innermost-liner of the upper section laps over the up-facing lip of the lower section so that any condensate runs in the flue not out of it.

As we note in our article link given above, "Amerivent stamps or embosses [an arrow] right into the steel surface as well as marking it again on a printed label, giving us two chances to get it right."

On 2019-12-08 by Chris

Thank you for the quick response Dan.

Thank you for the quick response Dan.

Htmlcommentbox went down just as I posted a response - I wonder if the included photo was too large.

I assure you that I'm aware of the risks and fully intend to install detectors as soon as I figure out which parts are missing and repair the damage.

The furnace is gas and the chimney type is a typical metal roof exhaust. From what I've read in product literature and in my locale, the fire clearance should be 1".

I can only add one photo per comment but I have more. Is it possible to communicate over email? I hope my comments can aid others in the future.

Please forgive the insulation and damaged sheetrock around the pipe, I haven't cleaned the attic area yet. The collar has been removed for the photo. You will note that there is a 1-2" gap between the sections. Eyeballing the ceiling support I linked earlier, I doubt I will have enough clearance to fit it in between the sections (even if it fit pipes).

On 2019-12-06 by (mod) -

I'd like to see some photos of the problem area, Chris;

Beware that making a mistake can kill you or burn down the house, so take care.

It sounds as if the original installation did not use all proper parts;

When I know more I'll be able to comment further.

Let's be sure we are on the same page about fuel and chimney materials:

What's the fuel?

What's the chimney type?

What are your fire clearance distances?

Do you have working smoke & CO detectors properly installed and located?

On 2019-12-06 00:49:58.354014 by Chris

My flue has recently separated at the ceiling. It appears that the installer simply anchored a pipe collar directly to the drywall via four sheet metal screws which have since given way.

My flue has recently separated at the ceiling. It appears that the installer simply anchored a pipe collar directly to the drywall via four sheet metal screws which have since given way.

I want to repair and support the flue properly by installing framing that can support the flue. I'm fairly handy with tools and general carpentry and whilst I know that this type of thing is best left to professionals, I'm unable to hire an expert at the moment. The piping is mostly made by MTL-FAB with a couple of bends by Simpson near the furnace itself.

My problem is that where the MTL-FAB pipes have separated there is a gap of ~1". Furthermore, it appears that these pipes don't join together properly, it's almost as if they are two female fittings. There is old aluminum tape at the interface suggesting that the two pipes were simply taped together before the collar fell from the drywall.

These two pipes do not seem to use the twist-lock mechanism that I see in the company's online literature and I am unable to find a short "coupler" available from them. They offer a "Ceiling Support" model 6TGCSP which looks like it may include a short piece of pipe that would join the two sections but the drawing in the installation literature is not clear on this.

I found your site and figured I should post my issue before buying something unecessary that may not fit.

I will try calling the company as well but I think they will simply refer me to a HVAC company.

On 2019-10-17 by Sam Slam

I am installing a tiny wood stove and I need to put the flue pipe through a metal corrugated roof (30 percent pitch). The company recommends a silicone based (and expensive) boot flashing to go on top of the roof and around the double walled 5 inch pipe (which insulates the double walled 3 inch pipe inside as well).

SO with TWO double walled pipes (with the purpose of the 5 inch being to insulate the 3 inch as it passes through the ceiling/roof) would just an EDPM rubber boot flashing work fine? I really feel like the temperature would not get that hot to melt the rubber. I dont want to take any risks though but the rubber boor flashing is about 120 dollars cheaper and seems all that is necessary when you have two double walled pipes. TIA

On 2018-11-23 by (mod) - fill abandoned chimney with vermiculite?

Al

Thanks for an interesting and somewhat subtle question.

I am not aware of any reason to fill the abandoned vent with loose fill insulation; If you cap both top and bottom there will indeed still be some convection currents that circulate air within the chimney but in my OPINION that should have no effect on the building UNLESS the chimney is exposed and passes through conditioned space.

