Roof Underlayment Installation

Roof Underlayment Installation

Requirements & Best Practices

- POST a QUESTION or COMMENT about the requirement for and installation of underlayment on asphalt roof shingles and similar materials.

Requirements & recommendations for use of underlayment on asphalt shingle roofs & on low slope roofs.

This article explains the benefits of and best practices use of roofing felt or other roofing underlayment products beneath asphalt shingles and other roofing materials.

We discuss underlayment or felt installation details for standard slope roofs, low slope roofs where shingles will be installed, and low slope roofs in freezing climates.

We also will describe the following: Underlayment for Standard Slopes. Underlayment on Low Slope Shingle Roofs. Flashing in Freezing Climates. Roof shingle warranty requirements for roof shingle underlayment. NRCA recommendations for roofing felt underlayment. Permeability of felt underlayments in hot humid climates. What are the benefits from using roofing underlayment or felt?

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Best Practices Guide to Uses of Roofing Underlayment

Our page top photograph shows 15# roofing felt underlayment being installed in preparation for placing a new roof on an older home in Poughkeepsie, NY.

Our page top photograph shows 15# roofing felt underlayment being installed in preparation for placing a new roof on an older home in Poughkeepsie, NY.

This article includes excerpts or adaptations from BEST ROOFING PRACTICES, adapted from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

[Click to enlarge any image]

Article Contents

- ROOFING FELT UNDERLAYMENT BEST PRACTICES

- UNDERLAYMENT for STANDARD SLOPED ROOFS

- UNDERLAYMENT opn LOW SLOPE SHINGLE ROOFS

- FLASHING in FREEZING CLIMATES

- Roof shingle warranty requirements for roof shingle underlayment

- NRCA recommendations for roofing felt underlayment

- Permeability of felt underlayments in hot humid climates

- What are the benefits from using roofing underlayment or felt?

Best Practices Guide to Residential Construction lists five good reasons to install roofing underlayment:

- Roofing underlayment or felt protects the roof deck from rain before the roofing is installed.

- Roofing underlayment or felt provides an extra weather barrier in case of blowoffs or water penetration through the roofing or flashings.

- Roofing underlayment or felt protects the roofing from any resins that bleed out of the sheathing.

- Roofing underlayment or felt helps prevent unevenness in the roof sheathing from telegraphing through the shingles.

- Roofing underlayment or felt is usually required for the UL fire rating to apply (since shingles are usually tested with underlayment).

The roof deck should be sound and level before laying the

underlayment. Fifteen-pound or heavier felt underlayment

is required by code in some areas. Whether or not it is

required, underlayment is cheap insurance against problems.

Note that building codes or roof product manufacturers also require using roofing felt in many circumstances including to protect the shingle warranty -

see ROOFING FELT UNDERLAYMENT REQUIREMENTS for details.

Guide to Roofing Underlayment or Felt Installation for Standard Roof Slopes

According to Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

According to Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

On roofs with a slope of 4:12 or greater, use a single layer of 15 lb. asphalt-saturated felt, starting at the eaves and lapping upper courses over lower by a minimum of 2 inches.

Vertical joints should lap a minimum of 4 inches and be offset by at least 6 feet in successive rows (see Figure 2-2).

On roofs with a slope of 4:12 or greater, use a single layer of minimum No. 15 asphalt-saturated felt, starting at the eaves and lapping upper courses over lower. Run the felt 6 inches over ridges and hips from each direction, and 6 inches up any adjoining walls.

Secure each course along seams and edges with enough corrosion-resistant nails to hold it in place until the roofing is installed. In high-wind areas, apply fasteners a maximum of 36 inches on-center along overlaps.

For best protection against leaks, run felt 6 inches over ridges and hips, from each direction, and 6 inches up any adjoining walls.

Valleys should be lined with a full width of roofing felt (or bituminous membrane) pushed tight into the valley so there is no slack. Side courses of underlayment should run over the valley lining and extend 6 inches past its edge.

