Refrigerant Gas Leak Detection

Refrigerant Gas Leak Detection

How to find & fix refrigerant leaks in HVACR equipment

- POST a QUESTION or COMMENT about buying and using refrigerant gas detection equipment to test for refrigerant leaks at air conditioners, heat pumps, and other refrigeration equipment

Refrigerant gas leak detection, location, & repair:

Guide to Refrigeration Gas Leak Detection & Tips for Using the TIF 5000 halogen leak detector as an example;

This article describes refrigerant gas leak detector tools and the methods used to find refrigerant gas leaks such as Freon leaks and other halogen gas leaks. We also discuss where refrigerant leaks most often occur.

We include a list of sources and manufacturers of refrigerant or halogen gas leak detection instruments and leak indicators.

In this article series we explain the effects of refrigerant leaks on air conditioners and heat pumps, refrigerators, freezers, etc. including both the effects of lost refrigerant and the effects of refrigerant piping leaks that admit moisture and dirt contamination into the system. We also explain how a refrigeration gauge set should be connected to HVAC equipment to avoid contamination damage.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Refrigerant Leak Detection & Types & Tips for Using the TIF 5000 automatic halogen gas leak detector

As we explain in our articles on lost cooling capacity or air conditioning systems or heat pumps that are not working, a refrigerant leak in your air conditioner or heat pump means that eventually it will just not produce cool air (during air conditioning) nor warm air (during heating if it's also a heat pump).

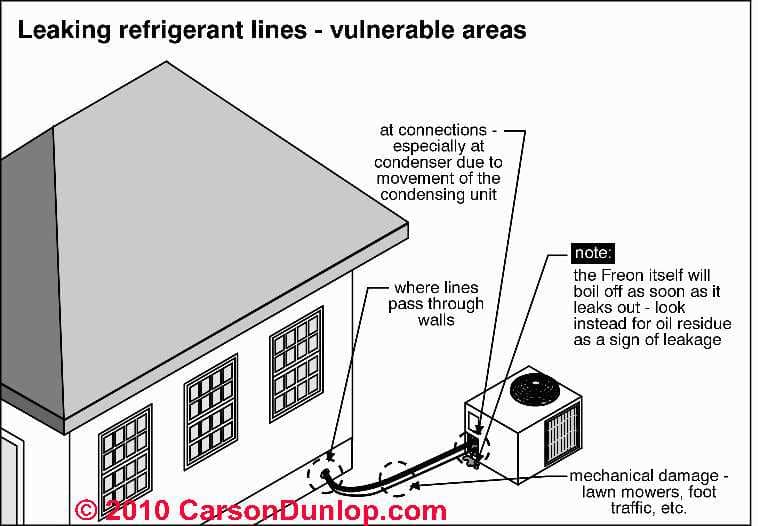

Carson Dunlop Associates' sketch (left) illustrates some of the common areas where vibration or other stresses or damage are often the cause of leaks in refrigerant piping at a home air conditioner or heat pump.

Before assuming that you need to add refrigerant, see the diagnostic steps

Refrigerant leak detection methods

Using a sensitive instrument such as the TIF 5000 is a useful way to quickly find refrigerant gas leaks on air conditioning and heat pump systems.

Alternative leak locating methods are also useful, such as a thorough visual inspection for stains or discoloration at HVAC refrigerant piping, evaporator or cooling coils, condensing coils, and fittings.

In addition, some HVAC technicians include a leak-detecting oil in the refrigerant charge in order to (possibly) provide visual evidence of where leaks are occurring in the system. You'll see this referred to also as refrigerant leak detection dye, discussed later on this page

at REFRIGERANT LEAK DETECTION DYE

Common causes of air conditioner or heat pump refrigerant leaks include:

- refrigerant lines rubbed together due to vibration

- ice pick damage from an inexpert "repairman" trying to get ice off of a cooling coil

- corrosion at either the condensing or evaporating coil

- dirt deposits: refrigerant leaks occur at service fittings at the compressor/condenser unit when dirt or debris cause failure of the service valve to close fully when the service gauge set or refrigerant charging equipment are installed and later removed.

