Guide to Assessing the Quality of Kitchen or Bathroom Cabinets

Guide to Assessing the Quality of Kitchen or Bathroom Cabinets

- POST a QUESTION or COMMENT about how to evaluate the quality of kitchen or bathroom cabinets, hinges, hardware, shelving

Kitchen & bath cabinet quality, hinges, hardware evaluatin: this article provides a guide for evaluating the quality of kitchen or bathroom cabinets.

We examine the types of cabinet boxes (framed and frameless), types of cabinet shelf material, types of cabinet drawers and drawer slides, the most visible cabinet components: cabinet doors and drawer fronts (frame and panel cabinet doors, high-pressure plastic laminate cabinet doors and drawer fronts, painted wood cabinet doors or drawer fronts, thermofoil (RTF) doors), and the basic types of cabinet hinges.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Assessing the Quality of Kitchen or Bathroom Cabinets

Our page top photo illustrates a good quality solid birch cabinet. At left we illustrate oak cabinets built on a particlboard case and finished by the owner. Purchased un-finished these cabinets were low cost to buy and install.

Our page top photo illustrates a good quality solid birch cabinet. At left we illustrate oak cabinets built on a particlboard case and finished by the owner. Purchased un-finished these cabinets were low cost to buy and install.

As explained in Chapter 6 of Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

Assessing a cabinet’s quality is not always easy due to the large number of components involved and the fact that much of the material and joinery is concealed.

One good indication of overall durability is certification by the Kitchen Cabinet Manufacturers Association, which has a rigorous testing and certification program that measures such things as structural integrity, shelf strength, hardware durability, and quality of finishes.

Also, many manufacturers offer two or three grades of quality. Comparing the specifications of each line can provide a good idea of what the upgrades are and whether the added expense is worthwhile. The main components to evaluate are covered below.

Types of Kitchen or Bathroom Cabinet Boxes

The cabinet box, or carcase, makes up the body of the cabinet and gives it structural integrity. Typically, the only visible parts are end panels, portions of the interior, and the front edges in frameless cabinets or faceframes in framed cabinets (Figure 6-43).

- Framed cabinets. These are the traditional style of construction with a frame of 3/4-inch-thick solid wood rails and stiles fastened to the front of the box. Hinges attach to these face-frames, which are usually partly or fully visible with the doors closed.

- Frameless cabinets. Also called 32-mm cabinets or

Euro cabinets, these have no face-frames in front. The

doors attach directly to the inside face of the cabinet

sides with cup hinges. Doors and drawers are usually

full overlay, concealing the front edges of the boxes.

However, some frameless cabinets now offer more traditional wooden doors that leave a narrow band of the cabinet fronts exposed. The front edge is typically finished in vinyl, melamine, or wood veneer. High-end cabinets may have solid wood banding.

[Click any image or table to see an enlarged version with additional detail, commentary & source citation.]

With either type of cabinet, the price is driven by the materials, hardware, and assembly techniques. The cheapest cabinets typically use 1/2 - to 5/8-inch particleboard with a vinyl or melamine face. Better quality cabinets use medium-density fiberboard (MDF), and the best generally use 1/2- to 5/8-inch plywood. The facings on better cabinets are usually high-pressure laminate or real wood veneer.

With some cabinet lines, it is possible to order plywood sides only where needed, for example, on the sink base and wherever there is an exposed end panel, which might be subject to wetting or the occasional dent or nick.

Backs and floors if cabinets range from flimsy 1/8- or 1/4 -inch hardboard to thicker particleboard, MDF, or plywood (in order of stiffness). The finish inside the cabinet is typically vinyl or melamine. Cabinet bottoms should be rigid enough not to flex under the weight of pots and pans.

Finally, look for securely installed corner blocks or stretchers across the top of the cabinet to hold it square during shipping and installation Some high-end cabinets have a full-size top panel to reinforce the top of the box.

Guide to Types of Kitchen or Bathroom Cabinet Shelves

Shelves in cabinets range from 1/2 -inch particleboard, which will bow under the weight of dishes, to 3/4 -inch plywood. Plywood is the strongest shelving material, followed by MDF, then particleboard.

In base cabinets, look for full depth shelves or roll-out shelving. Wall cabinet shelves should be adjustable and have solid clips, preferably metal. In general, shelves are designed to support a uniform load of 15 pounds per square foot (psf) for kitchens, 25 psf for closets, and 40 psf for bookshelves. If loads are likely to exceed these, upgrade to a stronger shelf (see Table 5-11, page 186).

Types of Kitchen or Bathroom Cabinet or Counter Drawers

It is important to have solidly built drawers, since they get a lot of use and abuse. High-quality drawers typically have solid hardwood or poplar sides and backs, with minimum 1/4 -inch plywood bottoms glued into dados. In the best cabinets, drawer sides are dovetailed or dowelled to the front and back and the drawer front is a separate piece screwed to the box.

Respectable drawers are also built with sides of 1/2 -inch or thicker plywood or melamine stock dowelled together. In lower-end cabinets, drawer sides are often particleboard or MDF wrapped in vinyl and nailed or stapled and glued together, with a particleboard or hardboard bottom. Also many lower-quality cabinets use the drawer front as the front of the drawer box, a weaker detail.

Types & Choices of Drawer Slides

All drawer slides, even with the same rating, are not alike. Look for heavy-duty epoxy-coated components with ball-bearing rollers that operate smoothly and quietly. At a minimum, use three-quarter extension drawer slides rated to carry 75 pounds.

Consider upgrading to full-extension slides rated for 100 pounds, particularly for any large, deep drawers. Under mount slides have the advantage of helping to support the drawer while remaining out of sight. Side-mounted slides that wrap around the drawer bottom also provide good support.

