HVAC Air Duct Problem Troubleshooting FAQs

HVAC Air Duct Problem Troubleshooting FAQs

Q&A on duct air flow, noise, sizing, water or condensate

- POST a QUESTION or COMMENT about air conditioner or heat pump system cooling diagnosis & repair

Diagnose & cure HVAC duct problems like weak air flow, leaks, noises, condensation:

If not enough cool air is provided by your air conditioner, or if the air temperature is not cool enough, or if you just can't get your A/C unit running, this article helps diagnose and correct the problem with step by step things to check and links to more detailed explanation when you need it.

This article forms part of our series on how to diagnose an air conditioner or heat pump that is not cooling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Air Conditioning Air Duct Problems and Air Flow Defect Q&A

These questions and answers about troubleshooting and fixing air conditioner or heat pump air ducts were posted originally

at DUCT & AIR FLOW PROBLEMS - be sure to check out the diagnostic suggestions on that page.

Article Contents

- DIAGNOSE & IMPROVE HVAC AIR FLOW & TEMPERATURE BALANCE

- DUCT INSPECTION CAMERAS & PROBES - avoid demolition to find duct problems

- Other HVAC Duct Troubleshooting Q&A

...

Steps to Diagnose & Improve HVAC Duct Air Flow

What is the impact of return duct joint crimps pointing the wrong way?

Return duct joint crimps pointing wrong way - how to calculate impact?

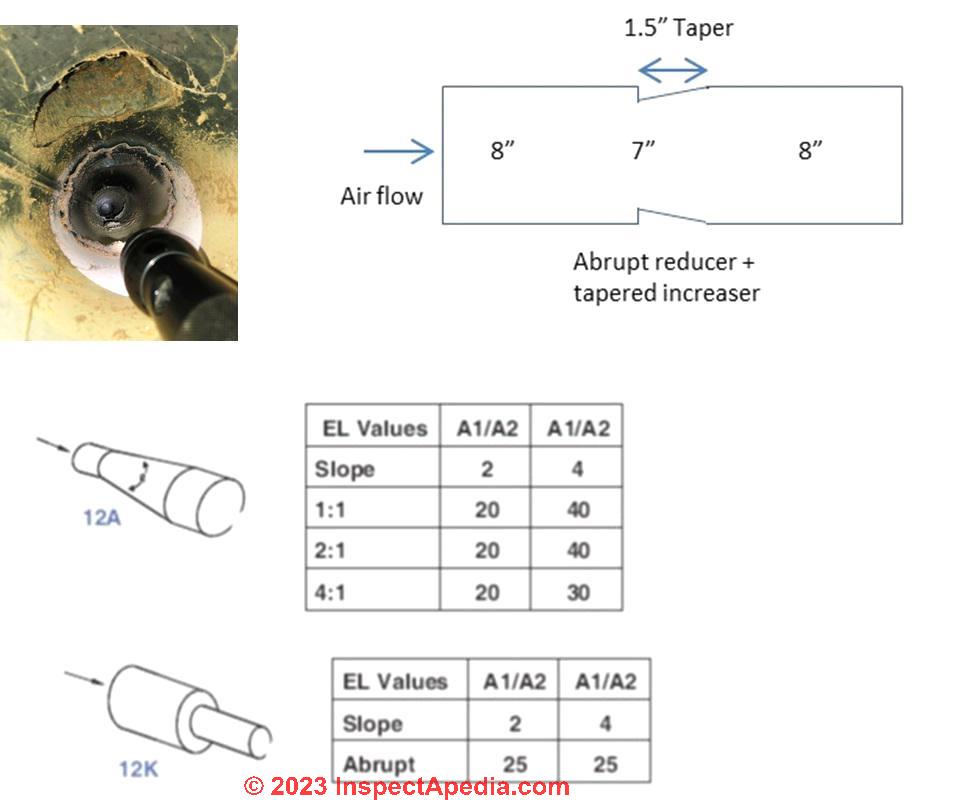

Hello. I was cleaning an 8" return duct and found the crimps were pointing upstream / against the airflow. My understanding was crimps should always be in the direction of the airflow. The crimp edges were bent further inward reducing the opening by about 1/2" all around (1st picture)

There are 6-7 joints like that on that duct run of 26 ft physical duct. The return duct is 8" for about 18ft, it increases to 10" dia. to the return plenum. There is another 10" return joining the plenum as well. The furnace is gas.

