How to Diagnose & Repair Clogged Hot Water Piping or a Clogged Tankless Coil

How to Diagnose & Repair Clogged Hot Water Piping or a Clogged Tankless Coil

Lime scale can quickly clog a tankless coil. How to de-clog & prevent future scale clogged pipes or heaters?

- POST a QUESTION or COMMENT about how to un-block or de-clog a tankless coil used for making hot water

Clogged tankless coils:

Here we explain how to correct clogging at the tankless coil in order to improve the hot water pressure, quantity, flow from a tankless coil used for making domestic hot water.

We include a simple diagnostic procedure to find out if your bad hot water pressure is due to clogging in the hot water piping or in the tankless coil itself.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How to Check for & Correct Clogged Piping at a Hot Water Heater Tank or Tankless Coil - Improve Hot Water Pressure / Flow

Hot Water Heater Tank Clogging Diagnosis & Repair - Tankless Coil De-Liming Procedure Details

Hot Water Heater Tank Clogging Diagnosis & Repair - Tankless Coil De-Liming Procedure Details

Article Contents

- FIRST DIAGNOSE THE PROBLEM ACCURATELY

- CLOGGED PIPE CLEANING by ACID FLUSH

- DOES ACID FLUSHING TO CLEAN PIPES REALLY WORK?

- CLOGGED PIPE FLUSH using LIME REMOVER PRODUCTS

- CLOGGED PIPE CLEANING BY COMPRESSED AIR - water supply pipe cleaning method that might be used as an alternative or in concert with the acid wash we describe next.

[Click to enlarge any image]

Diagnose the Cause of Weak Hot or Cold Water Pressure

Before starting on a project to de-clog or de-scale building water supply piping, let's be sure that we are solving the right problem by making a reliable hot water pressure or both hot and cold water pressure diagnosis.

Clogged hot water supply piping:

Water supply pipes may be clogged at the water heater or at other locations, from minerals, soil, or other debris.

and WATER HEATER SCALE DE-LIMING PROCEDURE for diagnosis and repair procedures.

Corrosion, debris, dip tube or anode problems in the water tank:

Accumulated debris in a water heater, and debris from a corroded or disintegrating hot water tank dip tube or hot water tank sacrificial anode can also block the hot water outlet opening, resulting in low hot water pressure in a building.

See ANODES & DIP TUBES on WATER HEATERS

Tankless Coil Clogging Diagnosis & Repair - Removing Lime & Scale from a Tankless Coil Water Heater - also for Side-Arm Coils

Hot water pressure and hot water flow in a building may be poor even where a mixing valve has been installed. This condition could be due to poor overall building water pressure or due to clogged pipes.

If cold water pressure is good and hot water pressure is poor,

the problem is not an overall building water pressure issue. There is a problem with the hot water system that needs to be found and corrected.

If hot water pressure is strong when the water is first turned on but flow quickly falls off

to a weak hot water stream, it's likely that the hot water piping (or tankless coil) are clogged.

Often this repair involves using acid to try to remove minerals that are clogging hot water system piping or a tankless coil, or the tankless coil may need replacement.

Abandoning a tankless coil altogether:

When we bought our house the tankless coil was almost totally clogged with minerals, and we figured that it wouldn't provide enough hot water anyway, so we abandoned it. In the photo at left you can see the round black tankless coil face, with two holes - where we removed the cold-water-in and hot-water-out pipes and simply abandoned the tankless coil.

A separate water heater was installed in our utility area. (We'd have preferred an indirect-fired water heater which is discussed later in this article but that's not what we got.)

For more detailed help in diagnosing the cause of poor water pressure or flow rate due to clogged pipes or clogged tankless coil

How to Acid Flush Clogged Tankless Coils or Clogged Hot Water Piping

Given first, just below, is the general procedure for using an acid flush to clear clogged water pipes or tankless coils.

Given first, just below, is the general procedure for using an acid flush to clear clogged water pipes or tankless coils.

