Gas Water Heater Vent Codes & Standards

Gas Water Heater Vent Codes & Standards

15 water heater venting checkpoints

- POST a QUESTION or COMMENT about proper venting and chimneys for gas fired water heaters

Venting requirements for gas-fueled water heaters:

This article outlines 15 key gas fired water heater flue-ventilation safety checkpoints for both LPG or propane and natural gas.

We include building code citations for gas water heater venting and we quote excerpts from manufacturers' water heater installation manuals, U.S. and Canadian model building codes, and other sources and water heater venting standards.

We also illustrate improper and unsafe gas fired water heater venting installations.

The natural gas fueled water heater shown at page top is improperly vented, lacking the recommended minimum 12" of vertical rise before the elbow and vented directly into a large masonry flue where it cannot develop adequate draft. This heater installation may be unsafe.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Proper & Safe Exhaust Vent Codes & Standards for Gas Fired Water Heaters

Summary of Good Venting Practices for Gas Fired Water Heaters

Summary of Good Venting Practices for Gas Fired Water Heaters

Water heaters must be vented using a listed and approved venting system that provides adequate size, height, and draft.

Otherwise such vents may be unsafe, venting combustion products, including dangerous carbon monoxide, into the building.

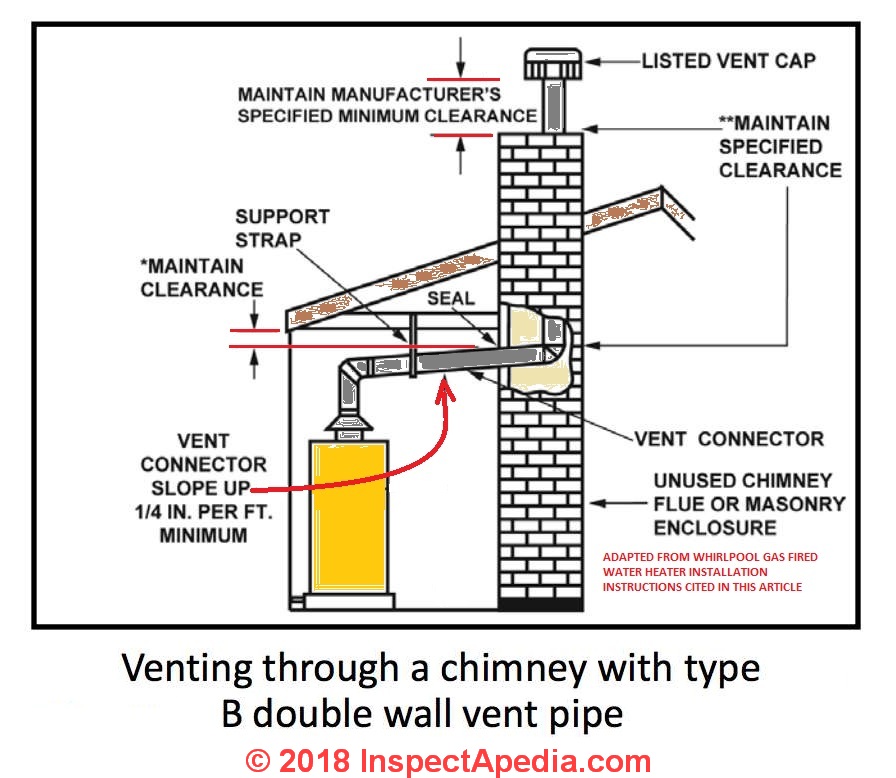

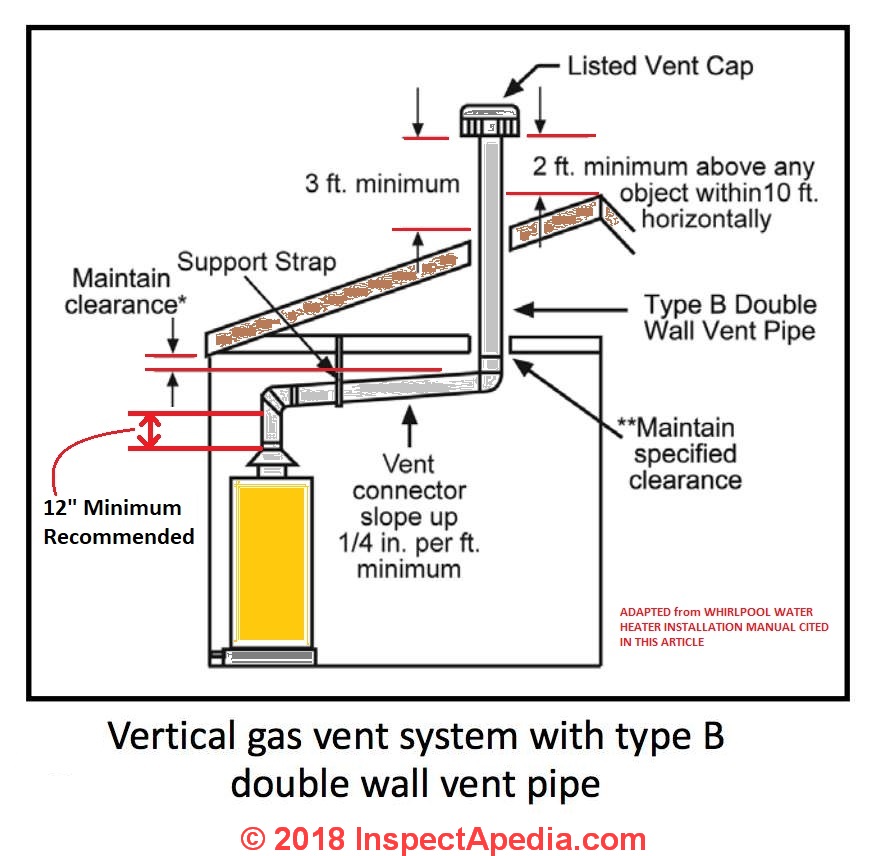

Illustrations of proper gas fired water heater venting using Type B- double wall vent pipe through a roof (above) or through a chimney (below on this page) include details for the flue vent connector such as the requirement of a minimum vent connector upwards slope of 1/4" per foot of horizontal run.