I cleaned up the duct but kept thinking what would the effect of the wrong way crimping be on the effective length of that joint, and if those joints make it too long an effective length.

ACCA Manual D have tables of various fittings and their equivalent lengths. So I thought of using those tables to calculate the EL on these wrong way joints. I drew a diagram of what I think the air will experience as it flows through that joint (2nd picture).

Two of ACCA tables seemed relevant; the tapered increaser and the abrupt increaseer (3rd picture). It wasn't clear what values to pick from those two ACCA tables. So I thought may be an EL of 10ft per joint? There are 7 joints like that. So, about 70ft added to the physical length of 26ft making the EL of that duct 96ft? (that's before adding the EL for the elbows etc.).

- Would like to know if calculating the EL is a reasonable way to estimate the effect of that joint?

- And, what values to select from the two ACCA tables based on the data provided in the 2rd diagram?

At this time, I am only trying to find a way to quantify the impact of these 6-7 wrong way crimps. Thank you. - On 2023-12-24 by rndiy -

Reply by InspectApedia Publisher - Return duct joint crimps pointing wrong way - how to calculate impact?

@rndiy,

I'll need to do more studying myself to give an engineering-line answer, buy my best guess is that you add up the effective length of reduced duct diameter to calculate the total effect on airflow through the duct system.We've addressed this in our articles on the effect on flow in gpm (or in your case flow if air in lpm) of adding a section of larger (or smaller ) diameter water pipe into an existing piping system.

Keep in mind that there are quite a few other important factors that touch your air flow rate: debris I see in the piping also reduces the effective duct diameter AND increases friction losses. There seem to be some bends that also reduce air flow rate.

An interesting amateur alternative is to get actual objective data - using a velocimeter to measure air output at the blower and air output in lpm at the supply register at the end of the duct run.Followup by rndiy

@InspectApedia Publisher, Thank you for the reply. Yes, there are three 6" dia. openings/saddle takeoffs that bring return air from the return vents, one U-bend visible at the far end to get this return duct over a cross beam, a 8"-10" tapered increaser to connect this to the primary return trunk,

and finally a 10" collar connecting the primary return trunk to the return plenum. I was able to find ELs for those fittings in the Manual D tables. I cleaned the duct of that dust and debris as well.

Reply by InspectApedia Publisher - Cleaning the duct interior is probably the easiest improvement in air flow.

@rndiy,

Thank you for that update.

Cleaning the duct interior is probably the easiest improvement in air flow.

An interesting technical question is the difference in effect on airflow rate for ducks that are connected as you described it earlier backwards.

What I mean is that the constriction in the diameter of the duct interior is the same regardless of the direction of air flow so what's different is the effect of turbulence or other more subtle technical effects on air flow as it passes over the wrong way facing edge of the crimps.

I don't know the answer to this but it's going to be interesting to look for it.

If you're concerned about improving the air flow in your HVAC system, especially if it's older and as you have found, has or had accumulated dust and debris inside the ductwork, in my experience the single most significant cleaning chore and one that people ignore or simply don't know about is cleaning the squirrel cage blower fan in your air handler.

I've seen a greater than 50% improvement in air flow from that cleaning step. If you want more detail, we have an article about that at this website as well.Followup by rndiy - Effect of cleaning the air handler blower wheel

@InspectApedia Publisher, thank you for that suggestion. I use a 4" thick Honeywell MERV 8 pleated filter.

