Mobile Home Belly Wrap & Insulation

Mobile Home Belly Wrap & Insulation

Manufactured home bottom board insulation & rodent barrier

- POST a QUESTION or COMMENT about repairing or installing insulation under the floor of manufactured or mobile homes or trailers: the belly insulation, belly board, or belly wrap.

Manufactured home, mobile home & trailer belly or floor insulation & rodent barrier or moisture barrier.

How to inspect, repair, or replace the insulation under the floor of a manufactured home, mobile home, or trailer.

What is a mobile home belly wrap or bottom board? Is it insulation or just a rodent barrier or moisture barrier? It depends.

This article series discusses how to inspect, diagnose and correct problems in mobile home, doublewide, or trailer & camper insulation or ventilation systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Add or Repair Manufactured Home or Mobile Home Belly Insulation

Question: What kind of insulation do I use for under the belly of my manufactured mobile home and where can I buy it ?

Question: What kind of insulation do I use for under the belly of my manufactured mobile home and where can I buy it ?

2018/07/22 Tina Wilson said:

What kind of insulation do I use for under the belly of my manufactured mobile home and where can I buy it ?

[Click to enlarge any image]

This question and reply were posted originally

at MOBILE HOME INSULATION & VENTILATION.

The reader has not provided photos of the crawl space under her manufactured - mobile home, but we have adapted photographs from several sources to illustrate belly-wrap problems and solutions.

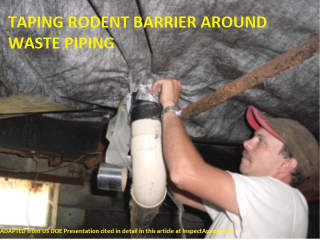

Photo above: adapted from MOBILE HOME BELLY INSULATION RETROFIT [PDF] a U.S. Department of Energy power point presentation cited in detail below.

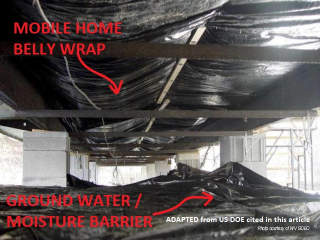

Our photo shows black plastic used to wrap or re-wrap the belly of a mobile home and additional plastic that has been placed on the ground to act as a moisture barrier. The skirting on this home has been removed but must be replaced at the completion of the work.

Watch out: when working under a mobile home, manufactured home, or any tight crawl space there may be serious health and safety hazards.

More than one reader have reported getting an electrical shock while working under a mobile or manufactured home. Hazards in such tight spaces are outlined

at MOBILE HOME CRAWL SPACES and also

Reply: Mobile home belly-board or bottom-board insulation suggestions & materials & sources:

Tina

When choosing an insulation to use under the belly or bottom board of your manufactured home or mobile home you want to answer a few questions first:

- Is there already insulation under the home?

If the home has no insulation or its insulation is extensively damaged or missing then you want to choose the right new insulation for the whole job.

If your present home has exposed fiberglass insulation over an un-protected crawl space, in my OPINION it would be an improvement to replace exposed fiberglass with a plastic enclosed insulation or a solid foam board insulation.

That's because I don't want to risk the un-protected insulation becoming damp, mold infested, or rodent infested.

That's also why it's important to put down a moisture/vapor barrier on the ground under the home and to be sure that surface runoff is directed away from the home, not under-it.

- Should the existing insulation be removed?

Is an existing rodent barrier damaged? Is the insulation rodent-infested, wet, or moldy?

In this case the insulation should be removed and the exposed surfaces, if moldy, cleaned and sealed.

Watch out: With the old rodent barrier and damaged insulation removed it is also easier to check for damaged (or rodent-chewed) wiring, damaged, loose, leaky ductwork, and for signs of water leaks from above.

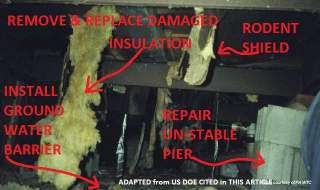

All of these need to be repaired before proceeding. The mobile home crawl space insulation damage, rodent barrier damage, and questionable concrete block pier shown in the photo are labeled and adapted from MOBILE HOME BELLY INSULATION RETROFIT [PDF] a U.S. Department of Energy power point presentation cited in detail below.