Some plumbers will attempt to clean out water supply piping that has become mineral-clogged.

Photo: lime scale fragments collected from a water heater. Similar hard limescale forms inside of hot water pipes and particularly in tankless coils used to produce domestic hot water.

[Click to enlarge any image]

- First, confirm the diagnosis

that the problem is clogged piping, not a clogged strainer, valve, or improper pipe connections (such as use of too much solder on copper piping connections).

Some types of pipe or tankless coil clogging such as due to sediment, rust, or mechanical damage will not be corrected by an acid flush.

See WATER PRESSURE LOSS DIAGNOSIS & REPAIR

and WATER PIPE CLOG REPAIR for more general water pressure diagnosis guidance. - Install shutoff valves and drain valves

at each end of the water supply piping (or right at the tankless coil inlet and outlet piping) - Shut off water supply

to and then drain the piping or tankless coil to be cleaned - Connect the two drain fittings

(at the two ends of the copper piping or tankless coil) to hoses (often washing machine hoses are used) as follows:- One drain hose empties into a bucket

- The other drain hose is connected to a "pony pump" capable of pumping acids

- Prepare the acid flush mix

The bucket receives a few gallons of a cleaning acid selected by the plumber (such as muriatic or dilute sulfuric acid)

CAUTION: Acids can cause dangerous burns or loss of vision: appropriate hand, eye, and skin protection are needed as well as protection against acid spills. - The acid is pumped

cycling through the piping or tankless coil to be cleaned. - The acid is flushed

from the piping or tankless coil using fresh water - The hoses and acid are removed

and the drain valves closed. - The plumbing water supply

to the cleaned section of piping or tankless coil is turned back on - The plumbing system is flushed

to be sure no acid remains in the piping

Watch out: Remove & clean faucet strainers & shower heads.

for any piping system flush-out to be successful you will need to remove faucet strainers, shower heads, or any other devices with small openings through which your water supply flows.

Otherwise, debris loosened by the pipe cleaning procedure will clog those small orifices and flow at fixtures will probably be worse than before.

Does acid flushing of water piping or tankless coils work?

Often an acid flush will indeed restore or improve water pressure and flow through previously-clogged building piping. But the process has these limitations:

- Etching speeds new clogging

Some plumbers have told us that the acid flush process also leaves the piping interior "etched" - this roughened surface may result in mineral-clogging recurring sooner than it did in the first place. - Acids can cause leaks

in previously marginal piping that is already thin and corroded - Acids may leak out

and cause damage if piping is not in good condition - Clogging will recur

If the cause of the original pipe clogging is not corrected, it will recur. For example, hard water that results in mineral clogging of pipes or clogging of a tankless coil can and should be treated with a water softener.

A water softener won't remove clogging in pipes but it will help prevent its occurrence or recurrence.

See WATER SOFTENERS & CONDITIONERS for a discussion of how to install and adjust a water softener to avoid clogging of hot water pipes and tankless coils while still protecting the septic system from excessive water or salt damage.

The pile of tankless coils shown at the top of this page is probably an example of terrible recurrent mineral clogging of tankless coils at the building where we took this photo. - Working with acid is dangerous

Some plumbers will therefore not provide this service.

Krappe described using an acid-resistant pump and tubing connected to fittings to circulate an acid-wash through scale-clogged copper piping back in 1940.

Plumbers still use this method today. The apparatus must be designed to let the scale particles and gases escape. Plumbers may simply use an acid-proof pony pump and fittings to cycle the acid wash using a plastic bucket as the rec

eiving sump.

Watch out: this is a dangerous procedure risking acid burns or other hazards. Don't try this procedure if you are not trained and equipped to do so.

But we have been informed by some plumbers that using acids to clean a tankless coil leave the coil internal surfaces etched and that the result can be faster scale formation than previously

See TANKLESS COILS for an explanation of how these water heaters work and why they clog up and how to stop clogging up the coil.

