Clothes Dryer Exhaust Vent Codes

Clothes Dryer Exhaust Vent Codes

- POST a QUESTION or COMMENT about clothes dryer exhaust venting, ducting installation procedures, codes, standards

Clothes dryer exhaust vent installation, materials, requirements, model building codes & mechanical codes.

This article series describes good practices for clothes dryer vent installation, lint traps, wall vents, filters, and screens.

We include a list of clothes dryer fire safety hazards and other clothes dryer installation or maintenance mistakes that are either unsafe or that interfere with effective, economical dryer operation. We discuss types of dryer vent ducting and dryer vent doors or opening protection devices

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Clothes Dryer Exhaust Vent Codes

Note: Excerpts from the IRC as adapted by various muinicipalities provide publicly-accessible copies of the model codes as presented here using Texas' adoption of the IRC. Purchase a complete copy at online vendors or from the authoritative source, International Codes Council, listed just below.

Note: Excerpts from the IRC as adapted by various muinicipalities provide publicly-accessible copies of the model codes as presented here using Texas' adoption of the IRC. Purchase a complete copy at online vendors or from the authoritative source, International Codes Council, listed just below.

- ANSI Z21.5.1-2017/CSA 7.1-2017 Gas Clothes Dryers, Volume I, Type 1 Clothes Dryers: https://webstore.ansi.org/Standards/CSA/ANSIZ212017CSA

Scope

1.1 This Standard applies to newly produced Type 1 clothes dryers (see Clause 3, Definitions), hereinafter referred to as dryers, constructed entirely of new, unused parts and materials:

a) for use with natural gas;

b) for use with manufactured gas;

c) for use with mixed gas;

d) for use with propane gas;

e) for use with LP gas-air mixtures; and

f) for mobile home installation (see Clause 4.1.12).

The construction of clothes dryers for use with the above mentioned gases is covered under Clause 4.

The performance of clothes dryers for use with the above mentioned gases is covered under Clause 5.

1.2 Clauses 7 and 8 include coverage for electrical equipment, wiring, and accessories built in or supplied for use with the dryer.

1.3 Clause 7 contains provisions that are unique to the United States.

1.4 Clause 8 contains provisions that are unique to Canada. - ANSI Z21.5.2-2016/CSA 7.2-2016 - Gas Clothes Dryers, Volume II, Type 2 Clothes Dryers

Scope

1.1 This Standard applies to newly produced type 2 clothes dryers (see Clause 3) hereinafter referred to as dryers, constructed entirely of new, unused parts and materials for use with:

a) natural gas;

b) manufactured gas;

c) mixed gas;

d) propane gas; and

e) LP gas-air mixtures.

The construction of dryers for use with the above-mentioned gases is covered in Clause 4.

The performance of dryers for use with the above-mentioned gases is covered in Clause 5.

1.2 This Standard also covers all electrical equipment, wiring, and accessories built in or supplied for use with the dryer. It covers only dryers whose electrical equipment, wiring, and accessories are intended to be installed in accordance with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1. This Standard covers dryers having supply voltage ratings of 120, 208, 240, 277, or 480 volts. - California Clothes Dryer Exhaust Vent Code - given below

Section 504: Clothes Dryer Exhaust Venting Code - California

504.1 Clothes Dryer Exhaust Installation.

Clothes dryers shall be exhausted in accordance with the manufacturer’s instructions. Dryer exhaust systems shall be independent of all other systems and shall convey the moisture and any products of

combustion to the outside of the building.504.2 Exhaust penetrations.

Ducts that exhaust clothes dryers shall not penetrate or be located within any fireblocking, draftstopping or any wall, floor/ceiling or other assembly required by the International Building

Code to be fire-resistance rated, unless such duct is constructed of galvanized steel or aluminum of the thickness specified in Section 603.3 and the fire-resistance rating is maintained in accordance with the International Building Code.504.3 Clothes Dryer Exhaust Cleanout.

Each vertical riser shall be provided with a means for cleanout.

504.4 Clothes Dryer Exhaust installation.

Dryer exhaust ducts for clothes dryers shall terminate on the outside of the building and shall be equipped with a backdraft damper. Screens shall not be installed at the duct termination. Ducts shall not be connected or installed with sheet metal screws or other fasteners that will be obstruct the exhaust flow.

Clothes dryer exhaust ducts shall not be connected to a vent connector, vent or chimney. Clothes dryer exhaust ducts shall not extend into or through ducts or plenums./p>504.5 Clothes Dryer Exhaust Makeup air.

Installations exhausting more than 200 cfm (0.09m3 /s) shall be provided with makeup air.