In the photo,adapted from the US DOE who used a photo from the PA WTC (cited below), we have pointed out damaged insulation that is likely also to be wet, perhaps moldy and rodent-infested - that insulation should be removed for health reasons and of course because falling into the crawl area below the mobile home it's also completely ineffective.

We also point out that the rodent shield has been torn and needs repair or replacement - since we're removing the insulation the rodent shield will be removed as well.

We also point out what looks like a dry-stacked tipped supporting pier of concrete blocks that, if it's leaning or too tall, is un-stable and thus unsafe.

- What is the climate where the home is located?

if your home is in a warm climate, a simple, thin “belly-board” or “bottom board} woven polyethylene fabric may be sufficient.

If you’re in a colder climate and if the home has little or no under-floor insulation, you probably want more insulation under the home using manufactured home belly insulation methods 2 or 3 that I’ll describe below.

Also see MOBILE HOME ENERGY ZONES for help deciding how much insulation you need. - Do we need all new materials or will some simple patching be sufficient?

If most of the mobile or manufactured home belly wrap and insulation are intact and un-damaged, and if inspection from below does not show signs that there have been leaks into the floor insulation and wrap from above, it may make sense to buy a patch kit or patching tape to simply repair the existing bottom board wrap.

You still want to assure that there is a good moisture barrier on the ground below the home, intact skirting, and that there are no other structural, pier, tie-down, or other damage or defects that would make the home un-stable or unsafe.

See MOBILE HOME CRAWL SPACES for more inspection points.

See also MOBILE HOME SKIRTING

Mobile/Manufactured Home Bottom Board Insulation #1 - replacing a rodent barrier

Photo: workers installing Typar, a synthetic fabric housewrap that keeps water out but also does not trap moisture under the mobile home floor. Notice that the workers are wearing protective clothing and hats but no gloves, no eye protection, no dust protection.

If the rodent barrier was damaged and insulation wet, moldy, or rodent infested, for health and sanitation that insulation should be removed, bagged, and discarded as construction waste.

A substitute commonly used to replace the factory-installed rodent barrier, and an alternative to polyethylene fabric bellyboard insulation is housewrap.

Housewrap is a water barrier that keeps water out but also won't trap water vapor or moisture inside the floor structure.

Details are at HOUSEWRAP AIR & VAPOR BARRIERS

Watch out: Before installing the housewrap or new belly wrap or bottom-board wrap, remember to check wiring, air ducts, plumbing, leaks, as I suggested above. Don't block a floor joist space that was used for HVAC duct purposes - install ductwork in that space first, connecting it to the HVAC air supply source and destination registers.

Watch out: if combustion air for a water heater or furnace is taken from underneath the home do not block that air inlet or your heating system will be unsafe, possibly fatal.

With any necessary surface cleaning done, ductwork complete and any needed repairs to wiring, plumbing, or damaged flooring, you are ready to install the housewrap as a new rodent seal.

Housewrap is stapled to the under-side of floor joists, wrapping it around the center I-beam and cutting and taping the wrap around any penetrations for plumbing, wiring, etc. To prevent the housewrap from sagging when insulation is added, you can use wood lath tacked across joist bottoms on 24" centers or any similar support.

With housewrap in place, if insulation is to be added continue with insulation option #3 given below.

Mobile/Manufactured Home Bottom Board Insulation #2 - bellyboard / bottomboard polyethylene

If you're doing just small repairs to the insulation under your manufactured home, there are repair tapes or "Gorilla tape" that may stick well to the existing belly-insulation covering layer.

If you're doing just small repairs to the insulation under your manufactured home, there are repair tapes or "Gorilla tape" that may stick well to the existing belly-insulation covering layer.

There are also small repair kits that include replacement sections of woven polyethylene bottom board or belly-board insulation.

Where to buy belly-board insulation

Manufactured home and mobile home builders and suppliers as well as Home Depot, Lowes building suppliers, Walmart, and even online vendors including Amazon all sell "bellyboard" or "bottom board" insulation as well as repair kits and repair tape.

Typically the material is a made of several layers of polyethylene, including a woven polyethylene, sometimes with an insulating fiberglass or other material sealed in the center ply - the belly-board insulation material is completely enclosed in plastic to be waterproof and is usually sold in rolls.

