Roof Intake and Outlet Vent Area Ratios for Proper Attic Venting

Roof Intake and Outlet Vent Area Ratios for Proper Attic Venting

- POST a QUESTION or COMMENT about attic moisture, condensation & ventilation: what is the proper ratio of soffit intake to ridge outlet venting for roofs?

This article discusses How to Specify the Proper Roof Intake and Outlet Vent Area Ratios to Stop Building Heat Loss and Provide Proper Attic Venting to Avoid Condensation, Ice Dam Leaks, Mold, & Roof Structure Damage.

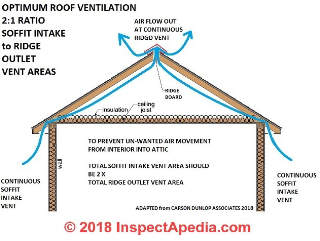

Our page top illustration, adapted and edited from Carson Dunlop Associates, a Toronto home inspection firm, explains that to avoid unwanted air movement from the occupied space into the attic or under-roof space, it is important to have the proper ration of soffit or eaves intake venting to ridge or roof top outlet venting: typically 2:1 soffit:ridge net free vent area.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Vent Area Ratios: Attic Ventilation Soffit Intake to Ridge Outlet Air Flow or Square Inches Ratio

Adding under-roof ventilation is usually a great idea, but if the relative sizes of the intake and outlet vents are not proper, the building

will suffer increased heat loss and thus an unnecessarily high home heating bill.

Adding under-roof ventilation is usually a great idea, but if the relative sizes of the intake and outlet vents are not proper, the building

will suffer increased heat loss and thus an unnecessarily high home heating bill.

[Click to enlarge any image]

Our photo (left) illustrates use of a turbine vent on a house roof as a means of improving attic exhaust venting. Wind powered turbine vents are useful in special applications but in our OPINION do not provide uniform under-roof ventilation across the entire roof surface.

We often find that spot vents or intermittently-placed roof exhaust vents (or inlet vents) result in incomplete attic or under-roof venting, leaving moist, sometimes mold-contaminated areas of attic sheathing and framing in the unvented spaces between the vent locations.

Details comparing various methods of roof ventilation are in the table below.

These recommendations are based on roofing industry standards, roof covering manufacturer recommendations, and on review of the literature on building insulation and ventilation, as well as on 30 years of building inspections, on the observation of the locations of moisture, mold, ice dams, condensation stains, and other clues in buildings, and on the correlation of these clues with the roof venting conditions at those properties.

We have also measured changes in airflow, temperature, and moisture before and after installing roof venting.

Continuous unblocked soffit or eaves intake venting combined with continuous roof ridge venting

(or equivalent area if the building framing does not permit a ridge vent) are needed to avoid ice dams, attic condensation, attic mold, rot, or insect damage from accumulating attic moisture.

But the ratio of intake air to outlet air is of critical importance too.

The ratio of soffit intake to roof outlet should be at least 2:1

to avoid unnecessary these heat losses from the building.

A serious error is a roof outlet vent net free area that exceeds the air inlets at lower roof edges or eaves.

See details at ROOF VENT NET FREE AREA

When this occurs in a climate where building heating is needed during part of the year, warm air leaking into the attic or roof space and exiting at the ridge vent (or other vents high on the roof) creates a convection air current that draws excessive heat out of the building during the heating season, leading to unnecessarily high heating costs.

But don't "fix" a bad intake to outlet air vent space ratio by reducing the ridge vent opening. Making this mistake can result in too little air flow under the roof surface, leading to indoor condensation and mold.

Roof intake venting with no outlet vent openings won't work

because there will be no air flow through the roof cavity. In a few cases, very wide, open soffit vents at building eaves seem to result in a dry attic, but the design relies on a prevailing wind pattern that sends air through the attic.

Even in this case most air flow will be across the attic floor, and an inspection of the attic near the ridge may reveal evidence of unwanted condensation and moisture staining or even attic mold.

Roof outlet venting with no intake venting won't work

because the absence of sufficient intake of outside air to satisfy the negative pressure from air leaving at the ridge will cause draw warm air up from the building interior, increasing heating costs and possibly mold or allergen movement through the building.

Providing more soffit or eaves intake venting than ridge outlet venting assures that the airflow required by attic air exiting at the ridge is satisfied by incoming outside air rather than by pulling air up from the building where it not only brings up building moisture, it also increases building heating or cooling costs.