So, I was able to access the blower wheel through the media cabinet hole. I cleaned the blower wheel a month ago using my shop-vac and a brush attachment. The fins were dusty but it was not thick or sticky.

Reply by InspectApedia Publisher - why cleaning the squirrel cage fan blower wheel blades is really important

@rndiy,

That was a good move cleaning the blower.

Because the curved blades on a squirrel cage fan don't really have much area inside the curve, it doesn't take much dust to make them nearly flat which significantly reduces their ability to push air.Effects of changes in duct diameter on HVAC duct airflow in cfm

@rndiy,

As I think you've found by now, we can look at the effect on airflow in cfm of changes in duct diameter with a general formula.

A1 x V1 = A2 x V2

for a given cfm starting rate the velocity will increase in the smaller duct section

but as I said before we haven't addressed the effect on cfm of turbulence at the reducing connections and my OPINON was that turbulence is probably greater (worse) when the pipes are joined "backwards" as in your illustrating photo.

You might just try some of the free online HVAC duct airflow calculator tools that are around the web. Those will let you plug in a friction (standard that IMO is going to underestimate friction unless the surfaces are nice and clean - as you say yours are).

Also I'm guessing that all of your ducts are round; rectangular ductwork behaves a bit differently in re airflow.

CD Engineering providesHVAC – HOW TO SIZE & DESIGNB DUCTS [PDF] - local copy saved as M06-032 - HVAC - How to Size and Design Ducts - US.pdf

The effect on flow in air ducts (or in water pipes) of sections that are in effect a smaller or later diameter is at

WATER SUPPLY PIPE DIAMETER vs FLOW [Web article]Followup by rndiy

@InspectApedia Publisher (mod), my thought was to replace that section of the return duct with a longer pipe (10ft) to eliminate joints and crimp the remaining joints the right way.

But, the return duct is in a chase and it would require disconnecting takeoffs as well.

I was looking for a way to quantify the impact of reverse crimping (and that more severe crimped edge than the factory crimps which are snug fit) so I can assess the cost & effort vs. the benefit. If they used the factory crimps as is I would not have bothered.

Reply by InspectApedia Publisher

@rndiy,

If that improvement also means you can clean the ducts more successfully over the life of the building it might be worth doing.

But beyond what we've already said, I don't know how to quantify the change impact on airflow.Followup by rndiy - temperature differences between left and right HVAC duct trunk sections

I was checking the temperature rise on supply trunks and found that the reading on the left trunk is about 20F less than the right trunk.

I attached an illustration of the set up.

Temp is taken about 12" away from the supply plenum.

There is no blockage in the supply plenum. As shown, the only difference between the left and the right are the blower outlet is closer to the right side and the whole house humidifier cutout is on the right.

The cutout is blocked as we don't use that humidifier.

This is a high efficiency gas furnace Lennox EL296UHV series.

The temp rise on the right is right at middle of the range, but the left side is well below the mid point due to this difference in temps.

Would like your insight into what may be causing this big difference between the two trunks. Thank you

Followup by rndiy

@InspectApedia Publisher, thank you. I appreciate your insight.

I reviewed the water supply pipe diameter and flow article in your reply and found the pressure loss doubles when I go from a 8" dia. pipe to a 7" dia. pipe.

While the absolute value of the delta is in the thousandths, adding 7-8 such joints brought the total delta to about 0.02" WC.

Still not enough to take up the project right away, but I will keep this on my list. Thanks again.

Reply by InspectApedia Publisher - difference in duct size will obstruct air flow

@rndiy,

There may be more subtle factors such as the shape and exact location of obstructions to air flow, but I think that the most significant effect is the difference in duct size between 12-in and 10 in.

That is to say, an equal volume and flow rate of air arriving at the t in your ductwork and counters a 10-in opening on the left and a 12-in opening on the right so much more air flow wants to move to the right.If you're getting inadequate airflow and heat output on the smaller duct line you may need to try installing a duct damper on the larger diameter duct so you can balance the air flow.

