Well Rings:

Well Rings:

Use Water Well Rings to Avoid Dug Well Collapse

- POST a QUESTION or COMMENT about methods for protecting a hand-dug well from collapsing

Well rings: what are well rings & how are they used in constructing a modern hand-dug well?

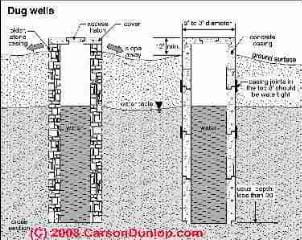

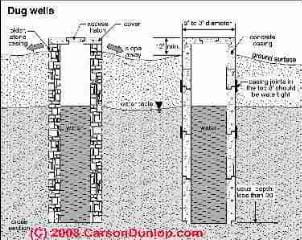

Carson Dunlop Associates' sketch (page top) shows two dug well constructions: a dug well lined with hand-laid stone or concrete block (left), or a dug well using pre-cast concrete sections (above right). This article describes the alternative to stone or concrete block for constructing a modern dug well: using pre-cast concrete "well rings".

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Deciding to Use or Omit Pre-Cast Well Rings or Anillos

Alvin Starkman M.A., LL.B., Casa Machaya, Oaxaca Bed and Breakfast.

Alvin Starkman M.A., LL.B., Casa Machaya, Oaxaca Bed and Breakfast.

This article series offers advice for Hand Dug Water Wells and the sanitation and maintenance concerns with this water supply type.

Alan Starkman is a retired Toronto attorney who operates the Casa Machaya bed and breakfast in Oaxaca Mexico.

[Click to enlarge any image]

At the very end of our well digging process we saw a problem: when we were using heavy machinery to deal with a fence issue (the debris from digging the well was so heavy and plentiful, that when the rainy season began it was pushed to the bottom of our hill and destroyed our fence).

When I wasn't looking, the loader operator cut away too much of our land, so now the well is dangerously close to a precipice. (Photo at left).

We had two concerns:

- Was the well likely to collapse or be unsafe because of the near-exposure of one side and uneven earth pressures?

- Was the whole well at risk of bursting out of the hillside below.

An inspection of the well interior as well as the surrounding terrain, and finally consulting with more experienced well diggers from the area will help assess these dangers.

Meanwhile, we took temporary steps to reduce eroding the little soil that remained: chicken wire (mallo) and posts were laid against the soil on the down-slope side, and we placed our un-used well rings (anillos) as planters at the base of the slope. It is interesting that while our well digger had to chisel through stone to construct the well, just a few feet away was loose soil on the hillside. Don't assume that rock formations or shale extend uniformly through the soil.

Dug Well Safety: Pre-Case Concrete Dug-Well Forms - Anillos Guard Against Well Collapse

Manufacturers of concrete forms do a brisk business selling anillos for wells. Personnel at one such company helped me to determine that the rings in our case should be a diameter which would, when inserted into the well cavity, result in an opening of one meter (de la luz – of light).

At that time there was never any question of whether or not rings would be needed. I assumed they were necessary, because people always talked about anillos, and while traversing the central valleys of Oaxaca I would see anillos at the top of wells, and lying on the ground alongside well-digging projects.

I never considered the quality of ground into which the wells had been dug. Some two years later, after having purchased ten rings, I learned that anillos are most often used when the earth is soft, in order to maintain the required well diameter without risk of collapse. I also learned that their use can actually impede water seepage into the well.

I went out and made all the purchases the well builder asked-for, and then some. I purchased “Y” connectors, shut-off valves, and everything else I thought I might need to get the water to both the fruit trees, and hopefully higher up to our flower boxes.

Fermín confirmed that given the quality of the rock he was excavating, we would not need to use the anillos.

The stone provided sufficient structural integrity without having to be shored up with concrete.

He agreed that using anillos could actually impede water seepage into the well, unless they had large holes in them, and that it just wouldn’t be worth the additional expense and effort to adapt and then use them.

Our photo (above left) shows how the pre-cast concrete well rings were put to use as planters once we realized we did not need them to assure safety or stability of the Dug well.

Carson Dunlop Associates' sketch (left) shows two dug well constructions: a dug well lined with hand-laid stone or concrete block (left), or a dug well using pre-cast concrete sections.

When pre-cast sections are used to line a dug well, and even in some cases where the well walls are lined with stone or concrete block, good design uses water-tight joints in the upper portions of the well.

The concrete well forms, "rings" or anillos shown in our photo above are solid, without perforations.

Using pre-cast anillos or well rings that include holes in their sides will permit assuring a safe, stable dug well in softer soils, and provided that the rings are sealed at their stacked joints, the well builder avoids allowing unsanitary surface water entry into the well.

Where unstable soil requires that pre-cast well rings or a masonry construction extend all the way to the bottom of the well, better water entry into the Dug well will be achieved if the bottom section section of the well permits water entry at the sides as well as the well floor.

