Rooftop Deck Construction Guide

Rooftop Deck Construction Guide

- POST a QUESTION or COMMENT about how to build a walk-on rooftop deck

Rooftop decks & walk-on roofs:

This article discusses rooftop deck construction details to avoid building leaks or rooftop deck safety hazards.

Page top photo: a rooftop deck in Guanajuato, Mexico, used as a bar-restaurant. (Notice those wide openings between horizontal bars of the guardrail?)

Here we discuss walk-on roof surfaces, roofing membrane to use below a rooftop deck, and construction of rooftop deck railings and posts.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Details for Building Rooftop Decks

Decks over living spaces can be detailed various ways, but all should have the following elements:

- Along-lasting membrane roof sloped at least 1/4inch per foot, designed to drain at the lower end

- Decking screwed to sleepers so that it can be removed for inspection or repair

- A sturdy railing system that, preferably, does not penetrate the roofing membrane

- Also see this separate article: WALK-ON ROOF SURFACES .

Single-Ply Membranes for Rooftop Decks

Our rooftop deck photo (above left) shows how the installer provided for future cleaning of debris accumulating below the nearly-flat roof deck. But it is the choice of roof membrane and how the deck panels are supported so as to avoid damaging the membrane that make a rooftop deck work ... or not.

Continuing as detailed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

A variety of roofing membranes have been used successfully under rooftop decks, but EPDM remains the most widely used on residential roofs.

EPDM owes its popularity to its longevity and durability. It is dimensionally stable and strong over a wide temperature range (it will not expand and contract or tug at flashings), is highly UV-resistant, and can stretch without tearing. In most residential jobs, EPDM is fully adhered to the roofing deck with a contact-type adhesive rolled onto both surfaces.

Seams can be avoided on small jobs, since rolls come as wide as 50 feet. If necessary, however, seams are relatively easy to seal, using a special double-sided seam tape and lap caulk at the exposed joint. To seal around corners and penetrations, use flexible uncured EPDM, which will conform to irregular shapes and seals well to the main roofing membrane (see EPDM, page 96).

EPDM roofing membranes typically come in .045- and .060-inch thicknesses and carry at least a 10-year warranty in residential work. If properly installed, however, the .060 material should last for decades. EPDM’s chief weakness is its vulnerability to petroleum products, such as oils, grease, and solvents.

If used under a deck, warn the homeowners not to splash oil or grease from cooking or solvent-based wood finishes on the decking.

EPDM is often installed over a base layer of fiberboard or rigid insulation, but most EPDM membranes can bond directly to a sanded wood underlayment such as a 1/4-inch AC plywood. If bonding directly to plywood or oriented-strand board (OSB), check with the roofing manufacturer regarding treatment of joints in the sheathing and the need for a primer.

To allow for some movement at sheathing joints, some manufacturers recommend holding the adhesive back one inch from the joints.

Also see WALK-ON ROOF SURFACES.

Terminations and Flashings for Rooftop Decks

Where the roofing membrane meets the house, run it 10 to 12 inches up the wall under the sheathing wrap. At outside edges, leave a 3- to 6-inch flap, depending on the edge treatment. A large metal drip-edge usually caps the roof along the fascia boards.

Deck Flooring Construction for Rooftop Decks

The decking sits on 2x sleepers, usually laid flat. If you want the decking surface to be level, the sleepers will need to be tapered to compensate for the slope in the roof deck. For a large deck where flat sleepers are too thin to taper, you can use 2x4s or 2x6s set on edge.

To protect the roofing membrane, set the sleepers on strips of EPDM or rooftop walkway matting (available from commercial roofing suppliers). Attach the decking with screws so it can be removed later for inspection or repairs.

The rooftop deck shown in our photo (left) is installed in a restaurant in Mexico City where it must endure very strong sun and intermittent very heavy rain (and an occasional earthquake).

Shading and sun protection are provided by canvas awnings. - DF.

Post and Railing Construction for Rooftop Decks

As with other decks, guardrails must be a minimum of 36 inches high, infill balusters less than 4 inches apart, and the whole assembly strong enough to resist a 200-pound horizontal load (or 20 pounds per linear foot, depending on the local code). Use the longest pieces available for railings.

If the deck is small enough, use a single continuous top railing on each side. Then tie the side railings to the house with steel angle brackets to create a rigid railing assembly.

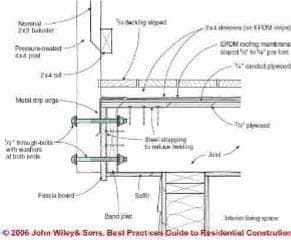

From a waterproofing standpoint, it is desirable to keep the posts outside of the roofing membrane. This can be achieved by bolting the posts to the rim joists or sub fascia in the roof framing (see Figure 4-17 below).