(see Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) “Valley Flashing” page 59.)

Guide to Roofing Underlayment Installation on Low Slope Roofs with Asphalt Shingles

Asphalt shingles can be used on roofs with a slope of 2:12 to 4:12 if double-coverage underlayment is used. Start with a 19-inch strip of 15 lb. asphalt-saturated felt along the eaves, and lap succeeding courses by 19 inches as shown in Figure 2-3.

Wherever there is a possibility of ice or snow buildup or the backup of water from leaves or pine needles, install a self-adhering bituminous membrane along the eaves that extends up the roof to a point at least 36 inches inside the interior wall line.

An alternative approach, not widely used anymore, is to seal all laps in the lower courses of roofing felt with lap cement or asphalt plastic cement.

In areas with extensive snowfall or windblown rain, the best protection against leakage is to cover the entire low-slope roof area with a bituminous membrane, as shown in Figure 2-4.

Vertical end laps should be at least 3 inches and horizontal laps 6 inches. If the roof changes to a steeper slope, for example, where a shed dormer joins the main roof, extend the membrane 12 to 18 inches up the main roof slope.

Bituminous membranes are self-healing around nail holes, and because they bond fully to the sheathing, any leaks that occur cannot spread. As a safeguard against expensive callbacks, many roofers now apply membrane to the entire surface of any roof with a slope of 4:12 or less.

Guide to Eaves Flashing by Roofing Underlayment Installation on Low Slope Roofs in Freezing Climates

For low slope roofs in cold climates where ice dams and ice dam leaks are likely, Steve Bliss recommends a double layer of No. 15 felt underlayment as shown in Figure 2-3 above.

With slopes from 2:12 to 4:12, use a double layer of No. 15 underlayment as shown.

Where water may back up from ice or debris from trees, protect the lower portion of the roof with a bituminous eaves flashing or fully cemented felt, as shown.

OPINION-DF: use a self-sealing self-adhering bituminous membrane such as Ice and Water Shield in these locations to provide maximum leak protection.

These products seal around nails used to secure the membrane in place.

Mr. Bliss makes this recommendation in text that follows and in Figure 2-4 (left).

The best defense against ice dams in cold climates is a so-called “cold roof,” consisting of high levels of ceiling insulation separated from the roof surface by a free-flowing vent space

(see “Preventing Ice Dams on Roofs,”

or see page 97 in the printed text Best Practices Guide).

Where a cold roof cannot be achieved due to

complex roof shapes, unvented roofs, or retrofit constraints,

ice dams may form during severe winters, in some cases,

causing pooled water to wet wall cavities and interior

finishes.

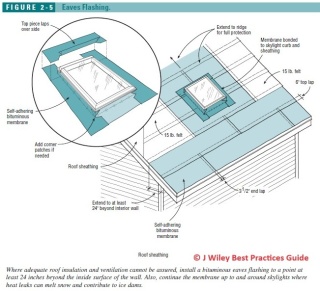

Where adequate insulation and ventilation cannot be assured, self-adhering bituminous eaves flashing should be installed. The membrane should go from the lower edge of the roof to a point at least 24 inches inside the interior wall line (Figure 2-5).

Where two lengths of eaves flashing meet at a valley, run each across the valley, starting with the length from the roof with the lower slope or lesser height. The valley flashing should later lap over the eaves flashing.

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Roofing Felt Underlayment Installation Position

Reader Question: is it ok for roofing felt to run at right angles to the roof eaves?