Where a closet is designed for the installation of a clothes dryer, an opening having an area of not less than 100 square inches (0.0645 m2 ) shall be provided in the closet enclosure.504.6Clothes Dryer Exhaust - Domestic clothes dryer ducts.

Exhaust ducts for domestic clothes dryers shall be constructed of metal and shall have a smooth interior finish. The exhaust duct shall be a minimum nominal size of 4 inches (102mm) in diameter. The entire exhaust system shall be supported and secured in place.

The male end of the duct at overlapped duct joints shall extend in the direction of airflow. C

lothes dryer transition ducts used to connect the appliance to the exhaust duct system shall be limited to single lengths not to exceed 8 feet (2438 mm) and shall be listed and labeled for the application. Transition ducts shall not be concealed within construction.504.6.1 Clothes Dryer Exhaust Maximum length.

The maximum length of a clothes dryer exhaust duct shall not exceed 25 feet (7620 mm) from the dryer location to the outlet terminal.

The maximum length of the duct shall be reduced 2.5 feet (762 mm) for each 45-degree (0.79 rad) bend and 5 feet (1524 mm) for each 90-degree (1.6 rad) bend.

Exception:

Where the make and model of the clothes dryer to be installed is known and the manufacturer’s installation instructions for such dryer are provided to the code official, the maximum length of the exhaust duct, including any transition duct, shall be permitted to be in accordance with the dryer manufacturer’s installation instructions.504.6.2 Clothes Dryer Exhaust Rough-in required.

Where a compartment or space for a domestic clothes dryer is provided, an exhaust duct system shall be installed in accordance with Sections 504.6 and 504.6.1.

504.7 Clothes Dryer Exhaust Commercial clothes dryers.

The installation of dryer exhaust ducts serving Type 2 clothes dryers shall comply with the appliance manufacturer’s installation instructions.

[Clothes dryer exhaust] Exhaust fan motors installed in exhaust systems shall be located outside of the airstream.

In multiple installations, the fan shall operate continuously or be interlocked to operate when any individual unit is operating.

[Clothes dryer exhaust] Ducts shall have a minimum clearance of 6 inches (152mm) to combustible materials.

Clothes dryer transition ducts used to connect the appliance to the exhaust duct system shall be limited to single lengths not to exceed 8 feet (2438 mm) in length and shall be listed and labeled for the application. Transitions ducts shall not be concealed within construction. - Florida CLOTHES DRYER CODE Section 613 (IFGC) [PDF] given below:

Section 613 (IFGC) Clothes Dryers

613.1 General

Clothes dryers shall be tested in accordance with ANSI Z21.5.1 or ANSI Z21.5.2 and shall be installed in accordance with the manufacturer's installation instructions. - Florida CLOTHES DRYER EXHAUST CODE Section 614 (IFGC) [PDF]

- International Codes Council, ICC Distribution Center 11711 W 85th Street Lenexa, KS 66214 [F] (913) 888-4526 Website: iccsafe.org 1-800-786-4452 International: (708) 799-2300, ext. 33801 order@iccsafe.org https://shop.iccsafe.org/2015-international-residential-code.html

- IRC M1502 VENTILATION, CLOTHES DRYER EXHAUST CODE [PDF]

- IRC M1502 VENTILATION, CLOTHES DRYER EXHAUST CODE [text]

- UL Standard 2158, voluntary standard for electric clothes dryers

- US CPSC "Overheated Clothes Dryers Can Cause Fires, CPSC Document # 5022 Updated June 2003", U.S. Consumer Product Safety Commission, www.cpsc.gov., websearch 11/25/2011, original source: cpsc.gov/cpscpub/pubs/5022.html

- US CPSC "Electric and Gas Clothes Dryers, Staff Evaluation and Contractor Report", US CPSC Memorandum, 25 Feb 2000

- US CPSC "Report on Electric and Gas Clothes Dryers", U.S. CPSC Memorandum, 25 Feb 1999, the Clothes Dryer Project, March 1999

IRC M1502 Ventilation, Clothes Dryer Exhaust code

User note: Code change proposals to this chapter will be considered by the IRC — Plumbing and Mechanical Code Development Committee during the 2015 (Group A) Code Development Cycle.

The air removed by every mechanical exhaust system shall be discharged to the outdoors in accordance with Section M1506.3. Air shall not be exhausted into an attic, soffit, ridge vent or crawl space.

Exception: Whole-house ventilation-type attic fans that discharge into the attic space of dwelling units having private attics shall be permitted.

Clothes Dryer Ventilation

Clothes dryers shall be exhausted in accordance with the manufacturer's instructions.

Dryer exhaust systems shall be independent of all other systems and shall convey the moisture to the outdoors.

