Refrigerant Leak FAQs

Refrigerant Leak FAQs

Questions & Answers on Causes of & Repairs to Refrigerant System Leaks

- POST a QUESTION or COMMENT about how to find and fix leaks in air conditioner or heat pump refrigeration piping systems

Questions & answers about finding & fixing air conditioning, heat pump or refrigerator / freezer refrigerant gas or liquid leaks:

FAQs about how to repair refrigerant leaks in air conditioning, heat pump, or other refrigeration systems.

This article series discusses how to repair refrigerant leaks in air conditioning and cooling systems, using as an example, repairing a leaky or damaged air conditioning the cooling coil (evaporator coil) in the air conditioning air handler unit. Our photo at page top shows the cooling coil in the attic air handler component of a central air conditioning system.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Questions & Answers on How To Repair HVAC Air Conditioner Refrigerant Leaks

These questions and answers about finding and fixing refrigerant leaks in air conditioners, heat pumps, refrigeration equipment were posted originally

at REFRIGERANT LEAK REPAIR - please be sure to see the advice given there.

Article Contents

- REFRIGERANT LEAK CAUSE FAQs

- REFRIGERANT LEAK LOCATION & DIAGNOSIS FAQs

- REFRIGERANT LEAK REPAIR COST & SERVICE ISSUE FAQs - cost & success & multiple visits?

- REFRIGERANT LEAK REPAIR METHOD FAQs - braze, solder, glue, or other ways to fix a leak

...

Refrigerant Leak Service & Repair Cost FAQs

A/C Service Techs have not been able to fix a refrigerant leak

1st visit by technician said freon leak and recharged it but didnt find leak. Worked 1/2 day. Charged for service call and Freon.

2nd visit replaced capicitor, and recharged freon, still couldnt find leak. Charged for service call and part. A/C worked fine for 1 week.

Now there is ice on the outside like before, so I presume freon is still leaking.

Should I call him back or get another technician? Also Where could the leak be, and is it costly if it is not in the tube? On 2012-07-17 by Michael

Reply by (mod) -

Michael, Sometimes the homeowner and the service tech are not on the same page even if the tech is sharp and well meaning - s/he may not have been an English major.

But from your description alone, it sounds like low refrigerant and a leak fast enough to take frequent charges - not a condition you can live with without finding and fixing the leak. I'd call the service company manager and review the history and politely ask for some experienced help.

Expensive bill to add lost refrigerant

Hi, I bought an older home, a/c was working great when I viewed the home and it was very cold.

The lines iced over in the first few days after taking possession and had a tech out who said the coil was too low and needed to be raised.

I had another friend look at it who noticed the a/c only had 50% of its freon/gas and need to be recharged.

He tells me the coil is fine but the company wants $1100 to reinstall the a/c and recharge.

I dont know what I should do? One guy says one thing and another says something else... help please. On 2011-08-04 by Peter T.

Reply by (mod) - what "too low" means on the cooling coil

Peter, I'm not sure what "too low" means on the cooling coil - maybe mounted so that it does not receive enough airflow?

If that were the problem I'd think the system would always have performed poorly. In any case, since being low on refrigerant can cause coil icing, as can a dirty filter, I'd check and fix those two things before doing something more costly.

Assuming air flow is not blocked by a dirty filter or crimped ductwork, ask a tech to check for a refrigerant leak and be sure the system is properly charged with refrigerant and see what happens.

Watch out: when there's a refrigerant leak what's needed is to find and fix the leak, then install the proper charge of refrigerant. Otherwise you're both contaminanting the environment with leaky refrigerant gas and simply pouring your money out into the A/C repair truck.

is $1700. to replace a coil and add refrigerant a ripoff n a 6 year old unit?

(July 19, 2011) Wilson

My A/C has been diagnosed with a coil leak and quoted $1694. to replace and add the 9 lbs of refrigerant. Sound reasonable or a rip off? The unit is only 6 y/o. Of course the 5 year warranty is gone.