2/10/2014 - Jenn Bullington said:

I live in Albany, New York and recently had a new roof put on my house. It has come to my attention (after the fact) that the roofer installed the tar paper/underlayment material vertically rather than horizontally. Is this against code? Is this something that should be addressed with my roofer and should I pursue action before a problem occurs? I'm worried. Thanks!Reply:

Roofing underlayment is specified in manufacturer's installation instructions and thus is indirectly require by building codes (stating that the manufacturer's installation instructions should be followed). Quoting

from UNDERLAYMENT REQUIREMENTS on ROOFS - home

Non-perforated, [Type I, No. 15] [Type II, no. 30], asphalt saturated felt complying with ASTM D 226, ASTM D 4869 or ASTM D 6757. - Oakridge Pro30™ shingle instructions.

But it is worth noting that some building codes such as the Canadian CBC do not require full roof underlayment below asphalt shingles. So at least in those cases the felt positioning question does not arise.

I'm not sure building codes describe underlayment positioning, but indirectly that installation probably is in violation of the best practices guides & probably the roofing manufacturer's instructions in that at least all the refs we have show placement parallel to eaves and with upper courses lower edges overlapping lower course top edges.

That said, if the finish roof has been installed this IMO not a sufficient defect to warrant re-roofing or a tear-off. The felt on a normal asphalt shingle roof installation is not intended to serve as the waterproof barrier - that's the shingle's job.

The jobs of roofing felt underlayment on an asphalt shingle roof are described in the article above. Of these, most of the functions are position independent. By "position independent" I argue that installing felt underlayment parallel or orthogonal to the house eaves does not affect those functions.

If there were NO felt installed we'd be missing an extra level of "insurance" against water damage from roof leaks following a partial shingle blow-off in a storm. With felt installed orthogonal to the eaves, the efficacy of felt as "leak insurance" would depend on wind direction as well as size of the blow-off: both conditions that could also affect the efficacy of felt even if installed properly, parallel to the eaves.

And in my OPINION, because the felt is punctured thousands of times by the roofing nails that fasten down roof shingles, its ability to protect a home from leaks after the shingles have been installed is reduced significantly anyway.

In fact a worse mistake than running felt at right angles to the eaves is probably running felt lapped "wrong way" with upper course lower edges underneath rather than on top of the upper edge of the courses below.

If some dope makes that mistake and if there is ever a shingle blow-off and water runs underneath the remaining shingles, a horizontal felt edge lap mistake will do a great job of sending nearly ALL of the leaked water underneath the felt. Still nothing much may happen until that water hits an open butt joint between two sections of roof sheathing. Then it may come pouring in at that opening.

If we have a high-risk roof for which we want to add real leak protection extending beyond that afforded by the roof covering shingles, we'd cover the roof with an ice-and-water-shield type barrier - a membrane that seals around the nails.

Watch out: What you should do before any arguing with your roofing contractor is give the manufacturer of your roofing shingles a call, speak to the warranty department, and ask if the position of roofing felt as we've discussed affects the shingle warranty. It might. I suspect that roof covering manufacturers are thrilled when a product failure claim can be blamed on improper installation - which is in my opinion often the case.

Put another way, if the roofer was inexperienced or uninformed enough to do something funny with the felt, one wonders what other mistakes were made: improper nailing for example.

Also see WARRANTIES for ROOF SHINGLES and for next time,

see CHOOSING A ROOFING CONTRACTOR.

Roof Underlayment Requirements for Wood Shingles, Shakes, or Clay Tiles

Please see our separate discussions in the recommended reading links below.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-11-29 - by (mod) - Should the underlayment be flat or can it be wrinkled.

The manufacturer's shingle installation specifications (check your specific product) usually say "install over smooth, dry underlayment"

But what's a "wrinkle" ?

A slight bulge or ripple that can be pressed flat by the weight of the shingles might show up in smooth dry roofing felt that has sat overnight and has absorbed some moisture without actually suffering exposure to rain- probably not a proiblem.

But an actual wrinkle of lifted felt or other underlayment that is folded over or more-severe and that's not flattened out when shingles are installed may result in a bulge or lifted surface and might impact shingle wear.

