Electrical Wire Insulation Stripping Procedure

Electrical Wire Insulation Stripping Procedure

How to properly remove insulation from electrical wires when making connections to devices

- POST a QUESTION or COMMENT about how to install and wire electrical outlets or receptacles in buildings.

How to strip insulation from electrical wires when wiring a light switch or electrical receptacle.

Here we explain how much insulation to remove and to avoid damaging the electrical wire when preparing wires for connections to receptacles or switches.

This article series describes how to choose, locate, and wire an electrical receptacle in a home. Electrical receptacles (also called electrical outlets or "plugs" or "sockets") are simple devices that are easy to install, but there are details to get right if you want to be safe.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How Much Insulation to Strip Off of the Electrical Wire?

If the wire insulation is stripped the perfect amount then after it has been inserted into the clamp or wrapped around the screw you'll see that no wire insulation is under the connector itself, but little or no bare wire is exposed past the edges of the connector.

Above our white wire was stripped correctly - the stripped end was pushed into the clamp until it stopped, and the screw was tightened against bare copper, but just about 1/16" or less of bare copper shows above the screw (photo shown above left).

Our black wire was stripped too much (photo above-right) and some unnecessary bare copper remains exposed after the screw was tightened.

If you going to wrap the electrical wire around the terminal screw on the electrical receptacle (or a light switch terminal) you need to strip back a bit more than 1/2-inch in order to have enough copper to go around the screw leaving no insulation under the screw head when it is tightened.

Our photo (left) shows the strip gauge marked on the edge of our receptacle - those two parallel lines cast into the black plastic housing just below our stripped-back white wire.

Readers of this article should also

see ELECTRICAL CODE BASICS, ELECTRICAL DEFINITIONS.

This website provides information about a variety of electrical hazards in buildings, with articles focused on the inspection, detection, and reporting of electrical hazards and on proper electrical repair methods for unsafe electrical conditions. Critique and content suggestions are invited. Credit is given to content editors and contributors.

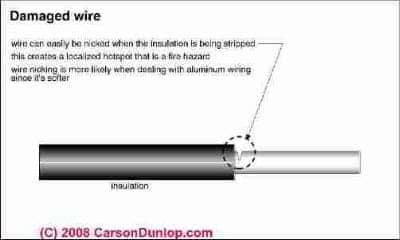

Nicks in Stripped Electrical Wires Make a Bad Connection & Risks Broken Wires

Don't damage electrical wires by nicking them: When installing, securing, or stripping insulation from wiring in order to make a connection, the wire and its insulation must not be nicked or damaged, as we show in the sketch at left, courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ]. Why?

Ultimately nicked electrical wires are far more likely to actually break off completely.

The risk of breakage is increased at an electrical receptacle (compared with say a light fixture) because repeated insertion and removal of wall plugs from the receptacle device itself tend to jiggle the device around in its mount, moving the wires connected to it, flexing them, and breaking at nicks.

Nicked electrical wires may also break off when the device is being pushed back into the electrical box.

Finally, where the available free length of an electrical wire inside of an electrical box is already short, you'll be very sorry if you nick the wire end and later break it off, making the remaining wire shorter still.

Ground Wire Stripping & Paper Removal

Typically the ground wire is bare of plastic insulation, but it may be necessary to remove paper around the wire before connecting it. We like to remove all of the paper around the ground wire rather than leave electro-kindling inside the junction box.

In our photo, left, I've pushed the paper off of the ground wire - but have not yet torn it away from the assembly.

If there is more than one feeder wire entering the electrical junction box then all of the grounds are connected together as well as being connected to the ground screw on the receptacle itself. Special crimp-on connectors are used by professionals to join multiple ground wires in the electrical box, but it is also permitted to use a twist-on connector (which takes more space).

If the junction box is plastic, you're done.

If the junction box is metal, a ground wire is also connected to the metal box using an approved grounding screw or clamp device to tie the wire end to the box.

