Well Screen or Well Bore Debris Cleaning

Well Screen or Well Bore Debris Cleaning

How to clean sediment out of the bottom of a well bore; how to clear a clogged well screen or foot valve

- POST a QUESTION or COMMENT on how two-line jet pumps work on water wells

Well bore & well screen cleaning:

This article describes approaches for removing silt, sand, or other debris from the bottom of a well bore or well casing; these methods may also be used to clear a clogged foot valve or well screen.

Water flow rate or water pressure improvements can be obtained if we un-block a clogged well screen or foot valve.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Methods Cleaning the Water Pump Intake Screen or Well Bore Sediment

Reader Question: how to clean the well bore sediment or screen clog without pulling well piping

(Aug 18, 2014) Bill K said:

Would it be conceivable to use a jet pump to clean out sediment at the bottom of a water well bore? We have six windmills on our ranch that are all around 140 feet deep that are 50 to 60 years old and sediment can get to be a problem over time.

I was hoping to achieve a new "lease on life" for these wells if I could clean them out in some way and a jet pump is the only thing I could think of that would be able to lift mud and such off the bottom if it could fit down the bore hole.

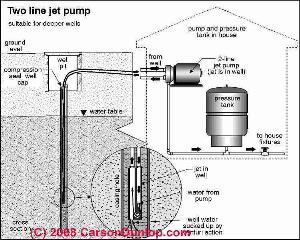

Page top sketch courtesy of Tornto home inspection & education firm Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Reply:

Bill

It's no surprise that articles on removing sand or silt from water wells mostly focus on filtering the water using various methods ranging from a cartridge filter to a centrifugal sand separator

. But for removing sand or silt from the bottom of a well bore, well drillers have had to deal with this matter for generations and have several approaches.

The most common approach, provided we're not also going to exhaust the well's flow rate, is to pump silty sandy water from the well bottom for an extended period of time - possibly days.

(Normally the water pick up in a well is set several feet above well bottom to avoid picking up settled debris).

You could use a 2-line jet pump whose pickup is at the end of the pair of pipes near well bottom COMBINED with some other jet to stir up muck to try to pump it out of a well bore, but you may destroy the pump in the process. Well drillers have a variety of approaches to removing debris from wells. Typically a pump particluarly designed to handle sludge is used.

Some examples are the Waterra pump line (waterra dot com)

Or search for sludge-pumps made by a variety of manufacturers.

Assuming your well bores are lined, it's possible that your lining has leaked or corroded or cracked. So you want to inspect the well bore (well bore camera) and if necessary, insert appropriate repair sleeves to cut the dirt or sediment or sand entry rate into the bore.

In 2010 the state of New Hampshire in the U.S. published a helpful article "Sand and Sediment in Water Wells", WD-DWGB-3-14 online as a PDF. des.nh.gov

Farmshow dot com has an interesting article about a home-made well-cleaner (Richard Guthrie's design) that uses a combination of a steel cylinder lowered into the well and compressed air - which may not be practical for deep wells such as you describe.

(Aug 19, 2014) Anonymous said:

Thanks Dan.

That gives me a lot more directions to go than I had before. I've been searching for an affordable well camera or even a rental place for one for several days now but they seem to be few and far between in West Texas. With six wells, not all working but we have plans for renewal on two, I'm tempted to buy one but at $3 to $4 grand or more each I'd hate to have one just sit for years after using it several times. I'd assume their resell value, if intact, would hold, though.

One personal theory of mine is that old well bores like this may also decline in production due to lime deposits at the layers of water production and may need to either be scraped in some way or acidized to promote continued flow.

This would produce a lot of debris that would need to be removed from the bottom of the bore but the cost of drilling another well (hit-or-miss proposition at $$$/ft regardless) and either moving the windmill or putting in a solar pump like we've done on one last year makes you go "hmmmm....".

The well that's given us the most problems over the years is a high sulfur content water well.

As of earlier this year the sulfur aquifer or layer has either played out or caked over and what little water is coming out is now sweet but production has gone down to almost nothing. Hence my longing for a well camera to reduce the guess work. Have any suggestions for any brands or opinions yea or nay on personal ownership?

Reply:

A bit costly to buy a well bore inspection camera. Here are a couple of ideas;

See if there are any chimney sweeps (probably not) in your area. Those guys may have a camera that can inspect the dry portion of the bore (which would be a partial exam)

OR

See if you can partner with a local well driller - one of the younger, more interested, technical fellows but who does not have an inspection camera. Offer to share the camera cost with him or her in exchange for examining your wells. S/he will then have a tool and expertise that expands her business.