These illustrations are adapted

from WHIRLPOOL RESIDENTIAL GAS WATER HEATER MANUAL [PDF] (2015) retrieved 2018/03/05, original source: http://www.whirlpoolwaterheaters.com/media/99595/100263111.pdf

[Click to enlarge any image]

Watch out: regarding these clearances, see

the SAFE GAS B-VENT CLEARANCE DISTANCES CLARIFICATION by Charles Buell near the end of this article.

- Watch out: Carbon Monoxide Hazard.

Gas fired water heaters like those illustrated here must be supplied with adequate combustion air and the heater's exhaust gases must be vented to outdoors.

Failure to properly vent a gas-fueled water heater can result in severe injury or death from carbon monoxide poisoning.

The vent system must be installed by a qualified person. Examples of a qualified person include gas technicians, authorized gas company personnel, and authorized service technicians. - Carbon Monoxide Detector(s):

To reduce the risk of carbon monoxide poisoning, install a fuel gas and carbon monoxide detector. Install and maintain the detector in accordance with the manufacturer’s instructions and local codes.

Review the location of the CO detector to be sure that it will protect building occupants. More information:

CO DETECTION OPTIONS - Clearance to combustibles:

for gas fired water heater vents: 6" minimum clearance from single-wall vent pipe or flue-vent connector to any combustible material.

Single wall vent pipes cannot pass through a ceiling, floor, firewall, or wall. [An exception is made for non-combustible walls such as solid masonry or concrete.]

Clearances for double-walled B-vent piping are given by the manufacturer and can be found also

at TYPE B-VENT CEILING FLOOR WALL CLEARANCES. Typically a double-walled metal B-vent chimney section is stamped as requiring 1-inch clearance to combustibles.