A typical example is Mobile Flex Bottom Board Material like that shown in our image above is sold in a roll that's 4 ft x 14 ft. This is a woven polyethylene material that is waterproof.

Here is how mobilehomepartsstore.com describes this material:

Repairs holes, cuts and tears resulting from plumbing repairs, weak seams and damage by animals. 30" Width x 100' Length Non Adhesive - A special bottom closure woven from black tapes of high density polyethylene and extrusion coated with a continuous layer of black low density polyethylene.

Mobile Flex is impervious to water, its strength can not be adversely affected by water. Because of its black polyethylene coating, Mobile Flex Qualifies as a vapor barrier. UL Classified as to flammability, tested at zero flame spread and zero smoke developed. Radco approval #1028. - 2018/07/22 https://mobilehomepartsstore.com

The U.S. DOE photo shown here illustrates a worker taping the waste pipe penetration of the rodent barrier in a basement under a manufactured home.

The gray material overhead is a synthetic housewrap fabric. The manufacturers of MobileFlex and similar belly-wrap materials argue that using that special material works better around penetrations.

The [Mobile Flex belly wrap] material is uniform in quality with no weak spots. Penetrations or cuts will not spread and can be easily patched. - 2018/07/22 https://mobilehomepartsstore.com

Costs of Bellywrap vs. Housewrap for Manufactured & Mobile Home Floors

Rolls of bottom board insulation are sold in 4ft x 14ft rolls as well as other dimensions.

- Costs range from under $20. U.S. for a repair kit to about $120. U.S. for woven tape high-density polyethylene bottomboard that's 14'4" wide x 70' long, to about $340. for a 4' x 600' roll of Mobile Flex material. (4' x 600' / 340 = $7.06 /sq.ft.)

- A 3' x 100' roll of DuPont Tyvek HomeWrap™ sells for much less: about $60. U.S. at a typical DIY home center. (3' x 100' / $60 = $5 ./sq.ft.)

- A 9' x 150' roll of Typar™ housewrap lists for about $325. U.S. at Home Depot (2018 prices). (9' x 150' / $325 = $4.15 / sq.ft.)

Mobile/Manufactured Home Bottom Board Insulation #3 - add solid foam board insulation under the home

In cold climates an approach to energy retrofit for manufactured or mobile homes bottom insulation is to cover the under-side of the floor frame (if it’s not already covered) solid foam and then blow-in insulation (approach #3 below) or to cut and fill the floor joist space with solid foam before covering the bottom with a continuous foam layer.

Really? I'm not a fan of trying to fill the space between floor joists with custom-cut solid foam insulation for a couple of reasons.

If the foam is not cut precisely and gaps are left at the sides or ends those form heat loss points that can lose a significant percentage of the benefit of insulating in the first place. If the floor joists are not very evenly spaced every joist bay insulation has to be custom-cut accurately

There may be also a bit of wastage: if you purchase 48" wide insulating board and the floor joists are 16" on center you'll find you are cutting 14 1/2" wide insulating board sections. You can get three pieces out of a 48" wide board, wasting 4.5" of every insulating board section. Owens Corning Formular 250 sold in 2" x 24" x 96" (8 ft.) sizes will be even more wasteful, wasting 9.5" of width of every piece of material.

Then loose fill insulation is blown-in to the floor space from the home floor edges, from outside or from under the home through slits in an existing belly-board covering.

With very little waste, however, following manufactured/mobile home floor insulation option #3 given below, you could cover the bottom of the joists with 1" thick High-R foil faced foam insulation. Use foil tape to seal all joints after installation of the foam board.

Watch out: See the practical and safety warnings about installing under-floor insulation of manufactured or mobile homes that we give in the next section below.

Mobile/Manufactured Home Bottom Board Insulation #4 - Blown-in loose-fill fiberglass or mineral wool

In cold climates an approach to energy retrofit for manufactured or mobile homes bottom insulation is to cover the under-side of the floor frame (if it’s not already covered) with belly-board or plastic sheeting or even solid foam.

In cold climates an approach to energy retrofit for manufactured or mobile homes bottom insulation is to cover the under-side of the floor frame (if it’s not already covered) with belly-board or plastic sheeting or even solid foam.

Then loose fill insulation is blown-in to the floor space from the home floor edges, from outside or from under the home through slits in an existing belly-board covering.