(Aug 19, 2014) Bill K said:

Thanks again Dan,

I finally had time to more carefully read over your suggestions and the well cleaner of Mr. Guthrie's in Early, TX is intriguing. My uncle may actually be acquainted with him as he's from that area. I may contact him or his family to get a better understanding of that cleaner's design. We have an old well cleaner in the barn that might be convertible to this method. And, yes, we have our own "magic pile" of junk that we've been re-purposing for three generations now! You NEVER throw anything away on a ranch or farm. Junk is a ag man's gold.

Our wells were drilled at a time that casing was only partially inserted down the bore to a depth, I'm assuming, that the rock layers began. I guess they thought the rock wall would hold for at least a generation or two but that would put us just about at the end of that time line.

Reply:

(Aug 20, 2014) (mod) said:

Indeed the casing is usually stopped some short distance into the rock if rock is encountered - since we expect water to enter the well bore through fissures in that very stone.

Other Sources of Debris that Clog the Water System & Reduce Water Pressure

Watch out: debris in the water supply system, including crud that clogs faucet strainers, shower heads, water filters, will also result in poor flow rate or "water pressure" at building plumbing fixtures. If the debris is not coming from the water supply itself it may be originating within the piping system or building equipment. See:

- CLOGGED TANKLESS COIL or PIPES, LIME SCALE - where the water supply is high in mineral content or "hard water"

- DEBRIS in WATER SUPPLY, Water Heater - for example from a deteriorated water heater pick-up tube or anode

- WATER FILTERS, HOME USE - debris-clogged water filters

Well Cleaning Research

- Clu-In A REVIEW OF BIOFOULING CONTROLS FOR ENHANCED IN

SITU BIOREMEDIATION OF GROUNDWATER [PDF] (2005) - retrieved 2022/11/19, original source: https://clu-in.org/download/contaminantfocus/dnapl/treatment_technologies/er-0429-whtpaper.pdf

Excerpts Enhanced in situ bioremediation (EISB) is increasingly being used for the remediation of chlorinated solvents and recalcitrant chemicals (e.g., perchlorate, nitrate, hexahydro-1,3,5- trinitro-1,3,5-triazine [RDX]) in groundwater, both for plume containment and source area treatment.

Biofouling occurs when bacteria attach, grow and block the well screen, filter pack, or formation surrounding a nutrient delivery well, thereby limiting or preventing the proper function of the well.

The bacteria may originate in the aquifer itself or may be introduced during well installation, amendment addition, or groundwater recirculation (Cullimore, 1999). Most groundwater environments contain an active and diverse microbial population, but growth is limited in the absence of high concentrations of nutrients (Fry et al, 1997).

Bacterial growth within delivery wells is generally accelerated by adding the provided nutrients to promote the desired EISB reactions. - Cullimore, R. Microbiology of Well Biofouling, Lewis Publishers, CRC Press, Boca Raton, Florida. 1999.

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2018-02-07 by (mod) - Is this a candidate for using a driven point well

I don't think a driven point well can work for the case you describe; the depth is too great and I'd question the achievable flow rate.

If there is a deep-enough STATIC HEAD (search InspectApedia for that phrase) you can push an old pump to the well bottom and pull up your foot valve above it, but since old motors can deteriorate and some may leak lubricants into the well it seems better to me to retrieve it (WELL RETRIEVAL TOOLS) if at all possible.

Oil well drillers actually use tools to grind up and cut through steel objects dropped into the well, then that debris is pumped out. Not common in water wells. Certainly you're not going to want to live with a 65 ft well reduced to 30 ft unless there is an incredibly good flow rate.

In Florida conditions will vary but a good well has casing extending from the surface into bedrock, and the well is drilled deeper than the casing bottom (into rock). The casing is sealed against surface water leaks (for sanitation).

The following excerpt is from the Florida DOH

The construction of drinking water supply wells is regulated by Chapter 62-532 of the Florida Administrative Code, adopted by the Florida Department of Environmental Protection.

The rule is typically implemented by the five water management districts that issue the well construction permits. In some cases, the districts have delegated the program to local agencies, including the following county health departments: Baker, Brevard, Broward, Clay, Flagler, Glades, Hendry, Highlands, Indian River, Lake, Marion, Martin, Miami-Dade, Nassau, Okeechobee, Orange, Osceola, Palm Beach, Putnam, St. Lucie, Sarasota, Volusia and St. Johns.

In these counties, the health department is the agency that issues drinking water well construction permits.

- source: Well Construction in Florida, retrieved 2018/02/07 original source: http://www.floridahealth.gov/environmental-health/drinking-water/Well-Construction.html 850-245-4240

AskEH@flhealth.gov

See FLORIDA WELL CONSTRUCTION STANDARDS 62-532.500 [PDF] found at https://inspectapedia.com/water/Florida-Well-Construction-Standards-62-532.500.pdf for your state's recommended well construction details = none of which help with having dropped a pump and jammed it in the well casing.