Exception: This section shall not apply to listed and labeled

condensing (ductless) clothes dryers.

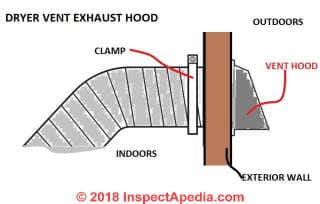

IRC UMC M1502.2 Dryer Exhaust Duct Termination.

Dryer exhaust ducts shall conform to the requirements of Sections M1502.4.1 through M1502.4.7.

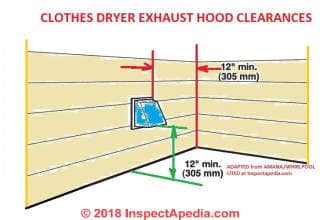

Exhaust duct terminations shall be in accordance with the dryer manufacturer's installation instructions.

If the manufacturer's instructions do not specify a termination location, the exhaust duct shall terminate not less than 3 feet (914 mm) in any direction from openings into buildings.

Exhaust duct terminations shall be equipped with a backdraft damper.

Screens shall not be installed at the duct termination.

Exhaust ducts shall have a smooth interior finish and be constructed of metal having a minimum thickness of 0.0157 inches (0.3950 mm) (No. 28 gage). The duct shall be 4 inches (102 mm) nominal in diameter.

Exhaust ducts shall be supported at intervals not to exceed 12 feet (3658 mm) and shall be secured in place. The insert end of the duct shall extend into the adjoining duct or fitting in the direction of airflow.

Exhaust duct joints shall be sealed in accordance with Section M1601.4.1 and shall be mechanically fastened. Ducts shall not be joined with screws or similar fasteners that protrude more than 1/8 inch (3.2 mm) into the inside of the duct.

Transition ducts used to connect the dryer to the exhaust duct system shall be a single length that is listed and labeled in accordance with UL 2158A.

Transition ducts shall be not greater than 8 feet (2438 mm) in length. Transition ducts shall not be concealed within construction.

Domestic dryer exhaust duct power ventilators shall conform to UL 705 for use in dryer exhaust duct systems. The dryer exhaust duct power ventilator shall be installed in accordance with the manufacturer's instructions.

See details and answers to specific questions

at CLOTHES DRYER VENT CLEARANCES & TERMINATION

IRC UMCM1502.3 Dryer Exhaust Duct size.

The diameter of the exhaust duct shall be as required by the clothes dryer’s listing and the manufacturer’s installation instructions.

IRC UMCM1502.4 Dryer Vent Transition Ducts.

Transition ducts shall not be concealed within construction.

Flexible transition ducts used to connect the dryer to the exhaust duct system shall be limited to single lengths not to exceed 8 feet, and shall be listed and labeled in accordance with UL 2158A.

IRC UMC M1502.4.2 Dryer Vent Duct Installation.

Exhaust ducts shall be supported at intervals not to exceed 12 feet and shall be secured in place.

The insert end of the duct shall extend into the adjoining duct or fitting in the direction of airflow.

Exhaust duct joints shall be sealed in accordance with Section M1601.4.1 and shall be mechanically fastened.

Ducts shall not be joined with screws or similar fasteners that protrude more than 1/8-inch into the inside of the duct.

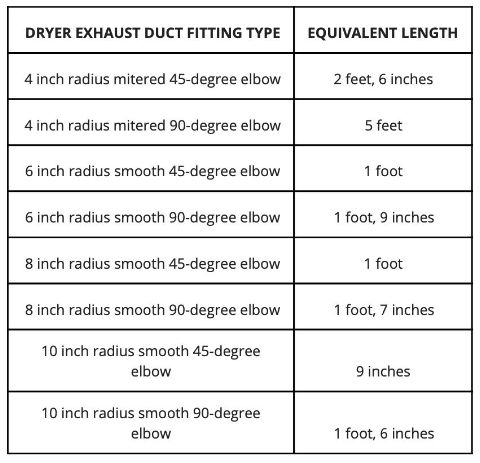

TABLE M1502.4.5.1 DRYER EXHAUST DUCT FITTING EQUIVALENT LENGTH

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 degree = 0.0175 rad.

The size and maximum length of the exhaust duct shall be determined by the dryer manufacturer's installation instructions.

The code official shall be provided with a copy of the installation instructions for the make and model of the dryer at the concealment inspection.

In the absence of fitting equivalent length calculations from the clothes dryer manufacturer, Table M1502.4.5.1 shall be used.

The maximum length of the exhaust duct shall be determined in accordance with the manufacturer's instructions for the dryer exhaust duct power ventilator.

