Definition of Flat-Sawn, Quarter-Sawn, Rift-Sawn Lumber

Definition of Flat-Sawn, Quarter-Sawn, Rift-Sawn Lumber

Wood board saw-milling methods

- POST a QUESTION or COMMENT about lumber saw cut methods: how boards are cut from a tree

This article defines the three main patterns from which lumber is sawn or milled from a tree: flatsawn, or plain-sawn, quarter-sawn, and the less-common and still more costly rift-sawn boards.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Wood Board Saw Patterns: Flat-sawn, Quarter-Sawn, Rift-Sawn

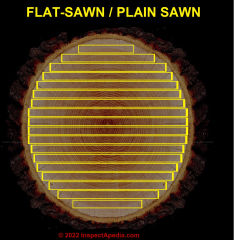

Definition of "flatsawn" or "flat-sawn" or "plain sawn" boards or lumber

A flat-sawn board is cut from a position in a tree such that its wide face is parallel to the growth rings.

A flat-sawn board is cut from a position in a tree such that its wide face is parallel to the growth rings.

[Click to enlarge any image]

Although conditions are different outdoors and indoors, still we find that deck boards as well as wood floor boards and stair treads tend to cup so that there are opposing forces:

- the concave side of the board is towards the board's more dry side, and

- the convex side of the cupped or curved boards tend to be facing the floor's more wet side

- the inherent properties of wood cells tend to make a flatsawn board cup towards the bark side (making that side concave)

Note: Concave means that a structure is cupped upwards at its outer edges and sunken in its center - like a teacup or a soup bowl. This U is concave and could hold a little bit of soup.

Note: Convex means that a structure is curved downwards at its edges and risen in its center. This n is convex like a soup bowl if you flipped it upside down (spilling out all of your soup).

Below we illustrate how plain sawn or flat sawn board are cut from a tree.

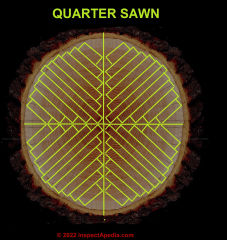

Definition of "quartersawn" boards or lumber

A quarter-sawn board is cut from the tree such that the annular growth rings tend to run nearly vertical between the two faces of the board.

Experts disagree about just how straight up and down between the board faces the growth rings must be, but typically a quartersawn board will have growth rings between 60° - 90° with respect to the board surfaces.

Looking at the end of a quarter-sawn board you'll see that the growth ring are not dead vertical between the two board faces, they may curve and angle slightly from 90°

We found some sources claiming that quartersawn boards can have growth rings at greater angles, such as anywhere between 45° - 90° (Hoadley 2000) with respect to the board surface while a few call for stricter (more vertical) growth rings that are 75° - 90° with respect to the board faces.

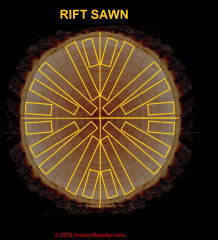

Definition of Rift Sawn Lumber

A rift-sawn board will be cut from the tree so that the growth rings are close to 45° with respect to the board faces and as a result they appear in essence perpendicular or close to 90° to the board faces.

Rift-sawn lumber may be cut so that the growth ring lines are between 30° - 60° with respect to board faces.

Looking at the end of a rift-sawn board you'll see that the growth rings appear almost straight up and down between the board faces.

Rift-sawn boards are considered the most stable and will show the least shrinkage or expansion in response to moisture changes, the least tendency to cup, but are also most expensive to cut from trees as there is more waste-wood produced by this method.

- Our rift-sawn board example below has been adapted from "Rift Sawn White Oak //Quercus alba, described by Woodworkers Source, 18115 N. Black Canyon Hwy Phoenix, AZ, 85023 USA, Tel: 602-504-1931 retrieved 2022/09/20, original source: https://www.woodworkerssource.com/lumber/rift-sawn-white-oak.html

Definition of Concave vs Convex Board Shapes

If you're not sure about cupping direction or the definitions of concave and convex, this U is concave (think "arch down" or think "fruit bowl") and this n is convex (think "arch up" or think "rainbow") - courtesy of James MacQueen Contractors.

A concave board has its outer edges curled upwards while a convex-cupped board has its outer edges curled downwards.

Flat-sawn boards cup more than quarter-sawn boards.

Research on Lumber / Board Saw Mill Cutting Methods & Lumber Milling Pattern History

- Clément, Charles, Rado Gazo, Robert Beauregard, and Torsten Lihra. COMPARISON OF ROUGH MILL YIELD FOR WHITE BIRCH LUMBER BETWEEN A CONVENTIONAL AND A SHORT-LOG SAWMILL [PDF] Forest products journal 55, no. 3 (2005): 71-80.

Abstract:

This study explored the potential use of white birch lumber manufactured at sawmills processing short logs (no more than 8 ft. long).

