Wall Vents Behind Sheathing?

Wall Vents Behind Sheathing?

- POST a QUESTION or COMMENT about ventilation requirements behind foil faced building wall sheathing

Foil-faced building wall sheathing installation:

Do we need to install vent strips behind foil-faced insulating wall sheathing? Is ventilation needed at the top and bottom of exterior walls sheathed with foil-faced insulating board?

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Exterior Wall Sheathing Vents?

Is Venting a Wall Recommended for Exterior Building Walls Covered with Foil-Faced Exterior Sheathing?

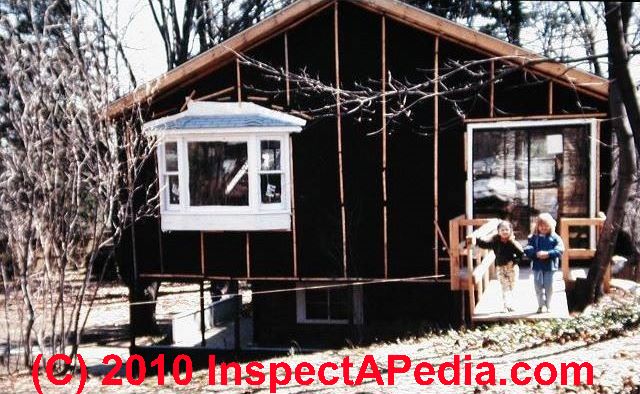

![]() Our photo at page top shows a super-insulated building addition constructed by the website author (DJF) in1978.

Our photo at page top shows a super-insulated building addition constructed by the website author (DJF) in1978.

Walls were framed with 2x6 studs, insulated with 6" of fiberglass batts, and sheathed on the wall exterior with 1-inch "High-R" foil-faced foam insulating board.

An additional layer of 15-pound felt was installed over the wall, topped with furring strips to give a 1/4" air space ( for a total wall R-value of about R28) over which we installed plywood T-111 grooved building sheathing.

The wall interior surface received a continuous 6-mil poly vapor barrier over which drywall was installed. This was an early experimental "superinsulated" design in response to soaring home heating costs during the U.S. oil price spikes in the 1970's.

By 1983 we heard that concern for possible wall cavity condensation had led manufacturers of foil faced sheathing to recommend corrugated vent strips nailed at the sills and wall top plates to ventilate the insulated wall - an idea that seemed odd at the time, since if we pass outside air behind insulating wall sheathing its insulating value would be wasted.

Other reps suggested that vent strips be installed between the exterior sheathing and the insulating board - but that's not where the condensate would occur anyway.

With the benefit of 30+ years of experience with this structure, we have learned that: the felt was unnecessary, no wall vent strips were needed, no moisture condensation has occurred in the walls (where we made test cuts from the interior), and workmanship that included careful sealing around wall penetrations for the electrical boxes was important to keep indoor moisture out of the wall cavities.

The April 1983 Solar Age Magazine addressed the question of whether or not vents are needed behind exterior sheathing when foil faced insulating boards are installed, in Solar Age Magazine Q&A details "Dew Point Dilemmas" that helped resolve these questions.

The text below paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Wall Vent Strip Question - are they needed?

I have been concerned with the moisture condensation issue for some time but have not found solid answers easy to come by.

The local representative for a major foil-faced sheathing insulating board product tells me that vent strips should be used behind the exterior sheathing in climates with more than 8000 degree days. In milder climates, apparently their product does not create moisture problems in the walls. I still find this somewhat disconcerting since, although we have only 5000 degree days, the humidity is so high, especially in winter.

When I questioned the representative for an extruded polystyrene insulating board product about its use as an exterior sheathing or for use as roof insulation over exposed-beam ceiling, I was told that the dew point is effectively moved to the center of the insulating board when the wall cavity is uninsulated.

This does not leave me convinced, however, and I am even less confident about what will happen if the wall or ceiling cavity is insulated. -- C.S., Seattle WA.

Wall Vent Strip Use Recommendations with Insulating Wall Sheathing Boards

We do not recommend venting a wall that uses foil-faced exterior insulating sheathing panels.

First, if the level of ventilation is high enough to relieve moisture problems, it will probably chill the wall cavity as well.

Second, recent research (1980's) at the USDA Forest Products Laboratory demonstrated that, in some cases, venting actually increases moisture accumulation in the building wall. Researchers suspect that the vented air is being replaced with moist inside air drawn through gaps and seams in the vapor barrier.

