Best Practices Guide to Wood Siding Flashing Details at Joints & Corners

Best Practices Guide to Wood Siding Flashing Details at Joints & Corners

- POST a QUESTION or COMMENT about how to install flashing at building exterior walls or siding corners and trim boards

Wall corner siding & trim flashing details:

Tthis article gives specifications for proper flashing & sealing detailing at building siding joints, corners, and window or door openings to provide an attractive and durable job that doesn't leak or rot.

InspectAPedia tolerates no conflicts of Interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Wood Siding Flashing Details at Joints & Corners

This article series discusses best practices construction details for building exteriors, including water and air barriers, building flashing products & installation, wood siding material choices & installation, vinyl siding, stucco exteriors, building trim, exterior caulks and sealants, exterior building adhesives, and choices and application of exterior finishes on buildings: paints, stains.

This article series discusses best practices construction details for building exteriors, including water and air barriers, building flashing products & installation, wood siding material choices & installation, vinyl siding, stucco exteriors, building trim, exterior caulks and sealants, exterior building adhesives, and choices and application of exterior finishes on buildings: paints, stains.

[Click to enlarge any image]

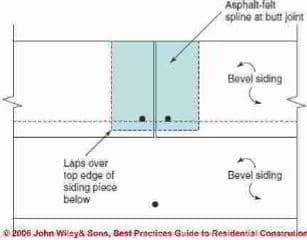

Adapted/paraphrased with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) . Steven Bliss.Proper detailing at joints, corners, and openings makes for an attractive and durable job. Key details follow: Lap Joints. The IRC requires that horizontal lap sidings have a minimum one-inch lap joint, or 1/2 inch if the siding is rabbeted.

Weather-proofing Butt Joints in Building Siding

In most climates, it is a good idea to slip a small spline of asphalt-felt paper behind each butt joint in horizontal sidings. Layer the spline so it overlaps the piece of siding below, directing any water out onto the siding (see Figure 1-12 at above left - click to enlarge this or any image at InspectApedia.com).

All end grain in the siding should be sealed after cutting with a water-repellent preservative (WRP) or primer.

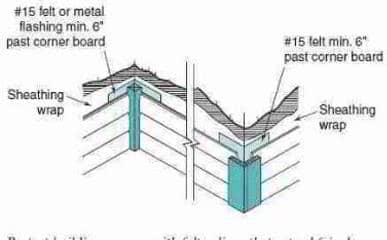

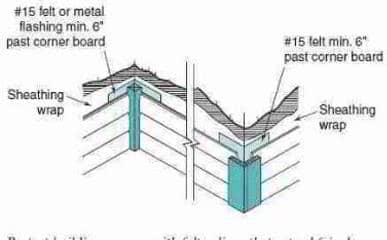

Building Siding Flashing & Finish Details for Building Corners

Use overlapping 1x4s or 1x6s at outside corners or use 5/4 stock for a heavier look. Use a felt paper spline, wrapped around the corner and extending 6 inches beyond the corner board, to protect the joints where the siding meets the corner boards (see Figure 1-5 at left).

Use a square length of 5/4 stock at inside corners with a spline underneath. All end grain in the siding should be sealed after cutting with a water-repellent preservative (WRP) or primer.

With the spline, there is no need to caulk the joint. With no caulk, the joint is free to dry out when wet.

Flashing Details for Windows and Doors

If windows and doors are properly protected with splines of felt or flashing tape, there is no need to caulk the joints where siding meets the side casings.

At the top of a door or window, always direct the sheathing wrap over the head flange or cap flashing. Never caulk the joint between the siding and the head casing or the sill, leaving these joints open to drain any trapped water.

Also see WINDOWS & DOORS.

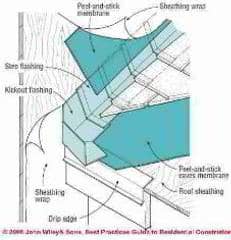

Siding Details At Roof-Wall Joint Step Flashings to Avoid Rot

Stop wood sidings at least 1 inch short of the bottom leg at step flashings and other roof flashings. [Click to enlarge any image]

Otherwise water will wick up into the flashing leading to paint failures and decay (see Figure 1-6 above left). Our wall siding photo (above right) shows the beginning of deteriorating wood clapboards that were installed touching the surface of an abutting lower asphalt shingle roof.

ALso see RAIN SPLASH-UP SIDING DAMAGE.

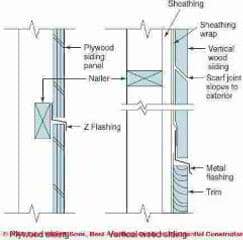

Vertical and Plywood Siding Butt Joint Details

Avoid horizontal butt joints in vertical siding. Where a butt joint is necessary, use a scarf joint sloped down toward the building’s exterior.

With plywood sidings, use a Z flashing at horizontal joints to shed water to the outside (see Figure 1-13 at above left).

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at it's page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: clearance between corner boards and lower story roof

8/10/14 Pat said:

second story has cornerboard that abbuts lower lst story roof. Should cornerboard be cut back so it doesn't touch lower roof? There may be some rot in it.

Reply:

Yes, Pat, I'd want to see a inch and a half or more between the bottom end of vertical trim and the roof surface below. Particularly if the corner boards are made of wood, the end grain of wood is like a sponge and will easily draw up water into the lower end of the board, leading to rot.

Question: Should siding cornerboard be cut back so it doesn't touch lower roof?

(Sept 30, 2012) bob said:

needs photo of corrected siding butt

(Aug 10, 2014) Pat said:

second story has cornerboard that abbuts lower lst story roof. Should cornerboard be cut back so it doesn't touch lower roof? There may be some rot in it.

Reply:

Yes, Pat, I'd want to see a inch and a half or more between the bottom end of vertical trim and the roof surface below. Particularly if the corner boards are made of wood, the end grain of wood is like a sponge and will easily draw up water into the lower end of the board, leading to rot.

Please see the exterior trim installation advice we offer beginning at

inspectapedia.com/BestPractices/Exterior_Trim_Choices_Installation.php

for details about trim choices, flashing, clearances.

See inspectapedia.com/exterior/Exterior_Trim_Installation.php

for details about clearances on vertical wood trim including corner boards and window or door trim.

Question: missing porch slab flashing

(Aug 21, 2014) Jenny said:

My builder lade a new porch slab over our basement where our old porch used to leak. He said he would put flashing in. The only thing I have seen is siding he used like flashing that comes off the wall and then on to the porch. Does this seem right or should the flashing be metal and hidden?

Reply:

Jenny I don't know your exact construction, but in general, pouring a slab on grade whose edge at the house simply abuts against existing siding is poor practice that invites termites into the structure.

...

Continue reading at FLASHING WALL DETAILS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

FLASHING SIDING DETAILS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FLASHING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see " Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectApedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use I llustrations from The I LLUSTRATED HOME .

Carson Dunlop Associates provides extensive home Inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.