See WATER PIPE CLOG REPAIR for a discussion of loss of water pressure due to clogged piping or clogged tankless coils.

At LARGER DIAMETER WATER SUPPLY PIPES we discuss the benefits of using larger diameter water supply piping both to improve water pressure and flow and also to delay the clogging of pipes due to minerals or rust.

Plum bing Scale Removal: Compressed air followed by acid cleaner

bing Scale Removal: Compressed air followed by acid cleaner

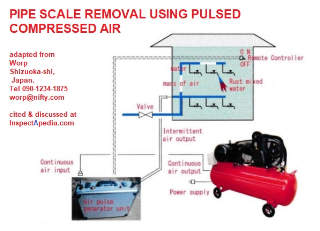

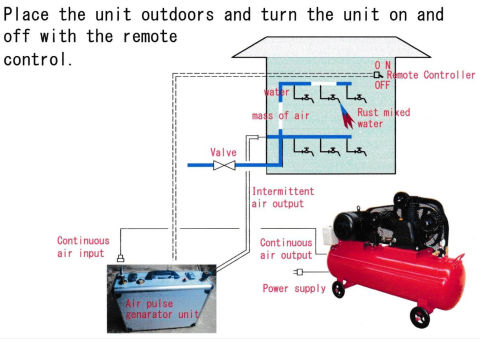

We received this un-solicited promotional information from Worp in October 2020. The company says that their portable de-scaling mahine uses a combination of compressed air and a pump to "strip off" mineral scale from the interior of almost any device: hot water pipes, tankless coils, water heaters, industrial equipment. Following their air treatment HCL (Hydrochloric acid) cleaner is used as a final step.

The briefcase device is the pulse generator, and you'll notice that the de-scaling system requires a separate source of compressed air.

We would like to see field reports from people who've tried this system.

- Worp, PORTABLE SCALE REMOVER [PDF] (2020) Worp Ogawa Kazutoshi7-19 Yokotacho, Kashi-ku, Shizuoka CityTel: 090-1234-1875 Email: worp@nifty.com

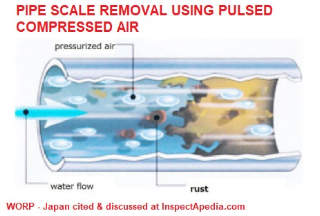

Excerpt: The air pulse generator unit intermittently shoots a mass of air into the piping. The fluid supply unit, on the other hand, puts fluid into the piping. When a mass of air is shot, it instantly becomes a large air bubble.

The fluid is pushed by air bubbles and advances at a speed according to the air pressure.

The fluid collides with the scale adhering to the piping and is stripped off. Peeled scale flows out with the fluid from the outlet.As the series is repeated over and over again, the scale will gradually decrease. Only 0.3-0.7 Mpa [43.5 - 102 psi] compressed air is required as a power. The shoulder straps and handbag handles are also useful for moving. Not only for water but also for hydrochloric acid solution is available.

From the company's Email: (excerpting and paraphrasing)

Worp is a Japanese manufacturer of plumbing scale removers. This time we will introduce an inexpensive type. Its power is only compressed air.

The purpose of the Worp cleaner is to remove scale layers such as calcium and iron rust adhering to the pipe inner wall.

By switching the air pulse generator unit, pulsed compressed air is supplied from the air pulse generator unit. On the other hand, the pump of the fluid unit starts operation by the output of the air pulse generator unit.

The fluid and air pulse merge at the cheese part and hit the plumbing scale. As a result, the scale is removed.

Field Report: Two Extra Steps to Improve the Effectiveness of Tankless Coil De-Liming Procedure

Reader comment: use Lime-A-Way or similar products to remove lime scale in p;ipes

Your information on how to remove scale in a tankless coil to improve hot water pressure and flow led to me doing this task myself. I am very mechanically inclined and rather technologically proficient but I still wanted to get an understanding of the processes.

I had a pump that would do the job but I was concerned about using an acid, even diluted.