If you cannot meet the 1-inch B-vent clearance you may be able to use a zero-clearance chimney material. More information:

CLASS A CHIMNEYS, MetalBestos™ - Code compliance:

The vent system for a gas fired water heater must be installed according to local and state codes, or in the absence of local or state codes, the current edition of

the NATIONAL FUEL GAS CODE, ANSI Z223.1 (NFPA 54) [link to 2012 edition]. - Draft hood:

use the manufacturer-provided draft hood. Don't omit it as shown in the photo below.

- Draft hood connection to flue vent connector:

provide at least 12" vertical inches of flue vent between the draft hood outlet and the first elbow or sloping flue vent connector.

This is a manufacturer-recommended detail to improve the flow of exhaust gases [we have not found this in the model codes].

But in effect this 12-inch rise before the first elbow is a building code requirement because the model and adopted building codes require that the installation follow the manufacturer's installation instructions.

See details at BUILDING CODE REQUIREMENT to FOLLOW MANUFACTURER'S INSTRUCTIONS - Horizontal flue vent connection length & slope:

Horizontal distance:

no more than 75% of total vertical height of the entire chimney assembly

Horizontal slope:

no less than 1/4" per foot upwards slope per foot of horizontal run.

A portion of the vent pipe (up to 75% of the total vertical height) can be horizontal, but the termination must be vertical. For the horizontal section, install without dips or sags with an upward slope of at least ¼ inch per foot. Install pipe avoiding unnecessary bends.

Pipe joints must be fastened

by sheet metal screws or other approved means.

Support the flue vent pipe

to maintain clearances and to avoid separation of joints or other damage.

Vent pipe must be accessible

for cleaning, inspection, and replacement. Running vent piping through a concealed space or inaccessible space is improper and unsafe. - Existing Vents: If using an existing venting system:

Inspect the existing vent system for obstructions, corrosion, and proper installation. Repair or replace the existing flue vent connectors and chimney components if necessary.

The existing vent system must be UL listed Type B double wall or single wall metal vent pipe of either 3 inch or 4 inch diameter and installed according to the vent manufacturer’s instructions and the terms of its listing.

More information: B-VENT CHIMNEYS.

Do not use other materials such as dryer vent hose.

Local codes may be more restrictive and may not allow single wall vent pipe.

Single-wall vent pipe cannot be used for water heaters located in attics

and may not pass through attic spaces, crawl spaces, or any confined or inaccessible location.

Single-wall vent pipe cannot pass through any interior wall.

[Exceptions may be made for non-combustible walls such as solid masonry].

- Power Vent Sharing - Common Venting: Do not share a power-vented-appliance flue:

Do not common vent a natural-draft gas fueled water heater with any power vented appliance.

The sketches below, adapted from the Whirlpool installation guide we have cited, are examples of vent pipe system installations and may or may not be suitable for your specific application.

Consult the NATIONAL FUEL GAS CODE, ANSI Z223.1 (NFPA 54) [link to 2012 edition], a current edition and your local building & fire codes.

[Click to enlarge any image]

- Venting through existing chimney: [Illustration above]

An unused chimney flue or masonry enclosure may be used as a passageway for the installation of the water heater vent pipe.

Watch out: Before connecting a vent to a chimney,

make sure the chimney passageway is clear and free of obstructions. The chimney must be cleaned if previously used for venting solid fuel appliances or fireplaces.

Also consult local and state codes for proper chimney sizing and application or, in the absence of local and state codes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-current edition.