Followup by rndiy - Air Temperature differences between HVAC ducts and registers

@InspectApedia Publisher, the airflow from registers connected to the 10" is about the same as those connected to the 12" trunk.

However, the temperature difference at the registers is about the same as at the trunks.

I understand the capacity of a 10" duct is less than the 12", but why would the temperature be that much lower?

The distance from top of the furnace to the center of plenum is 45". if both trunks were the same diameter, would the air temperatures inside the trunks be equal?

Reply by InspectApedia Publisher - temperature differences at entry points into duct sections

@rndiy,

The temperature is indeed almost certainly the same at the point of entry to the two different duct sections.However from that point quite a few variables can cause differences in air flow and thus also apparent air temperature and supply registers.

Examples include leaks and variation and insulation and variation in route length and route locations such as through warmer or colder areas.

To answer this question more accurately requires both a detailed and thorough on site inspection of the conditions of your air handler and ductwork and its routing, insulation, etc as well as carefully made objective measurements.We don't know how your measuring or what you're using to measure or where you're measuring or what are the sources of variation but these are some examples.

Followup by rndiy - Using a Klein CL390 temperature probe to measure the temperatures in the duct system

@InspectApedia Publisher, I understand having an expert look at this is the best way to go. I wanted to provide some more information.

I used Klein CL390 temperature probe to measure the temperatures at the points marked in red in the edited diagram.

The probe was inserted about 5-6" into the ductwork. I was surprised to see the same temp difference from left to right inside the riser connecting the top of evap coil box and the plenum (measured through the two red circles).

I had an HVAC tech from a reputable company in for maintenance and he did not know why the difference. He looked up the blower exit hole and did not see any obstruction. He suggested I close some takeoff dampers on the 12" trunk.

I did that and it did not make a difference. I found this article about static regain and wondered if the height from blower exit to plenum (45") is enough for 100% static regain and if that is the root cause.

https://hvacrschool.com/duct-takeoffs/

What specific qualifications and experience would someone need to accurately diagnose such a condition?On 2024-01-19 by InspectApedia Publisher

@rndiy,

Thank you that's very helpful additional detail. Sorry that my replies are constrained, I'm in the middle of traveling between countries.On 2024-01-29 by rndiy - Details of air flow and temperature differences in the HVAC duct trunk line