That is to say, a capped, unused metal flue passing through a chimney chase framed around and enclosed ought not affect the structure.

On 2018-11-23 by Al

I had my gas furnace replaced recently & changed to a hi-eff & also the gas water changed to a power vent type.

So the B-vent chimney is no longer needed. The bottom is capped & I will cap the top in the spring. Before I cap it, should I fill it with a loose insulation like vermiculite ?

On 2018-02-21 by (mod) -

Ces

If we're talking about replacing the chimney cap on a b vent, replacing that with an unlisted alternative device would be improper and unsafe.

On 2018-02-21 by Ces

Hi - I had a contractor replace the roof the home I am buying. My worries is that he put a turtle vent where there use to be a type B vent - is this okay?

On 2017-09-03 by Bob , rrredmond1@yahoo

I'm replacing a wood burning stove with direct vent straight out wall . The inner pipe from the chimney fell so we removed it . All that remains is the galvanized pipe to roof with stack . Should I remove this or just leave and seal ? If I leave it how should I seal it ?

On 2018-11-11 by (mod) - center the B-vent between rafters when penetrating the roof?

Scott

Scott

As long as you are meeting the B-vent manufacturer's fire clearance distances including from the nearest rafter, I don't know of any reason that it needs to exit the roof precisely in the middle between two rafters.

Photo: Scott's B-vent during installation, before cutting the hole in the roof.

However looking at your photo I see a few items worth mentioning:

1. You will need to remove the B-vent up close to the roof underside or otherwise protect it from both damage and from sawdust and roof debris that otherwise will fall into the vent during the cuttting of the roof exit opening.

2. Your roof decking looks liike two or more generations of pine boards, possibly on an older home that originally was roofed with wood shingles. Or were those nailers overlaid with plywood? I can't quite make that out.

In any case, if the roof opening cuts through one of the original roof nailer boards, you may need to add blocking to support free end of the board.

3. The roof framing looks a bit hodge-podge to me with incomplete rafters tacked together to the left of your B-vent, abutting what may have originally been a lower ridge board with almost no visible nails - the connections could be questionable.

If I were a roofer asked to work on this roof from above, and if I had any experience with old roofs (and workers falling through them or of later being blamed for subsequent roof failures) I would want to inspect the condition of the roof framing and support from the attic side before going on the roof itself. I might then have some suggstions.

On 2018-11-11 by Scott

I have my B-Vent securely anchored to a rafter (maintaining a 1" clearance using AmeriVent Vent Pipe Hangers). Should I relocate it directly between 2 rafters instead before I have a roofer cut the hole and install flashing, extension pipe, storm collar, and cap?

On 2018-10-07 by (mod) - requirement for a glass door on a fireplace

Thank you for the question Chuck.

I think you'll find that the requirement for a glass door on a fireplace is going to come from the fireplace design, or on occasion from energy codes or fire codes in new construction, not the chimney to which it is connected.

On 2018-10-07 by Chuck

Do b vent fireplaces need a glass front?

On 2018-09-28 by (mod) - How do I tell the manufacturer of my B vent

Look for a data tag or raised metal stamping on the vent.

On 2018-09-28 by RogerVicory

How do I tell the manufacturer of my B vent as I hear the different manufacturers are not compatible

On 2018-06-20 by (mod) -

Why don't you start by picking up a copy of the installation manual for your heater. That will give you the specifications on venting and you can be sure that you're using the right materials

On 2018-06-19 by John

I live in a newer mfd.home.........the gas hot water ventpipe from factory is too short......snow gets in every time.

Would like to add two feet?? And with back of the elbow facing where the snow and rain comes from. And put factory capback on. I do mot think i need a guy with a masters degree lol to charge me 300 to do this. So appreciate ideas, assurances,etc. Much thx. I lovvvvvvvve this site.:):)

On 2017-11-23 by (mod) -

Brian,

I'm not sure exactly what kind of Appliance you have. I thought the Vermont casting made space heating equipment. In any case if we have the brand and model number we could check with the installation manual, or give Vermont casting your call directly to be absolutely certain that we understand the situation and there Factory - expert advice.

