Electrical Wire Splice Procedure

Electrical Wire Splice Procedure

Step by Step details show how to join electrical wires or make splices

- POST a QUESTION or COMMENT about electrical wiring splices, connections, connectors

Six steps to good electrical wiring splices & connections at electrical boxes or devices:

This article shows how to joint electrical wires using twist-on connectors at an electrical box.

This article series answers most questions about how splices (connections between two or more electrical wires) are made to connect & secure electrical wires together in residential or commercial building electrical wiring systems. We also discuss the use of electrical splices or wiring connectors outside of electrical boxes.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Six Easy Tips for Successful Installation of A Twist On Connector Make a Good Electrical Wire Splice

In making copper wire splices using a twist-on connector you should watch all of the six details we describe and illustrate below.

In making copper wire splices using a twist-on connector you should watch all of the six details we describe and illustrate below.

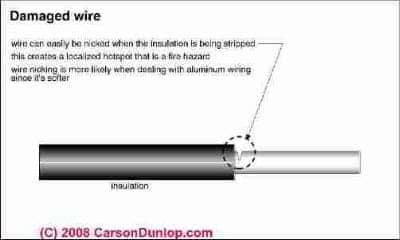

- Cut away damaged or nicked wire ends that might break off, causing a splice failure and a dead circuit or fixture that can be difficult to diagnose later. Sketch provided courtesy of Carson Dunlop Associates, a Toronto home inspection & education & report writing tool company.

- Strip back insulation 3/8" to 7/8" - depending on wire size and connector size

- An Ideal Wingnut 451 requires stripping 3/8"

- An Ideal Wingnut 452 strips to 1/2"

- An Ideal Wingnut 454 Strips off 7/8" of insulation

Watch out: If you don't strip enough insulation the insulation that is up under the twist-on connector cap may prevent a tight electrical connection between the wires even though the connector itself feels "tight" - you'll have a loose connection and flickering lights or overheating or even a fire.

Watch out: if you strip away too much wire insulation you'll see bare wire extending out below the bottom of the twist-on connector - inviting a shock or short circuit.

Also see ELECTRICAL WIRE STRIPPING TIPS

- Be sure the wire ends are straight and un-damaged and of equal length (photo below)

- If one of the wires is a multi-stranded wire such as for a light fixture, let that end extend about 1/8" past the solid wires.

In my photo below I've extended the light-fixture's multi-strand ground wire about 1/8" past the end of the solid copper ground wire before installing the twist-on connector.

- Hold the wires closely together. In my photo below I don't have the white neutral wires fully touching and close together but I'm working on it. Also I need to extend that white multi-strand lamp wire about 1/8" out past the solid copper wires before I start installing the twist on connector.

If the wires are not straight I will use my pliers to make them as straight as I can before inserting them into the twist on connector.

- Twist on the twist-on connector (clockwise) until tight. Some electricians (and I) twist firmly until the wires themselves begin to twist together below the connector.

My photo below shows all three sets of wires connected using orange twist-on connectors: white netural, black or hot wires connected using the twist-on connector, and the light fixture's ground wire connected to my circuit ground.

At ELECTRICAL BOX GROUND WIRING we point out that if this had been a metal electrical box I'd also have had to bond the ground wire to the box itself.

Some electricians, to make a particularly secure connection, perhaps where they feel there is extra risk, also wrap the assembly in electrical tape - a step not discussed in any of the manufacturer's instructions or catalogs we reviewed. I do this too, particularly when working with old house wiring installations.

See complete details on wire spicing given at ELECTRICAL SPLICES, HOW TO MAKE

References on twist on connector or Wire Nut® connector choices, wires, applications

- 3M™ WIRE CONNECTORS, [PDF] Electrical Markets Division 6801 River Place Blvd. Austin, TX 78726-9000 800 245 3573 FAX 800 245 0329 www.3M.com/electrical, (2005)

- Ideal® Wire-Nut® WIRE CONNECTORS, Models, Specifications, [PDF] 18 page catalog with specifications, quantities, features, color-coded wire nut connector models, Ideal Industries, IDEAL Electrical 1375 Park Ave Sycamore, IL 60178 USA, Tel: 800-435-0705 Email:L Ideal@idealindustries.com Website: https://www.idealindustries.com, additional offices in the UK (Anderson Power Products), China, Taiwan, Shenzhen, Casella UK, Casella US, Shanghai, Australia, Brasil, Canada, India, Puerto Rico, Mexico

- Ideal Wire Connector CATALOG, full product line, [PDF] 21 page catalog op. cit.

- Wing-Nut® WIRE CONNECTOR INSTRUCTIONS [PDF], Ideal Corporation, retrieved 2017/07/03, original source: https://www.idealind.com/content/pdfs/instructions/wing-nut-connector-instructions.pdf

- ELECTRICAL SPLICES, HOW TO MAKE - alternative electrical wire splicing devices, methods, tools

On 2017-07-03 by vb - do I have to pre-twist wires before installing a wire-nut?

If you splice 2 number 12 wires in A J Box do they have to be twisted before you put a wire nut On

...

Continue reading at ELECTRICAL SPLICES, HOW TO MAKE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ELECTRICAL SPLICES, HOW TO MAKE

- ELECTRICAL SPLICE WIRING DETAILS

Suggested citation for this web page

ELECTRICAL SPLICE WIRING DETAILS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Timothy Hemm, Yucala, CA, contributed various photographs of electrical equipment installed in California buildings. Mr. Hemm can be contacted at TimHemm@yahoo.com

- NFPA - the National Fire Protection Association can be found online at www.nfpa.org

- The 2008 NEC National Electrical Code (ISBN 978-0877657903) Online Access LINK (you'll need to sign in as a professional or as a visitor)

- The 2008 Residential Wiring Code, a subset of the 2008 NEC, can be understood through Mastering the NEC at http://www.2008nec.com/shopping/pgm-more_information.php?id=18

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- "Electrical Systems," A Training Manual for Home Inspectors, Alfred L. Alk, American Society of Home Inspectors (ASHI), 1987, available from ASHI. [DF NOTE: I do NOT recommend this obsolete publication, though it was cited in the original Journal article as it contains unsafe inaccuracies]

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.