Watch out: do not blow insulation under the floor of a home without first checking the location and condition of heating supply and return air ducts. You also must map the location of any electrical boxes or plumbing traps that might need future access, and for electrical boxes, maintain a point of access.

You’ll also need to seal any holes through which insulation might be lost, and where any between-floor-joist spaces were used for HVAC air returns, those will need to be converted to actual ductwork before insulating. - Midwest Weatherization Best Practices Field Guide Section 3201 Floor Insulation (2007) - cited below.

Watch out: inspect and secure any loose electrical wiring, plumbing, or other mechanicals before blowing-in insulation.

Watch out: also if blowing in insulation over bellyboard fabric that’s loose or sagging: secure any loose belly-board or bottom-board membranes and add support where sagging.

Watch out: putting any non-permeable insulation under the floor framing of a manufactured home, mobile home, or any structure can lead to trouble IF water leaks from above or moisture from below pass through openings, tears, or omitted spaces where it can then become trapped in the floor structure - inviting insect attack, mold, and rot.

So if there's not already a good moisture barrier on the ground, add one first - it'll make working under the home easier and cleaner. Use a 6-mil or thicker polyethylene sheeting sold for that purpose.

Using solid foam board can give higher insulation or R-value (useful if your home is in a cold climate), but I would consider either taping the joints with foil or polyurethane tape or adding a 6-mil plastic barrier on the "down" side of the floor since getting a barrier on the warm or upper side when working from below is an excruciating amount of trouble once a home has already been constructed.

Watch out: foam insulation (except for fire-rated foam) cannot be left exposed in the living area of homes - that’s a fire hazard and code violation.

Check with your local building department as well as your home’s manufacturer before choosing any insulation that’s different in properties from what was used by the original manufacturer.

Sources & Codes for Insulating & Weatherizing Mobile Homes & Manufactured Homes

Where to buy mobile home or manufactured home insulation & belly board or belly-wrap products. These products are sold by local building supplies such as Home Depot, Lowes, Menards, and also by online vendors of whom we include examples below.

- HSMHS Bottom Board Fabric, 28' x 100' (not self-adhesive) ($20 TO $200 depending on size) at HS MHS, 15445 Lee Hwy Bristol VA, 24201 USA, Tel: 276.669.9133 Website: https://hsmhs.com/ also sold (at a higher price) on Amazon

- Mobile Flex Black Bottom Board, 16' x 80' (shown above) at about $150. USD, is sold by various online and local vendors such as Mobile Home Parts Store, website: mobilehoepartsstore.com Tel: 888-277-7720

Website excerpt: Repairs holes, cuts and tears resulting from plumbing repairs, weak seams and damage by animals. 16' Width x 80' Length - A special bottom closure woven from black tapes of high density polyethylene and extrusion coated with a continuous layer of black low density polyethylene. The material is uniform in quality with no weak spots.

Penetrations or cuts will not spread and can be easily patched. Mobile Flex is impervious to water, its strength can not be adversely affected by water. Because of its black polyethylene coating, Mobile Flex Qualifies as a vapor barrier. UL Classified as to flammability, tested at zero flame spread and zero smoke developed. Radco approval #1028.

- RecPro 8' x 10' (shown above) Mobile Home Coated Underbelly Material - Bottom Board Material, also available in lengths to 50', from online vendors (including Amazon) and from mobile and manufactured home suppliers.

- CRAWL SPACE MOISTURE CONTROL, [PDF] U.S. Department of Energy

- MOBILE HOME SKIRTING - including insulated mobile home skirting panels

- Scott, Bob & Lyn M. Bartges, WEATHERIZING MOBILE HOMES” [PDF] Home Energy, July/August 2004, Website: www.homeenergy.org, copy provided by the U.S. DOE at the link cited below

- U.S. DOE, MOBILE HOME BELLY RETROFIT [PDF] Midwest Weatherization BEST PRACTICES , WEATHERIZATION INSTALLER/TECHNICIAN MOBILE HOMES - CHAPTER 3: [PDF] U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, Retrieved 2018/07/22, original source: https://www.energy.gov/eere/wipo/downloads/weatherization-installertechnician-mobile-homes-chapter-3-mobile-home-belly

- US DOE MOBILE HOME BELLY INSULATION RETROFIT [PDF] (converted from power point presentation, U.S. DOE, Website: eere.energy.gov, retrieved 2018/07/22, original source op. cit. file: PPT-3-mobile-home-belly-retrofit.ppt

- US DOE WAP, Midwest Regional Field Office. Midwest Weatherization Best Practices Field Guide May 2007: 191-194.