Reply:

Wilson, replacing the coil involves more work than just a bolt-on repair: the system has to be emptied (and refrigerant saved for disposal), the old coil cut out, new coil soldered or brazed in place, a vacuum pulled on the system, tested for leaks, probably a drier installed, and then the system recharged;

I don't think that quote is weird, but certainly for any repair over $1000 it makes sense to get two estimates from two experts and to make sure that they are bidding on doing the same job so you can make an apples to apples comparison.

Cost $1300 to replace a coil and pan on my 2 year old Air Conditioner

I got an estimate today from Airtron in San Antonio $1298 to replace the coil/pan/ and a few other things for my Carrier A/C it's 2 years old and has 5yr warranty. Tehy came out and said i had a coil leak and drain pan leak my freon level was 75 and the norm is 125.

The $1298 i guess is for labor since the other parts should be covered by Carrier warranty. I may try to have someone who works there do it on the side for a smaller fee. It just seems so expensive to fix. (July 19, 2011) AC Coil leak and drain pan leak

Reply:

Some reasons that an A/C coil leak/replacement and drain pan leak repair is costly (more than $1000) are listed in the Q&A above.

Who pays for repairs if an underground AC line leaks?

In Florida...If an AC system line set is underground and leaks are detected, who is accountable for repairs? The homeowner or the builder? Possible cause is water in the pvc causing copper to erode? Thanks - On 2021-04-21 by Okeefe

Reply by (mod) -

@Okeefe,

That's an interesting legal question, not one I can answer (After hanlding a stream of court cases while in the Army I decided to quit law school early).

I pose that an attorney would look at the age of the installation, the original contracts for work, any warranty terms, and she'd also want an opinion from an independent expert on exactly what failure has occurred and on its cause. If someone caused damage by negligence you may have a case.But my priority of attention would be on a proper diagnosis and repair of the leak.

AC tech says a refrigerant leak at a quick connect valve is not repairable

(June 8, 2016) Soph said:

A tech had told me my AC was not repairable due to fact that it was leaking at the quick connections. Why is this?

Reply:

Soph:

I can't fairly guess your AC tech by a mere e-text, but it sounds rather suspicious if not downright lazy.

The truth may be less irritating. Sometimes a tech will tell you "it can't be done" when of course it could be done, because she is making a judgment call that when you hear the cost you'll say that's not cost-reasonable.

But in the case of an AC system that is otherwise in good working condition and has a forward life, to condemn it because of a leak is rather odd.

Only if the leak were, for example, at the tubing brazed to the bottom of the compressor can might I think so negatively.

If the "quick connect" used a perforation method to make a connection to a refrigerant line and that perforation is leaking it would probably be necessary to cut ot that section and braze in a new one. It's a bit of work since it'd be good practice to also cut in a filter dryer on the same line after such repairs.

But "not repairable" sounds a bit extreme to me.

Refrigerant re-charged but A/C unit still isn't cooling

In June, I received service for refrigerant. Two weeks ago it was well over 100 degrees and my air started to feel warm on the first and basement level.

I noticed the thermostat was going over the set temperature, like it was struggling to keep up.

So now it is warm in the house but it is trying to give cool air but not cool enough. The fan and motor seems to be runnng but I noticed yesterday the air above the unit was cool. What could be problem. Thanks On 2011-08-03 by Dean

Reply by (mod) -

Dean I'd start by reviewing the LOST COOLING diagnostic steps (use the search box to find that article)

There is a variety of possible causes of the A/C system blowing warm air - you need first to see if all the equipment is even running. If the compressor is not running you won't have any cooling.

Because you recently received service I'd first look at that bill to see what was done. If refrigerant was added, you may have a refrigerant leak;

Will the outdoor compressor unit still run if refrigerant is low?

Will a compressor fan outside still run if low on freon? On 2011-08-02 by Eddie

by (mod) - yes the compressor/condenser fan will still run in a system short on refrigerant charge

Eddie, in most residential systems, yes the compressor/condenser fan will still run in a system short on refrigerant charge

IN some HVAC systems there may be pressure sensing switches that can shut the system down if abnormally high or low refrigerant pressures are measured. In that case the whole system should shut off.