Building Code Requirements for Roof Ventilation

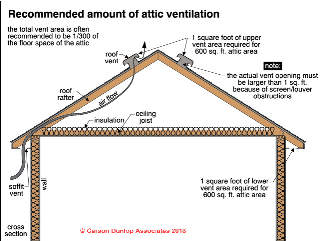

Carson Dunlop Associates' sketch above as well as several building standards and codes cited below provide recommendations for the total amount of under-roof or attic space ventilation.

Really? we do not recommend the individual roof vents such as illustrated in the sketch above as some areas under the roof will be left poorly-vented. See the page top illustration in which we prefer continuous exit ventilation at the ridge along with continuous soffit intake ventilation openings.

As detailed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter

The rules of ventilation developed by researchers in the 1940s were adopted first by the Federal Housing Administration (FHA) and later by all the major residential building codes, including the 2003 IRC, with few changes. Most asphalt shingle manufacturers will void their warranties if these rules are not followed. They require:

- 1 square foot of net free vent area (NFVA) per 150 feet of attic floor.

- 1 square foot of NFVA per 300 square feet of attic floor if a vapor barrier is installed on the ceiling below.

- The IRC adds that the NFVA ratio can also be reduced to 1:300 if 50% to 80% of the required ventilation is located in the upper portion of the attic (or cathedral ceiling) and the rest is located at the eaves, with the upper vents at least 3 feet above the lower.

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Types of Ridge Vents and Net Free Venting Area per Linear Foot |

|

Roof Ridge Outlet Ventilation Product Examples |

Sq. In. of net free ventilation |

| GAF Cobra® Ridge Runner™ exhaust vent | 12.5 sq. in. per linear foot, covered by cap shingles |

| GAF Cobra® exhaust vent: mesh type, roof nailing-gun-nailed | 14.1 sq. in. per linear foot, covered by cap shingles |

| GAF Cobra® exhaust vent: mesh type, hand nailed | 16.9 sq. in. per linear foot, covered by cap shingles |

| GAF Cobra® rigid Ridge Vent-2, Ridge Vent 3, & Snow Country ridge vent products | 18 sq. in. per linear foot, covered by cap shingles |

| Adjustable aluminum ridge vent (typical) | 18 sq. in. per linear foot, covered by cap shingles |

| Conventional rigid aluminum ridge vent (typical) | 20 sq. in. per linear foot, covered by cap shingles (est). |

| Roof louvers or "spot vents" (typical) | 50 sq. in. per vent, does not provide uniform ventilation between all rafter bays. Vent area ranges from about 35 sq. in. to 70 sq. in. for non-powered vents. |

| Turbine vents (wind-powered rotary, typical 12" to 14" diameter) | 120-240 sq. in. estimated equivalent vent area, does not provide uniform ventilation between all rafter bays. Varies by wind speed and turbine diameter/design. Installing without adequate air intake can result in significant building heat loss. Can be installed on sloped or flat roofs; consider for flat and low slope roofs. |

| Smart Vent™ by DCI for eaves with no overhang | |

| AccuVent™ attic ventilation roof baffle | |

Comments & Opinion About Statements of Net Free Ventilation Area of Various Roof Venting Products

Besides the rated air ventilation area described by various vent product manufacturers, other roof and vent opening details can significantly affect the actual airflow and level of under roof ventilation at a building.

While roofing product companies give useful general guidance on the amount of roof ventilation are recommended as a function of the square feet of attic space, here are some factors that could significantly change the actual recommended under-roof ventilation for a specific building:

- How wide was the cut made on either side of the ridge board to permit airflow into the ridge vent?

- Is the roof over an open attic, a partial attic with knee walls, or a cathedral ceiling?

- Is the building subject to usually high indoor moisture levels for any reason?

- What intake ventilation has been provided under the roof at the building eaves?

- How long and how open is the air flow pathway from building eaves (soffit) to ridge?

- How uniformly will the roof be ventilated by a given product? Will some roof areas or rafter bays be left unvented?

Looking at a linear foot of a typical thick mesh-type ridge vent and before considering that power-nailing compresses the mesh to further reduce airflow:

If we cut a 1.5" gap between ridge board and remaining roof deck, 12" long, on each side of the ridge board, that's

12" x 1.5" x 2 = 36 sq. in. of open vent area (before any covering with the ridge vent material).