Also see the FL well regulations directly at https://www.flrules.org/gateway/ChapterHome.asp?Chapter=62-532

We discuss well recovery rate and how it's measured starting at WELL FLOW RATE - https://inspectapedia.com/water/Well_Flow_Rate.php

You can just pump down the well and measure the time for the static head to recover and calculate the gpm, but that is NOT even close to the whole story since that does not describe

the variation in recovery rate at different depths at which water enters the well, nor does it describe recovery rate vs time. Most wells do not have a constant recovery rate.

A well driller might use a pump with an adjustable flow rate to find the rate at which she can keep taking out water over a 24-hour period. (That too may vary by season).

On 2018-02-06 by Francis M - Is this a candidate for using a driven point well

I purchased a 100 ft endoscopic camera and the iron casing is intact. The sand screen has about two feet exposed with the old pump blocking the rest. I use a 2" gas pump to pump out the well before and after I examined it. There was rusty water but very little sand.

But I still haven't figured out how to measure the recovery rate. I also filled the pipe and tried to see if there were any places I could see a hole in the screen.

Is this a candidate for using a driven point well with the built in screen acting as a secondary sand screen in case I missed something, that camera is really tough to use? My thought is that I would be able to use as much of the unplugged pipe as possible.

And does driving an old pump through your well ever work? The pictures I've seen of well construction all seem to show a slightly smaller sand screen tube at the bottom. Maybe its just the graphics.

And finally, if the screen is indeed damaged, how do I repair it?

Do I get the old pump driven down further and then send a perforated sleeve down?

I REALLY appreciate your insights and advice. Our well has been down for almost 6 weeks, and the generosity of our neighbors is the only thing keeping us going.

Thank you

On 2018-01-26 by (mod) -

I would start with a well camera inspection of the casing to see if there are repairs needed or if the well is truly beyond economic salvage.

On 2018-01-26 by Francis M

This is a long saga, and I appreciate any help, so here goes.

I live in Florida and my well, which was drilled in 2004, started to gush water out of the well head. I contacted the original installer who came out and tried to pull the pump.

This is a 4 inch iron casing in a low ph water area that goes down approximately 65 feet and the pump jammed at 40 feet. In their struggles to pull the pump, they unscrewed it...lefty loosy. The pipe was totally corroded through in several places.

I was told they could drive the old pump down into the aquifer and simply install a new smaller diameter pump at a cost of 3200.00. 3 weeks later they came and drove the pump to 60 feet where it encountered resistance.

The pump eventually stopped at 65 feet, and they said there was a LOT of sand at the bottom and the well is shot.

I live in a biohazard zone near old citrus groves which were treated with a chemical for nematodes, EDB, and wells in EDB areas are subject to special building needs?

Bottom line...a new well will cost 12 to 15,000.00.

I have been reading this blog, incredibly helpful, and have removed the sand from the well bottom using a 2 inch pipe attached to a 1 horse sludge pump. The water at night is clear, but in the morning it's full of trust.

Questions-

1. How do i check the water recovery rate using my existing pump and hoses, I have a 30 foot column of water now. I filled the 4 inch pipe to the top and watched the water level drop 1 foot per 15 seconds.

2. How do i keep the sand from returning? Is it feasible to use a two inch sand point in lieu of a submersible pump? Neighbors are using submerged and surface pumps here with equal results.

3. Is there a cure for the rusty water other than water treatments?

4. Is there something else I'm not doing yet?

This was a great well, wonderful clean water and I want to recover it, besides not being able to afford a 15k well on social security benefits.

Thank you for reading this Ode to Water saga.

On 2017-10-19 by Vikrant

While inspecting water level a piece of pipe got struck in the bore well and fell down .....what should i do now ? Is there any way to take it out?

On 2017-02-20 by (mod) -

I'd search InspectApedia for WELL RETRIEVAL TOOLS to see how to pull junk out of your well

On 2017-02-19 by Timothy James Clark

I have a deep well on property that I just bought for recreation. There is a pic pipe covers with a cement cap.i ran 40 foot of 1 1/4 pvc down the well and it stopped.when I pulled it up it had rotting wood in the end of the new pipe.My plan was to hookup a pitcher pump but I think someone dropped a log down the well.How can I get it out or work around it. Thanks.

On 2016-11-24 by anwaar rao

Tubewell straino choked in botom 8" plastik pipe & 120 ft depth

On 2016-11-06 by (mod) -

JS

Is there a question here?

On 2016-11-06 by Jsandhu

8 INCH PLASTICK 400 FEET BORE WITH 4 INCH delivery pipe with submersible pumps

On 2016-11-06 by Ano.nymous

I have a 8 inch diamete 400 ft deep plastic deep borewell.In the borewell, there's 4 inch diameter plastic delivery pipe

On 2016-05-15 by (mod) -

Ravindra

I would hesitate to use caustic chemicals to try to unblock a collapsed well as you're likely to contaminate the well and the surrounding aquifer - giving you a difficult time later flushing out such toxic substance.