Air conditioning unit stopped working after being charged

My air conditioning unit stopped working after being charged 2 weeks ago (ran great afterwards).

After bringing out a different AC company, he said the last guy overcharged the system and the compressor was shot.

He said he was certain of this because he found liquid refrigerant on the "gas side". Is this true?

Is there no other way for liquid to be on the gas side of the system unless the system was overcharged? (Long story short, my landlord is trying to stick me with the bill because I called the first company to come out, which he had no used before) - On 2011-06-06 by Michael -

Reply by (mod) - Liquid Slugging can ruin an air conditioner compressor motor

If an A/C system is over-charged, then yes it is definitely possible to accidentally send liquid refrigerant into the compressor motor - damaging or even destroying the motor. It's called "liquid slugging" and is a well-known problem.

Daniel

New (replacement) AC is not working

I had my furnace replaced a couple of months ago. The A/C was in fine working condition last summer.

When we turned on the A/C last week it wasn't working so we called the company that replaced the furnace to come out and make sure that it was all properly hooked up since the furnace was replaced

After inspecting it, they told us that the intake valve wasn't working and it needed to be replaced, at about $450.

Does this sound a little fishy seeing that it was all working fine last summer? I feel like they are trying to take advantage of us.

Any comments, suggested questions to ask or feedback would be GREATLY appreciated! Thanks! - On 2011-05-31 by Laura -

Reply by (mod) -

Laura: I'm not sure what the "intake valve" is referring to.

Certainly there are come controls such as the thermostatic expansion valve that meters refrigerant into the evaporator coil that are not so costly for the part, but because its replacement requires the time and labor to empty, vacuum, and then recharge the system, the total cost of the job can be several hundred dollars.

And there is a refrigerant gas inlet valve in the A/C compressor motor.

Ask the A/C repair company to be more clear on just what part failed and what's involved in its replacement. Let us know what you're told as it may permit further comment and/or it may help other readers.

Followup by Laura

Thanks, I'll update tomorrow after they visit.

Air conditioner unit had a refrigerant leak, was recharged, and now we have the trouble again 2 months later! Also air flow is weak and warm.

Our ac was serviced two months ago and the repairman said it had a leak.

$400 later it was recharged with coolant and now the A/C is doing the same thing.

Very little pressure coming out of vents and no cold air coming out. Does anyone know what I can do for the weekend? It is stifling! - On 2011-05-28 by Les

Reply by Mod: don't just keep adding refrigerant to a leaky air conditioner or heat pump

Les:

Watch out: A refrigerant leak that was "fixed" simply by adding refrigerant - a re-charge - is not as good a repair as a leak that was fixed by finding and fixing the leak - you'll just have to keep adding refrigerant. And your system will keep contaminating the environment.In my opinion the right repair is to find and fix the refrigerant leak. That is especially true and urgent when the new refrigerant charge was lost in just a couple of months.

But weak air flow out of the vents would not be due to a refrigerant leak; more likely a clogged filter or crushed or disconnected ductwork, or a blower fan problem.That's something you can check right away, yourself.

See these diagnostic procedures

AIR CONDITIONER BLOWS WARM AIR

Service tech came 3 times to add refrigerant at new A/C unit, now says have to run new lines in the attic: why there?

1 1/2 years ago a friend installed an a/c unit, brand new. In the 1,1/2 years he had come three times to add freon; he said the main lines are leaking and so must be replaced with new lines run through the attiv. Why not underneath the house?On 2017-09-28 by Miguel

Explanation by (mod) -

Miguel,

I agree that it sounds like the air conditioning refrigerant system is leaking. It might be possible to use a leak detection device to find the leak. That would be a happier approach and less costly approach than simply replacing everything.Routing refrigerant lines through the attic may be enormously less expensive than trying to dig or bore beneath a building's basement or crawl space or slab to run lines there.

...

Causes of HVAC Refrigerant Leak FAQs

Did corrosion cause this refrigerant leak in piping at the compressor?

The contractor did not purge the line set before brazing, and did not pressure test after, so he discovered a leak on the liquid line upon opening the valves on the compressor/condenser unit.