Refrigerant leaks occur at a number of locations on cooling equipment, including

- Corroded cooling coil in the air handler unit - costly repair, usually need to replace the coil

- Corroded condensing coil in the condenser unit - costly repair, usually need to replace the coil

- Mechanically damaged refrigerant lines, for example due to vibration against hard surfaces

- Poorly soldered fittings or controls

- Leaky connections at controls or control valves

Practical tips for checking for refrigerant gas leaks

What most refrigerant gas leak testing instrument instructions fail to point out is a practical procedure for actually examining air conditioning or refrigeration systems for refrigerant gas leaks.

- The refrigerant piping and cooling and condensing coils will need to be exposed for ready access.

- The leak detector is turned on and its proper operation confirmed.

- The detector tip is held close to the refrigerant piping and cooling coil surfaces, sequentially, starting at a convenient point and following all of the piping and tubing throughout its length.

- Look for stains on refrigerant piping or controls which may indicate a history of leaks (and refrigerant oil leakage too) at those locations.

- Listen for a whistling thermostatic expansion valve - a sign of low refrigerant discussed in detail

at THERMOSTATIC EXPANSION VALVE (TEV) or Capillary Tube Installation, Inspection, & Testing Guide

How to Diagnose Types of Leaks of Refrigerant Leaks in HVAC Systems

Effects of refrigerant leaks or loss of charge show up in different ways depending on where the refrigerant leak is occurring.

Leaks on the high side of a refrigeration system

show up as loss of refrigerant and will be discovered.

Leaks on the low side of a refrigeration system

are harder to discover until enough air leaks into the refrigerant piping system.

At that point the compressor head pressure goes way up until a safety device shuts down the compressor motor or a service tech discovers a problem. A leak on the low side is ugly because now the whole system has become contaminated with air, moisture, and dirt.

Effects of Refrigerant Leaks: Dirt & Moisture on Thermostatic Expansion Valves or Capillary Tube Refrigerant Metering Devices

Moisture freezes in the refrigerant metering device, further interfering with proper cooling system operation, and dirt can also jam up a TEV or clog a capillary tube. When moisture is freezing up a thermostatic expansion valve the system will stop working (and thus begin to warm up) until the ice melts. The system may run normally for some time - until water droplets pass through the system and again reach the TEV and cause it to freeze again.

Unlike moisture, dirt in the refrigeration system is more likely to cause the Thermostatic Expansion Valve to clog and just stop working permanently, as it can also do a capillary tube metering system.

You might diagnose a moisture-in-expansion valve or cap tube problem by adding heat to the device to see if it will thaw and begin operating.

See THERMOSTATIC EXPANSION VALVES for details about these devices.

Moisture in the refrigerant piping system also mixes with the refrigerant to form an acid which can short out compressor motor windings by dissolving the lacquer on the wire windings.

Refrigerant combined with moisture becomes a black stinky liquid.

Effects of Air in the refrigeration system; how we diagnose the presence of air inside the air conditioner or heat pump

The pressure of air is additive to the pressure of the refrigerant in any refrigeration system. And of course the amount of air pressure that is added to the system depends on the temperatures of the refrigerant gas, compressor, coils, etc.

Put simply, air inside the refrigerant handling system (piping, controls, compressor, coils) raises the pressure on both the HIGH and LOW sides of the system even if the air is not also adding moisture. The result is that the air conditioner or heat pump operates at a lower efficiency.

For example, at 70 degF and using R12 refrigerant, we would expect the static or idle (compressor not running) pressure of the refrigerant in the system to be at 70 psi.

How We Know Air has Contaminated the Refrigerant System

If you know that your refrigerant is R12 and that the pressure should be 70 psi when the A/C or heat pump has not run in some time, and ambient temperature is also 70F.

So provided there are no blockages or clogs in the system refrigerant piping, coils, compressor, controls,

see REFRIGERANT DRIERS & FILTERS for a blockage example

Then IF you see a gauge pressure higher than 70 psi that suggests you have air in the system. You may in fact see high head pressure and high back pressure if there is significant air contamination in the refrigerant.

See GAUGE, REFRIGERATION PRESSURE TEST

And if the air conditioner/heat pump or other refrigeration system is contaminated by any of the problem materials we've discussed: air, moisture, dirt and debris, you will need to evacuate and vacuum the system to remove these contaminants.