Guide to Types of Cabinet Doors and Drawer Fronts

Doors and drawer fronts

are the most visible part of a kitchen and take a lot of abuse.

Many cabinet manufacturers buy doors and drawer fronts

from large specialty door manufacturers, so they may not reflect

the overall quality of the cabinets.

Doors and drawer fronts

are the most visible part of a kitchen and take a lot of abuse.

Many cabinet manufacturers buy doors and drawer fronts

from large specialty door manufacturers, so they may not reflect

the overall quality of the cabinets.

When selecting a material and finish, consider durability and ease-of-cleaning as well as appearance. Frame-and-panel wood doors are typically more expensive than laminate or thermofoil doors.

At left our photo illustrates an inexpensive stock cabinet system comprised of vinyl-clad cabinet facing and doors and particleboard carcases. These cabinets are quite heavy.

- Frame and panel cabinet doors or drawers have either a raised or flat panel of solid wood or veneer. Veneered panels are more stable but more difficult to repair if nicked or scratched. Avoid frames with mitered corners, as they may open with seasonal changes in humidity.

- High-pressure plastic laminate cabinet doors and drawer fronts are more durable than melamine (low-pressure laminate). Melamine is fine, however, for the backs of doors.

- Painted wood cabinet doors or drawer fronts may show small gaps (over time) at joints due to seasonal movement of the wood. Also the center panel in a frame-and-panel door may show a paint line if the panel shrinks during the heating season.

- Thermofoil (RTF) doors can provide a frame-and panel look with the convenience of a durable PVC plastic facing. It is best to use matching RTF moldings as well, since colors may change over time.

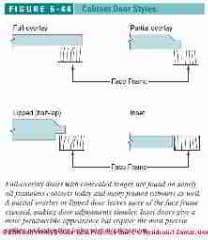

Frameless cabinets typically have full overlay doors, while framed cabinets may have doors that are inset, rabbeted, or overlaid partially or fully (Figure 6-44). Rabbeted or partial-overlay doors are the easiest to fit and adjust since they have considerable play.

Inset doors provide an attractive furniture like appearance, but they are also a common cause of callbacks, since the slightest movement in cabinets or hinges can cause the doors or drawers to rub. Full-overlay doors also need careful adjustment, since they have only about an 1/8-inch gap to the next door. Fortunately, most are hung with easy-to-adjust cup hinges.

Guide to Types of Cabinet Hinges

Good quality hinges are sturdy, smooth to operate, and easy to adjust. Undersized or poor quality hinges, on the other hand, can lead to sagging or rubbing doors and are a common problem with low-end cabinets.

- Cup hinges.

Originally designed for full-overlay doors on frameless cabinets, concealed cup hinges (photo at left) are now available for most types of doors and cabinets

(Figure 6-45).

Most can be adjusted in three directions, which makes it easy to align the doors and compensate for minor irregularities in the cabinets.

Plus, many cup hinges have a convenient “snap-on” feature that allows removal of the door without tools.

Swing angles range from 95 to 175 degrees, with typical doors opening from 105 to 110 degrees.

Special hinges are available for nearly every door configuration and self-closing types eliminate the need for magnetic or mechanical catches.

- Barrel and knife hinges. These are partially concealed when closed and are usually adjustable in two directions by loosening the hinge-mounting screws. They are common on lower-end cabinets.

Cabinet Hardware Manufacturers List

Accuride International www.accuride.com Ball-bearing drawer slides

Amerock Corp. www.amerock.com Comprehensive catalog of cabinet hinges, pulls, slides, and accessories

Grass America www.grassusa.com Cup hinges, slides, shelf supports, and storage accessories

Hafele America www.hafeleamericas.com Cup hinges, ball-bearing slides, pulls, and KD connectors

Mepla Inc. www.mepla-alfit.com Cup hinges, ball-bearing slides, drawer systems, shelf supports, and KD connectors

Hettich America www.hettichamerica.com Cup hinges, ball-bearing drawer slides, shelf supports, and KD connectors

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Also see CABINETS & COUNTERTOPS This article describes common defects found at installed cabinets and countertops.

This article series discusses current best design practices for kitchens and bathrooms, including layout, clearances, work space, and accessible kitchen and bathroom layout, clearances, turning space, grab bars, controls, etc. We include advice on choosing and installing kitchen countertops, cabinets, and kitchen or bathroom flooring, sinks, and other plumbing fixtures and fixture controls such as faucets. A list of kitchen and bath product manufacturers and sources is included.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question:

(Feb 14, 2015) mm hench said:

can I use mdf fiberboard as a base for bathroom sink?

the countertop will be tile.

Reply:

Yes if it is thick enough not to deform. But keep in mind that tile is not waterproof, and if your countertop leaks at all ultimately the MDF may begin to swell or disintegrate.

...

Continue reading at CASEWORK, CABINETS, SHELVING INSTALLATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CABINETS & COUNTERTOPS - home

- CABINET CHOICES, Bath / Kitchen

- CABINET DESIGN GUIDE, KITCHEN

- CABINET DOOR HINGES

- CABINET FALLING HAZARDS

- CABINET INSTALLATION & REPAIR MANUALS

- CABINET MOLD & WATER DAMAGE

- CASEWORK, CABINETS, SHELVING INSTALLATION

- COUNTERTOPS, KITCHEN & BATH

- COUNTERTOPS, KITCHEN & BATH

- FORMALDEHYDE GAS HAZARD REDUCTION

- DOORS, INTERIOR

- HOME CONSTRUCTION CATALOGS 1950

- INTERIOR FINISHES: BEST PRACTICES

- TRIM, INTERIOR

- TRIM, INTERIOR INSTALLATION

Suggested citation for this web page

CABINET CHOICES, Bath / Kitchen at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BATH & KITCHEN

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, www.apawood.org

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.