- [1] "Energy Efficient Mobile Homes", retrieved 5/15/14, original source http://energy.gov/energysaver/articles/energy-efficient-manufactured-homes

Excerpts:

Like site-built homes, new manufactured homes (formerly known as mobile homes) can be designed for energy efficiency and renewable energy. You can also remodel or retrofit older manufactured homes to improve energy efficiency and/or add renewable energy equipment. Manufactured homes are built in a factory on a permanent chassis, then transported to a building site and installed.

Manufactured Home Energy-Efficient Retrofit Measures There are many differences between manufactured (mobile) homes built before the U.S. Department of Housing and Urban Development (HUD) Code took effect in 1976 and those built afterward. If you have a pre-1976 manufactured (mobile) home, you can make the following energy efficiency improvements to reduce heat loss:

Install energy-efficient windows and doors

Add insulation to the belly Make general repairs (caulking, ducts, etc.)

Add insulation to your walls Install insulated skirting Install a belly wrap Add insulation to your roof or install a roof cap.

Experiments conducted on pre-1976 manufactured homes by the National Renewable Energy Laboratory (NREL) from 1988 to 1991 found that these retrofit measures resulted in a 31% reduction in heating fuel usage.

There are three common methods used to add roof insulation to the existing cavity: drilling and tube blowing from the inside, drilling and tube blowing from the top, and rolling back the roof and blowing into the now open cavity. Instead of filling the existing cavity, some installers prefer to use roof caps for insulating.

Although the insulating performance of roof caps is inferior to blown-in insulation, they come in kits that include insulation boards (usually of dense fiberglass) with a synthetic rubber or metal covering. Roof caps can insulate the roof to R-19 without disturbing the existing roof, and if all leaks in the old roof covering are sealed, the old roof acts as a vapor retarder, eliminating moisture problems and the need for ventilation.

Be aware that rolling back the roof to add insulation can lead to realignment problems and leaks, necessitating mechanical ventilation to alleviate moisture condensation problems in the roof cavity.

Blowing loose-fill insulation into an existing manufactured home is difficult because of the narrowness of the wall and roof cavities. Pre-1976 home walls often have only 2-inch by 2-inch studs (5.08 cm × 5.08 cm) (new manufactured houses are required to have at least 2-inch by 4-inch [5.08 cm × 10.16 cm] studs), and roof trusses complicate the process of adding more roof insulation.

Blowing insulation into wall or ceiling cavities and/or installing roof caps is a job for a trained professional with proper equipment. Neither activity should be attempted by even the most capable do-it-yourselfer, as permanent structural damage and/or personal injury could easily result. A good source for a recommendation of a capable contractor-installer would probably be the Weatherization Department of your local Community Action Agency.

To further improve your manufactured home's energy efficiency, consider:

Caulking and weatherstripping windows and doors, especially if you can't replace them with more energy-efficient ones Air sealing any openings around plumbing fixtures and ducts Using energy-efficient lighting and appliances.

Manufactured Home Renewable Energy Applications You can use renewable energy to provide electricity, heating, and cooling for your manufactured home. Renewable energy systems not only lower energy costs, but also reduce pollution from fossil fuels.

You might consider:

Installing a geothermal heat pump (GHP), which can provide space heating and cooling. GHPs are most cost-effective to install at the same time as the manufactured home. The systems can’t be moved, so GHPs only work for permanently sited manufactured homes. Using passive solar design by adding a sunspace, orienting the home to maximize solar exposure, landscaping for energy efficiency, and using shading devices. Investigating solar water heating.

Although the lightweight construction of some manufactured homes limits roof support for heavy solar collectors, you can use lightweight roof-mounted air collectors for water heating or install the heavier liquid-type solar collectors on the ground. These systems are best suited for manufactured homes that are seldom moved.

Installing solar electric or photovoltaic (PV) systems, which are light enough to install on the roof of a manufactured home.

Installing a small wind electric system to generate electricity if your manufactured home is or will be located in a rural area on at least one acre of land. Installing a microhydropower system to generate electricity if your manufactured home is or will be located where you have access to flowing water. Although you can move a microhydropower system, you can't take the hydropower resource with you, which makes these systems best suited for permanently sited manufactured homes.