I'm reluctant to guess considering that there are life safety issues here.

On 2017-11-22 by Brian

Do you apply high temp

Sealant at the draft hood appliance connection? (Vermont casting gas fired stove)

On 2017-09-06 by Heidi

Is there a standard size for the "cap" diameter?

I've only been able to find size 4", but need larger.

On 2017-03-09 by (mod) - calculate base or plate length and width for b- vent flashing

Stunning question, Vin. I've never considered calculating the flashing dimensions because I buy pre-fab vent flashings.

The vent flashing I buy has to have a boot that is properly sized for the diameter of the vent pipe. Some of these pre-fabs use a boot that can be trimmed to fit larger diameter pipes but take care that the fit is snug and uniform or there will be a leak.

For gas venting, there is typically a collar that mounts around the flue above the vent flashing. I seal that collar with a high-temperature silicone caulk/sealant as insurance against water traveling down through the metal boot. (Plumbing flashings use a rubber boot).

Width typically extends half of a shingle tab under at sides and 6" above, and below far enough to bring water out atop the next shingle course below, typically 4-6".

You're right to infer that on a low slope roof you might need a larger extension of vent flashing but I'venot encountered problems with factory pre-fab units.

I would not

On 2017-03-09 by VIn

How to calculate base or plate length and width for b- vent flashing for any shape. Is there any thumb rule?

On 2017-02-15 by (mod) - chimney cap blew off of B-vent: ok to run the heater?

I'm a bit scared to bet your life and safety on a "yes" for a home and system about which I know not a darn thing, but in concept, the heat will work; the risk is downdrafts or inadequate draft - that could produce fatal CO - carbon monoxide.

If you're running the system while waiting for replacement of the missing cap be SURE you have working carbon monoxide detectors properly located, installed, tested.

On 2017-02-13 by C Stuart

We had a windstorm today and the vent along with its oval tpye B gas vent cap blew off the roof. Is it OK to turn on heat until it's repaired?On 2016-10-28 by (mod) what to do about a hole in the inner metal pipe of a multi-wall metal chimney

For safety, and considering the risk of a fatal carbon monoxide poisoning or a fire at a building of which we know so little, if it were my job I'd replace the damaged section of B-vent.

If nothing else we're unsure how much remaining life there is in the inner pipe that you found as "undamaged"

On 2016-10-27 by Larry

my B. chimney has a 1 inch hole in the outer pipe, the inner pipe is undamaged. Is it safe to patch the outer pipe, then use metal tape to seal it? I await your advise thank youOn 2016-09-29 by (mod) trying to replace parts of the b type vent pipe from the attic thru the roof

I think the manufactuer question was asked because newer replacement sections of B-vent may not clip properly, nor safely, to older B-vent parts from a different manufacturer.

To replace parts and keep parts of the existing system, why not bring along a section of the existing B-vent when you're shopping? That way you can compare features and connections.

On 2016-09-28 by MIKE

My house was built in 1962 and I am now trying to replace parts of the b type vent pipe from the attic thru the roof. when I went to buy the materials they asked what manufacturer?

They told me it was stamped on the pipe? I can't find any stamping on any of the sections?

How do I replace this vent pipe?

On 2016-02-13 by (mod) For flat and very low slope roofs the above-roof chimney height may in some cases be less than two feet

AaronYou're right. For flat and very low slope roofs the above-roof height can be less than two feet, as shown in the TYPE B-VENT ROOFTOP CLEARANCE TABLE given in TYPE B-VENT CHIMNEYS

Keep in mind that on these low slope or flat roofs, at least in some buildings, you'll need to consider the adequacy of draft - a too-short chimney may not provide enough draft, so its above-roof height may need to be extended for that reason.

I've clarified the text in the article. Thank you for careful reading and for taking the time to comment.

