Heating System Diagnostic FAQs-5

Heating System Diagnostic FAQs-5

Heating system repair Q&A

- POST a QUESTION or COMMENT about this article topic.

Heating system installation, repair, maintenance questions & answers set #2:

More frequently-asked questions & replies on how to troubleshoot & repair heating systems in buildings.

These heating system articles answer questions about all types of building heating systems and describe how to inspect, diagnose, and repair heating system problems, how to cut heating bills, and heating system safety, heating system efficiency and heating trouble-shooting advice.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Heating System Q&A Set #5

These questions & answers about troubleshooting heating systems in buildings were posted originally at HEATING SYSTEMS - home - that's a place to start diagnostics for your heating system type and its problems. aces, and other equipment

These questions & answers about troubleshooting heating systems in buildings were posted originally at HEATING SYSTEMS - home - that's a place to start diagnostics for your heating system type and its problems. aces, and other equipment

[Click to enlarge any image]

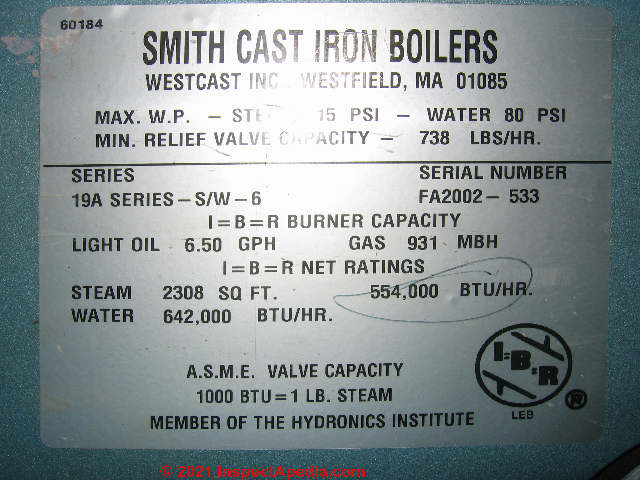

Photo: example data tag for a boiler. More examples of data tags and notes on finding them are

at DATA TAG IDENTIFICATION & LOCATION

- What kind of heat have I got? If you don't know whether your heat is provided by a furnace (hot air) or boiler (hot water), or whether your fuel is oil, gas, or electric,

and whether your heat is hot water, steam, or warm air,

see HEATING SYSTEM TYPES. - How to fix the heating system: If your heating system is not working properly choose one of the following diagnostic procedures:

- see DIAGNOSTIC GUIDE A/C or HEAT PUMP

- or DIAGNOSE & FIX HEATING PROBLEMS-BOILER

- or DIAGNOSE & FIX HEATING PROBLEMS-FURNACE

These Q&As were posted originally at HEATING SYSTEMS- home.

On 2015-11-06 by (mod) - Furnace duct is backdrafting

Good question for which I can but speculate wildly.

First: as you suggest, a good diagnostic question to ask is "what has changed" - after considering that maybe nothing changed except that we noticed a problem we didn't notice previously.

Presuming something has changed:

- have we made the house tighter?

- have we closed a door or window?

- have we changed the dyer model or cleaned out a previously lint-clogged dryer, vent, or vent opening?

WATCH OUT: I'm not entirely sure I know what you mean by "furnace duct is backdrafting" now that I think about it.

If you're talking not about the ducts that move heated air into the building occupied space but rather the furnace flue or flue vent or flue vent connector intended to release combustion gases outdoors, then your system may be unsafe and risks fatal carbon monoxide poisoning or a soot puffback or a fire - in which case it's time to call for an inspection by an exprienced heating tech or a certified chimney sweep.

Don't run an unsafe system, or if you're going to ignore that safe advice, then don't go to sleep without tested, properly located, working smoke and CO detectors.

On 2015-11-05 by lorne

Furnace duct is backdrafting when the furnace kicks in, while dryer(located in next room 20feet) is running.

This hasn't happend in the past 3 years, so why suddenly now? Furnace flue is not clogged, And I am pretty sure I got no fresh air intake, because only vent on the side of the house is the dryer.

On 2015-10-29 by Colleen

I live in an apartment building that was built in the late 1950's or early 60's. The building is heated by a hot water boiler system. There are thermostats in each apartment. They control small electric circulating pumps in each apartment. Currently the thermostat installed can only turn on or off the pump but not according to temperature

. I might as well have a light switch in its place. I am trying to find a simple or programmable thermostat that will control the pump's circulation according to temperature. Which thermostat do I need? I have spoken to the owner of the building, but he either had no solution or cannot be bothered. I actually find the apartment too hot most of the time.