A database of random width and length white birch boards obtained from a conventional and a short-log sawmill was developed. To analyze the effects of lumber source, grade, cutting bill, and processing method on yield, 5,576 board feet (13.16 m3) of Selects, No.1 Common, and No.2A Common lumber were used.

ROMI-RIP and ROMI-CROSS simulation software were used to model two processing methods, rip-first and crosscut-first, respectively. Four cutting orders, Furniture, Panel, USDA Easy, and USDA Tough were processed in the simulation. Processing of lumber from the conventional sawmill resulted in significantly higher furniture part yields: 8.8 percent for Selects and 10.3 percent for No 2A Common as compared to the yields derived from lumber manufactured at the short-log sawmill.

These differences were explained by:

1) a shorter average length (i.e., the longer conventional-length lumber offers a greater number of part combinations); and

2) the increased presence of wane and void. However, there was little difference in yield, when comparing the No.1 Common part yields obtained from lumber from the short-log and conventional sawmills, with appropriate cutting bills.

Results also indicate that crosscut-first rough milling generates, on average, a 4.2 percent higher yield than rip-first rough milling.

This analysis is of interest to a value-added industry faced with resource scarcity and increasing lumber costs. - Galligan, William L., and Kent A. McDonald. "Machine grading of lumber: practical concerns for lumber producers." Gen. Tech. Rep. FPL–GTR–7 (Revised). Madison, WI: US Department of Agriculture, Forest Service, Forest Products Laboratory. 39 p.: ill.; 28 cm. 7 (2000).

- Harding, O. V., T. F. Shupe, E. T. Choong, and R. H. Mills. "Potential of two processing methods to reduce sweetgum and sassafras lumber defects." Holz als Roh-und Werkstoff 55, no. 6 (1997): 361-364.

Excerpt: … It appears, then, that any reduction of drying defects can be attributed to the drying schedule rather than the milling method. - Kellogg, Royal Shaw. Lumber and its uses. UPC book Company, Incorporated, 1919.

- Popadić, Ranko, Borislav Šoškić, Goran Milić, Nebojša Todorović, and Mladen Furtula. INFLUENCE OF THE SAWING METHOD ON YIELD OF BEECH LOGS WITH RED HEARTWOOD [PDF] Wood Industry/Drvna Industrija 65, no. 1 (2014).

Abstract

The paper presents the research of differences in quantitative and value yields, and structure of sawn timber and residues, whose appearance is caused by different methods of sawing beech logs with red heartwood.

In order to achieve the goal, 45 logs were divided into three even groups and sawn into commercial timber using three methods: round, cant and live sawing. Similar quantitative yields were found for round sawing and cant sawing (60.63 % and 60.52 %, respectively), while a lower result of 56.79 % was observed for live sawing.

Less timber (edged and red heartwood boards) and smaller products were found in live sawing than in other two methods, meaning that live sawing resulted in a lower value yield.

Keywords: beech, sawmill processing, methods of sawing, yield, red heartwood - Smith, R. Geoff B., Graeme Palmer, Martin Davies, and Allie Muneri. A METHOD ENABLING THE RECONSTRUCTION OF INTERNAL FEATURES OF LOGS FROM SAWN LUMBER: THE LOG END TEMPLATE [PDF] Forest products journal 53, no. 11/12 (2003): 95-98.

Abstract:

Knowledge of the internal characteristics of logs enables the optimization of sawn recoveries. This has led to the development of various nondestructive and destructive methods for characterizing interior log features.

The objective of this study was to develop a method for tracking the origin of individual lumber boards through a commercial sawmill, allowing the reconstruction of logs from data gathered from the sawn lumber.

Log end templates were designed that are glued to each log end. After sawing, a portion of the template remains glued to each end of every piece of lumber, from which polar coordinates and a unique log identifier can be read.

This can then be incorporated into a database with grade data such as knot and feature locations, together with tree and stand data.

The method provides an efficient, accurate, robust,and reliable way of tracking boards through a sawmill while the mill operates normally. - Steele, Philip H. Factors determining lumber recovery in sawmilling. Vol. 39. US Department of Agriculture, Forest Service, Forest Products Laboratory, 1984.

- Zuo, Xiaoqiu. Improving lumber cut-up manufacturing efficiency using optimization methods. North Carolina State University, 2003.

...

Continue reading at BARK SIDE UP or DOWN on DECKS & STEPS? or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BARK SIDE UP or DOWN on DECKS & STEPS?

- DECK & PORCH CONSTRUCTION - home

- FLOOR DAMAGE DIAGNOSIS

- FRAMING TABLES, SPANS

- MOISTURE METER CHOICES

- WOOD CUPPING vs WET SIDE

- WOOD FLOOR DAMAGE

- WOOD FLOOR MOISTURE

Suggested citation for this web page

LUMBER SAWING METHOD DEFINITIONS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.