Suppose a roof vent product company indicates that their product is giving you 17 sq. in. of roof venting in a 12" length - roughly that's a 50% airflow restriction over the free opening, before allowing for other obstructions (rafters, air flowing downhill) - by this analysis.

But another step is needed:

This is how we think about vent area with a roll-out mesh ridge vent material:

The exposed *edge* of the mesh vent is all that can possibly vent out - that's typically about 1/2" to 3/4" high between the roof surface and the underside of the cap shingles on the roofs we have walked recently.

For a linear foot, after the cap shingles are installed, and counting both sides of the ridge, that's about 12 sq. in. of available space (1/2" x 12" x 2 sides),

We then cut that area in half to factor in the 50% mesh-restricted air flow rate that we found above, so we're really seeing an effective vent outlet, in the best case, of 6 sq. in. per foot.

Which is too little compared with the intake.

The appeal of the low profile roll-out type mesh ridge vent materials that are covered with cap shingles is aesthetic - the ridge vent looks nicer from the ground, and it's convenient on the truck - doesn't get dented, rolls up and stores nicely for transport, and installs over a non-straight ridge line, something that's a problem with the old vent type.

So we understand why it's a popular product. It just does not pass as much air as the older vent type.

We asked one manufacturer's mesh-type roll-out ridge vent vent tech-ref-salesman about their actual airflow tests and airflow venting rates at a JLC conference in the 1980's: he was flabbergasted - replying that he had no idea about any actual tests or measured numbers.

Happily most roofing product manufacturers such as the GAF are kind enough to provide their estimates of the amount of ventilation provided by each product.

A low profile mesh type and some other plastic ridge vents do not pass much air compared to an older (uglier) higher-profile rigid aluminum ridge vent. Where we are having difficulty obtaining good airflow under a roof (such as where there is limited air space between insulation and the roof deck, aggressive intake venting and properly sized outlet venting at the ridge can help assure that the limited vent space under the roof would have adequate airflow.

That's why we often suggest that uglier alternative exit vent, as well as suggest making sure that the roof decking slots for outlet venting at the ridge are cut correctly on both sides of the ridge board.

In general, you want 2x as much intake venting (at the eaves) as outlet (at the ridge) but keep in mind that if you use a mesh type "ridge vent" the ridge opening is obstructed by the mesh and the air flow will may be insufficient, so you can't just measure the sq. in. of vent opening, you have to also adjust the calculation for the degree to which the vent opening is obstructed by mesh, screening, and any other airflow obstructions such as under-sized cuts into the roof deck.

On older homes where rafters are wider apart than standard modern framing specifications (16" o.c.), a baffle that extends the full width between the rafters is the best you're going to get unless the owners opt for the more labor intensive and thus more costly approach of a site-built vent path that uses furring strips alongside rafters and solid foam insulation sheets to give a deeper vent path under the roof than provided by a baffle.

You'll want to look at the baffle selected to be sure it won't be compressed when insulation is added into the remaining roof space between the rafters.

About ice dams and roof ventilation

Increased air flow under the roof will prevent, not cause, ice dams, provided that insulation is also completely installed.

Ice dams occur because lost heat at the eaves melts snow there where the snow melt runs further down the roof to the cold overhang where it freezes. If we can vent enough air under the roof surface to keep the roof uniformly cold you won't ever see ice dams.

Take a look at ROOF ICE DAM CURE: Comparing Two Houses where we compare two under roof venting schemes on houses that happened to be side by side. We installed continuous soffit intake and ridge vent on the house at left; the house at right had almost no soffit intake venting.

See ROOF ICE DAM LEAKS for details about this topic.

You'll want to be sure air FLOWS continuously from soffit to ridge- if the baffles compress or the air space is too little (say less than 1/2"), or if the ridge outlet is obstructed by low-flow plastic mesh, then the risk of ice dams is increased - not because of the soffit inlet but because of inadequate outlet.

Put it another way, if you had no roof venting at all, heat lost into the roof cavity will cause ice dams.