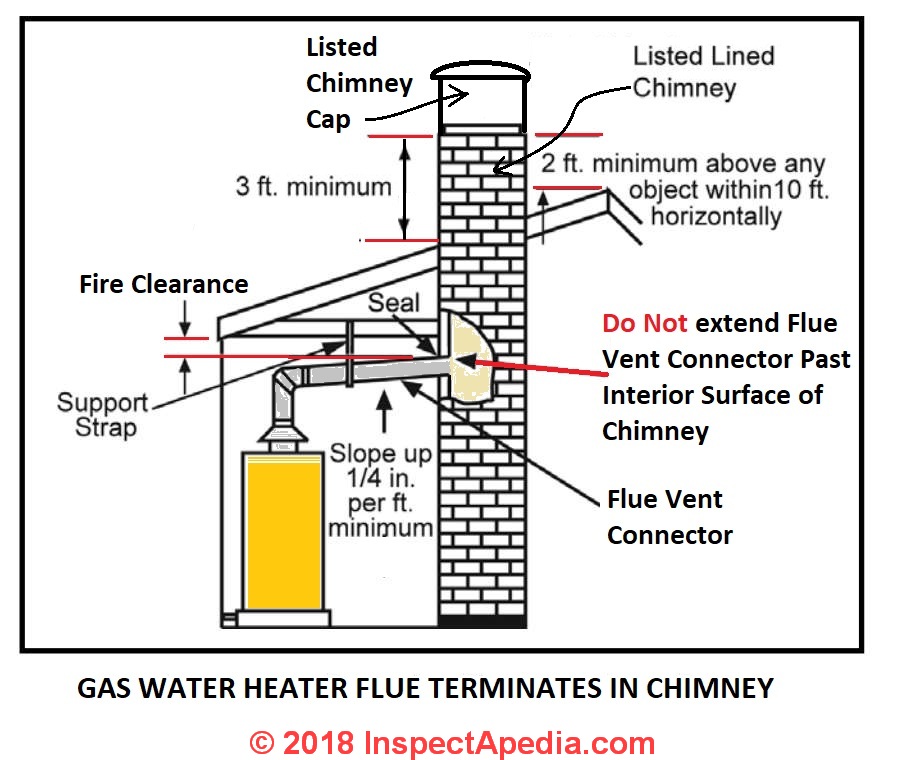

- Termination of flue vent connector at an existing chimney: [Illustration above].

This item refers to terminating the flue vent connector for the water heater right in the chimney, without extending the vent upwards through the chimney interior, relying instead on the existing chimney flue.

This item refers to terminating the flue vent connector for the water heater right in the chimney, without extending the vent upwards through the chimney interior, relying instead on the existing chimney flue.

If local codes allow, some [manufacturer specified models] gas-fueled water heaters may be terminated into an existing chimney using the instructions below.

Otherwise, this water heater’s vent must terminate vertically (sidewall or other horizontal terminations are not allowed).

Watch out: Do not terminate the vent pipe in a chimney that has not been certified for this purpose.

Some local codes may prohibit the termination of vent connectors in a masonry chimney. [We warn about this just below].

Common (combined) venting is allowable with vertical Type B vent systems and lined masonry chimneys as long as proper draft for the water heater is established under all conditions of operation.

As you can see in this photo, this gas-fueled water heater vent was installed without the manufacturer-recommended 12" vertical rise in the flue vent connector before the first elbow.

Below we show a close-up of heat damage around the draft hood of a gas-fueled water heater installed in a Minneapolis home.

As the homeowner pointed out, that's because this water heater is essentially TOO TALL for this LOCATION [photo of the entire Rheem gas-fired water heater below a low ceiling].

But in our OPINION even with a 12" vertical rise this heater would not vent adequately because it is directly-vented into a large, otherwise unused masonry flue.

But in our OPINION even with a 12" vertical rise this heater would not vent adequately because it is directly-vented into a large, otherwise unused masonry flue. Watch out: in our experience and opinion, the direct termination of a gas fired water heater into a large masonry flue, as illustrated just above, is likely to give serious venting problems, particularly in cold weather when the heater is the only appliance venting into the chimney.

The lower-BTUH of a gas water heater (compared with a heating furnace or boiler) will very often be unable to heat the chimney interior sufficiently to develop a draft.

The result is a back-draft of combustion products out of the water heater's draft hood and into the building.

Such installations are potentially unsafe and risk carbon monoxide poisoning.

See CARBON MONOXIDE - CO.

Do not install the flue vent connector from the water heater into the very bottom of a chimney.

The vent pipe must be installed above the extreme bottom of the chimney to prevent potentially blocking the flue gases.

The vent pipe must be firmly attached and sealed where it enters the chimney

in order to prevent it from falling out, to prevent air leaks into the chimney - reducing the effective draft, and to prevent flue gas leaks out of the chimney. To aid in removing the vent pipe, a thimble or slip joint may be used.