Most metal electrical boxes have a threaded hole intended for use as a connection point for the ground wire connecting screw, as illustrated in our photograph (left).

Details about how to wire up an electrical receptacle are

at ELECTRICAL RECEPTACLE CONNECTION DETAILS - where to connect black, white, red, green, ground wires.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: armor around wire through concrete?

I am running a new 15A outlet into the back of a bookcase in a 50 year old house with updated electrical. The wire runs out the back of the retrofit box and down through the concrete foundation into the crawlspace to a wire I plan to splice into. Do I need to put armor around the wire run through the foundation? It goes through open air for about 2 feet and there is no way to secure it to anything.

Thanks!

Tom - 7/19/12

Reply:

You need to look at the type and rating of the electrical wire to determine if it is permitted to bury it in concrete or not.

Question: how do I fix a stripped screw opening in an electrical box?

The little metal tabs to which the electrical outlet screws should mount have holes that have been stripped. Can I just use a sheet metal screw to hold the receptacles in place?

Reply: step by step tips for replacing a stripped electrical receptacle or switch box mounting screw

or screw opening

Julia,

If the problem is the screw itself is stripped, simply purchase a replacement screw or a hand full of them from your electrical supplier. These screws are a standard thread and length, but longer versions are available at any hardware store.

For the case you describe, if the stripped problem is the mounting hole you'll need to either enlarge and tap the hole for the next size larger screw, or purchase a clip-on adapter that slips over the stripped ear through which the original hole passed.

Taking care to move electrical wires out of the way of your drill bit, in a metal electrical box you can drill out the 6/32 screw opening to tap and accept an 8/32 screw.

Watch out: do not just screw a sheet metal screw willy-nilly into any electrical box or component: the pointed tip of the screw can easily penetrate the insulation of an electrical wire in the box, causing a dangerous short circuit.

For photos and step by step details on how to repair stripped electrical outlet mounting screws,

...

Continue reading at ELECTRICAL RECEPTACLE TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ELECTRICAL WIRE STRIPPING TIPS for more deatils about preparing electrical wires for connection to devices.

Suggested citation for this web page

STRIPPING ELECTRICAL WIRES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Aronstein, J., P.E. Ph.D., ELECTRO KINDLING: Easily-Ignited Free-Burning Plastic Materials in Electrial Applications [PDF] (1996)

- Timothy Hemm has provided photographs of various electrical defects used at the InspectAPedia TM Website. Mr. Hemm is a professional electrical inspector in Yucala, CA.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- [3] NFPA - the National Fire Protection Association can be found online at www.nfpa.org

- [4] The NEC National Electrical Code (ISBN 978-0877657903) - NFPA might provide Online Access but you'll need to sign in as a professional or as a visitor)

- US NEC Free Access: See up.codes at this link: https://up.codes/code/nfpa-70-national-electrical-code-2020

- [5] Special thanks to our reader Steve who pointed out prior errors in our illustrations.

- [6] Simpson Strong-Tie, "Code Compliant Repair and Protection Guide for the Installation of Utilities in Wood Frame Construction", web search 5/21/12, original source strongtie.com/ftp/fliers/F-REPRPROTECT09.pdf, [copy on file as /Structures/Framing/Simpson_Framing_Protectors.pdf ]. "The information in this guide is a summary of requirements from the 2003, 2006 and 2009 International Residential Code (IRC), International Building Code (IBC), International Plumbing Code (IPC), International Mechanical Code (IMC), 2006 Uniform Plumbing Code (UPC) and the 2005 National Electrical Code."

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- "Electrical Systems," A Training Manual for Home Inspectors, Alfred L. Alk, American Society of Home Inspectors (ASHI), 1987, available from ASHI. [DF NOTE: I do NOT recommend this obsolete publication, though it was cited in the original Journal article as it contains unsafe inaccuracies]

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.