If the thermostat will simply turn off the pump when a comfortable heat is reached I would be a happy camper. I appreciate any and all info.

On 2015-10-24 by (mod) -

Reply:

Sure, Sally, Use the page bottom CONTACT link to find our email address and then send photos for comment.

On 2015-10-24 by (mod) -

Re-posting a question posted on an obsolete copy of the article above (probably loaded in someone's browser cache)

PAGE:https://inspectapedia.com/heat/heating.htm

AUTHOR:Sally (no email)

COMMENT:I have a really weird furnace setup. It kinda looked like one of the pictures but totally different. Is there anyway I can upload pics? Si I can get advise. They used pvc pipes and this " insulation" type stuff as the vent its like shiney silver on the outside with that insulation on the inside, being held by zip ties.

On 2015-10-22 by (mod) -

Anon: diagnostic details of "furnace fan won't stop" are found at

https://inspectapedia.com/heat/Furnace_Fan_Wont_Stop.php

On 2015-10-22 by (mod) -

Anon:

1. Check the thermostat settings to be sure that you are calling for heat (set-temperature is above room temperature)

2. Check that the thermostat FAN switch is set to AUTO not to ON

3. Check that the manual FAN ON switch at the fan limit switch in the furnace or air handler is not in manual ON position

4. Check the furnace primary controller to see if the "reset" button on the control (or on the burner motor) has popped out - you can try pressing the switch in ONCE but don't keep pressing it as doing so is unsafe.

5. Check for voltage at the oil burner primary control.

6. If there is voltage to the primary control, no reset buttons are popped, and the thermostat is calling for heat (check that right at the primary control thermostat wires) then I suspect a bad primary control unit itself.

On 2015-10-22 by Anonymous

my fan keeps running with no heat on furnace

what can I do

On 2015-09-26 by (mod) -

Anon

See MANUALS & PARTS GUIDES - HVAC - at https://inspectapedia.com/heat/HVAC_Manuals.htm

On 2015-09-26 by (mod) -

RE-posting from an obsolete page

AUTHOR:Anonymous (no email)

COMMENT:I need to install a international comfort product electric furnace model# fxm4x3600at where can I get a installation manual

On 2015-09-08 by (mod) -

Don't know, Peter; I've researched Flame-Master furnaces (produced by BVR in Calgary) without finding a manual nor reliable furnace images; any photos or details you can send will help other readers.

On 2015-09-08 by peter c

Hello, Does a 70,000 btu Flamemaster gas furnace have 3 burners as does 105,000 Flamemaster gas furnace?

On 2015-07-24 by (mod) - How do i check the age of my tru flo hot water system

If you are asking about a TruFlo water heater, Check the serial number, not the model number.

If you TruFlo water heater was made by American (Tru-Test or Tru Value water heaters) or by U.S. Craftsmaster, then the age is encoded in the serial number as follows:

First two digits of the serial number are the year

Second two digits of the serial number are the week

Example: 9201nnnnn would translate as 1992, first week

See WATER HEATER AGE - https://inspectapedia.com/plumbing/Water_Heater_Age.php

On 2015-07-22 by tru flo

How do i check the age of my tru flo hot water system

On 2015-07-21 by Anonymous

Hello. we have a Weil/ mcclain gold furnace to heat building in winter as well as heating hot water year round conected to a hot water storage booster tank:

QUESTION;

we recently replaced the storage booster tank, the preset temp on the storage booster tank is 130*f, can I reduce that temp to a lower temp and save on oil costs because the hot water temp gauge in the tank will not call to the circulating pump and furnace to keep reheating water for storage tank? Thanks

On 2015-06-13 by (mod) -

Greg, with a large boiler supplying so many buildings surely there is a full-time and boiler-certified mechanic on duty 24/7, right?

What did he find. I expect he or she will find that a mixing valve is closed or not working allowing only cold to flow into the hot lines, but of course an on-site expert will see far more than we can from a one line e-text.

On 2015-06-13 11:35:37.448220 by Greg J

I have a boiler system supplying water to 22 apartment buildings, why would there be cold water only running out the hot side in 3 buildings closest to boiler room? All other buildings have hot water. thanks

Greg

On 2018-04-27 by (mod) - thermostat seems to respond too slowly to temperature changes

I'd be surprised that the thermostat would not act "fast enough" it the thermostat is actually working at all and assuming it's properly located.