The contractor did not purge the line set before brazing, and did not pressure test after, so he discovered a leak on the liquid line upon opening the valves on the compressor/condenser unit.

While R410 spewed from the leak, the tech rebrazed the liquid line

Now 5 years later, the system develops a leak, which appears to be from corrosion, but the contractor claimed, in court, that the leak was caused by vibration.

I cannot find any literature citations which discuss the causes and effects of corrosion on heat pump systems.

Any guidance would be helpful. - Anonymous by private email 2019/01/28

Reply: Common causes of a refrigerant leak include & extend beyond corrosion

Vibration OR a poor initial brazing connection ( or both

) is more likely to cause a leak in refrigerant piping except in the most-extreme case of corrosion.

I see no obvious corrosion on the piping exterior in your photo.

I do see that the leak is close to the point at which what looks like a swaged copper line is brazed to the compressor motor.

The root problem could be any of several of the more broad list I give below of

Common Causes of Refrigerant Leaks

- damaged or over-thinned copper flare or swage due to swaging to expand the copper line to fit the compressor's fitting: flare too small, flare over-thinned, flare ridged during preparation

- overheating during brazing

- incomplete braze joint, e.g. from inadequate cleaning of the joint or inadequate or improper flux or brazing rod application

- vibration possibly combined with absence of a flexible copper bend to dampen vibration effect (more-difficult or less common in heavy piping installations)

- corrosion inside or outside the line (not visible)

- other refrigerant piping installation errors described

at REFRIGERANT PIPING INSTALLATION- sealant on threads; improper use

- missing caps on refigerant fittings such as gauge ports or TEV adjustment cap

- missing O-rings in fittings or caps

But note in your refrigerant leak photo close-up above (my enlargement) that the pattern of the refrigerant leak revealing spray appears to have a linear shape close to the tubing, suggesting a crack or open braze joint rather than a more-round or pinhole corrosion leak.I suspect that an examination of the piping interior - if it were cut away to permit inspection - would not show significant corrosion, since in my OPINION if corrosion were the cause of this leak, by the time it perforated the tubing or piping you'd see very thin copper around the perforation and visible corrosion - probably green.

Vibration is a particular leak risk when there we have both heavy tubing - resisting flexing or bending. A bad or loose motor mount could be a factor too.

You'll see on many installations where smaller lines are involved there's an extra bend or length to permit some movement without breakage.

I'll do some research on corrosion studies.

Reader follow-up:

Your evaluation seems rational, and conforms with my own understanding of broad corrosion patterns, particularly with regard to the thinning that normally occurs

I did not expect this to be corrosion from an outside source, and we did not cut the leak out for examination, which would be the only way to confirm the mechanism by which the leak occurred. However, the leak appears to be within the heat affected zone of prior brazings.

We know that heating changes the orientation of drawn copper tubing, and can make it susceptible to other contaminants, such as flux, which might have been on the interior surface when the heating occurred.

Such a potentiated localized site would then be susceptible to pinhole corrosion, in this case perhaps facilitated by high velocity gas flow sweeping the outside of the curve. The piping itself has two long radius curves over a net fall of 26 inches, and the compressor is firmly shock mounted.

There is obviously high frequency vibration being transmitted to the piping extending out from the compressor, a Copeland Compliant Scroll, but I have difficulty understanding how such vibration can separate the silver/copper bond, which is rated at some 15,000 psi tensile strength.

Have you seen actual evidence of such failures? Perhaps cutaway views of the separated area?

Also, I cannot find any significant information on the consequences of brazing refrigeration lines when they contain refrigerant and polyolester lubricant.

I did find that valeric acid based esters have a thermal decomposition temperature range starting at 530*F, which is why the manufacturers urge that newly installed systems be leak checked and evacuated before any refrigerant is introduced to the indoor coil side of the system (for split system heat pumps).

Can you steer me to some research on the likely decomposition products of the thermal breakdown of polyolesters?

Would this brazing temperature break down R410? The mechanism of mineral acid corrosion would be different from organic acid attack, and is known to slightly favor pinhole type attacks largely due to electrochemical factors which are less important in organic acids.