The vent pipe must not extend beyond the inner edge of the chimney a

s it may restrict the space between it and the opposite wall of the chimney.

- OK to vent into a shared B-vent chimney?

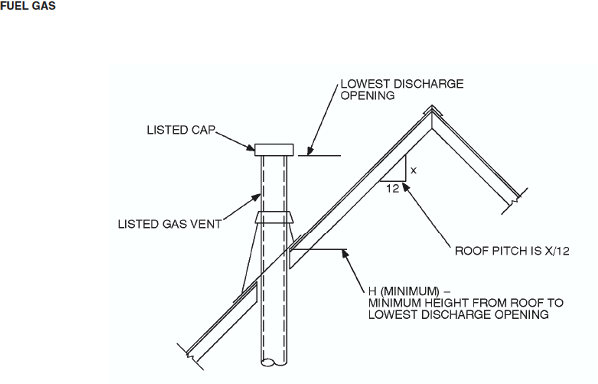

Common (combined) venting is allowable with vertical Type B vent systems and lined masonry chimneys as long as proper draft for the water heater is established under all conditions of operation. Do not common vent this water heater with any power vented appliance. - Vertical Termination with Listed Chimney Cap:

The gas vent must be terminated in a vertical position to facilitate the removal of exhaust gases.

Vertical exhaust vents must terminate with a listed cap or other roof assembly and be installed according to their manufacturer’s instructions. - Vent dampers: Do not install a vent damper

anywhere in the venting system of natural draft gas fueled water heaters.

Gas Fired Water Heater Chimney Codes in the U.S.

See the National Fuel Gas Code, Chapter 24, Fuel Gas, that includes discussion of venting requirements in Section G2427 p. 360, Venting of Equipment

(cited at the end of this page).

See the National Fuel Gas Code, Chapter 24, Fuel Gas, that includes discussion of venting requirements in Section G2427 p. 360, Venting of Equipment

(cited at the end of this page).

G2427.3 (503.3) Design and construction. A venting system shall be designed and constructed so as to develop a positive flow adequate to remove flue or vent gases to the outdoor atmosphere.

G2427.6.5 (503.6.6) Gas vent termination. A gas vent shall terminate in accordance with one of the following:

1. Above the roof surface with a listed cap or listed roof assembly. Gas vents 12 inches (305 mm) in size or smaller with listed caps shall be permitted to be terminated in accordance with Figure G2427.6.5, provided that such vents are at least 8 feet (2438 mm) from a vertical wall or similar obstruction.

All other gas vents shall terminate not less than 2 feet (610 mm) above the highest point where they pass through the roof and at least 2 feet (610 mm) higher than any portion of a building within 10 feet (3048 mm).

G2427.7.3 (503.7.3) Termination. Single-wall metal pipe shall terminate at least 5 feet (1524 mm) in vertical height above the highest connected equipment draft hood outlet or flue collar.

Single-wall metal pipe shall extend at least 2 feet (610 mm) above the highest point where it passes through a roof of a building and at least 2 feet (610 mm) higher than any portion of a building within a horizontal distance of 10 feet (3048 mm).

(See Figure G2427.5.) An approved cap or roof assembly shall be attached to the terminus of a single-wall metal pipe. [Also see Section G2427.7.8, Item 3.]

G2427.7.6 (503.7.6) Installation. Single-wall metal pipe shall not originate in any unoccupied attic or concealed space and shall not pass through any attic, inside wall, concealed space or floor.

The installation of a single-wall metal pipe through an exterior combustible all shall comply with Section G2427.10.15.

G2427.7.10 (503.7.10) Termination capacity. The vent cap or a roof assembly shall have a venting capacity not less than that of the pipe to which it is attached.

Gas Fired Water Heating Venting Standards for Canada

See Chapter 7 beginning at page 152 and also see "Combustion Spillage" beginning on p. 160 in this example code: B149.1HB-00 Natural Gas and Propane Installation Code Handbook

Excerpt:

Gas appliances may be vented to either a chimney flue or a certified vent or factory-built chimney.

When vents are used, they must be certified to the applicable standard and bear a label that indicates that they have been so tested and approved.