[Click any image to see a larger, detailed version.]

If this is not practical or if it is unacceptable from a design standpoint, then the EPDM will need to be sealed around each post. This is best left to a professional roofer.

Typically, the roofer will fashion a metal or membrane flashing collar around the base of each post and seal this to the roofing membrane, as with the boots used for plumbing vents.

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Deck & Porch Resources, Products, Manufacturers: Where to Buy

See Deck & Porch Products, Manufacturers for our complete/updated listings of manufacturers of porch & deck products, materials, coatings, fasteners, lumber, tools.

Reader Question: minimizing sound transmission through a rooftop deck

(May 22, 2014) Jared said:

Do you have any suggestions for minimizing sound transmission, especially if bedrooms are below. Thanks!

Reply:

Sure Jared, we have a series of articles on noise transmission & control.

Take a look at

inspectapedia.com/roof/Roof_Noise_Control.php

Rooftop Deck Height, Walkout Decks, Door Clearances

Reader Question:

(June 16, 2014) rich said:

The height of the deck is an issue relative to the finished floor inside. To gain one half inch, will it work to use 5/4 by four cedar sleepers with 2x6 deck boards on top?

(9 January 2015) Anonymous said:

I have a question about a walk-out roof deck with composite decking and 2x sleepers floating on the membrane roof. For best practice, how much lower should the finished decking elevation be below a door threshold. Is there a IRC code to reference. Thanks for the help!

Reply:

Rich, I can't say from just the details in your note.

5/4" lumber sleepers + a 2x6 (which is 1 1/2" in thickness) will give you approximately 2 3/4" of overall thickness or height gain over the existing roof surface.

Your design doesn't mention the use of any padding material that is often applied below sleepers to prevent them from damaging the roof surface.

IRC code on height of door sill to rooftop deck surface

Anon I'd pass the question to your local building department who may tell you what applies in your area. Interestingly some codes want an exit porch or walk to be the same level as the indoor floor - worrying about trip hazard. In my opinion that's a terrible design that invites leaks from rain or melting snow if you're in a snow area. Ideal would be a standard step height down - say 7" but less, even a couple of inches, can if properly flashed, at least address the leak risk at this location.

In a follow-up comment I'll paste in some relevant portions of the IRC on Exit doors:

IRC citations on exit door details:

R311.2 Egress door.

At least one egress door shall be provided for each dwelling unit. The egress door shall be side-hinged, and shall provide a minimum clear width of 32 inches (813 mm) when measured between the face of the door and the stop, with the door open 90 degrees (1.57 rad).

The minimum clear height of the door opening shall not be less than 78 inches (1981 mm) in height measured from the top of the threshold to the bottom of the stop. Other doors shall not be required to comply with these minimum dimensions. Egress doors shall be readily openable from inside the dwelling without the use of a key or special knowledge or effort.

R311.3 Floors and landings at exterior doors.

There shall be a landing or floor on each side of each exterior door. The width of each landing shall not be less than the door served. Every landing shall have a minimum dimension of 36 inches (914 mm) measured in the direction of travel. Exterior landings shall be permitted to have a slope not to exceed 1/4 unit vertical in 12 units horizontal (2-percent).

Exception: Exterior balconies less than 60 square feet (5.6 m2) and only accessible from a door are permitted to have a landing less than 36 inches (914 mm) measured in the direction of travel.

R311.3.1 Floor elevations at the required egress doors.

Landings or finished floors at the required egress door shall not be more than 11/2 inches (38 mm) lower than the top of the threshold.

Exception: The landing or floor on the exterior side shall not be more than 73/4 inches (196 mm) below the top of the threshold provided the door does not swing over the landing or floor.

Where exterior landings or floors serving the required egress door are not at grade, they shall be provided with access to grade by means of a ramp in accordance with Section R311.8 or a stairway in accordance with Section R311.7.

R311.3.2 Floor elevations for other exterior doors.

Doors other than the required egress door shall be provided with landings or floors not more than 73/4 inches (196 mm) below the top of the threshold.

Exception: A landing is not required where a stairway of two or fewer risers is located on the exterior side of the door, provided the door does not swing over the stairway.

R311.3.3 Storm and screen doors.

Storm and screen doors shall be permitted to swing over all exterior stairs and landings.