Daniel

On 2016-02-13 by AaronBrauer

I'm confused. The article TYPE B-VENT CHIMNEYS states,"type-b vents should be at least two feet above the roof's surface."

But the table shows that they can be as short as one foot above the roof's surface. Huh?

Question:

(Oct 14, 2011) Chris said:

what is the definition of vertical wall regarding b-vent termination? Interior wall or exterior wall continuing higher than the roof

Reply:

Chris, as we are terminating the B-vent outdoors and above the roof line, the "vertical wall" pertains to outside conditions.

Question:

(Oct 26, 2011) anthony pace said:

I have a Carrier mod. 58pav090-16 (Dec.1999)-the bottom of the flue pipe (cap) is corroded and has accumulated (sand like) debris. The pipe up thru the attic looks good and there is a raincap on the top.

Reply:

Anthony,

When a gas flue vent or chimney is corroded it is potentially unsafe as it may perforate and leak. It most likely needs replacement.

Further, corrosion of a metal flue on gas-fired equipment is a red flag warning to look out for improper and thus unsafe heating appliance operation.

For example, insufficient combustion air, leaks into the chimney, improper chimney installation (too cold to vent properly) can increase the rate of flue corrosion while at the same time those conditions can threaten the production of dangerous, even potentially fatal carbon monoxide gas.

To be able to sleep safely while waiting for your chimney or HVAC expert, be sure you have working carbon monoxide detectors properly installed.

Question: elbows in vents

(Mar 22, 2012) Gettinitright said:

Is there any code regulation against installing 90's (elbows) 1 or 2ft from the protrusion of the roof? Updating a unit from 1990 and the new code says I need to have 1" clearance around all wood framing. I would like to install 2 elbows instead of cutting a new hole in the roof to effectively relocate it.

(Oct 30, 2012) Tom Painter said:

I have a two store house built in 1923. I was thinking of closing up the fireplace and walling it off. A new water heater and gas furnace vent a flue in the basement that by-passes the first floor fireplace.

The top of the chimney leans a little and needs to be repaired. With the fireplace walled off, and its very existence hidden behind drywall, can I have the top rows of chimney bricks removed down to B vent height requirements?

(Nov 30, 2014) George Drexel said:

How far can I run b-vent horizontally from a furnace before turning upward?

Reply:

George I can't guess at an answer on horizontal B-vent limits - as I think it depends on the appliance being vented. Smaller BTUs, for example will probably permit only shorter runs. An easy solution is to check the installation instructions for the appliance being vented - or tell us the appliance brand and model and we can help research the question.

(Apr 27, 2015) George said:

I have a B vent extending up thru the roof of a commercial building. We added a parapet wall 12" away from the vent.

It presently extends up 24" Do in need to extend up above the new parapet wall ?

I neglected to say the new parapet wall is 48"

Reply:

George I think we've answered this in the clearances above and in a separate article that should be helpful:

B-Vents should be at least two feet above the roof surface as well. See the detailed table below and also see TYPE B-VENT CHIMNEY CLEARANCES - separate article compares with other chimney types.

If a vent terminates next to a wall it may fail both fire clearance and suffer draft interference. Your local building code inspector is the final authority so that's whom to ask. If I were inspecting (and I"m not) I'd want the vent to terminate 2 feet above roof components including a nearby parapet wall.

Question: code on passing a B- Vent chimney through a "sheetrock" wall

(July 23, 2015) woody mwhac@aol.com said:

what is the calif.code requirement for furnace (type B-vent) passing thru a sheetrock wall or can i use single wall

Reply:

Woody,

Please see the B-Vent clearance distances from combustibles given at inspectapedia.com/chimneys/Metal_Chimney_Clearances.php

FIRE CLEARANCES, METAL CHIMNEYS

There you'll see that for gas appliances you'd need 6-inches from combustibles (including drywall and wood framing)

Do not run a single wall flue vent connector to pass through building walls. You'd need (varying by location and local codes), typically 18" to combustibles.