I turned off the valves separating the tankless coil in my Burnham oil burner and luckily had tees in place already. All I had to do was get fittings for the garden hose adapters and screw them in place, I then connected the hoses to the pump and one to drain freely into my 5 gallon pail filled with about 2 gallons of water.

I then added a 28 ounce container of Lime-A-Way and started pumping. The water was nearly non-existent when I started and the pumps thermal overload went off giving me a break.

I did this pump on-thermal off routine about three times, each time letting the solution sit in the tankless coils for approximately a half hour. I was getting almost no improvement. I then decided to reverse the flow thinking what could be the harm.

The pump started and the bursts of gray water were getting more and more frequent. After three more thermal overloads I was running freely. Success is at hand!

But wait! All this bragging of success has its downside. As best as I can remember this issue isn't covered anywhere on your site.

Flush Debris from Faucet Strainers & Valves after De-Liming Water Pipes or a Tankless Coil

What I found is that after the water flow had returned to normal I still had low flow after a few bursts in my faucets upstairs. I then removed the aerators and strainers from the faucets and all flow had finally returned!

It might be a good idea to add a step to your water pipe or tankless coil de-liming or de-scaling process to remove the strainers and aerators from their faucets before turning them all on to rinse the tankless coil and system.

[See WATER PIPE CLOG DIAGNOSIS

and WATER PIPE CLOG REPAIR for details about diagnosing and clearing clogs in pipes, faucet strainers, and plumbing valves, including debris flushing - Ed.]

Bernie Daraz, Newtown, CT

Watch out: using Lime-A-Way, EasyPaks®, or Jelmar CLR® ("stain removing" cleaners designed to remove rust, calcium or lime) and similar cleaners to remove the white mineral crust on exposed metal surfaces such as a stainless steel kitchen sink can leave a black stain that is difficult to remove.

If you already have this problem, try using a nonabrasive cleaner designed for cleaning stainless steel surfaces, such as ScotchBrite™.

How do we Prevent Tankless Coil Clogging Again in the Future?

See WATER HEATER SCALE PREVENTION

Research & Products for Cleaning / Preventing Pipes Clogged with Rust or Scale

- Also see the RECOMMENDED ARTICLES at the end of this page.

- Chaturvedi, Shalini, and Pragnesh N. Dave. "Removal of iron for safe drinking water." Desalination 303 (2012): 1-11.

- Cho, Hyunwook, Jong-Sang Youn, Inhwan Oh, Yong-Won Jung, and Ki-Joon Jeon. "A new air-washing method to clean fabric filters clogged with submicron fume particles: A pilot-scale study." Journal of Hazardous Materials 383 (2020): 121186.

Abstract:

This study investigates a new air-washing cleaning system that directly injects compressed air on the filter surface for filter regeneration in a fabric filter (FF) dust collector.

A pilot-scale FF is designed to test the new system and to compare it with the conventional pulse-jet cleaning system with regard to filter clogging by fume particles. A pleated filter with a filtration area of 2.4 m2 is installed in the FF and a thermal steel spraying gun is used to supply the fume particles.

Pressure drop and particle emission concentration are monitored to examine the effect of the new system on filter regeneration and collection efficiency.

The results show that the air-washing cleaning is effective for filter regeneration, as it allows the FF to operate stably for a long time, whereas the pulse-jet cleaning fails to achieve filter regeneration, resulting in a continuously increasing pressure drop.

In addition, air-washing cleaning shows better performance on collection efficiency than the pulse-jet cleaning method, as it reduces the outlet particulate matter concentration to less than half that of the pulse-jet cleaning. - Hong, C. K. and Choi, M. S., 1999, A Study of CaSO4 Scale Formation and Heat Transfer ina Vertical Tube Evaporator, The Korean Society of Mechanical Engineers, Vol. 23, No. 11, pp. 1363-1370.