Many well drillers have equipment to retrieve debris, motors, pipes, tools, or stuff that fell into a well; once those are cleared out mechanically you may need to install a well bore sleeve to repair the damaged well casing section. Search InspectApedia.com for

WELL RETRIEVAL TOOLS

and for

WELL CASING REPAIR SLEEVE

for more details

On 2016-05-15 by ravindra thepane

Your information is very good

I have bore well and debris collapsed on motor nearly 10 feet how to unblock with chemical

Question:

(Dec 11, 2011) Ken said:

Problem: Pump will lose it's pressure very quickly.

It is a Two Line Jet Pump.

Question: If I put a check valve at the pump side do you think this will fix the problem?

The small line pushes the water down the well. The large line is pulling the water up the pipe. If the pressure leak is cased by something at the small pipe how could I put a check valve on the pump side to prevent the problem?

(June 30, 2012) Mike said:

Hi,

I just bought the house with old Myers 2 line jet pump which is used for the sprinkler system only. On the instruction for home owner ( paper on the basement wall ) said to keep one valve ( intake) open , the other one ( from the pump) closed. I thought they both should be open. Any idea why ?

Reply:

Mike I'd like to help but am flying blind here - I just don't understand what valves are where - certainly if you close a valve found immediately on the outlet side of a water pump (that is between the pump outlet and the pressure tank or any other piping) you're likely to blow the pump seals or damage the unit.

I am making a WILD GUESS that perhaps your home converted from private well to municipal water, and that the old pump and well were kept for yard watering, and you are being instructed not to feed pump output into the house (try following the pipes to see what's going on).

If this is the case, the installation is improper and unsanitary. If it's the case I describe the pump should have no connection to house piping whatsoever.

Question: need for a double foot valve?

(May 11, 2014) Harold said:

I need to know if a double foot valve is requuired when the pump is drawing water from a lake.

Reply:

Harold:

You might need a larger size or larger capacity foot valve when picking up water from a lake if fast or frequent clogging of the foot valve screen is a problem.

You might need multiple check valves over the height of a long vertical water pick-up line if, for example, the total rise in height was more than 250 feet. In that case experts often say you need an additional check valve for every 250 feet of vertical rise.

Question: switch from 2 line to 1-line well piping system?

(July 8, 2014) Anonymous said:

can i switch from a two drop pipe system to a one drop pipe system

Reply:

Anon it depends on the well depth - the total lift that the pump has to achieve. If your well water pick-up point is more than 27 ft. below ground level you'll need a 2-line jet pump or if you need to go to just one pipe, then you'll need to use an in-well submersible pump.

Question: jet pump won't turn off

(Sept 14, 2014) frank s said:

pump wont go up to forty lbs only goes to 36 and wont stop running

Reply:

Frank

IN the More Reading links in the article above see

WATER PUMP WONT STOP RUNNING

...

Continue reading at WELL CLEANING BY GLYCOLIC ACID or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DEBRIS in WATER SUPPLY, Water Heater - for example from a deteriorated water heater pick-up tube or anode

- HAND DUG WELL CLEANING & RESTORATION PROCEDURES

- IRON & SEDIMENT REMOVAL

- WELL BORE CAMERA SYSTEMS

- WELL CAPS & COVERS

- WELL CONSTRUCTION & MAINTENANCE

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE

- WELL CASING LEAK REPAIRS - a cracked or rusted well casing can be a source of well contamination, mud, water loss.

- WELL CHLORINATION & DISINFECTION - if the cleaning your well needs is to address bacterial contamination

- WELL CLEANING PROCEDURES

- WELL CLEANING BY GLYCOLIC ACID - remove biofilms, scale, restore well flow

- WELL PIPING LEAK DIAGNOSIS - leaks out can also suck debris into water piping

- WELL WATER CONTAMINATION: CAUSES, CURES - home

- WELL WATER PRESSURE DIAGNOSIS - other reasons (besides clogged well screens or clogged filters) that can explain poor water pressure or flow.

- WELL RETRIEVAL TOOLS - fish out stuff dropped into a well

- WELL WATER CONTAMINATION: CAUSES, CURES - home

- WELL YIELD IMPROVEMENT

Suggested citation for this web page

WELL CLEANING PROCEDURES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER TREATMENT SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- Thanks to our reader, Carole Cimitile, 2/17/2009, for reminding us that small problems like faucet o-rings, clogged faucet strainers and similar local plumbing fixture defects can have a big impact on hot water flow, cold water flow, or both hot and cold water flow and pressure problems.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.