Suggestions for Using the TIF5000 to detect refrigerant leaks

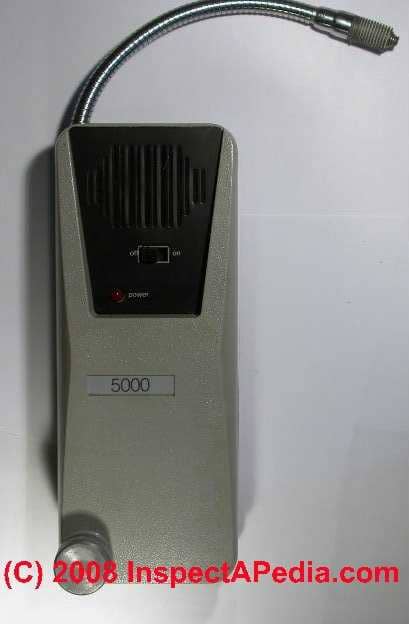

The TIF 5000 automatic halogen leak detector is used for air conditioning and cooling system refrigerant leak detection. The TIF 5000 replaces and combines functions previously provided by the TIF HLD440 halogen leak detector, with an added circuit which TIF refers to as "automatic ambient control".

This feature "adjusts and corrects for the atmospheric ambient refrigerant in the vicinity of the tip." [TIF 5000 product literature].

As you'll notice in our photograph of our instrument, its external appearance is similar to the TIF 8800 except that the 8800 detects a wide range of combustible gases while the TIF 5000 is designed to focus on the halogen gases - air conditioning refrigerants such as the now discontinued R12 and R22.

The instrument weighs about 28 ounces and is 8" x 3" x 1.8" in size, not counting the length of the flexible sensor tip.

What gases does the TIF 5000 leak detector detect?

The TIF 5000 halogen leak detector is used principally on air conditioning and refrigeration equipment, heat pumps, and possibly dehumidifiers.

This leak detector also detects the following halogen gases or halogen gas mixtures:

- Ethylene Oxide gas leaks (hospital sterilizing equipment - detects the freon mixture)

- Most gases containing Chlorine

- Most gases containing Fluorine

- Most gases containing Bromine

- Dry cleaning industry cleaning agent or solvent gases can also be detected using this instrument

Step by Step Guide to Using the TIF 5000 Leak Detector on Refrigeration and Air Conditioning Equipment

Instructions for use of the TIF5000 to check for refrigerant gas leaks couldn't be much simpler, and they are printed on a label affixed to the device:

- Turn the TIF 5000 on.

a. If the red LED does not light, replace the batteries in the detector. The instrument has a virtually instant "on" feature and should not require a warm-up time.

b. If the red LED lights but the instrument does not emit a tone, replace the sensing tip - Begin searching for leaks of refrigerant gas or halogens

But as with other gas leak detection devices of this type, if you're using the TIF 5000 refrigerant gas leak detector in an area which may already be contaminated with a high level of gas leakage, special (but simple) steps are needed to permit the leak detector to find the point of refrigerant gas leakage:

In an area heavily contaminated with refrigerant, (when a rapid, high pitched beeping signal [is heard]), turn [the] instrument off and then back on [while in the contaminated area] and resume testing for leaks.

This procedure is the opposite of what we do with the TIF8800 when testing for combustible gases (and the hazards are different since halogen gases do not present an explosion hazard).

Critical Maintenance Tips for Refrigerant Gas Leak Detectors

The sensing tip on the TIF 5000 and some of the electronics of the instrument therefore are of course different.

Because debris contamination will interfere with proper operation of the TIF5000 halogen leak detector (refrigerant gas leak detector) the sensor is supplied with filter paper pre-cut into a cross shape which is inserted around the sensing tip under its protective spring cover. When the paper is soiled it is simply replaced.

The glass vial shown in our photo contains a substance used to confirm that the sensing tip will respond to a halogen gas (refrigerant gas) leak as it should.

Tips from TIF for maintenance of the TIF 5000 Halogen Leak Detector

To change the sensing tip: turn of the TIF 5000 leak detector before changing the sensing tip. Turn the tip counter-clockwise to remove it, and attach the new tip by turning it clockwise when screwing it in place.