The electrochemical factor is probably diminished somewhat in an environment which is largely free of water, thus inhibiting extensive dissassociation and significantly lower pH.

Thank you for your time and interest in this matter.Mod reply: don't confuse brazing refrigerant line theory with actual field conditions

The shortcoming of our discussion is that it ranges in Theory without having the benefit of the actual physical conditions involved.

That sort of exercise is useful for understanding underlying Theory but too often fails to notice determining factors in the field.

It's very common, for example, for a worker to fail to properly clean or breed a copper surface. The result would be an effort at breathing that makes a poor connection that may in fact be incomplete or later crack or break.

Those details are usually obvious only when you come across sectionally cut or disassemble the prior joint.

That leads me to infer that the leak could well be a failure to have properly made the joint in the first place. But I wouldn't assume that the only explanation is corrosion.

Here is some research on refrigerant leaks, but none of these sources address your question about the effect of brazing heat on refrigerant itself.

I suspect that a greater concern is the effect of brazing on the copper fittings, oxidation, flux combustion, debris, that can cause later HVAC malfunction if not properly-handled, or more basic, improper original joint construction and brazing.

See the refrigerant leak research citations given

at REFRIGERANT LEAK REPAIR

A/C refrigerant tubing is making a strange hissing noise

Our conventional AC is making a strange noise. It is coming from the inside unit.

It sounds as though there is air hissing into the insulated flexible tube that connects the interior and exterior units.

In addition there is a small copper tube on top of the insulated tube. It is hot. Should it be? Thanks, -On 2011-07-10 by Kris Alan

by (mod) -

If the hissing is from a refrigerant tube - you have a refrigerant leak and by now you will have NO cooling at all.Particlularly when you hear hissing that's confirmed to be a refrigerant leak, that's a big leak that will lose the refrigerant charge quickly.

Your service tech should fix the leak before re-charging the system.

Cause & prevention of sulphur gase refrigerant piping damage

Why is refrigerant leaking caused often around area were sulphur gas passes in the atmosphere and what is the permanent solution? (Apr 27, 2016) pankaj shah

Reply:

Search InspectApedia.com for CHINESE DRYWALL to read about this sort of problem, causes & cures.

Insulating your refrigerant piping will reduce its exposure to the atmosphere, but you can't prevent sulfur gases in the air from passing through the evaporator coil or cooling coil nor the outdoor condenser coil

For those cases you might choose copper materials over aluminum for better (but not complete) corrosion resistance.

A siding nail perforated the refrigerant line

Discovered a nail in the insulated line a year after the siding was done. Turned on the cooling no freon in system. Had short dist of pipe replaced should a gas and low filter be used after repair (June 23, 2016) Anonymous

Reply:

Anon:

I hate those nails through piping - at least it was refrigerant leaking out rather than water costing thousands of dollars in moldy wall and insulation repairs.

The use of a filter after repair is an interesting one in this case because the system is new. Still it'd be best-practice to install a filter or filters (in my OPINION) for a couple of reasons:

- the brazing of new line itself can place debris into the piping system

- the system sat empty for a year so there could be moisture in the system or other debris that never was caught

Even a small amount of crud, if it jams into the TEV, can foul up system operation.

What are the right repair steps when an air conditioning system isn't holding freon?

In a split air-cond. system, if the system isn't holding the freon enough for proper cooling does the entire system have to be replaced, or can we try replacing the condenser in the attic first and then if it dosen't work then replace the compressor? On 2011-06-02 by lloyd

by (mod) -

Lloyd:

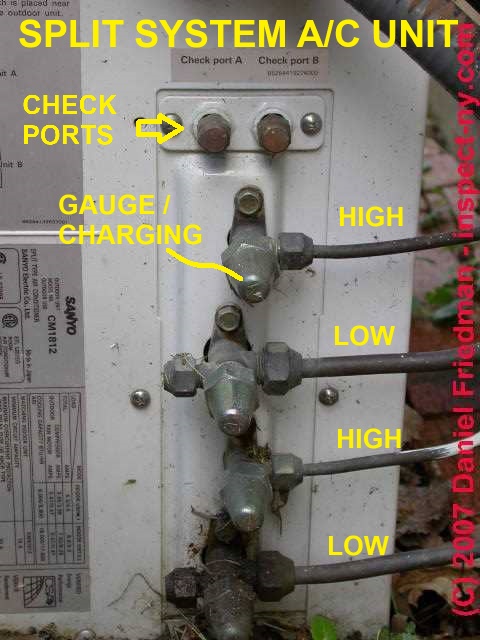

if the split AC cooling system is not holding freon I would not start by replacing parts, especially costly ones like the condenser or compressor.