Where the exhaust duct equivalent length exceeds 35 feet (10 668 mm), the equivalent length of the exhaust duct shall be identified on a permanent label or tag. The label or tag shall be located within 6 feet (1829 mm) of the exhaust duct connection.

Where space for a clothes dryer is provided, an exhaust duct system shall be installed. Where the clothes dryer is not installed at the time of occupancy the exhaust duct shall be capped or plugged in the space in which it originates and identified and marked "future use."

Exception: Where a listed condensing clothes dryer is installed prior to occupancy of the structure.

Protective shield plates shall be placed where nails or screws from finish or other work are likely to penetrate the clothes dryer exhaust duct.

Shield plates shall be placed on the finished face of framing members where there is less than 11/4 inches (32 mm) between the duct and the finished face of the framing member.

Protective shield plates shall be constructed of steel, shall have a minimum thickness of 0.062-inch (1.6 mm) and shall extend not less than 2 inches (51 mm) above sole plates and below top plates.

IRC UMC M1502.6 Dryer Exhaust Duct Length.

The maximum allowable exhaust duct length shall be determined by one of the methods specified in Sections M1502.4.5.1 through M1502.4.5.3.

The maximum length of the exhaust duct shall be 35 feet (10 668 mm) from the connection to the transition duct from the dryer to the outlet terminal. Where fittings are used, the maximum length of the exhaust duct shall be reduced in accordance with Table M1502.4.5.1.

The maximum length of the exhaust duct does not include the transition duct.

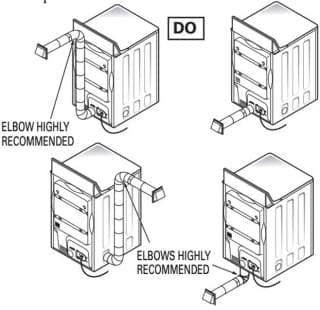

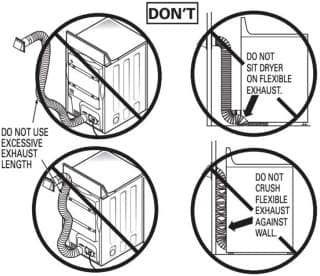

Dryer Vent Manufacturer's Instructions Include Routing, Elbows, Clearances

Watch out: some dryer vent installations are a bit self-contradictory. A manufacturer may recommend using elbows (presumably 90 degrees though 45s are available) of solid metal exhaust duct and may recommend against using flex-duct for dryer venting (Whirlpool as shown above and immediately-below) (we agree) ...

... while other documents from the same manufacturer may show flexible dryer exhaust ducts installed and may recommend against 90 degree turns (Amana - Whirlpool 2017) - shown below.

That may be fine if the dryer flexible exhaust duct is flexible stainless steel rather than plastic (mylar) and wire ducting.

...

Continue reading at CLOTHES DRYER VENT CLEARANCES & TERMINATION, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BUILDING CODE DOWNLOADS

- CLOTHES DRYER INSTALLATION & REPAIR - home

- CLOTHES DRYER FIRE HAZARD WARNINGS

- CLOTHES DRYER LINT FILTER HAZARDS

- CLOTHES DRYER SAFETY CHECKLIST

- CLOTHES DRYER TEMPERATURES

- CLOTHES DRYER VENTING - home

- CLOTHES DRYER VENT BOOSTER FANS

- CLOTHES DRYER VENT CLEARANCES & TERMINATION

- CLOTHES DRYER LINT CLOG RESISTANT SCREENS

- CLOTHES DRYER VENT CODES

- CLOTHES DRYER VENT ENERGY SAVINGS

- CLOTHES DRYER VENT INSTALLATION

- CLOTHES DRYER VENT TERMINATION & SCREENS

- DRYER EXHAUST VENT DUCT MATERIAL & SIZE

- DRYER EXHAUST VENT HOOD TYPES

- DRYER EXHAUST VENT INSTALLATION & ELBOWS

- DRYER EXHAUST VENT ROUTING OPTIONS

- DRYER EXHAUST VENT MISTAKES

- DRYER EXHAUST VENTED INTO ATTIC

- DRYER EXHAUST VENTED THROUGH ROOF

- DRYER EXAUST VENTED INTO CRAWL

- DRYER INSTALLATION & OPERATION MANUALS

Suggested citation for this web page

CLOTHES DRYER VENT CODES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to APPLIANCE REPAIR

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & Answers on bathroom vent fan and fan ducting installation procedures, codes, standards.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Heartland 21000 Dryer Vent Enclosure

- [1] Lambro Industries 289W Dryer Vent Enclosure

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.