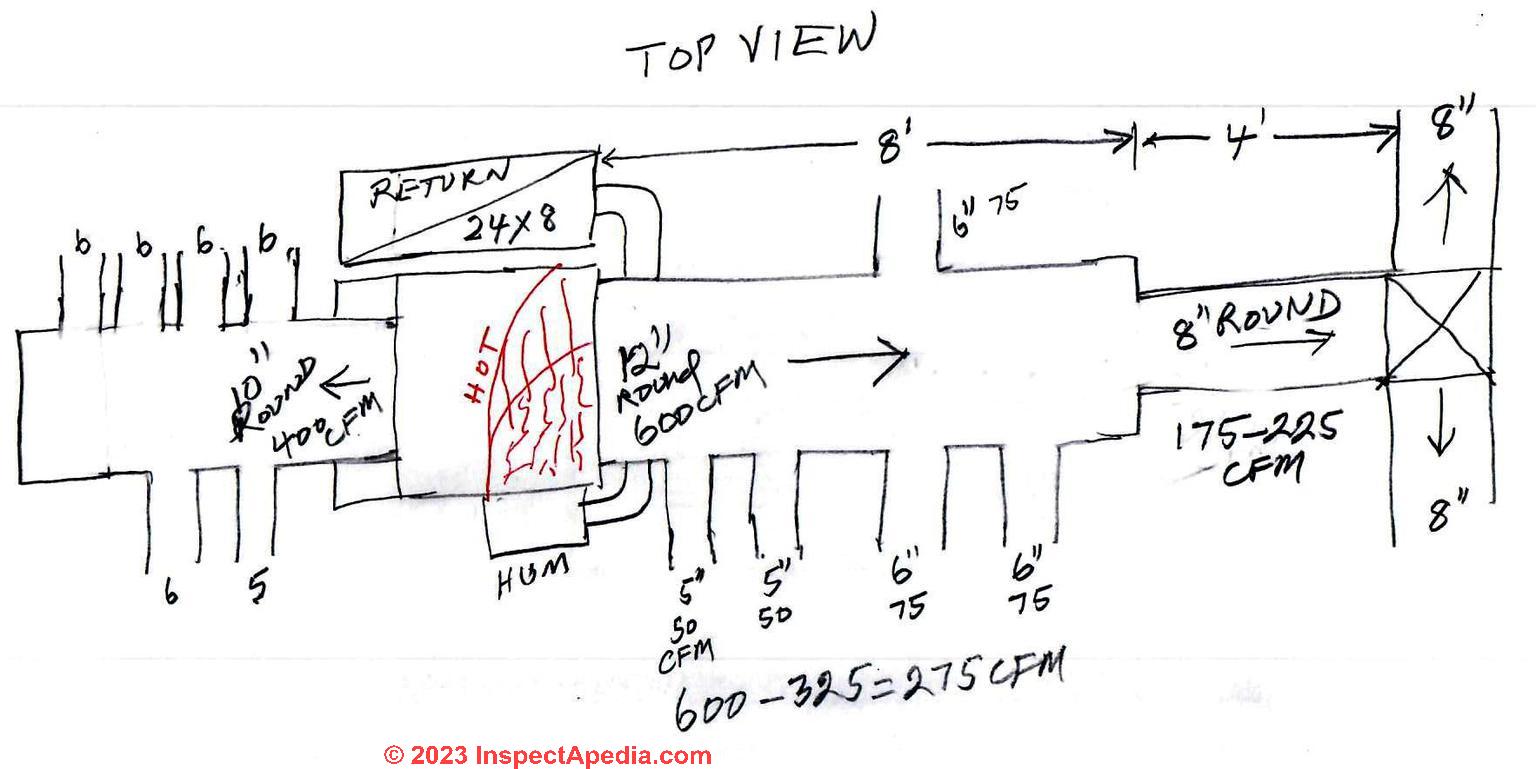

@InspectApedia Publisher, I wanted to provide an update.

The 12" trunk on the right has an abrupt reducer 12-to-8" about 8ft from the supply plenum.

The 8" trunk goes for another 4ft and forms a "U" to go over a cross beam and tees into a 8" secondary trunk.

I think 4-5 adjustable elbows were used to go over the beam. I used values from the duct sizing tables found on this web site.

Assuming 600CFM are going into the 12" trunk, 325 CFM are taken out before the air reaches the abrupt reducer, leaving 275CFM Using 225 CFM capacity for the 8" trunk leaves 50CFM of airflow without a forward path.

Could this lack of trunk capacity in that supply plus the restrictive "U" transition be causing the heat build up in the 12" supply trunk and in the plenum near the entry to that trunk?

I attached a top view of the duct layout and shaded the portion of the plenum that is hot. Temperature was measured using Klein CL390 thermocouple.

Reply by InspectApedia Publisher - thorough inspection of the duct routing is what's needed when tracking down an airflow problem

@rndiy,

Thank you so much for taking the time to add that important update to this duct airflow restriction discussion.

What you found is a reminder that a thorough inspection of the duct routing for bends etc. is what's needed when tracking down an airflow problem.On 2024-01-29 by rndiy - Adding duct branches to balance air flow for overall improvement?

@InspectApedia Publisher, Thank you. I appreciate your reply. I have no way to eliminate the U-jump over the cross-beam. I could replace that abrupt reducer with a tapered one, but cannot upsize the 8" trunk due to available space.

So, to provide a path to those surplus CFMs, I am thinking of adding a 6" tap on that 12" trunk on the right, upstream to the abrupt 12x8 reducer.