Manufactured Home HUD Code Requirements

Manufactured homes are subject to the Manufactured Home Construction and Safety Standards or “HUD Code” rather then local building codes, and display a red certification label on the exterior of each transportable section.

The HUD code is a set of manufactured home industry standards published and maintained by HUD that establishes standards for design and construction, strength and durability, fire resistance, energy efficiency, transportability, and quality control. It also sets performance standards for the heating and air conditioning, plumbing, thermal, and electrical systems. - HUD Manufactured Housing Construction and Safety Standards, The Hud Code 24CFR 3280, available from the U.S. Government Printing Office, online at http://www.gpo.gov/fdsys/pkg/CFR-2001-title24-vol1/content-detail.html

- HUD CODE: 42 U.S.C. 17071 - ENERGY CODE IMPROVEMENTS APPLICABLE TO MANUFACTURED HOUSING [PDF], retrieved 5/15/14, original source: http://www.gpo.gov/fdsys/pkg/USCODE-2010-title42/pdf/USCODE-2010-title42-chap152-subchapIII-partA-sec17071.pdf

- HUD CODE: 62 FR 24337 - MANUFACTURED HOUSING: STATEMENT OF POLICY 1997-1, STATE AND LOCAL ZONING DETERMINATIONS INVOLVING... [PDF], retrieved 4/15/14, original source: http://www.gpo.gov/fdsys/pkg/FR-1997-05-05/pdf/97-11535.pdf

- HUD CODE: 70 FR 61178 - MANUFACTURED HOUSING DISPUTE RESOLUTION PROGRAM [PDF] , http://www.gpo.gov/fdsys/pkg/FR-2005-10-20/pdf/05-20953.pdf

- *HUD CODE: 78 FR 73965 - MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARDS [PDF] , "24 CFR Part 3280, Manufactured Home Construction and Safety Standards, Final Rule, (2013), * this is the key legislative rule from the U.S. Department of Housing and Urban Development, 24 CFR Part 3280, Docket No. FR-5221-F-)2, RIN 2502-!717, "Manufactured Home Construction and Safety Standards", 9 December 2013.

http://www.gpo.gov/fdsys/pkg/FR-2013-12-09/pdf/2013-28775.pdf - HUD Code: 3. Serial No. 112-96 (HOUSE Hearing) - IMPLEMENTATION OF THE MANUFACTURED HOUSING IMPROVEMENT ACT OF 2000 [PDF] , http://www.gpo.gov/fdsys/pkg/CHRG-112hhrg75068/pdf/CHRG-112hhrg75068.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-10-01 by InspectApedia (Editor) - 1999 modular home floor joist measurement

@Mike Petersen,

Floor joists are usually 16" on center.

On 2022-09-30 by Mike Petersen

1999 modular home how far are The floor Joyce In Wisconsin it’s a double wide modular

On 2022-08-06 by InspectApedia-911 (mod) - find the mold and remove it and fix its cause

@Jett,

You need to find the mold and remove it and fix its cause - leaks or moisture.

I doubt that just the belly-wrap is the problem. I advise against just replacing the belly wrap before the moldy materials are removed.

On 2022-08-06 by Jett

Who lives in N. Phoenix AZ that knows how to replace our belly wrap ? This is an emergency, the mold smell is entering our house when the ac goes on. PLEASE Today is August 06 2022|

On 2021-11-02 by inspectapedia.com.moderator - easier and cheaper just to buy and install new belly wrap

@Mike Sellers,

It may be easier to make a few cuts in the belly wrap to get it around obstacles then would be working with plywood.

Perhaps you can post a photo so that we have a better understanding of the situation.

On 2021-11-02 by Mike Sellers

@inspectapedia.com.moderator, there's no doubt it would be cheaper. I just don't see how I could possibly get wrap through all the obstacles. I have absolutely no experience with this, but I have to do something soon.

On 2021-11-01 by inspectapedia.com.moderator

@Mike Sellers,

Thank you for the follow-up.

Would it not be easier and cheaper just to buy new belly wrap and install that?

On 2021-11-01 by Mike Sellers

@inspectapedia.com.moderator, I just don't see how to get the fabric back even close to factory.