Question: a rafter is in the way of the direct route for my B-vent chimney

(Aug 13, 2015) Robert said:

My gas furnace uses a B-Vent, I have a rafter in the way. Does the B-Vent have to be straight or can I use 2 90 degree with a short straight piece to go around rafter?

thanks

Reply:

Robert, depending on total flue length and the free space available you may be able to turn around the rafter, but you may want to use 45's rather than 90's for better draft. I'd sketch the whole flue length and dimensions and then check once more with the appliance manufacturer to be sure they agree that it will vent adequately. A mistake could be fatal.

Question: why do B-vents rust near the chimney top and at the rain cap?

(Aug 30, 2015) gregh said:

Many experts seem confused as to why some b vent pipes tend to rust near the top under the rain cap. The rust has absolutely nothing to do with the age or condition of the gas appliance. The rust is a result of the flue gas coming in contact with the outer shell of the b vent which is a type of galvanized metal.

This outer shell is generally cool to the touch , so when the warm flue gasses contact the outer shell and condense on it over a long period of time rust will result as the flue gasses are highly corrosive. Several manufacturers became aware of this 40 years ago. Selkirk designed a rain cap around 1971 which incorporated a lower ring shield to direct flue gas away from the b vent pipe. Both Selkirk and Ecco manufacturing sold a painted termination pipe from 1973-1985 .

By this time most cap designs used some type of shield to keep flue gas from drifting down onto the b vents outer surface. Also mid efficient furnaces are terrible for creating more corrosive vapor in flue gas as these appliances don't have a draft hood to introduce dilution air which would help dry the flue gas somewhat.

Reply:

Interesting details, Greg, thank you. Indeed condensate from gas fired appliances is quite corrosive. Understanding just where the corrosion shows up is both diagnostic and interesting. We'll edit your comments into the article on Chimney wet time over at

Question:

(Oct 17, 2015) Ralph rangel said:

There is a machine screw sticking into the inner B-vent wall (flue.

it sticks in approx. 1/3".

Is this permitted by code (Chicago)

On 2015-12-30 at RID:11 by jim H. [delete]

wanted to find out, what are the requirements for installing a chimney in a half round building. i have a building im going to use as a shop to tinker in, and need some heat. any ideas. its getting cold and winter is coming.

Reply:

Ralph: I don't know but I doubt that it's an issue (except on dryer ducting).

Jim you'll want to meet the same roof clearances and fire clearances as for other buildings, keeping in mind that I can't answer a question like this: we don't know the fuel, type of heater or what the heck you're venting.

...

Continue reading at TYPE B-VENT CHIMNEYS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ADJACENT METAL CHIMNEY SEPARATION - separation between metal chimneys and their rain caps

- CHIMNEY WET TIME & CORROSION for a discussion of causes of corrosion in B-vents and other metal chimneys

- HEIGHT REQUIRED for L VENTS & B VENTS

- METAL CHIMNEYS & FLUES - home

- METAL CHIMNEY INSTALLATION MANUALS

- TYPE B-VENT CHIMNEYS - home

- TYPE B VENT vs L VENT DIFFERENCES

- TYPE B-VENT CEILING FLOOR WALL CLEARANCES

- TYPE B-VENT ROOFTOP CLEARANCE

Suggested citation for this web page

TYPE B-VENT CHIMNEY FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about B-vents chimneys & flues: installation specifications.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Thanks to Luke Barnes for suggesting that we add text regarding the hazards of shared chimney flues. USMA - Sept. 2008.

- Arlene Puentes [Website: www.octoberhome.com ] , an ASHI member and a licensed home inspector in Kingston, NY, and has served on ASHI national committees as well as HVASHI Chapter President. Ms. Puentes can be contacted at ap@octoberhome.com

- Roger Hankeyis principal of Hankey and Brown home inspectors, Eden Prairie, MN, technical review by Roger Hankey, prior chairman, Standards Committee, American Society of Home Inspectors - ASHI. 952 829-0044 - hankeyandbrown.com

- NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore)

- NFPA #211-3.1 1988 - Specific to chimneys, fireplaces, vents and solid fuel burning appliances.