Would that help improve the flow and reduce the build up of heat in that trunk?

Reply by InspectApedia Publisher

@rndiy,

We have gotten beyond my expertise here but I certainly think that's worth a try.Comment by rndiy - moderator is willing to go a little deeper to understand the issues and troubleshoot solutions

@InspectApedia Publisher, Thanks again.

This is the only place I find where the moderator/pro is wiling to go a little deeper to understand the issues and troubleshoot/brainstorm ideas/potential solutions. Much appreciated.

...

Probe to inspect ductwork without demolition?

I have some vents that air is not flowing through. They're open. Is there any type of probe (like a plumbing snake) made to inspect duct work to avoid taking down drywall? - On 2022-06-01 by Doug -

Reply by InspectApedia-911 (mod) - plumbing or duct inspection camera can examine otherwise inaccessible duct sections

@Doug,

Yes a plumbing or duct inspection camera can examine otherwise inaccessible duct sections.

Be sure you've read the Recommended Articles near the end of the page above - that may help diagnose your lack of air flow at your supply registers.

Below: the FLX-108REC from Shenzhen Flexi Electrical Co., LTD, an inspection camera sold by HVAC suppliers and other vendors and online, providing a 100 ft. cable and video screen on which is displayed the view of the cable-end camera.Described as a "...pipe inspection camera supports video & audio record, picture snap, distance count, LED lights adjust, battery recharge and waterproof IP68 (can work underwater at least 33ft/10m depth), it can inspect the pipeline dia from 1inch(25mm) - 8inch(200mm)."

Keep in mind you need enough light, a sharp lens, and plenty of borescope length to inspect the whole assembly without having to drill hundreds of holes and to be able to inspect longer inaccessible duct sections.

Better to rent a proper tool or hire a technician. I've done this task. A 30 inch dim borescope can't do what's needed.

On 2023-04-17 by Alexander Riccio - Found crimped HVAC duct behind drywall

Pfft, you think that's an oddly crimped duct?

Check out what we found after demolition for the family kitchen renovation:

...

Other HVAC Duct Diagnostic Q&A

On 2020-08-26 by Mike - Do I need cold air returns for radiant floor heat?

So I’m in the process of finishing my basement and have a question.

I have radiant floor heat throughout the basement and I was unsure about cold air returns.

Do I need to add some as there is none? And if so should they be up high or down low. The upstairs is heated and cooled by forced air

On 2022-03-24 by Inspectapedia Com Moderator

@Mike,

Radiant heat through a floor uses electrical cables or hot water tubing from a boiler. There will be no cold air returns to the heating system.

The radiant tubing or cables warm the floor that in turn radiates heat into the occupied space above it.

On 2020-08-17 by Barry - running on high the air is not as cold as when its running on low

I have a question, I have a 2 stage ac unit, when its running on high the air is not as cold to when its running on low. This problem just started any thoughts?

On 2020-08-20 by danjoefriedman (mod) -

Barry

The system may be working normally; faster air movement across the cooling coil means the air won't be as cooled as when the air movement is more slow.

On 2019-07-17 by Wil Dupuy

I have small bits of plastic coming out of my vents in all rooms. The particles are of different sizes some big as a grain of sand?

I have small bits of plastic coming out of my vents in all rooms. The particles are of different sizes some big as a grain of sand?

On 2019-07-17 by (mod) - white debris coming out of the air ducts

While a lab analysis might help point to a source, I'd start in the air handler, looking for a plastic component that's getting shredded.

On 2017-07-23 by Kent kessler

Having trouble with air flow for a/c. I would like some insight. I can go into great detail but am checking to see if there is anyone here first

. It may take a little time for me to give all the info needed for someone to recognize the problem. So if your ready for a problem and would like to help me solve this please respond

Thanks kent

On 2017-07-24 by (mod) - get more air flow out of my ducts

Kent,

Did you try the diagnostics at

AIR FLOW IMPROVEMENT, HVAC ?

