Shingle Roof Snapping, Popping, Flapping Noises

Shingle Roof Snapping, Popping, Flapping Noises

Diagnose & fix loose shingles flapped by wind

- POST a QUESTION or COMMENT about building roof noise

Flapping shingles in windy conditions can produce a variety of sounds described as flapping, popping, snapping, and on occasion moaning and howling as well.

Here we describe the diagnosis and cure of noises traced to wind uplift of loose asphalt shingles: to avoid a roof leak, find and fix these before the shingles break off.

These articles discuss building noise control: how to inspect, diagnose & cure noise or sound problems in homes or commercial buildings.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Shingle Noises: Wind-Lift Causes Flapping Shingles

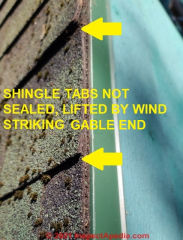

At the lakeside Minnesota cabin shown in these photos we heard a flapping, popping, snapping sound that occurred when wind was blowing off of Lake Superior.

A quick inspection by our partner J.C. during windy conditions revealed a remarkable amount of shingle tab flapping up and down as wind gusts struck the gable end of the cabin facing the oncoming wind.

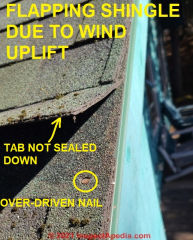

Our photos above show the flapping shingle at rest and during wind up-lift. (We waited for a warm, dry winter Minnesota day - just above freezing, to climb onto the roof to inspect and repair these noisy shingles.)

Watch out: flapping loose asphalt shingles eventually break off entirely and blow or fall off of the roof or slide down to show a missing shingle. At that point there is a risk of leaks into the roof structure.

Incidentally, check that roofing nail in our second photo above and you may notice that it was over-driven, cutting into the shingle surface. This is an improper installation detail that increases the risk of loss of roofing shingles under windy conditions and as the roof ages.

Watch out: flapping loose asphalt shingles eventually break off entirely and blow or fall off of the roof or slide down to show a missing shingle. At that point there is a risk of leaks into the roof structure.

We inspected below the loose shingles to see if the course below was near breaking-off. Some shingles could be lifted easily but if do this with care and don't lift more than necessary - so as not to break off the asphalt shingle tab.

Even though the asphalt shingle roof was more than a decade old, shingles along the cabin eaves were so shaded by nearby trees that the sun and heat-activated self-sealing tabs under the shingles had never succeeded in sealing all of the shingles to the course below.

About a third of the asphalt shingles along the lakeside eaves of this building were not sealed down, but one shingle was particularly loose and lifted several inches at each gust of wind.

Again working carefully to avoid breaking a shingle tab, we lifted the (also not-sealed-down) asphalt shingle tab just above loud flapper, so as to show that the shingle with the most flapping movement had actually cracked and was near the point of breaking-off. [Photo below]

Our repair included both sealing the crack along the almost-broken-off asphalt shingle (to reduce the risk of leaks there). Normally I'd just put a couple of dabs below the shingle tab to seal it down, leaving space for any wind-blown rain under the tab to drain out onto the upper surface of the shingle course below.

But in the photo below we were sealing the entire length of the opening in cracked leaky shingle that had flapped up and down so much as to nearly break itself free of the roof.

Inspecting the rest of the shingles along the gable end by gently lifting to see which ones were not adhered down, we sealed each remaining loose shingle tab down to the course below.

We also tested to be sure that our sealant was in fact adhering well to the shingle surfaces [photo below].

Normally we would use a conventional asphalt-based roofing mastic for this repair, but because the repair was being made during cold Minnesota winter weather, we used a silicone sealant that was rated for cold weather application.

Watch out: notice in the photo above that I'm using a flat-bladed putty knife to lift the shingle just enough to insert the sealant below the tab. To avoid breaking off older asphalt roof shingles during this repair, work on the warmest day you can and avoid lifting the tab any higher than necessary to insert the sealant.

Along the gable end of this roof my preferred location for applying sealant is illustrated in the photo below.

Below you can see the roof after our snapping flapping shingle noise repair was complete. Happily we confirmed that in subsequent windy conditions this roof had fallen silent.

Watch out: don't try this repair if the shingles are wet or snow and ice-covered as you're likely to get a poor seal and poor adhesion of the shingle tabs.

...

Continue reading at ROOF NOISE TRANSMISSION - home or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ROOF NOISE TRANSMISSION - home

- CATALOG of ROOF NOISES

- ROOF COVERING MATERIAL ROLE IN NOISES

- METAL ROOF UNDERLAYMENTS

- METAL ROOF PROFILE vs NOISE

- METAL ROOF FASTENERS vs NOISE

- METAL ROOF NOISE REDUCTION MEASURES

- ROOF IMPACT NOISE: ACORNS ANIMALS HAIL RAIN

- SHINGLE FLAPPING POPPING SNAPPING CAUSE & CURE

- POPPING SNAPPING NOISE DIAGNOSIS

- SOUND TRANSMISSION CLASS STC & OITC

- TRUSS UPLIFT, ROOF

- TEMPERATURE CHANGE & ROOF NOISE

- WIND NOISES ON ROOFS

- POPPING SNAPPING NOISE DIAGNOSIS - includes roof noises

Suggested citation for this web page

SHINGLE FLAPPING POPPING SNAPPING CAUSE & CURE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ACGIH "A Guide For the Control of Audible Sound Hazards" 1st Ed., ACGIH, American Conference of Government Industrial Hygienists, Threshold Limit Value for Physical Agents Committee, (2020) Website: acgih.org

- Acoustical Society of AmericaElaine Moran, ASA Office Manager, Suite 1NO1, 2 Huntington Quadrangle, Melville, NY 11747-4502 516) 576-2360, FAX: (516) 576-2377 email: asa@aip.org. - http://asa.aip.org/standards/s_development.html - ASA is an excellent source of noise and sound standards.

- ANSI/ASA S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools, 2002.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Developments in Noise Control, [PDF] NRCC, National Research Council, Canada, suggestions for noise control, sound transmission through block walls, plumbing noise control, noise leaks, and sound control advice. Web search 01/17/2011, original source: https://www.nrc-cnrc.gc.ca/eng/ibp/irc/bsi/90-noise-control.html

- Thanks to audiologist Cheryl P. Harllee, licensed hearing specialist, for discussing noises and noise problems in preparation for this article. Ms. Harllee can be located at the Village Hearing Center, 249 U.S. Highway One, Tequesta FL 33469 561-744-0231

- Thanks to reader Sue Hazeldine, from the U.K. for discussing how she tracked down a whistling chimney noise to an antique hanging sign on the building exterior - 01/19/2010.

- Thanks to reader Michael Anderson, 8 May 2009, for discussing clicking sounds coming from air conditioning equipment.

- Thanks to reader Erna Ross who described loss of sleep due to a hissing noise at her home 06/15/2008.

- Sound Oasis sound conditioners are produced by Sound Oasis: http://www.sound-oasis.com/ email: info@sound-oasis.com or 1-866-625-3218

- "Measurement of Highway-Related Noise", US Department of Transportation, Federal Highway Administration, http://www.fhwa.dot.gov/environment/noise/measure/chap8.htm

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.