I'd also check that you're not circulating boiler water through the heat exchanger involuntarily, such as can happen if there is a defective zone valve or check valve that doesn't close when it should.

On 2018-04-26 by Don

The thermostat is the first thing I checked. It is working properly. The stat pulls a relay which turns on the fractional hp pump and opens the zone valve at the boiler. Zone valve end switch makes and pulls another relay which turns on whole house circulating pump and fires the boiler.

The water from the boiler is less than 200 since that is what the limit is set to.

The 1" pex supply line to the heat exchanger is about 50' away from the zone valve, however the valve is on the return side and I would think there would not be any hot water to the heat exchanger if not calling for heat, however, the supply side at the heat exchanger is usually very hot.

Could it be the water temp is so hot and the rate of rise, temp, is faster acting than the thermostat? You said not the right model. I bought it thru a pool/jacuzzi supply house. I have tried two models to no avail.

On 2018-04-26 by (mod) -

If your hot tub is too hot then I suspect that the controlling thermostat is improperly-set or is not the right model to provide the necessary temperature.

On 2018-04-26 by Don Hoolihan

I have a hot tub heated by a stainless steel heat exchanger. on the tub side I have a 4 hp pump for the jets and a fractional hp pump for heat and filter. Either pump circulates thru heat exchanger and filter. Small pump only circulates on timer for filtering or Tstat for call for temp.

Call for temp also opens a zone valve with end switch that pulls a relay to fire the home heating system gas boiler and start the main heating system circulating pump. The zone valve for the tub is on the return side of the piping. I have had constant problems maintaining temp (always too hot) and am looking for recommendation for improvement.

Should I install another zone valve on the supply to the heat exchanger?

Should I be using domestic hot water heater instead of directly off boiler? Is it possible the zone valve is stuck open and circulating hot water thru heat exchanger on call from any other zone?

On 2018-04-03 by (mod) - I want to separate one large zone into four separate zones

Yes a four-zone controller connected to four thermostats and four zone valves will do what you want providfed that your existing piping for the actual heating water is already divided into four separable piping loops.

Otherwise you're going to need a plumber first.

On 2018-04-02 by charlie

I want to separate one large zone into four separate zones. current setup is a b&g pump controlled by a Honeywell 845a relay. i would like to have four thermostats controlling 4 Honeywell zone valves (about 30 feet away from pump and boiler)

not sure how to do this will a simple 4 zone controller do the trick like a taco zvc404? One more thing to note there are three other pumps in system each controlled individually by Honeywell 845a's.

On 2018-03-24 6 by (mod) - never force the burner to run and never bypass safety controls on a heating boiler

Sorry to be obtuse, Gene but this makes no sense to me.

If you're trying to FORCE your heating boiler's gas burner ON when a thermostat calls for heat (thus turning on the zone valve) that shouldn't be necessary, as I explained earlier: the water temperature turns on the burner.

Watch out: You certainly don't want to ever force a burner on past or circumventing the aquastat nor any other safety control - such a system would be unsafe.

In Canada systems are wired differently from the U.S.: often a hydronic heating system circulator runs continuously all during the heating season and the thermostat operates the boiler. Perhaps that's closer to what you want.

On 2018-03-24 by Gene - I want to force my pilot lights or burners to stay on

It is all working ok I just wanted to put a pilot light on there . I don't have a problem with it .

How can you tell which one is the hot wire on 24 volt you cannot connect the yellow to the same white wire as 110 volt. Maby I should not be trying to connect a pilot wire on there but it just something I wanted to do.

I ment there are 2 zone valves per pump . The zone valves are working great I just wanted a pilot light that would come on when the vale turned on .. OK thank you

Well are the end switch wire shoud it be hot all the time ? It still runs the pump when it should run .

It is just I did not think that those end switch would be hot all the time . On the Omron switch we set it up to have all the power wires to the bottom of the Omron switch and the end switch on the top but that is not the way it ended .

Maybe I should not try to do what I am trying to do .

On 2018-03-24 by (mod) - I am trying to put a pilot light on for each zone they are 24 volt but the are all hot all the time .

Gene

If you mean that your heating zones never turn off then you have a problem with the thermostats, thermostat wiring (such as wires mis-connected or shorted together), or (less likely) you are in unusually cold weather and your heating system cannot deliver enough heat.

Compare the actual room temperature to the SET temperature on the room thermostats.

I cannot give advice for a non-standard pilot light control. A mistake can burn down the building or blow it up.