- NFPA # 54-7.1 1992 - Specific to venting of equipment with fan-assisted combustion systems.

- GAMA - Gas Appliance Manufacturers' Association has prepared venting tables for Category I draft hood equipped central furnaces as well as fan-assisted combustion system central furnaces.

- National Fuel Gas Code, an American National Standard, 4th ed. 1988 (newer edition is available) Secretariats, American Gas Association (AGA), 1515 Wilson Blvd., Arlington VA22209, and National Fire Protection Association (NFPA), Batterymarch Park, Quincy MA 02269. ANSI Z223.1-1988 - NFPA 54-1988. WARNING: be sure to check clearances and other safety guidelines in the latest edition of these standards.

- Fire Inspector Guidebook, A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- Uniform Mechanical Code - UMC 1991, Sec 913 (a.) Masonry Chimneys, refers to Chapters 23, 29, and 37 of the Building Code.

- New York 1984 Uniform Fire Prevention and Building Code, Article 10, Heating, Ventilating, and Air Conditioning Requirements

- New York 1979 Uniform Fire Prevention & Building Code, The "requirement" for 8" of solid masonry OR for use of a flue liner was listed in the One and Two Family Dwelling Code for New York, in 1979, in Chapter 9, Chimneys and Fireplaces, New York 1979 Building and Fire Prevention Code:

- "Top Ten Chimney (and related) Problems Encountered by One Chimney Sweep," Hudson Valley ASHI education seminar, 3 January 2000, contributed by Bob Hansen, ASHI

- Chimney Inspection Checklist, Carson Dunlop, Associates, Toronto, Ontario

- "Rooftop View Turns to Darkness," Martine Costello, Josh Kovner, New Haven Register, 12 May 1992 p. 11: Catherine Murphy was sunning on a building roof when a chimney collapsed; she fell into and was trapped inside the chimney until rescued by emergency workers.

- "Chimneys and Vents," Mark J. Reinmiller, P.E., ASHI Technical Journal, Vol. 1 No. 2 July 1991 p. 34-38.

- "Chimney Inspection Procedures & Codes," Donald V. Cohen was to be published in the first volume of the 1994 ASHI Technical Journal by D. Friedman, then editor/publisher of that publication. The production of the ASHI Technical Journal and future editions was cancelled by ASHI President Patrick Porzio. Some of the content of Mr. Cohen's original submission has been included in this more complete chimney inspection article: CHIMNEY INSPECTION DIAGNOSIS REPAIR . Copies of earlier editions of the ASHI Technical Journal are available from ASHI, the American Society of Home Inspectors.

- "Chimneys and Vents", 789 CMR 68.00 Massachusetts Building Code, web search 10/15/2010, original source:

http://www.mass.gov/Eeops/docs/dps/780%20CMR/780068.pdf 03/23/2007

780 CMR: STATE BOARD OF BUILDING REGULATIONS AND STANDARDS THE MASSACHUSETTS STATE BUILDING CODE - quoting:

6801.11 Multiple-Appliance Venting Systems. Two or more listed and labeled fossil fuel-fired appliances shall not be connected to a common natural draft venting system unless permitted per applicable requirements of 248 CMR or 527 CMR. For solid fuel-burning appliances, see 780 CMR 6801.12. - Chimneys and Vents, Chapter 18, M1801,model building code - [on file as Code_Chim_Res_C_18.pdf] - widely used by U.S. & Canadian Municipalities,

- "Model DFS L-Vent / Type B Gas Vent Installation Instructions", Selkirk Corporation, 5030 Corporate Exchange Blvd., Grand Rapids MI 49512, Tel: 800-433-6341 & Selkirk Canada Corporation, PO Box 526, Depot 1, Hamilton ON L8L 7X6, 888-735-5475, web search 10/15/2010, original source: www.mass.gov/Eeops/docs/dps/780%20CMR/780068.pdf