Deck & Porch Wood Treatment Companies

- Arch Wood Protection www.wolmanizedwood.com Copper-azole and borate-treated wood products with optional water repellent

- Osmose www.osmose.com ACQ- and borate-treated wood products with water repellent

- Chemical Specialties www.treatedwood.com ACQ-treated wood products with optional water repellent

Suppliers of Composite Structural Lumber for Decks & Porches

- U.S. Plastic Lumber, Boca Raton, FL www.usplasticlumber.com Trimax and Durawood structural plastic lumber

-

Composite Decking System Suppliers

- Certainteed Corp. www.certainteed.com Boardwalk solid composite decking with hidden fasteners and optional railing system

- Composite Building Products International www.xtendex.com Xtendex hollow composite decking system with optional railing

- Correct Building Products www.correctdeck.com Solid composite decking with hidden fasteners and optional railing system

- Fiber Composites www.fibercomposites.com Fiberon solid composite decking and optional railing system

- Kadant Composites www.geodeck.com Geodeck hollow composite decking and railing system

- Kroy Building Products www.kroybp.com Timberlast solid composite decking with optional hidden fastening system

- Louisiana-Pacific Corp www.weatherbest.lpcorp.com. WeatherBest solid composite decking, railings, and accessories

- Nexwood Industries Limited www.nexwood.com Hollow composite decking and railing systems

- Tendura www.tendura.com TenduraPlank solid tongue-and-groove composite flooring for porches; natural finish or primed for painting

- Thermal Industries www.thermalindustries.com Dream Composite solid tongue-and-groove composite decking system with optional vinyl railings

- TimberTech Limited www.timbertech.com Floorizon hollow composite decking system, solid composite decking planks, and optional railing system

- Trex Company www.trex.com Solid composite decking

- Weyerhaeuser Building Products www.choicedek.com ChoiceDeck solid composite lumber and optional railings

Plastic Decking Systems

- Kroy Building Products www.kroybp.com Classic Manor embossed vinyl decking with clip system

- L.B. Plastics www.lbplastics.com Sheerline interlocking vinyl decking system and deck cladding systems

- Renew Plastics www.renewplastics.com Solid recycled high-density polyethylene (HDPE) plastic decking with embossed wood-grain texture

- Royal Crown Limited www.royalcrownltd.com Brock Deck and Deck Lok interlocking vinyl decking systems

- Thermal Industries www.thermalindustries.com Dream Deck interlocking vinyl decking and railing system

- U.S. Plastic Lumber Corp www.carefreexteriors.com Carefree Xteriors recycled plastic HDPE decking with embossed wood grain and optional railings

Metal Decking Systems

- FSI Home Products Division www.lockdry.com. LockDry aluminum decking and railing system

Prefabricated Deck & Porch Railing Systems

- Avcon Structural Railing Systems www.avconrail.com Thermoplastic and aluminum railings

- CertainTeed www.certainteed.com EverNew PVC railing system

- Global Dec-K-Ing Systems www.globaldecking.com DEC-K-ING aluminum railing system

- DecKorators Inc. www.deckrail.com Decorative aluminum balusters and connectors for wooden railing systems. Also, tempered-glass balusters

- Duradek www.duradek.com Durarail powder-coated aluminum railing system and walk-on vinyl decking membrane.

- FSI Home Products Division www.railingworks.com Aluminum railing systems

- Fypon www.fypon.com Polyurethane railing systems in classic architectural styles

- HB&G www.hbgcolumns.net PermaPorch cellular-polyvinyl chloride (PVC) railings and posts reinforced with wood or aluminum; cellular-PVC or aluminum balusters Kroy Building Products www.kroybp.com Classic Manor PVC-railing system

- L.B. Plastics www.lbplastics.com Sheerline PVC-railing systems and PVC- post cladding

- Royal Crown Limited www.royalcrownltd.com PVC railing system with steel reinforcing

- Shakespeare Composites Structures www.armor-rail.com Armor-Rail structural fiberglass (FRP) railing system with turned balusters

- Thermal Industries www.thermalindustries.com Dream Rail PVC-railing system with optional tempered glass balusters

- U.S. Plastic Lumber Corp. www.carefreexteriors.com Recycled HDPE railing system

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons)

This article series discuss best porch & deck construction practices, including choice of framing materials, decking or flooring choices & installation, how to select and use deck and porch structural and flooring fasteners, actual deck & porch framing construction details & connections, deck joist & beam span tables, how to build leak-proof rooftop decks, construction of covered & screened porches, deck & porch railing construction & materials, choices of finishes and stains for decks & porches, and past & current deck lumber preservative treatments with related health & environmental concerns. This article series includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons. Also see our BOOK REVIEW of that book.

...

Continue reading at GUARDRAIL CONSTRUCTION, DECKS & RAMPS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

ROOFTOP DECK CONSTRUCTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Prescriptive Residential Wood Deck Construction Guide, based on the 2009 International Residential Code, American Forest & Paper Association, Inc., provided by reader Mark Morsching from Everflashing.

- Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.