Question: My Air Conditioner won't turn off - what to do?

Carla said: My outside air unit will not turn off on its own. I have to manually turn the breaker off to turn it off. Does anyone know why or how I can fix it?

Reply:

Carla if your A/C won't turn off it could be that the thermostat is set to a temperature that the system cannot reach - due to lost cooling or due to a setting below the capability of the system.

If your A/C won't turn off even if you set the thermostat to a temperature that is above the current room temp, then the thermostat or an A/C control board or switch is bad and needs replacement - in that case you need a service call from a trained HVAC Technician.

See OPERATING TEMPERATURES HVAC and

also CONTROLS & SWITCHES, A/C - HEAT PUMP

Question: Why is my A/C not producing enough cool air?

A/C not producing enough cool air - I had my air conditioning system gassed up last week - $210. ! The unit is not producing enough cold air.

The unit is set on 72 and does great at nights but during the day where the temp. outside is reaching mid 90"s it's getting up to 80 in the house. Is my duct work screwed up?

How do you repair trailer metal ducting? - Amanda

90 degrees outside and 83 inside with thermometer at 76. Cools off to 76 when sun starts to go down and house then gets cold.

New capacitor and condensor just put in. Help. - Ginny 5/17/12

Reply:

Amanda: if your system is not cooling there could be any of a number of problems - see the article above as a place to start. If your basic complaint is that the A/C temperature at the supply registers is cool enough but the volume of air flow is too weak, we'd start by:

- Install a new clean air filter

- Check that the air supply registers are open

- Check that ductwork has not become disconnected or crimped or crushed

- See DUCT SYSTEM DESIGN SIZE & DEFECTS where we list quite a few steps in diagnosing poor air flow out of an HVAC duct system

Weak air conditioner air flow - is there a relationship between refrigerant charge level and weak cool air flow rate?

Les said: Weak air conditioner air flow: Our A/C was serviced two months ago and the repairman said it had a leak. $400 later it was recharged with coolant and now the ac is doing the same thing. Very little pressure coming out of vents and no cold air coming out. Does anyone know what I can do for the weekend? It is stifling!

(mod) said:

Les: A leak that was fixed by a re-charge is not as good a repair as a leak that was fixed by finding and fixing the leak - you'll just have to keep adding refrigerant.

But weak air flow out of the vents would not be due to a refrigerant leak; more likely a clogged filter or crushed or disconnected ductwork, or a blower fan problem.

Weak air Flow traced to Clogged Air Filters: Can Clogged Air Filters Affect the Room Thermostat?

If air conditioner filters are clogged will it cause the thermostat to shut off? (May 13, 2011) Jim said:

Reply

Jim: clogged A/C filters won't cause a room thermostat to shut off. The thermostat responds to room temperature.

However clogged A/C filters that reduce air flow, cause coil frosting, or otherwise reduce or stop the flow of cool air into the room where the thermostat is located would mean that the thermostat would remain "unsatisfied" and should mean that the thermostat says "on" - continuing to call for cooling.

Thank you to our readers for their generous comments

On 2024-01-29 by rndiy - moderator is willing to go a little deeper to understand the issues and troubleshoot solutions

@InspectApedia Publisher, Thanks again. This is the only place I find where the moderator/pro is wiling to go a little deeper to understand the issues and troubleshoot/brainstorm ideas/potential solutions. Much appreciated.

...

...

Continue reading at DUCT & AIR FLOW PROBLEMS - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see AIR LEAKS in DUCTWORK FAQs diagnostic questions & answers posted originally at this page.

Or see these

Recommended Articles

- DUCT SYSTEM DESIGN SIZE & DEFECTS - home

- AIR FILTER LOCATION

- AIR FLOW IMPROVEMENT, HVAC

- AIR FLOW TOO WEAK

- SUPPLY DUCT AIR LEAKS

Suggested citation for this web page

DUCT & AIR FLOW PROBLEM FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HVAC DUCT SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.