- Kang, Hyung Seok, Won Suk Yang, Young Il Kim, Sean Hay Kim, and Dong Hee Choi. "A Study on the Performance of Pipe Scale Cleaner using Natural Organic Acid." Korean Journal of Air-Conditioning and Refrigeration Engineering 29, no. 10 (2017): 530-537.

천연 유기산을 이용한 배관 스케일 세정제 성능에 관한 연구

Abstract

Scales generated inside pipes cause negative effects on heat transfer performance, pressure loss and flow rate due to increased thermal resistance and reduced flow cross-sectional area.

If these scales are not prevented or eliminated, thermal-fluid performance of the facilities can be deteriorated, or in extreme cases, accidents such as explosion due to overheating can occur. There are two ways to remove the scales, physically and chemically.

Removing the scales physically needs specific machines which are expensive, and removing them chemically may provoke corrosion or shorten the age of the facilities. In this study, an eco-friendly pipe scale cleaner using natural organic acid is developed by applying the concept of a limestone cave generation.

The manufactured scale cleaner is applied to remove the scales in industrial, water heating and urinal pipes.

The results show that this cleaner removes scales more effectively and safely compared to existing scale treatments. Scale removal efficiencies of this work is 1.2~10.7 times for industrial pipes and 1.8~15.5 times for boiler water heating pipes higher than those of conventional cleaners.

- Navien, PeakFlowE ANTI-SCALE SYSTEM [PDF] Model #GXXX001725 PeakFlowE Chemical-Free, Salt-Free Scale Prevention

Excerpt: The PeakFlowE Anti-Scale System provides protection from scale formation on internal plumbing surfaces.

The PeakFlowE system is a single cartridge-based system that must be installed on a cold water line prior to a single residential water heating device (water heater or tankless water heater).

The PeakFlowE system is built with the finest and most advanced materials and each system is quality inspected and pressure tested prior to shipment.

With proper installation and routine maintenance, you will have years of trouble-free operation. Please refer to this manual when performing routine filter changes. The instructions make periodic maintenance quick and easy and ensure you will receive maximum benefit from your system. - Sohaili, Johan, Hon Siau Shi, Noorul Hassan Zardari, Noraziah Ahmad, and Shantha Kumari Muniyandi. "Removal of scale deposition on pipe walls by using magnetic field treatment and the effects of magnetic strength." Journal of Cleaner Production 139 (2016): 1393-1399.

Abstract

Scale deposition on pipe walls is prevalent in water distribution systems and is difficult to remove. Commonly, chemical treatment is applied to remove the hard scale. However, it is detrimental to users' health and causes adverse environmental impacts.

The need for clean water production for potable and other applications is essential. This study shows the application of magnetic water treatment as a safe and effective method for scale removal in water purification.

Permanent magnets were installed in the designed treatment devices that consisted of pipes with scale deposition and the effect of magnetic field on scale reduction was monitored.

The scale removal efficiency was evaluated based on calcium concentration in the outlet, after passing through the magnetic field. Magnetic strength was varied between 0.1 T to 0.4 T to investigate its effect on scale reduction.

The morphology were analyzed by field emission scanning electron microscope. It was found that magnetic field enhanced scale removal from pipe walls by 46.7%. With respect to the increasing the magnetic field strength to 0.4 T, the efficiency of removal also increased to 30%.

Possible mechanisms involved in the magnetic treatment that affects scale reduction such as the effect of magneto-hydrodynamics and magnetically modified hydration are discussed. Magnetic technology is a simple, cost-effective and environmentally friendly treatment approach for clean water production with significant scale removal efficiency.

Magnetic treatment can be used either as a stand-alone technology or in water purification systems.

- Worp, CLOGGED PIPE SHUTTLE CLEANER CATALOGUE [PDF] Op. Cit. The Shuttle cleaner is used for scale removal in cooling water piping systems.