First I'd ask the service technician to find where the freon leak is occurring. It could be a bad service port or a leak in refrigerant piping. In either case those leaks can be found and fixed.

If the leak is discovered to be in the evaporator coil (indoors) or the condensing coil (outdoors) then those more costly parts would usually need replacement as patching leaks there is less reliable.

Refrigerant charge in my car lasts only a few months

My car air con leaks but lasts for two or three months, after which I hook up the bottle and rev until the vents chuck out air at 4c ( from 34c ambiant) Good to go for another couple of months.

My question is if the gas leaked out, how come there is negative pressure (I Dont have a vacuum pump) to suck the refrigerant back in, why isn't the system full of air? (July 4, 2016) Mike

Reply:

MIke:

There may be air contamination in your car AC system. But typically refrigerant remains in the system but at too-low a concentration to provide cooling. When the AC compressor runs that creates the suction to raw refrigerant back into the system from your charging can.

Often car AC systems leak around the compressor motor drive shaft - unlike building A/C compressor motors that are in a completely-sealed can and driven by electricity, the automotive AC compressor has to be driven by an external drive shaft, pulley, and motor fan belt.

The seal around that drive shaft often dries out and leaks during long periods of inactivity. For that reason in my vehicles I make a point of running the AC at least once a month regardless of weather, and when leaving a vehicle parked for a few months I make a point of running the AC for 15 minutes or so of driving before we leave the vehicle.

What causes a refrigerant leak in split system air conditioning systems?

What is the causes of leakage in split unit air conditioning? (July 4, 2016) Og

Reply: Refrigerant leaks are caused by

Refrigerant leaks are caused by

- mechanical damage

- poorly-made connections, brazing errors

- vibration that wears a hole

- external corrosion at a cooling coil, condensing coil, or sometimes along the refrigerant piping itself

- internal corrosion in the system due to contaminants

- defective service valves

- something else I've not thought-of

See REFRIGERANT PIPING DAMAGE & LEAKS for details

AC refrigerant leaks in winter are common? (Really?): the tech just added refrigerant - said bad Schrader valve

Systems leaking refrigerant over the winter is a common issue and most techs won't fix it because a recharge is a revenue generator and a easy service call.

Systems leaking refrigerant over the winter is a common issue and most techs won't fix it because a recharge is a revenue generator and a easy service call.

The tech I called was here for 15 minutes and charged $400 to put in 6 pounds of R410A which had leaked out in about 6 months time.

So as soon as he left it kept leaking as before and by the end of the season it again needed charged.

Despite much bad information on youtube and the web, most leaks occur at the service valves.

This is because the schrader valve is dry rotted or was damaged during the install or servicing.

While replacing the high and low side valves would be the best fix, merely buying "o" ring service valve caps can slow or even stop small leaks.

The King valve caps can also leak and "O" rings can also be found for them.

My leak detector confirmed low and high side service valves leaking and after installing the "O" ring dust caps, the leak was no longer detectable and the system has been holding charge. - On 2021-03-19 by Jim Navotney

Reply by (mod) - Find and fix the refrigerant leak, don't just say "they all do that"

@Jim Navotney, thanks for the comment

I agree with you. With some service technicians will claim is that they have so much trouble finding and fixing the leak that their customers actually prefer the much lower charge of Simply delivering refrigerant periodically.One could add to your comment that it is both illegal and an unfortunate contribution to environmental damage to keep leaking refrigerant into the atmosphere.

The correct fix, as you so emphatically state, is to find and fix the refrigerant leak

...