Using pre-cast anillos or well rings that include holes in their sides will permit assuring a safe, stable dug well in softer soils while still allowing entry into the well.

From that depth and below some well builders use pre-cast well forms that include holes to permit water entry. The combination of solid concrete forms high in the dug well and perforated well forms at the well bottom reduce dug well contamination from more-contaminated surface runoff.

Our photo (left) shows a round pre-cast form originally designed for use as a drywell or cesspool, but including the side perforations that we explained just above.

Fermín lived up to billing, in short order digging down to over 11 meters. [In the U.S. and Canada most dug wells stop at about 10 meters or around 30 feet deep.]

It took over an hour every morning to pump out the water from the night before. Then Fermín disappeared.

He just didn’t show up one Monday morning, and didn’t answer his cellular for a few days. Eventually he did respond, and advised that he’d return in two weeks. Five weeks later he was back, advising that we’d probably have to go another three meters down.

He just didn’t show up one Monday morning, and didn’t answer his cellular for a few days. Eventually he did respond, and advised that he’d return in two weeks. Five weeks later he was back, advising that we’d probably have to go another three meters down.

After three or four days of digging, Fermín told me that he would not be returning. He said that it was now taking him about two hours in the morning to pump out the water before he could begin digging, and that there was about five meters of water to be removed.

Our well photo (left) shows the rocky sides thorough which Fermín had been chiseling.

To Fermín that signified that the well would produce sufficient water for our requirements and that there was no need to dig further.

To me that meant we had ourselves an honest pozero who could have continued (he didn’t have another job pending, since my friend had altered his plans regarding using Fermín in the foreseeable future), but let us know it wasn’t necessary for him to continue.

As is often the custom with trades in Oaxaca, Mexico, a brief “discussion” ensured about how much we owed him (measuring his progress by lowering a stone attached to a rope to the bottom of the well, and then using a tape measure), followed by the friendly departure of Fermín & Son.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2017-10-31 by (mod)

Anon,

While the construction of an above-ground surround and cover is important both for safety and to keep animals and runoff out of a dug well, given the shallow water source, it's pretty much impossible to guarantee that contaminants don't seep or leak into a dug well. Regular testing and possibly treatment are often required.

On 2017-10-26 by Anonymous

How hand dug well and springs are protected

On 2016-10-07 by tewodros girma

Hi my name is tewodros i am plamber places i have no ideas to hand dug well installation so place learn to me technical step to installation

(Jan 29, 2013) paul said:

ive got a dug well about 9mtrs deep. it is lined with pre cast concrete well rings. about 3 mtrs down where the rings meet, when it rains i got water gushing where the crack is....im wondering how to repair this without taking out the upper rings.thanks

Reply:

Paul I've had luck patching conditions like the one you describe by using hydraulic cement. There are foundation repair products that are basically a fast-setting high-portland cement, perhaps with some latex, that are mixed up and shoved into the crack, held in place for a few minutes, and are usually successful at stoping a leak through a foundation wall or through the well ring in your dug well.

...

Continue reading at DUG WELL DEPTH: HOW DEEP IS ENOUGH? or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see

Recommended Articles

The links below provide the details of how to dig and construct a hand dug water well.

- HAND DUG WELLS - home

- HAND DUG WELL PROCEDURE

- SAFETY WARNINGS for WELL DIGGERS

- BUILD A HAND DUG WELL

- DECIDING TO DIG a WELL: QUESTIONS

- CHOOSE WELL LOCATION & DIGGING METHOD

- BEGIN DIGGING THE WELL

- SUSPEND DIGGING THE WELL: WET SEASON

- WELL RINGS: WHEN TO USE or OMIT

- DUG WELL DEPTH: HOW DEEP IS ENOUGH?

- DUG WELL WATER QUANTITY: HOW MUCH IS ENOUGH?

- WELL ARCH: BUILDING

- WELL SAFETY WALL & COVER

- DUG WELL POTABILITY TEST

- DUG WELL SANITATION PROTECTION

- HAND DUG WELL WATER in PHUKET

- WELL PITS

Suggested citation for this web page

WELL RINGS: WHEN TO USE or OMIT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS & SPRINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Alvin Starkman, Casa Machaya, Oaxaca Bed and Breakfast, Sierra Nevada 164, Col. Loma Linda, Oaxaca, Oaxaca 68024, Mexico, cel: 0449515057793, casa: (951) 1328203, For inquiries, rates and reservations, email Casa Machaya at oaxacadream@hotmail.com

Mr. Starkman is a retired Toronto attorney who operates the Casa Machaya bed and breakfast in Oaxaca Mexico. - Dempster Industries is a contemporary manufacturer of hand pumps for shallow wells or hand dug wells. At http://www.dempsterinc.com/html/Handpump.html you can find Dempster Industries who can tell you exactly how to repair mechanical problems with your well pump. Here is the Dempster installation manual for a typical hand pump used on shallow wells or dug wells: http://www.dempsterinc.com/PDF%20FIles/Typical%20Hand%20Pump%20Installation.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.