- Worp, PIPE DE-SCALING using AIR PULSE GENERATOR MANUAL [PDF] an alternative to acid cleaners, Worp, Sales Kazutoshi Ogawa, 7-19 Yokota-Cho, Aoi-Ku, Shizuoka-City, Japan, Tel: 090-1234-1875 Email: worp@nifty.com - contributed by Worp, 2022/03/05

According to the company the Worp pipe de-scaling process uses only air pressure (and water) to remove rust and scale from piping systems.

- Worp, PORTABLE SCALE REMOVER [PDF] (2020) Worp Ogawa Kazutoshi7-19 Yokotacho, Kashi-ku, Shizuoka CityTel: 090-1234-1875 Email: worp@nifty.com

- Zhang, L., Wu, P., Zhu, D. and Zheng, C., 2017. Effect of pulsating pressure on labyrinth emitter clogging. Irrigation Science, 35(4), pp.267-274.

Abstract

Emitter clogging has a direct impact on the performance and service life of a drip irrigation system. A study of labyrinth emitter clogging was conducted to determine the effects of pulsating versus constant pressure on average emitter flow rate (𝑞⎯⎯⎯), the Christiansen uniformity coefficient (Cu), and the location of clogged emitte

rs. Under constant pressure, emitters in this study began to be clogged after the 8th irrigation, whereby 15 emitters eventually became clogged; the average emitter flow rate decreased to 75% of the original emitter flow rate (𝑞0) after the 15th irrigation, and Cu decreased rapidly by 68.2%.

For pulsating pressure, emitters began to be clogged after the 14th irrigation, only 5 emitters became clogged, and 𝑞⎯⎯⎯ only decreased to 85.3% of 𝑞0, and Cu declined by onl

y 22.6%. These results demonstrate that the anti-clogging performance of emitters with pulsating pressure is better than with constant pressure. Emitter clogging at a constant pressure generally occurred at the inlet and front of labyrinth channels, mainly due to deposition of sediment particles.

Emitter clogging with pulsating pressure is due to other impurities (e.g., debris of Teflon tape) besides sediment particles plugging the labyrinth channel. Pulsating pressure is recommended for use in drip irrigation to prevent emitter clogging.

- Zollinger, W. Thor, and Frank Carney. Pipeline blockage unplugging and locating equipment. No. INEEL/CON-03-01459. Idaho National Lab.(INL), Idaho Falls, ID (United States), 2004.

Abstract:

This paper describes the development of a pulsed hydraulic system, specifically designed to unblock plugged piping. It uses the differences between the resonant vibrations of the fluid column and pipe walls to separate the blockage from the pipe wall, break it up, and clear the line.

Using resonant frequencies, the system can stay below the design pressure of the system, preventing pipe failures from occurring, which is a major concern with DOE radioactive waste transfer lines.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-11-28 by InspectApedia (Editor) (mod) - lifespan of a tankless coil for hot water production

@Bob,

A tankless hot water coil can clog, and reduce flow in just a few years, ot it may last decades.

The determinants are

The rate and volume of hot water used

- more hot water used = more scale accumlation at a faster rate

The hardness (level of mineral content) of the water

- harder water = higher mineral content = more scale accumlation at a faster rate

The operating temperature of the heating boiler - higher operating temperatures - more scale accumlation at a faster rate

A big difference between hot and cold pressures when it's the hot water flow rate that is much less than cold, will often point to a clogged tankless coil.

If that condition developed slowly over time, it's even more likely.

On 2022-11-28 by Bob

What's a typical lifespan for a coil? I am having a problem at a Holby mixing valve. Holby says it's not the valve but a flow problem with the hot water source — too big a difference in pressure between hot and cold sides.

My plumber says it's not the (19 year old coil). The valve works at low flow but has a temperature drop when the demand for water increases. In directions the coil is clogged up but my plumber insists it's not the coil. Amy ideas?

On 2022-10-01 by InspectApedia (Editor) (mod) - vinegar for mineral scale removal

@joe majcher,

I agree, though you'll also need longer soak time. I've found that heavy scale deposits can take days of vinegar soak to soften.