On 2020-11-29 by emily collings

Should the underlayment be flat or can it be wrinkled. Will wrinkled underlayment affect the new shingle

On 2020-06-26 - by (mod) - The roofer for my home has four different colors of underlayment/felt and it looks like patchwork.

Color is not significant but proper placement and installing shing look es on a smooth surface are typical manufacturers' requirements.

On 2020-06-26 by Carrie

The roofer for my home has four different colors of underlayment/felt and it looks like patchwork. There are gaps and the shingles are to go on tomorrow. He said the white underlayment is for a 50 year roof and that I should be impressed. He had it leftover from another job.

Should I be worried? There doesn't seem to be a uniform way that the underlayment was put down and pieces are blowing in the breeze and there are buckled gaps between nails. Please advise.

On 2019-10-19 - by (mod) -

Siu

So sorry not to be able to offer more detailed information but that's not a product for which I have found reviews. I'm more familiar with and have it installed and also seen many reviews of the more common brand names such as Velux

On 2019-10-18 by SIU

Solar Industries Inc. (manufacturer) is the roofer's skylight supplier. Need to order customized skylights to fit the current roof skylight frame size. This manufacturer has vinyl or aluminum curb mount fixed skylights (flat glass or acrylic). Is it a good choice for aluminum curb mount frame with flat glass? Thanks.

On 2019-10-16 by (mod) - skylight flashing system compatible with a tile roof;

Indeed, Siu, it may be that it's actually the skylight flashing system that is not compatible with a tile roof;

IF the old skylights are energy-losers, leak, or damaged themselves then this is the right time to replace them.

Just for your information, skylight companies such as Velux produce special skylight flashing for use on tile roofs, such as the skylight flashing I'll show below in an excerpt from Home Depot.

Click the image above for more details.

On 2019-10-16 by SIU

Roofer work team replaced damaged plywood and fascia boards with new pieces as needed. They have done so. It appears that they removed majority of the old underlayment.

Passed first inspection. However, the field supervisor stated that they need to replace the old skylights.

He indicated the old ones were not the correct type for tile roof. Since the skylights are 20 or more years old, I guess ok to replace with new ones. Probably, they want to use new ones so it will be much easier for resealing the skylights....Hope that they are not misleading me.

On 2019-10-04 - by (mod) -

Two layers of sheathing may be permitted; But the contract is a bit unclear. What "damaged wood" ? Just sheathing? Or including the structure?

On 2019-09-29 by SIU

Roof type: Mission clay tile

Roof Renovation Job

Contractor is to only remove existing underlayment as neede, inspect for wood damage and replace damaged wood as needed, and will install APOC CX-L Crossover Hybrid Roof Underlayment to entire roof.

Is this approach that there will be a major portion of the roof with new underlayment being install over the old underlayment acceptable and effective?

Please provide advice.

On 2019-10-04 by (mod) -

Two layers of sheathing may be permitted; But the contract is a bit unclear. What "damaged wood" ? Just sheathing? Or including the structure?

On 2019-09-29 by SIU

Roof type: Mission clay tile

Roof Renovation Job

Contractor is to only remove existing underlayment as neede, inspect for wood damage and replace damaged wood as needed, and will install APOC CX-L Crossover Hybrid Roof Underlayment to entire roof.

Is this approach that there will be a major portion of the roof with new underlayment being install over the old underlayment acceptable and effective?

Please provide advice.

On 2019-03-04 by (mod) -

Ice and water shield is much safer to install - as it's a peel and stick product.

On 2019-02-28 by Bill Randolph

I have a 1/12 pitched roof over my deck at Lake Livingston, TX. The remainder of the roof is a 10/12 pitch.

The roof over my deck has leaked ever since I have owned the house. I have recently enlarged the deck roof and want to either use ice/water or torch down to eliminate the leaking and glue down roll roofing or fiberglass shingles over that. It is only a water problem.