After looking at this and thinking about it, my idea is to put some sort of vent hole in the plywood. And have it where I can remove sections to access pipes, wires etc. It's a mess under there. Thanks for the reply.

On 2021-10-31 by inspectapedia.com.moderator - cost and access are barriers to repair

Mike

You could indeed do that,

although the cost is probably greater than the alternatives we describe here, and there is the problem of not being able to access wiring or plumbing when needed, and there is a potential problem of creating a double vapor barrier in the moisture trap in the floor cavity.

On 2021-10-31 by inspectapedia.com.moderator

Re posting

AUTHOR: Mike Sellers (no email)

COMMENT: Why can't I just take plywood and attach it to the metal frame and put insulation between the plywood and flooring? I have a 28x80 and need to replace about 50%.

On 2021-09-06 by mak.church (mod) - Need rotten belly pan insulation replaced

@Doyle conn,

Sorry, but we cannot provide the product or service that you asked about.

We do not sell anything. No products, no services.

InspectAPedia.com provides building and environmental diagnostic and repair information.

In order to absolutely assure our readers that we write and report without bias we do not sell any products nor do we have any business or financial relationships that could create such conflicts of interest.

By doing a local directory or online Google search for the mobile home repair you need, you should get a list of possible providers, often with customer reviews attached. If you review the following pages, you will have more information in order to ask the repair person the right questions which will also help you choose who to hire.

MOBILE HOME BELLY WRAP & INSULATION

MOBILE HOME INSULATION AND VENTILATION CODES

Let us know if you have additional questions.

On 2021-09-06 by Doyle conn

Need rotten belly pan insulation replaced by contractor quaifyed foam was sprayed need belly vapor shield installed contractor had a tailgate guarantee out of. Sight out of guarantee

On 2021-05-24 by danjoefriedman (mod) - mobile home outside wall parameter sagging, how to re-level and support

@keith,

If you haven't already done so you will want to inspect very carefully the underside of your home to see if it's support system has been damaged or if the damage is inside the wall itself. It wouldn't make sense to try to begin a repair plan before we understand where the damage lies and what is its cause such as rot, insect damage, damaged supporting piers, for something else.

On 2021-05-19 by keith

double wide mobile home outside wall parameter sagging, how to re-level and support.

On 2020-11-14 by (mod) - can you legally remove the belly wrap and blown in insulation and just seal / insulate the crawlspace?

Richard

Thanks for asking about mobile home crawl space belly wrap alternatives.

I'm not sure about "legally" since that's the decision of your local building code official.

Practically you can do what you want but you should figure there's a reason for that belly wrap: generally to keep out critters and moisture who, if either invades the insulation, will make the home occupants sorry.

You could try to build a conventional crawl space around the home and also put down a sufficient poly vapor barrier to keep the space dry, provided you also keep water from entering from roof or surface runoff;

But I think that the total cost will be quite a bit more than using belly wrap and conventional skirting.

On 2020-11-14 by Richard Hartsfield

Everyone that I have read, addresses repairing and replacing the belly wrap under a mobile home.

My question is simple, can you legally remove the belly wrap and blown in insulation and just seal/insulate the crawlspace like on a site built home?

(Encapsulation) I have a brick and mortar skirt/foundation, so I don't see why you couldn't.. Please give advice pertinent to North Carolina.. Thank you

On 2020-07-26 - by (mod) -

Jared

If you can remove the belly wrap carefully and without tearing it up - to give access to the insulation - then you should certainly be able to reuse it.

Just make your cuts at a place where you can staple the belly wrap back up. Don't make a cut in between floor joists.

On 2020-07-25 by Jared - squirrels in under belly means insulation needs replacement in Yukon home

Question I have squirrels that got in my under belly and are now in my insulation there are a few holes from where they entered but other then that the belly wrap is good . I live in the yukon so I what I need to do is replace the insulation I'm just wondering if I would have to replace the under wrap or could I cut holes in replace the insulation and then repair

On 2020-06-18 - by (mod) - how to vapor seal the crawl space

Fair question, Ken

Reducing the moisture transmission under any home reduces the chance of a mold or rot or insect attack problem. Building and weather conditions and home conditions change over the homes life so I don't assume that because home hasn't had a problem yet that it can't have one.