Refrigerant Leak Location & Diagnosis FAQs

No refrigerant pressure on the high side means what?

I have a Lennox model#TGA150S2BH1G, serial# 5604K06732, reading 26hg on the suction line when in operation? compressor is working but no psig, added a few lbs of r22 still reading 26 hg when I close the valve? is my compressor bad ? On 2018-08-17 by Narcisono

by (mod) -

With no pressure on the high side I suspect that you're either essentially out of refrigerant or is it bad compressor

Refrigerant leak in the joint between the body of the compressor and the plate that containd the elctric terminals

I found a leak in the joint between the body of the compressor and the plate that containd the elctric terminals, the leak is very tiny.

I was planning to perform vacuum and add a little cyanoacrilate for high temperature, expecting the leak to be sealed. What do you think? On 2016-07-08 by Mario

Reply by (mod) -

Mario:

If I were working on my own unit I'd try that, with some careful surface cleaning first.But I would not warrant the repair for a customer beyond the time that my truck left the end of the driveway.

Recurrent leaks in low pressure side of AC

Recurrent leaks in low pressure side of AC

My friend in Tucson,Az just lost her ac unit due to low pressure (leak) for the second time.

I'm writing this on July 3rd 2011 and it is going to be 115F here today on a holiday weekend and trying to get service is almost impossible.

I might ad that her neighbor is having their system charged every year by another company.

I've found that this seems to be the norm in this part of the country and is not specific to the AC industry. I would like to see these incompetent companies held accountable for their practices.

I can only imagine the frustration reliable companies must feel. Thank you for your time and work posting this information.

Best Reguards,jim (July 3, 2011) james

Reply:

James:

about recurrent air conditioning refrigerant leaks:

it is very common for a tech to just add refrigerant and leave; it's a quick, profitable, recurrent service call.

Good practice is to find and fix the leak.

Of course some home or business owners decide on the less costly service call and just keep adding refrigerant but the cost of repeated service calls says to me we ought to find and fix the leak.

Can a lack of refrigerant stop theA/C compressor from running?

I have an A/C system that is no longer cooling. The serviceman came out and said we needed a new compressor. He stopped by to drain Freon/r22 or what ever cooling agent but said there was none in the system.

Can a lack of cooling agent stop the compressor from running? - On 2011-07-08 by Ken -

Reply by (mod) - A lack of refrigerant will not stop a compressor motor from running right away but pretty soon it will ruin the motor due to lack of lubricant

A lack of refreigerant will not stop a compressor motor from running, the motor will run but if there is too little or no refrigerant gas (in your case Freon R22 which is obsolete) the system just won't cool the air blown across the evaporator coil.

But because refrigerant also includes a lubricant needed by the compressor, if your system loses all of its refrigerant and the compressor motor keeps running, yes it may be ruined by lack of proper lubrication.

You need a new compressor if the old one is seized or if it is so worn that it won't compress the refrigerant gas. If your system is not cooling because it's lost refrigerant, it may be possible to re-charge it. Ask for specifics of how the tech knew the problem is the compressor.

When is a refrigerant line supposed to be cool or cold?

Discharge line cold - is that OK? On 2018-08-25 by Arbbie

Reply by (mod) -

Abbie, it is normal for the suction line to be cold. If the high pressure refrigerant line is cool or cold and your system is a heat pump in heating mode, that would also be normal.

...

Refrigerant Leak Repair Method & Repair Success FAQs

Can a refrigerant overcharge Ruin a Compressor?

A service tech left my air conditioner with a huge overcharge according to the next guy who came to my house to fix it. The second guy says the first guy killed my compressor motor.

Can a refrigerant overcharge ruin an air conditioning compressor? - Michael

Reply by (mod) - Yes!

Michael:

Can a refrigerant overcharge ruin an air conditioning compressor? Sure. Liquid slugging - liquid refrigerant from an overcharge can enter the compressor motor.

I'm not expert enough to make a general comment about ALL A/C compressors, but certainly there are some designs in which an overcharge that sends liquid refrigerant into the compressor piston or valve area can ruin it promptly.