Screw the new tip finger tight. Do not contaminate the new tip with oil or grease such as hand cleaner or refrigerant oil, and do not get your sweat on the tip. To protect the tip from contamination by dust and grease during use, use the filter paper we show in the photo above. Use a new filter paper when installing a new sensor tip.

Spare sensor tips: A spare leak detector sensing tip can be stored in the battery compartment.

Batteries: Use two fresh "C" alkaline batteries to power the TIF 5000. Batteries are installed by removing a battery cover on the back of the instrument. If the batteries are fresh you should see the red LED turn on when the power switch is turned on.

If the LeD does not light, change the batteries.

If the LeD lights but the unit does not operate (won't respond to refrigerant or test gases) change the sensing tip. If that doesn't work you'll need to return the instrument to TIF for repairs.

Operating temperature range: the TIF 5000 is rated to operate between 30 deg. F. and 100 deg. F. This warmer temperature function can be important when sniffing around a hot compressor motor.

Other specialized gas detection methods include use of solid state circuitry, CMS chips, and special instruments which may be designed to give a quick alarm or a reading in PPM for specific gases.

Other gas and air monitoring equipment use pumps which collect and insert a specific volume of air into a vacuum container for later analysis. We've found that for typical field use, the colorimetric gas detector tube method is extremely convenient and very accurate, and it presents minimal requirements for instrument calibration.

In related documents we give references and explanation regarding toxicity of several of the most common indoor gases, based on literature search and obtained from the U.S. government and expert sources. This text may assist readers in understanding these topics. However it should by no means be considered exhaustive.

How quickly does refrigerant leak detection dye show up?

Shown here: Spectroline's kit for using Glo-Stick flouorescent dye added to refrigerant systems to help spot leaks.

This amber-colored liquid flourescent dye is added to a refrigerant system where it passes through the compressor and other components as a lubricating oil that will seep out of the referigerant piping or coils or fittings where there is a leak, leaving an easy-to-see dye. - (Spectroline 2018)

Dyes in refrigerant are, as is apparent, intended to help spot a refrigerant leak by leaving a colored oily deposit in the area where the leak occurs.

And unless the leak is extremely small, that dye is being deposited within hours of operating the A/C or heat pump system, as refrigerant is cycling through the system and presumably leaking out at the leak point.

But the rub is that you might never ever see the dye.

Everything depends on just where the leak is occurring; if the leak is in a location that cannot be readily seen by visual inspection then the colored oily dye left at the point of leakage also won't be seen.

An example might be a leak on the indoor cooling coil on the down-stream side of the coil in certain supply air plenums where there is no direct view of that area in the plenum or ductwork.

Another example might be a pinhole leak in refrigerant piping that is occurring in a run of piping that is insulated and tightly sealed; such a leak might have to accumulate a lot of dye before enough dye is provided to run out of the insulation.

For these reasons, dye is a helpful tool in locating a refrigerant leak and it will quickly show up common leaks such as at service fittings for refrigerant line charging such as at the outdoor condenser unit.

Watch out: an HVAC service technician won't rely on dye alone. She might use, for example, a refrigerant gas detector whose sensor is moved along lines and at connections and at various locations on the system.

And an experienced technician knows to look for refrigerant leaks in areas where there are common causes of or sources of such leakage: fittings, brazed joints, and locations along tubing where there is abrasion from vibration, and, of course, at the evaporator and condenser coils themselves.

Halogen or Refrigerant Leak Detection Tools & Companies

All of these halogen gas or refrigerant leak detection instruments and tools are sold by HVACR suppliers locally as well as at online vendors such as grainger.com

All of these halogen gas or refrigerant leak detection instruments and tools are sold by HVACR suppliers locally as well as at online vendors such as grainger.com

Take note that while all of these instruments are highly sensitive to even very low levels of refrigerant gas, their sensitivity varies. Refrigerant leak detection instrument sensitivity is expressed as some quantity of refrigerant gas at a leakage rate ranging from 0.006 oz/year to 0.2 oz/year or in some cases expressed as rams, 1.7 g./ year.