That said if you want to hear an argument of the opposite view we could say that building scientists give advice that's generally correct. If every problem that we worried about it happens all the time and every instance no one would raise these questions. Problem is we don't know which instance will turn into a problem in which will not

On 2020-06-18 by Ken

just in the process of purchasing a trailer and a recommendation to vapor seal the crawl space ? It is 40 years old why now

On 2020-05-31 - by (mod) - water leak near the fresh water turn off

Georgia

Before we can suggest any repair methods or materials we need to know what we're repairing: are you replacing wet insulation, torn underbelly wrap, or something else?

On 2020-05-28 by Georgia DUININCK

Had a water leak near the fresh water turn off. Big one...emergency repair but need Info on the repair of the underbelly .....its not a huge space. Under back bathroom vanity and camode. 1975 double wide . So what do I need to do. Prices here are just robbery.

On 2020-05-14 - by (mod) -

Greg

Thank you so much for taking time to read with care and to write about an error in our text; I reviewed and edit the article to correct a couple of calculation errors that were off just a few cents.

The basic formula we used is

(Square feet of insulation) / Cost for that unit or package

Example:

A 3' x 100' roll of DuPont Tyvek HomeWrap™ sells for much less: about $60. U.S. at a typical DIY home center.

(3' x 100' / $60 = $5 ./sq.ft.)

or

300 sq.ft. / $60. per roll giving that many sqft. = $5. US

On 2020-05-13 - by (mod) -

Greg

Thank you so much for taking time to read with care and to write about an error in our text; I will review and edit the article accordingly.

Daniel

On 2020-05-12 by Greg

Check your math in section on cost of belly wrap.

You have the divisor and dividend reversed. It is much less per square foot than your figures.

On 2019-11-18 - by (mod) - How much does a contractor charge to replace Insulation and under belly on mobile home

Cory

To insulate and install belly wrap under a typical mobile home has these costs for which we provide a VERY rough estimate in U.S. Dollars, as I'll explain in a moment.

- Insulation: assuming a fiberglass insulation blanket, batts, or rolls, $50. to $300. varying by material and thickness

- Belly wrap material: $150. to $400. depending on area or size needed, may be combined with the insulation in a single product, making installation easier;

- Labor: $250. - $500. / day of labor; readily-accessible crawl space jobs can be completed in a day if there are no other repairs to be made;

There are some variables that will change the installation cost of mobile home belly-insulation and belly wrap: such as

- size of the home: singlewide (14-18' wide x 60-90' long), doublewide 28'-36' wide x 60'-90' long): length, width.

- labor costs for the country and city where the home is located

- ease of access below the mobile home

- whether or not there are repairs that must be made before installing the insulation and belly wrap, such as plumbing leaks or damaged electrical wiring

- choice of insulating material (e.g. foam spray may be more effective but also more costly, blown-in requires that a rigid board insulation be already in place under the home's

floor frame).

On 2019-11-18 by Cory Hall

How much does a contractor charge to replace Insulation and under belly on mobile home

On 2019-08-01 - by (mod) -

Ken

Please take a look through the article above on this page where I describe the different types of mobile home belly insulation and in the article also give some examples of types, Brands, and places to buy starting at the article section titled

Where to buy belly-board insulation

after you've read that if you have any question whatsoever please don't hesitate to ask and we'll be glad to research or get into further detail

On 2019-08-01 by Ken

For mobile home underbelly what kind of insulaton should I use

...

Continue reading at MOBILE HOME INSULATION & VENTILATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CRAWL SPACE VENTILATION CODES

- HEAT LOSS R U & K VALUE CALCULATION

- HOUSEWRAP AIR & VAPOR BARRIERS

- INSULATION AIR & HEAT LEAKS

- INSULATION LOCATION - WHERE TO PUT IT

- MOBILE HOME CODES, STANDARDS & MANUALS

- MOBILE HOME CRAWL SPACES - how to inspect the mobile home crawl space

- MOBILE HOME ENERGY ZONES

- MOBILE HOME HEATING SYSTEMS

- MOBILE HOME INSULATION & VENTILATION

- MOBILE HOME LEAKS & MOISTURE

- MOBILE HOME SKIRTING

- MOBILE HOME SKIRTING CODES

- WINTERIZE A BUILDING

Suggested citation for this web page

MOBILE HOME INSULATION BELLY WRAP at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to MANUFACTURED & MOBILE HOMES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.