It is important not to remove these labels in order to enable field inspection. In the case of Type B or Type L vents, each length extending above the roof line must be certified for exterior use and so identified.

Excerpt:

7.14.4 A chimney shall extend not less than 3 ft (900 mm) above the highest point where it passes through the roof of a building and not less than 2 ft (600 mm) higher than any portion of a building within a horizontal distance of 10 ft (3 m).

Nowhere in these standards is there an acceptance of a short-rise, horizontally-vented, dryer-vent flapper capped or painted-screen-capped water heater vent termination.

Side-wall vented appliances, without exception, make use of some form of power exhaust, never simply atmospheric exhaust. Such vent exits and terminations, if your water heaters were power-vented, cannot be obstructed and must use a listed (approved) termination cap or cover.

Excerpting from GAS FIRED WATER HEATERS - home

Check for proper exhaust venting of combustion products from your gas fired water heater.

Gas-Fired Water Heater Chimney & Vent Codes, Guides, Standards

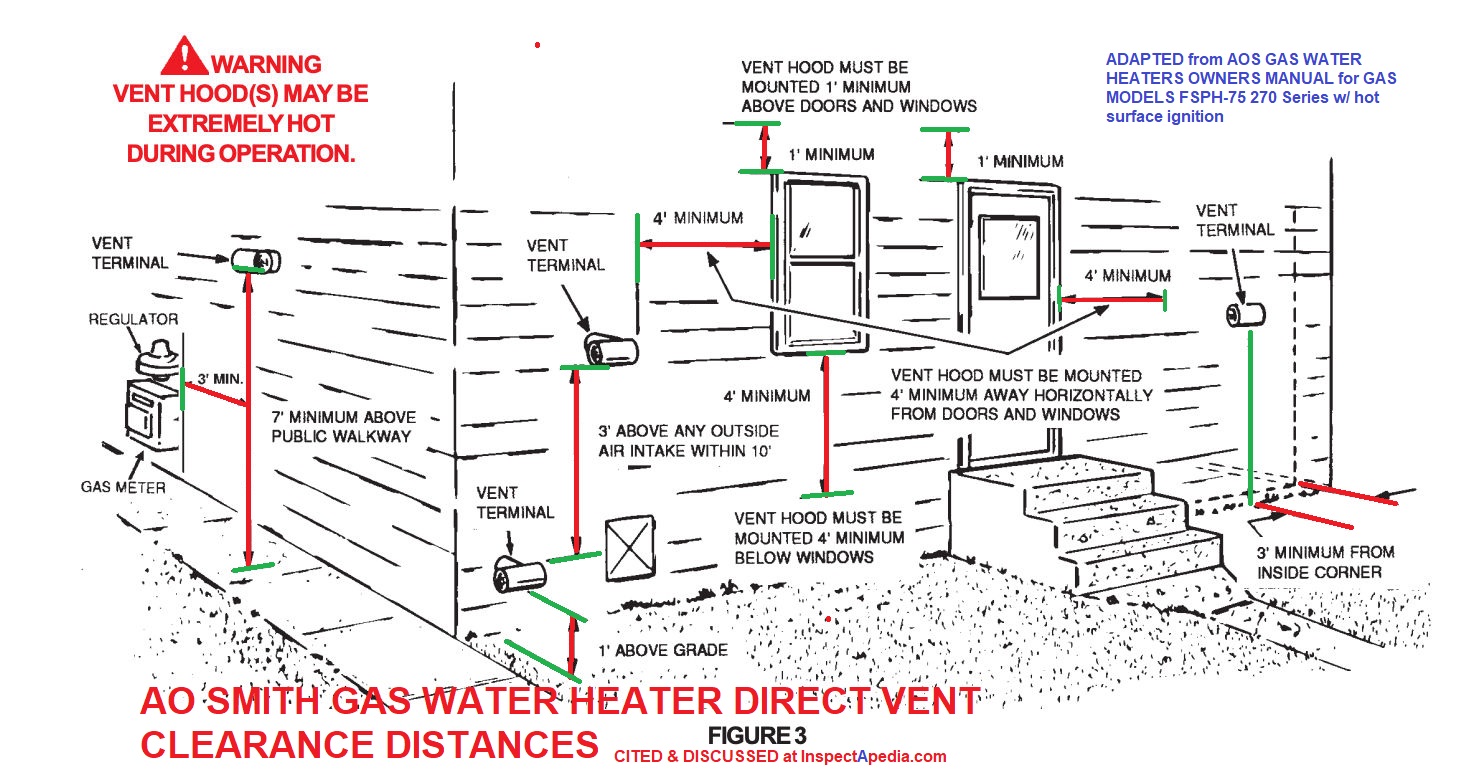

Above: Gas water heater direct vent clearance distances, adapted from AO Smith's Gas Water Heater's Owners Manual for Gas Models FSPH-75 270 series, cited at WATER HEATER AGE & MANUALS - for all brands.

[Click to enlarge any image]

For more details see the citations below as well as these gas water heater venting guides:

Gas Water Heater Calorifer Geyser Cylinder Codes & Guides

- Canada: B149.1HB-00 Natural Gas and Propane Installation Code Handbook [PDF] (2000) retrieved 2018/02/09, original source: http://www.tagengineering.ca/wp-content/uploads/2015/02/B149-1handbook.pdf

- Canada: CSA Standard B149.1-10 Natural Gas and Propane Installation Code [PDF] (2010) retrieved 2018/02/09, source: http://www.enefen.com/images/previews-CSA_B149.1-10_pre.pdf

- AMERICAN WATER HEATER VENT DETAILS [Illustration] retrieved 2018/02/09,

- BOCK WATER HEATERS, ENGINEERING MANUAL [PDF] retrieved 2018/03/05, original source: http://www.bockwaterheaters.com/Portals/0/Engineering%20Manuals/BWH-Eng%20Man_3-13-Web.pdf

Excerpts, p. 28