Imagine a piston trying to move in a cylinder that has liquid in it where just compressible gas is supposed to be found.

Can I re-solder a leaky air conditioner coil that has a tiny leak?

I have a micro leak in the small diameter line from the outside compressor to the inside unit. the hole is at the junction of the tube to the connector, bad weld.

I want to try and re solder it but I don't know what would happen to all the freon in the pipes. I doubt that it is flammable but the molecules could break down to something bad. I still have sufficient freon so I don't want it to go to waste. (July 22, 2012) Jim

(July 22, 2012) Richard O'Hara

In looking for an a/c leak in a central a/c unit, why not first check for a loose wrench nut fitting? See if any of the nut connections are loose? You didn't even mention that.

Reply:

Richard your suggestion to try to fix a single leak in an AC coil makes sense - though there should be almost no wrench nut fittings except at the very ends of the refrigerant piping - all the rest are more often brazed.

YOu can often spot a leak at a threaded fitting because the leaking refrigerant gas also brings along a bit of lubricating oil that leaves the fitting dark and sticky.

The oily surface on the outside of the fitting around the leak also collects dirt and dust.

Watch out: you may have trouble soldering aluminum coil tubing or brazing and thus melting and destroying other thin-walled tubing materials.

You may contaminate the refrigerant system with debris that can then cause a cap tube or TEV vailure. If the leak is on the low pressure side perhaps an epoxy repair would work better.

Possible contaminants when brazing refrigerant lines?

What would be the expected result of brazing on the liquid line connection while the system is charged with R410?

Contractor claims he pumped out the refrigerant and replaced it, but I doubt that he did so.

Five years later the filters are so clogged the hot gas off the muffler is at 80*F (shows a 40*F temperature drop across the muffler). Was this predictable, and if so, what could have been done to prevent it? - On 2019-01-28 by Fred G

Reply by (mod) - Good practice when brazing A/C refrigerant piping includes the following:

Fred

Good practice when brazing A/C refrigerant piping includes

1. evacuate the system and pull a vacuum

2. do the brazing

3. evacuate and pull a vacuum again

4. Install a filter dryer on the suction line, possibly two.

5. Change out that filter dryer after a year

Debris from oxidized copper and flux inside the braze is unavoidable, so those steps are important.

Should I try using glue to seal a refrigerant leak?

I found a leak in the joint between the body of the compressor and the plate that containd the elctric terminals, the leak is very tiny. I was planning to perform vacuum and add a little cyanoacrilate for high temperature, expecting the leak to be sealed. What do you think? (July 8, 2016) Mario

Reply:

Mario:

If I were working on my own unit I'd try that, with some careful surface cleaning first. But I would not warrant the repair for a customer beyond the time that my truck left the end of the driveway.

Can I just pump in R407C in an R22 system?

Having to change out my condensing unit with R22 and wondering to save a $ if using 407c, I'm to the understanding that this gas works to the same pressure as R22 so wouldn't have to change out evap coil and just flush sys throughly will this work.

Can someone help ? #to good to be true On 2019-06-16 by jimmy z

Reply by (mod) - Yes but ...

Jimmy

You can compare refrigerant gas properties and allowable substitutions in our article on REFRIGERANT GASES & PIPING

where you'll see that you can use R407C in a system designed for R22 refrigerant,

but

Watch out: you cannot mix R 407C and R22 gases - you'll have to evacuate (and recover) the R22 for proper disposal, then fix the refrigerant leak, then re-charge the system with R407C including installing a new filter drier.

...

Thank you to our readers for their generous comments

(Dec 9, 2015) a Houston appliance repair company

sam gordon said: very nice concepts.

...

...

Continue reading at REFRIGERANT LEAK REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- LOST COOLING CAPACITY

- REFRIGERANT GASES & PIPING - home

- REFRIGERANT CHARGING PROCEDURE

- REFRIGERANT LEAK DETECTION

- REFRIGERANT LEAK REPAIR

- AIR CONDITIONING & HEAT PUMP SYSTEMS - home

Suggested citation for this web page

REFRIGERANT LEAK REPAIR FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.