With a perfect vapor barrier [on the wall's warm interior side], the venting would be unnecessary in the first place. Leaving the insulating sheathing un-sealed at the joints, as most manufacturers recommend, should be adequate if a good inside vapor barrier is used.

As for the use of extruded polystyrene foam board insulation on the exterior of building walls, we have spoken to a number of manufacturers, builders, and researchers and have heard of no problems with or without cavity insulation. Since the insulating sheathing warms the wall cavity, less moisture is driven there by vapor diffusion.

[DJF Note: subsequent research has shown that vapor diffusion is the minor player in wall or ceiling cavity moisture problems, and that air leaks at penetrations is what carries and accumulates moisture in building walls.] And with a perm rating of 1.2 per inch, the foam board sheathing provides some moisture relief. [DJF Note: compared with foil-facing that, if not perforated, has a very low perm rating, close to zero.]

Reaching the dew point (calculated as a function of inside building conditions) within the foam insulating board is generally not a problem, since the low rate of diffusion through the material effectively lowers the vapor pressure and dew point in that region to a safe level.

See DEW POINT TABLE - CONDENSATION POINT GUIDE.

In unvented roofs, flat or pitched, the situation is complicated by the relatively impermeability of most roofing materials.

A high-quality vapor barrier on the warm side of the insulation is recommended. In high-moisture situations, this may be combined with a vented air space between the insulation and the roofing underlayment or sheathing [DJF OPINION: this is the best construction practice and gives a longer cooler roof life as well.]

This approach can be very effective in hot climates (using foil faced insulating board products) for cooling, or in cold climates to prevent the formation of ice dams.

Evidence of Moisture Penetration into Building Wall Cavities at Penetrations

DJF notes: there was no research actually demonstrating significant air or moisture movement through these butt joints or seams; probably most important are a very good interior vapor and air barrier, especially sealing at wall penetrations, combined with interior moisture control that keeps indoor humidity below excessive levels.

Our photo (left) shows thermal tracking (and possibly mold) around the electrical receptacle in a building wall that combined poor sealing around wall penetrations with high indoor moisture. Even before making a test cut to explore the condition of the wall cavity and its insulation, the marks on three sides of the outlet cover plate tell the story.

The reason we see no moisture and air leak related marks along the left side of this wall outlet - can you guess? Yep - that's the side of the electrical box that was nailed snugly to the wall stud.

See MOISTURE CONTROL in BUILDINGS

and HUMIDITY CONTROL & TARGETS INDOORS

as well as VAPOR BARRIERS & CONDENSATION in buildings for details.

Original article

- Dew Point Dilemmas - Wall Sheathing Vent Strips Needed? Q&A - PDF version, use your browser's back button to return to this page

Here we include solar energy, solar heating, solar hot water, and related building energy efficiency improvement articles reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: why are rooms with exterior walls so cold in winter? Missing Insulation!

(Jan 2, 2013) Eddie said:

Why is the rooms with exterior walls always so cold in winter, we thought it was the windows, so we improved the windows, maybe its the insulation,

Checked to find " WHAT INSULATION ", Just a hollow gap between the plaster walls and the outside walls.

Reply: fix the drafts first

Eddie:

Exterior walls that are un-insulated will be a significant source of heat loss to the exterior.

Once you've fixed any obvious drafts - the first and most important step - the next option is to insulate those wall cavities.

...

Continue reading at HOUSEWRAP / SHEATHING WRAP or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SIDING WOOD, FAILURES OVER FOAM BOARD where we describe wood siding failures when wood is installed over foam insulating sheathing board.

- PAINT FAILURE, DIAGNOSIS, CURE, PREVENTION as well as the other siding types listed at page top or at the MORE READING links at the bottom of this article

Suggested citation for this web page

SHEATHING, FOIL FACED - VENTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to EXTERIORS of BUILDINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Solar Age Magazine was the official publication of the American Solar Energy Society. The contemporary solar energy magazine associated with the Society is Solar Today. "Established in 1954, the nonprofit American Solar Energy Society (ASES) is the nation's leading association of solar professionals & advocates. Our mission is to inspire an era of energy innovation and speed the transition to a sustainable energy economy. We advance education, research and policy. Leading for more than 50 years. ASES leads national efforts to increase the use of solar energy, energy efficiency and other sustainable technologies in the U.S. We publish the award-winning SOLAR TODAY magazine, organize and present the ASES National Solar Conference and lead the ASES National Solar Tour – the largest grassroots solar event in the world."

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.