In sum the building design least likely to give ice dams includes

- good soffit intake venting -

not blocked by insulation, building framing, nor by my grandfather's boxes of stuff stored there since 1942 - good ridge outlet venting -

watch out for faux ridge vents nailed along the ridge without cutting the necessary opening through the roof sheathing - good air path soffit to ridge -

unblocked as air flows under the roof sheathing - good insulation installation -

no voids, extending all the way to the to plate over the walls but not blocking the soffit intake openings; or use baffles to keep insulation off of the roof sheathing to assure air movement at the tops of walls - proper balance between intake and outlet vent openings:

soffit vent opening = 2 x ridge vent opening - assurance that airflow moves under all roof slopes and all areas of the roof -

not just on one side of the building and not just between occasional bays formed by rafters on either side of a few spot vents installed in the roof surface

Last: don't forget the importance of also avoiding excessive interior moisture levels (a key factor in attic condensation and thus mold) - that wet basement or dirt crawl space needs to be addressed.

This is a section the article series, ROOF VENTILATION SPECIFICATIONS and is also part of our discussion

of ATTIC CONDENSATION CAUSE & CURE.

This article series describes inspection methods and clues to detect roof venting deficiencies, insulation defects, and attic condensation problems in buildings. It also describes proper roof ventilation placement, amounts, and other details.

Reader Comments & Q&A - also see the FAQs series linked-to below

On 2023-11-10 by InspectApedia Publisher - proper venting prevents drawing conditioned air out of the building through the attic floor

@Cal,

Thank you for the discussion.

I've inspected buildings with inadequate intake vent openings and a rather open ridge vent - and found significant drafts up from the occupied space such as around an attic pull-down stair and even around ceiling light fixtures.

If someone simply measures output air at a ridge they may not notice that some portion of that is coming not in at the eaves but rather in from the building below.

On 2023-11-10 by Cal

@InspectApedia Publisher,

Thank you for this discussion.

Interestingly, I found this paper (https://www.mdpi.com/1996-1073/5/9/3218), which showed mass air flow rate & attic cooling load under 3 different soffit/ridge ratios. Balanced (soffit=ridge), and two unbalanced (1/2*soffit = ridge; 2*soffit=ridge). I wish it included more unbalanced ratios. It did NOT include a variable of conditioned air leakage/draw.

Looking closely, doubling total NFA in the soffit dominant venting (from 1/400 to 1/200), did not reach the amount of airflow in the previous NFA (1/400) with balanced air flow. At larger ratios, this did not hold.

I understand it is important to not make firm conclusions from the paper as experience in these situations is significantly more important/helpful.

On 2023-11-10 by InspectApedia Publisher - having more available intake than exhaust doesn't hurt the building a bit and is an error in the "safe" direction

@Cal,

This is an instance in which Joe and I are in agreement.

My OPINION is that pretending we can measure and provide precise intake and exhaust vent openings is a mistake - as anyone with much field experience will agree.

So to be "safe" that is to not draw conditioned air out of the building through the attic floor we want to be sure that we have more eaves intake than ridge exhaust.

In my experience having more available intake than exhaust doesn't hurt the building a bit and is an error in the "safe" direction.

Just consider traditional soffit intake vent strips along the eaves. For a house with one lower roof edge facing into the wind that side will see much more air intake than the downwind or "lee" side of the building which might see no air intake or even a negative pressure depending on site conditions.

On 2023-11-10 by InspectApedia Publisher

@Cal,

The venting topic can be tricky to navigate.

The fallacy of apparently precise square inch ratios is that the square inches of "opening" are not usually equivalent between ridge and soffit or eaves.

For example, where roof sheathing is cut out along a ridge board just measuring the area of that opening can be misleading: nailing down a mesh type vent will pass less air per square inch than the older (uglier) aluminum louvered ridge vents.

My OPINION is that by assuring that I have much more intake than outlet venting I can at least assure that I'm not drawing conditioned air out of the building when convection currents send air "up and out" along a ridge vent.

On 2023-11-10 by Cal

@InspectApedia Publisher,

Wow. That's crazy. I would have never had guessed. Thank you for sharing. I would have thought box vents every 1-2 rafter bays would be fine, provided ventilation requirements were met. I guess it's ridge vent or bust.

Haha, except, when ridge vents are installed, the roof decks often aren't cut uniformly either, unless the whole ridge is cut. Often roofers/builders will cut a calculated # of linear feet and center it on the ridge, leaving the ends of the ridge without ventilation. Or they space the ridge cutouts in 2-3 intermittent sections. A whole ridge cut would then greatly increase intake ventilation design.

It's too bad there is not more single sided ridge vents, for aesthetic reasons (yes, overall trivial).