On 2022-10-01 by joe majcher

Try vinegar through coils less corrosive

On 2019-03-21 by (mod) - how to find a plumber to flush a tankless coil

A simple web search for plumbing services in Queens or "plumbing scale removal service in Queens NY) provides a number of such plumbers.

On 2019-03-21 by raj

where can i find a plumber in queens new york who can flush my tankless water heater

On 2015-11-18 by danjoefriedman (mod) - acid pumping time for successful scale removal?

Zeke I don't know of an objective acid pumping time criteria but I figure when I stop seeing new chunks of mineral debris and silt leaving the coil and water runs freely it's time to stop.

On 2015-11-18 by zeke

How long should I pump acid through my hot water coil after full flow has begun?

Question: time to use an acid wash in my tankless coil?

(Apr 29, 2014) john popa said:

rusty water coming from hot water in bathtub that is never used. Also from another sink. All found during home inspection. We have found nothing.Inspector suggested could be a issue w/heating coil. We think it is from non use. Acid wash? Suggestions?

Reply:

John,

Don't do anything yet.

If the home has galvanized iron pipes and water sat in piping without flowing for some time, rusty water would be no surprise and should flush out with use.

An acid wash has other risks including toxicity - not something to undertake lightly.

And tankless coil tubing is copper, not likely to be a source of red rusty water.

As long as you are not seeing the same discoloration elsewhere, the unused pipe theory holds water.

I took this photo of reddish brown water running into a bath tub

inspectapedia.com/water/waterbrown.jpg

under just the same conditions as you describe.

There may be other implications: galvanized pipes in an older home mean new piping is in your future.

Question: no hot water from our geyser

(June 6, 2014) Anonymous said:

After municipal stoppage of water to our home we are unable to get any hot. water flow from our geyser even though the cold water tap is fine

. Can you assist with a solution

Reply:

Are you seeing no water flow at all or water flows but is not at all hot?

If the former look for a debris-clogged valve or pipe elbow and try flushing the piping system

If the latter the problem is with the geyser itself not the water stoppage

Question:

(Aug 15, 2014) D. Laws. Near Bedford, Beds. said:

My 36 year old house has an indirect hot water cylinder that I suspect contains a huge amount of limescale, as I live in area with very hard water! Due to size of the airing cupboard, I'd guess the plumbing problems would be huge, as there is very little room to get at the pipework surrounding the cylinder?

I can figure out how to dissolve the limescale OK, but as the hot water flows out of the cylinder at the top, I'd guess that any solid residues will stay in the cylinder, due to gravity? I might remove the immersion heater and work through the hole somehow?

Am I going to run into problems afterwards, if I use chemicals here and it might thereafter build up again quite quickly? Perhaps I should consider a follow-on yearly descale, to keep on top of it afterwards? Being a pensioner, I don't have the funds, to get a new cylinder fitted!

Reply:

D.L.

You're correct that scale or lime will tpically remain in and on the bottom of the hot water cylinder. We've removed such scale by removing the heater's bottom drain, draining out all of the water, and then GENTLY probing and breaking up loose scale into fragments that would flow out through the drain opening. We then flushed the heater by briefly sending bursts of cold water in at the heater inlet.

If scale is absolutely solid on a hot water cylinder interior surface, only by using a de-scaling agent are we likely to get that out. If you use chemicals you'll want to be sure the cylinder is very thoroughly flushed to avoid drinking or bathing in something harmful.

Once cleaning the cylinder, (for U.S. & Canadian readers - a hot water tank) the most effective long term fix for hard water high in mineral content is to install a water softener. You may hesitate at that expense, but consider that a longer-lasting solution is likely to be less costly and less disruptive than ruining the building piping and heater with scale.

Question:

5 Feb 2015 Robin said:

I have had to replace my heating coil, for my hot water, on my oil furnace 3 times in the last 3 years. It is now at a point where my hot water again is just trickling, I'm assuming due to the coil being clogged again. The heating coil on there was just replaced about a year ago. This is getting extremely costly and I want to know how I can fix this problem once and for all?