I am going to run the underlayment up the 10/12 pitch 3 feet past my chimney crocket, which intersects both roofs. Down here, both are almost identically priced. My question is, which is best for my situation?

On 2018-10-10 by (mod) - Why didn't the felt cover the bottom drop edge?

Agreed anon. I would have run the felt to the edge of the drip edge; however it's not critical as long as the felt laps an inch or more over the upper edge of the drip edge.

I also agree that our page top photo of felt underlayment would not be a great ad for a roofing company's work. But, then, here where we focus on both good practices and on snafus to avoid, by design many of our photos will provide examples of building conditions to be avoided.

To protect the trust of our readers, InspectApedia.com does not market nor otherwise sell any product or service.

On 2018-10-1 by Anonymous

Why didn't the felt cover the bottom drop edge?

ROFL. Terrible marketing photo

On 2017-05-01 by Gene

My contractor recently installed a new roof on my house. However, the underlay and shingles were installed in wet snow conditions. I am concerned that the moisture on the roof wood which is under the underlay and the moisture between the underlay and shingles may cause problems in the future.

The contractor assures me this moisture will dissipate over time. I am not not convinced. What are your comments and experiences with this situation. thankk.

(Apr 14, 2012) milton said:

Thank you this was very helpful on my back porch with its low slop roof problem

Reply:

Thank you for the nice comment Milton. And if question should arise about a building related topic for which you can't find a clear answer at InspectAPedia, please ask.

Your questions help us see where more work is needed. We are dedicated to making our information as accurate, complete, useful, and unbiased as possible: we very much welcome critique, questions, or content suggestions for our web articles. Working together and exchanging information makes us better informed than any individual can be working alone.

Question: opinions about 15# felt on low slope felt: double felt + ice & water shield

(Apr 17, 2012) Low pitch roof 3:13 said:

From the information I have garnered from the above we feel confindent in installing double 15# felt plus ice & watershield along the eveas, gutters and under all vents to prevent leaking. Two of our contaacting bids include double 15# felt with one also having ice and water shield along with the double layers of felt.

Reply:

Thanks

Question: roofer installed felt vertically rather than parallel to eaves

(Feb 10, 2014) Jenn Bullington said:

I live in Albany, New York and recently had a new roof put on my house. It has come to my attention (after the fact) that the roofer installed the tar paper/underlayment material vertically rather than horizontally. Is this against code? Is this something that should be addressed with my roofer and should I pursue action before a problem occurs? I'm worried. Thanks!

Reply: Roofing Underlayment SNAFU

I'm not sure building codes describe underlayment positioning, but indirectly that installation probably is in violation of the best practices guides & probably the roofing manufacturer's instructions in that at least all the refs we have show placement parallel to eaves and with upper courses lower edges overlapping lower course top edges.

That said, if the finish roof has been installed this is certainly not a sufficient defect to warrant re-roofing or a tear-off. The felt on a normal asphalt shingle roof installation is not intended to serve as the waterproof barrier - that's the shingle's job.

The felt does cushion the shingles off of the plhywood - which is position independent, and it forms a vapor barrier (most likely not significant) and it affects the roof's fire rating (which is position independent as well). By "position independent" I argue that installing felt underlayment parallel or orthogonal to the house eaves does not affect those functions.

If there were NO felt installed we'd be missing an extra level of "insurance" against water damage from roof leaks following a partial shingle blow-off in a storm. With felt installed orthogonal to the eaves, the efficacy of felt as "leak insurance" would depend on wind direction as well as size of the blow-off: both conditions that could also affect the efficacy of felt even if installed properly, parallel to the eaves.

And in my OPINION, because the felt is punctured thousands of times by the roofing nails that fasten down roof shingles, its ability to protect a home from leaks after the shingles have been installed is reduced significantly anyway.

If we have a high-risk roof for which we want to add real leak protection extending beyond that afforded by the roof covering shingles, we'd cover the roof with an ice-and-water-shield type barrier - a membrane that seals around the nails.