The only one I found, DCI's SmartRidge I, claims a NFA of 18in2, but I don't believe it. Dimensionally, it only has 9in of open area (excluding any screening/mesh area), and identical products of theirs for use as rain screens are listed with 9in2 NFA. And for adequate roof ventilation, ridge vents of 9 NFA just doesn't give enough total NFA.

Thank you again for your replies.

On 2023-11-10 by Cal

@InspectApedia Publisher, Thanks for your reply. Here are the authoritative sources I was referring to:

https://codes.iccsafe.org/content/IRC2018/chapter-8-roof-ceiling-construction#IRC2018_Pt03_Ch08_SecR806.2

https://buildingscience.com/sites/default/files/migrate/pdf/PA_Crash_Course_Roof_Venting_FHB.pdf

In Joe Lstiburek's article, I missed that he does say intake venting should be from 50%-75% (which includes the 67%, you recommend) of total venting, and only remembered his 60/40. So mea culpa.

Most of any resources found online say only 50/50 balance, including roofing & construction trade publications. Do you have any authoritative sources that provide more information on the science of intake:exhaust ventilation? I've asked building scientists & searched deeply but can't find very much info on any testing, modeling, or empirical data.

I do agree to have more intake ventilation than exhaust, but was surprised to the degree you recommend. I suppose you can't have too much. But I assume that you should have at least some minimum exhaust ventilation amount.

For example, minimum exhaust might be selected to be 50% of the minumum total NFA 1:150 requirement. Keeping the total NFA the same to reach code, but increasing the intake to reach 67%/33% (2:1), your exhaust NFA would become smaller, perhaps too small to maintain the necessary air flow/exchange rate.

So, the order of optimizing roof ventilation would be: 1) meet minimum exhaust NFA (50% of 1:150 ratio), 2) increase intake NFA to achieve 67%/33% intake/exhaust balance, while keeping exhaust NFA constant. 3) Maintain 50%/50% intake balance front to back.

Yes, other variables come into play. Perhaps the largest is the ceiling air leakage rate. Sealing the attic floor/conditioned ceiling would be of greatest aid.

On 2023-11-10 by InspectApedia Publisher - what ratio of intake and exhaust ventilation is needed

@Cal,

Thank you for the question.

Any authoritative reference citations you can give will be helpful.

The essential point about roof / attic venting intake and outlet opening sizes is that if the intake air source to a vented attic or roof space is less than the outlet air opening area then that pressure differential will draw conditioned air out of the occupied or conditioned space, thus increasing building heating or cooling costs.

Of course building air movement is affected as well by more factors such as wind, temperature differences, fans, etc

It is also worth noting that "box" vents at intermittent locations do not move air uniformly across all roof underside areas.

We often see mold, moisture, or even frost on those under-vented surfaces.

You'll find photos of those conditions in this article series.

On 2023-11-10 by Cal

Really? 2:1 ratio (67%/33%) for total intake NFA to total exhaust NFA? That seems counter to all other guidelines you find online recommending 50/50 to 60/40. Even in the Code, they recommend no more than 60%/40% intake/exhaust balance to qualify to use the 1:300 ratio.

I'm currently redoing my roof. I have 2500sf attic requiring 2400 in2 NFA. So I should have 800 in2 exhaust NFA and 1600 in2 intake NFA? I currently plan to install 1200 in2 exhaust (up from 600in2), so would I need to increase my intake NFA to 2400 in2, for a total of 3600 in2 NFA?

Increasing from 600in2 to 800in2 wouldn't have uniform exhaust across the ridge so it's easier to just add box vents in between current box vents.

On 2023-06-22 by InspectApedia Publisher - closed cell foam applied to underside of deck in a cross-gable roof

@Barry,

I appreciate the trouble with this roofing insulation vs ventilation schema.

You can always force a cold-roof design by adding spacers and baffles, though if I were doing it I'd want 2" or more to be sure, after all that trouble and cost, that my roof venting will be effective.

Problem is the cost - where I've done that it was labor intensive. For a DIY project you might not care but if you're hiring people to do the work, you may find a hot roof design a better choice.

On 2023-06-22 by Barry

I plan to have closed cell foam applied to underside of deck in a cross-gable roof. The current total soffit length for a 1500 square foot roof is approximately 15 feet. Due to many valleys it doesn’t seem possible to obtain adequate soffit air inflow.

Insulators have recommended a hot roof because even if they achieve a cold roof in the areas of continuous intake to exhaust, 2/3 of the roof could not be vented. I prefer a cold roof but not sure how to accomplish that.