The purpose of venting a gas or oil-fired water heater is to completely remove all products of combustion and to vent gasses to the outside air without condensation in the vent or spillage at the draft hood (except in cases of downdraft or poor stack conditions).

To assure correct venting, use a strong, gas-tight insulated pipe with a cross section equal to that of the flue collar or draft hood outlet and of sufficient vertical height.

During vent installation, avoid sharp turns, long horizontal runs and improper pitches. Maintain proper support of vent connectors and joints, observe clearances from all combustibles, and top the vent outlet with an approved cap.

Type “L” vent is double walled vent. Type “L” is stainless lined and used for oil and Power Gas heaters. Type “B”, due to its temperature rating, can only be used with atmospheric gas water heaters.

All venting installations must conform with local codes. In the absence of local codes, refer to “National Fuel Gas Code” NFPA 54 and “Standard for the Installation of Oil-burning Equipment” NFPA 31 (Tables 21-33 are based on NFPA 54). - BRADFORD WHITE GAS FIRED WATER HEATERS [PDF], retrieved 2018/02/09, original source: http://www.bradfordwhite.com/sites/default/files/product_literature/238-44219-00G.pdf

- STATE GAS WATER HEATER INSTRUCTION MANUAL [PDF] retrieved 2018/02/09,

- U.S. NATIONAL FUEL GAS CODE CHAPTER 24 [PDF], retrieved 2018/02/09,

Excerpt:

G2401.1 (101.2) Application. This chapter covers those fuel-gas piping systems, fuel-gas utilization equipment and related accessories, venting systems and combustion air configurations most commonly encountered in the construction of one- and two family dwellings and structures regulated by this code. - WATER HEATER AGE & MANUALS - for all brands

- More citations and documents are atReferences or Citations

Examples of Improper & Unsafe Gas-Fueled Water Heater Chimneys & Vents

This discussion has moved to its own page

at GAS FIRED WATER HEATER UNSAFE VENT

...

...

Continue reading at GAS FIRED WATER HEATER CHIMNEY & VENTING DEFECTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

GAS FIRED WATER HEATER VENTING CODE FAQs - questions & answers posted originally on this page.