- "Type L Temperature Venting Systems [on file as L_Vent_Metal_Fab.pdf] - ", Installation and Maintenance Instructions, Metal-Fab Inc., PO Box 1138, Sichita KS 67201, 316-943-2351, Email: info@mtl-fabinc.com website: www.mtl-fabinc.com

- "Type L Vent Vent for Oil/Gas Fired Appliances, Installation and Maintenance Manual", Energy Vent Ltd., 241 Arvin Ave., Stoney Creek Ontario Canada L8E 2L9, web search 10/15/2010 original source: www.selkirkcorp.com/WorkArea/downloadasset.aspx?id=2380 www.selkirkcorp.com/WorkArea/downloadasset.aspx?id=1802

- Natural Gas Weekly Update: http://tonto.eia.doe.gov/oog/info/ngw/ngupdate.asp Official Energy Statistics from the U.S. Government

- US Energy Administration: Electrical Energy Costs http://www.eia.doe.gov/fuelelectric.html

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Ceramic Roofware, Hans Van Lemmen, Shire Library, 2008, ISBN-13: 978-0747805694 - Brick chimneys, chimney-pots and roof and ridge tiles have been a feature of the roofs of a wide range of buildings since the late Middle Ages. In the first instance this ceramic roofware was functional - to make the roof weatherproof and to provide an outlet for smoke - but it could also be very decorative.

The practical and ornamental aspects of ceramic roofware can still be seen throughout Britain, particularly on buildings of the Victorian and Edwardian periods. Not only do these often have ornate chimneys and roof tiles but they may also feature ornamental sculptures or highly decorative gable ends. This book charts the history of ceramic roofware from the Middle Ages to the present day, highlighting both practical and decorative applications, and giving information about manufacturers and on the styles and techniques of production and decoration.

Hans van Lemmen is an established author on the history of tiles and has lectured on the subject in Britain and elsewhere. He is founder member and presently publications editor of the British Tiles and Architectural Ceramics Society. - Chimney Inspection Checklist, Carson Dunlop, Associates, Toronto, Ontario

- Chimney & Stack Inspection Guidelines, American Society of Civil Engineers, 2003 - These guidelines address the inspection of chimneys and stacks. Each guideline assists owners in determining what level of inspection is appropriate to a particular chimney and provides common criteria so that all parties involved have a clear understanding of the scope of the inspection and the end product required. Each chimney or stack is a unique structure, subject to both aggressive operating and natural environments, and degradation over time. Such degradation may be managed via a prudent inspection program followed by maintenance work on any equipment or structure determined to be in need of attention. Sample inspection report specifications, sample field inspection data forms, and an example of a developed plan of a concrete chimney are included in the guidelines. This book provides a valuable guidance tool for chimney and stack inspections and also offers a set of references for these particular inspections.

- Fireplaces, a Practical Design Guide, Jane Gitlin

- Fireplaces, Friend or Foe, Robert D. Mayo

- NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore)

- Principles of Home Inspection: Chimneys & Wood Heating, in (Principles of Home Inspection), Carson Dunlop, Associates, Toronto, Ontario

- NFPA 211 - 3-1.10 - Relining guide for chimneys

- NFPA 211 - 3-2 - Construction of Masonry Chimneys

- NFPA 211 - 3-3 - Termination Height for chimneys

- NFPA 211 - 3-4 - Clearance from Combustible Material

- NFPA 54 - 7-1 - Venting of Equipment into chimneys

- Brick Institute of America - Flashing Chimneys

Brick Institute of America - Proper Chimney Crowns

Brick Institute of America - Moisture Resistance of Brick - American Gas Association - New Vent Sizing Tables

- Chimney Safety Institute of America - Chimney Fires: Causes, Effects, Evaluation

- National Chimney Sweep Guild - Yellow Pages of Suppliers

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.