On 2018-03-24 by Gene

I am trying to put a pilot light on for each zone they are 24 volt but the are all hot all the time .

Is this normal I also tried to put it on the thermostat wire but it appears hot all the timeas well. only one not hat are the white wire which ios the one wire from thermostat and transformer which are tied togather.

which I brought over to the end switch wire on right side . Then a red wire to the Omron switch . So how could I connect a pilot light to that I do have one pilot light on the pump but I got 2 pumps for each zone valve.

On 2018-03-23 by (mod) - I like to have a pilot light when the valve opens

Gene

I don't understand your requirement. Typically in US installations the zone valve end switch turns on the circulator and boilet temperature turns on the burner.

On 2018-03-23 by Gene LAIR

I have hydronic heating with Honeywell zone valves and Omron relays with the zone valves 24 volt and I like to have a pilot light when the valve opens I tried to connect a 24 volt light to the end switch but the that wire on Omron is hot all the time .

I put one pilot wire with the pump but I have 2 valves to each pump . How can I have a pilot on each valve ? I should be able to use the thermostat but that did not work either .Should the end switch wire be hot all the time ?

On 2018-03-08 by (mod) - Once the air filter is blocked below say 80%

Dave

Once the air filter is blocked below say 80% of its clean flow rate, the furnace efficiency impact expressed as a percent reduction air flow and thus a percent-increase in operating time before the thermostat is satisfied is probably a roughly-linear relationship with the blockage of air flow percentage.

Phillips, Bert G. "Impact of blower performance on residential forced-air heating system performance." ASHRAE Transactions 104 (1998): 1817.

Fisk, William J., David Faulkner, Jari Palonen, and Olli Seppanen. "Performance and costs of particle air filtration technologies." Indoor air 12, no. 4 (2002): 223-234.

Fraden, Jacob, and Alex Rutstein. "Clogging detector for air filter." U.S. Patent 7,178,410, issued February 20, 2007.

Ward, Matthew, and J. A. Siegel. "Modeling filter bypass: Impact on filter efficiency." ASHRAE Transactions 111, no. 1 (2005): 1091-1100.

On 2018-03-08 17:11:49.482448 by Dave

How much of the return air can actually be blocked off by a dirty filter before the efficiency of the furnace is jeopardized ?

On 2018-02-27 by (mod) - Trane Day/Night programmable thermostat

See this Trane XL824 Thermostat guide

http://www.nexiahome.com/wp-content/uploads/2016/02/xl824-user-guide.pdf

On 2018-02-18 by Tony

It is a trane XL824 thermostat

On 2018-02-12 by (mod) - problems with Trane Day/Night programmable thermostat

Tony I think the control is not properly programmed

We'd need the brand and model of the thermostat to figure out more specific advice - or you could use that yourself to download the programming guide.

On 2018-02-10 by Tony

We just had a new trane furnace and ac installed with one of the train WiFi digital thermostats. Ever since the installation we set the day temp at 69 and night temp at 66, but after the furnace gets done running during the day, the reading on the display shows 72/73,

prior to changing our furnace, we never had this problem, if it dropped below set point it kicked on and it kicked off maybe one degree above. Any idea what maybe happening?

On 2018-01-31 by (mod) -

Anon

IN some installations such as throughout much of Canada installers wire the heating system such that the circulator runs continuously and the thermostat turns the boiler on or off in response to a call for heat. So your installation could be correct.

On 2018-01-28

by Anonymous

thermostat off but circlator pump runs

...

Continue reading at HEATING SYSTEMS - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see HEATING SYSTEM FAQs-6 - more-recent questions & answers posted orignally at the heating systems home page.

Or see these

Recommended Articles

- HEATING SYSTEMS - home

- AIR HANDLER / BLOWER UNITS - home

- BLOWER FAN OPERATION & TESTING

- BOILERS, HEATING - home

- DUCT SYSTEM DESIGN SIZE & DEFECTS - home

- ELECTRIC HEAT - home

- FAN, AIR HANDLER BLOWER UNIT - home

- FURNACES, HEATING - home

- HEATING SYSTEM INSPECT DIAGNOSE REPAIR - home

- MANUALS & PARTS GUIDES - HVAC - home - Master Index to All Brand Names & HVAC manuals, wiring diagrams, installation and repair guides

- RADIANT HEAT - home

- STEAM HEATING SYSTEMS & CONTROLS - home

- THERMOSTATS, HEATING / COOLING - home

Suggested citation for this web page

HEATING SYSTEM FAQs-5 at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.