What you should do is give the manufacturer of your roofing shingles a call, speak to the warranty department, and ask if the position of roofing felt as we've discussed affects the shingle warranty. It might. I suspect that roof covering manufacturers are thrilled when a product failure claim can be blamed on improper installation - which is in my opinion often the case.

Put another way, if the roofer was inexperienced or uninformed enough to do something funny with the felt, one wonders what other mistakes were made: improper nailing for example.

(Feb 10, 2014) Jenn said:

Thanks Dan! I'll check into that. I appreciate your help

(Feb 10, 2014) (mod) said:

Let us know if I / we can be of further help, and let me know what the manufacturer says about the felt for your installation.

Don't knock yourself out over this; IMO shingle warranties are not something owner seem to collect upon very easily anyway, and IMO they're at least as much a marketing tool as a product quality promise.

Question: how long can self-adhesive roofing underlayment be left exposed to weather?

(May 3, 2014) Penny Fox. Pennrae2003@yahoo.com said:

My stick on underlayment has been on roof for over a month awaiting shingle s to go on. A brown like substance is running off of roof.

It has been extremely hot and rainy this month. Is the brown stuff glue and is the underlayment not likely to function as well because of the substance that is running off(Glue)?.?

Reply:

Penny, I've seen self adhesive underlayment remain exposed to weather for quite some time in hot weather without harm.

I think we want someone to take a careful lookmat your roof to see what is the source of the brown goop. Keep me posted.

Question: replace underlayment when doing a roof tear-off

(June 9, 2014) Tom Witt said:

I am purchasing a home and during the inspection it was determined the felt paper started 6" above the drip line on 3 steep planes.

What are the implication of this missing felt? And what is the fix, if any. Tom Witt

(June 12, 2014) Diane Dertinger said:

We are getting our shingles replaced due to wind and hail damage. House is 12 yrs old. When having the house re roofed, should the previous underlayment be taken off or left on? Does it matter?

Reply:

I'd replace it. The tear off is going to rip up much of the old felt underlayment.

...

Continue reading at ROOFING FELT UNDERLAYMENT REQUIREMENTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

ROOFING UNDERLAYMENT BEST PRACTICES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - "The Uses and Performance Requirements of Steep-Slope Roof Underlays in North America and the United Kingdom", Robert J. Booth, Keith Roberts, Proceedings of the North American Conference on Roofing Technology, p. 112-118 - Web Search 07/12/2010. This scholarly article cites 33 research articles on the role of roofing underlayments.

- "Unvented Roofs, Hot-

Humid Climates, and

Asphalt Roofing Shingles

Research Report - 0306

Feb-2003

Building Science Corporation", Building Science Corporation, 30 Forest Street,

Somerville, MA 02143

Quoting from the article abstract: "When constructing unvented roofs with asphalt shingles in hot-humid climates, a vapor barrier must be installed between the asphalt shingles and the roof deck." - Web Search 5/21/2010 - NRCA Roofing & Waterproofing Manual, 5th Edition, National Roofing Contractors Association, 10255 W. Higgins Road Suite 600 Rosemont, IL 60018-5607 Telephone: (847) 299-9070 Toll Free: (866) ASK-NRCA (275-6722), e-mail: info@nrca.net. - http://www.nrca.net/rp/pubstore/details.aspx?id=243&c=9

- Asphalt Shingle Roofing [Inspection & Installation Guide], Coon Rapids Minnesota, Coon Rapids City Hall 11155 Robinson Drive Coon Rapids, MN 55433 763-755-2880, - Web search 07/12/2010 City Website - http://www.ci.coon-rapids.mn.us/ Contact the City of Coon Rapids at 763-755-2880

- Oakridge Pro30™ shingle installation instructions for Owens Corning Oakridge® PRO 30™ fiber glass-based asphalt shingles - Web Search 07/12/2010

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.