In reference to my question below, the house is only about 8-9 years old and went unoccupied for 2 of those years.

Reply:

Robin:

I would first have the water tested for hardness and for aggressiveness or corrosivity. Based on those results you may want to install a water treatment system to process all of your home's incoming water to avoid these problems.

An alternative worth considering is to abandon the tankless coil approach to making hot water completely by installing a separate water heater. An option to consider is the installation of an indirect-fired water heater. See

...

Continue reading at CLOGGED SUPPLY PIPES, DIAGNOSIS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CLOGGED SUPPLY PIPES, COLD WATER - clogged cold water pipes only

- CLOGGED SUPPLY PIPES, DIAGNOSIS

- CLOGGED SUPPLY PIPES, REPAIR

- CLOGGED TANKLESS COIL or PIPES, LIME SCALE - clogged hot water pipes only

- HOT WATER PRESSURE IMPROVEMENT If only hot water pressure and flow are poor

- HOT WATER QUANTITY IMPROVEMENT for how to get more hot water pressure, flow, quantity, temperature.

- HOT WATER IMPROVEMENTS - home

- TANKLESS COIL HOT WATER INCREASE If you need to improve the hot water temperature and flow from a tankless coil system that is not clogged

- TANKLESS COILS - home

- WATER PIPE CLOG DIAGNOSIS

- WATER PIPE CLOG REPAIR

- WATER HEATER SCALE DE-LIMING PROCEDURE

- WATER HEATER SCALE PREVENTION

- WATER HEATER TEMPERATURE TOO COLD or TOO HOT steps to correct water that just won't get hot.

- WATER SOFTENERS & CONDITIONERS for suggestions about dealing with hard water in buildings.

Suggested citation for this web page

CLOGGED TANKLESS COIL or PIPES, LIME SCALE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER HEATERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to reader Bernie Daraz, Newtown, CT for discussing additional steps to improve the results of tankless coil scale removal, November 2010.

- Lime-A-Way, Jelmar CLR-CL-12 Cleaner, Vanish DRK cleaner, Simple Green Lime Scale Remover, Eco Friendly lime and scale remover and other plumbing de-liming and de-scaling products mentioned in this article are examples of products used to remove calcium, lime, other minerals, and in some cases rust or other clogs or scaling in piping and on plumbing fixtures. Other products are available from your plumbing supplier.

- Pounds of lime deposited vs. temperature and hot water usage: see Purdue Bulletin #74 (also provided by A.O. Smith in the article below). Purdue's chart shows the number of pounds of lime deposited per year as a function of the water usage in gallons per day, with an assumed 10 grains of water hardness.

- Krappe, Justus Maximilian SCALE FORMATION IN WATER HEATERS AND METHODS OF PREVENTION [PDF] Krappe, Justus Maximilian, Engineering experiment station. Gas engineering bulletin; no. 6; Research series; no. 74; On cover: Engineering bulletin, Purdue university. Vol. xxiv, no. 3a. June, 1940 (Layfayette Indiana) commonly referred to in some references as "Purdue University Bulletin No. 74"

- thanks to researcher Robyn Goldstein for the full citation. LCCN: 4008844 & OCLC: 1038544 - Water analysis, water softening, hot-water supply. 27pages. You can obtain this document through your local library. Retrieved 3/31/2010) Purdue B074 can be hard to locate online. - Wilkes University Center for Environmental Quality Environmental Engineering and Earth Sciences Hardwater, Water Hardness "Hard Water Hardness Calcium Magnesium Water Corrosion Mineral Scale" http://www.water-research.net/hardness.htm

- Chemical Engineering, Joseph D. Hagerty Editor, McGraw-Hill, 1989,

ISBN 0685270831, 9780685270837

"To calculate the amount of material that will be deposited in 1000 gal. of water per day, take the number of grains per gallon of each as shown by the ..." also difficult to obtain except as a used copy. - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.