Example shown above: Bachrach's H-10 Pro universal refrigerant leak detection instrument detects CFC, HCFC, and HFC gases at a sensitivity to leakage rates as low as 0.006 oz per year

Grainger.com excerpt:

With a positive ion emission-heated diode sensor and selectable sensitivity for greater accuracy, this BACHARACH refrigerant leak detector can quickly locate small, medium, or large leaks.

Model features a visible LED leak rate indicator on the probe tip and an audible buzzer. Unit can detect as low as 0.006 oz./yr. and comes with a visual sensor calibration system (with included reference leak bottle).

- Amprobe Halogen Leak Detectors, multiple models, sensitivity 15g, 20g 40g, 30g,R-404A, 407C, 410A 4g, R-22,134a 3g / year

- Bachrach Refrigerant Leak Detectors - multiple electronic tools, gas detectors, sensitivity varying by instrument/model, 0.006 oz/year to 0.25 oz (6g) / year

- Extech refrigerant leak detectors, sensitivity: 0.25/0.50/0.99 oz / year

- Imperial refrigerant leak detectors, sensitivity 0.05 oz/yr R-134, 0.025 oz/yr R-22

- Infrared leak detectors, e.g. Inficon Refrigerant leak detectors

- Inficon refrignerant leak detectors, sensitivity varying by instrument model, 0.10 oz/year to 0.25 oz/year of CFCs, HCFCs, HFCs, and HFOs.

- JB Industries halogen gas leak detection instruments, sensitivity by instrument model varies, 0.05 oz to 0.10 oz/year for CFCs, HCFCs, HFCs

- Johnson Controls refrigerant leak detecctor kits, sensitive to 0.1 oz/year

- Leak-Seeker refrigerant leak detetors, sensitivity 0.1 oz/year

- REFRIGERANT LEAK DETECTION DYE - [Web article]

- Robinair refrigerant leak detectors, sensitivity varying by instrument model, typically 0.05 oz/yr R-134, 0.025 oz/yr R-22

- Spectroline, Glo-Stick Flourescent DYE SDS [PDF] (2018) Spectronics Corporation 956 Brush Hollow Road Westbury, New York 11590 USA Tel: 800-274-8888 516-333-4840 (For Calls Originating Outside Continental U.s.) Email: sds@spectroline.com, retrieed 2021/07/14 original source: http://complyplus.grainger.com/grainger/msds.asp

- Test Products International, refrigerant leak detector sensitivity by model, 0.1 - 0.2 oz/year

- TIF 5000 - discussed above on this page. TIF Instruments, Inc., 9101 NW 7th Avenue, Miami, Florida 33150 (This is where we've sent our TIF 8800 and TIF 5000 for repairs).

- UEI Test Instruments used for refrigerant leak detection, sensitivity 0.05 oz/yr R-134a, 0.025 oz/yr R-22

- Yellow Jacket refrigerant leak detectors, multiple models, sensitivity varying by instrument model, typically 0.2 oz to 1.7 g. / year

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

...

Continue reading at REFRIGERANT LEAK REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see REFRIGERANT LEAK DETECTION FAQs - questions & answers about finding and fixing refrigerant leaks at A/C, heat pumps, refrigerators, etc. posted originally on this page.

Or see these

Refrigeration Gas Articles

- GAS DETECTION INSTRUMENTS - home

- GAS DETECTOR WARNINGS

- LOST COOLING CAPACITY - Air conditioner or heat pump no longer produces cool air

- REFRIGERANT GASES & PIPING

Suggested citation for this web page

REFRIGERANT LEAK DETECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about buying and using refrigerant gas detection equipment to test for refrigerant leaks at air conditioners, heat pumps, and other refrigeration equipment

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Jennifer Moore, Sales Administrator, Nextteq, LLC, Tampa FL, Nexteq 813-249-5888. Nextteq is the master Distributor for Gastec in the United States. According to the company's website, Gastec Gas Sampling Pumps are the industry’s first and only pumps to provide on-the-spot measurement of ambient temperature. [Private email, JM to DF 5/23/08]

- Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- "Air Conditioning & Refrigeration I & II", BOCES Education, Warren Hilliard (instructor), Poughkeepsie, New York, May - July 1982, [classroom notes from air conditioning and refrigeration maintenance and repair course attended by the website author]

- Refrigeration and Air Conditioning Technology, 5th Ed., William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.