Or see these

Recommended Articles

- CHIMNEY CODES & STANDARDS

- CHIMNEY HEIGHT & CLEARANCE CODE

- DRAFT REGULATORS / HOODS GAS HEATERS

- GAS APPLIANCE / HEATER DIRECT VENT CLEARANCES

- GAS FIRED WATER HEATERS - home

- GAS FIRED WATER HEATER CHIMNEY & VENTING DEFECTS

- GAS FIRED WATER HEATER VENTING CODES

- GAS FIRED WATER HEATER VENT UNSAFE

- GAS HEATERS, HIGH EFFICIENCY

- HEIGHT REQUIRED for L VENTS & B VENTS

- METAL CHIMNEYS & FLUES - home

- METAL CHIMNEY INSTALLATION MANUALS

- TYPE B-VENT CHIMNEYS

- TYPE B-VENT ROOFTOP CLEARANCE

- TYPE L VENT CHIMNEYS

- WATER HEATER AGE & MANUALS - for all brands

Suggested citation for this web page

GAS FIRED WATER HEATER VENTING CODES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER HEATERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- GAMA - Gas Appliance Manufacturers' Association has prepared venting tables for Category I draft hood equipped central furnaces as well as fan-assisted combustion system central furnaces.

- National Fuel Gas Code, an American National Standard, 4th ed. 1988 (newer edition is available) Secretariats, American Gas Association (AGA), 1515 Wilson Blvd., Arlington VA22209, and National Fire Protection Association (NFPA), Batterymarch Park, Quincy MA 02269. ANSI Z223.1-1988 - NFPA 54-1988. WARNING: be sure to check clearances and other safety guidelines in the latest edition of these standards.

- Fire Inspector Guidebook, A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- Uniform Mechanical Code - UMC 1991, Sec 913 (a.) Masonry Chimneys, refers to Chapters 23, 29, and 37 of the Building Code.

- New York 1984 Uniform Fire Prevention and Building Code, Article 10, Heating, Ventilating, and Air Conditioning Requirements

- New York 1979 Uniform Fire Prevention & Building Code, The "requirement" for 8" of solid masonry OR for use of a flue liner was listed in the One and Two Family Dwelling Code for New York, in 1979, in Chapter 9, Chimneys and Fireplaces, New York 1979 Building and Fire Prevention Code:

- "Chimneys and Vents," Mark J. Reinmiller, P.E., ASHI Technical Journal, Vol. 1 No. 2 July 1991 p. 34-38.

- "Chimneys and Vents", 789 CMR 68.00 Massachusetts Building Code, web search 10/15/2010, original source:

http://www.mass.gov/Eeops/docs/dps/780%20CMR/780068.pdf 03/23/2007

780 CMR: STATE BOARD OF BUILDING REGULATIONS AND STANDARDS THE MASSACHUSETTS STATE BUILDING CODE - quoting:

6801.11 Multiple-Appliance Venting Systems. Two or more listed and labeled fossil fuel-fired appliances shall not be connected to a common natural draft venting system unless permitted per applicable requirements of 248 CMR or 527 CMR. For solid fuel-burning appliances, see 780 CMR 6801.12. - Chimneys and Vents, Chapter 18, M1801,model building code - [on file as Code_Chim_Res_C_18.pdf] - widely used by U.S. & Canadian Municipalities,

- Natural Gas Weekly Update: http://tonto.eia.doe.gov/oog/info/ngw/ngupdate.asp Official Energy Statistics from the U.S. Government

- US Energy Administration: Electrical Energy Costs http://www.eia.doe.gov/fuelelectric.html

- NFPA 211 - 3-1.10 - Relining guide for chimneys

- NFPA 211 - 3-2 - Construction of Masonry Chimneys

- NFPA 211 - 3-3 - Termination Height for chimneys

- NFPA 211 - 3-4 - Clearance from Combustible Material

- NFPA 54 - 7-1 - Venting of Equipment into chimneys

- Brick Institute of America - Flashing Chimneys

Brick Institute of America - Proper Chimney Crowns

Brick Institute of America - Moisture Resistance of Brick - American Gas Association - New Vent Sizing Tables

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.