The existing roof boards (1x12) exceed the 1x6 recommended by shingle manufacturer and the board spacing exceeds ¼”, the roofer will install sheathing over the existing roof boards.

Since I will be paying for this additional layer, I wonder about installing staggered sleeper blocks under the additional sheathing to create a 1” air gap under the entire roof and ventilate with a Hicks inflow and continuous ridge vent.

On 2023-04-04 by InspectApedia Editor - what kind of venting needed for hip and valley type roof

@Brad,

In my OPINION, "meeting code" is not the same thing as having a trouble-free building over its life. Building codes are a minimum standard, and building codes do not in any way even try to address every possible building and construction situation.

For example, code-specified ventilation ratio alone does nothing to consider roof shape, dead space areas that will not get any ventilation, irregularities of airflow up the underside of the roof and inconsistent air flow (where soffit intake venting is not continuous) and worse, generally no functional air flow if there is no exit venting along the ridge or high-enough in the roof to support air movement by natural convection.

Except when luck gives a particular wind direction that suits the orientation of a building and the location of its soffit vents, venting soffit only will result in no actual roof ventilation - no air movement.

And use of discontinuous soffit vents, regardless of "meeting code" means that the spaces of roof between vents will experience less or no ventilation. Each rafter pair forms a "bay" or passage for movement of air from the soffit up to a ridge vent.

An experienced building inspector who has seen mold growth on the attic side of roof sheathing will have seen buildings at which the rafter bay fed by a soffit vent is mold-free while one or two rafter bays away from that vent where the soffit is not vented, there is mold growth.

I think that your roof shingle manufacturer has had similar field experience to my own [DF]. I am disappointed in the reaction of your architect. The cost of making soffit venting continuous is in fact probably less than cutting in intermittent vents. So I just don't understand what your design professional is thinking.

Tell your architect that you want functional roof ventilation for 100% of the roof surface, regardless of whether or not that "exceeds" code. That means both continuous intake vents and ridge vents. If your roof is practically a pyramid with too little ridge area then add spot vents close to the ridge on the side less visible from the front of the home.

I have to stop answering this question to avoid lapsing into less generous remarks.

On 2023-04-04 by Brad

I have a new home that is under construction with a hip and valley type roof meaning the soffits are only at the lowest part of the roof. The architect specified soffit venting only (7”x22”) with 8’ spacing between vents around the perimeter of the roof.

When I asked why no upper vents were provided I was told the total vent area of the soffit exceeds 1/150 of the attic space so no upper vents are required by code (Florida Building Code (based off IRC)).

Is this true? Nothing seems to say you can’t do it, just that it is bad practice. The Shingle manufacturer says they won’t honor the full warranty because of it.

On 2023-01-26 by InspectApedia Publisher - "Do I need a ridge vent for the exhaust airflow or will a gable end vent be adequate for exhaust?"

@Koby,

You need a continuous ridge vent.

Without that, even though there's a "mini attic" below the upper roof, air flow won't be uniform under the roof deck, and the adequacy of exhaust venting will vary significantly depending on building orientation and wind direction and velocity.

On 2023-01-25 by Koby

I am retrofitting an attic to a cathedral ceiling and adding R50 insulation to the underside of the roof deck with a 1" air space using rigid baffles for airflow.

This is an old house without soffits or the ability to install them as the rafters finish flush with the edge of the top plate and eaves where added on to the exterior.

I plan on installing intake venting using the Cora-vent, In-vent product that works by cutting a 1 inch slot in the roof deck and covering it with the product, water/ice shield and shingles.

The cathedral ceiling will not run entirely up to the ridge but will stop at collar ties about 3 feet down from the ridge. So their will effectively be a mini attic at the top of the cathedral assembly that is a 24" tall air space (after insulation) triangle in profile and 30' long.

My question is: Do I need a ridge vent for the exhaust airflow or will a gable end vent be adequate for exhaust?

...

Continue reading at ROOF VENTILATION NEEDED? or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ROOF VENTING RATIOS FAQs - questions & answers posted originally at this page

Or see these

Recommended Articles

- PROBLEMS with PARTIAL ROOF VENTILATION

- ROOF VENT SOFFIT, CONTINUOUS

- ROOF VENTILATION ENERGY SAVING DETAILS

- ROOF VENTILATION IMPROVEMENTS

- ROOF VENTILATION INTAKE-OUTLET RATIOS

- ROOF VENTILATION NEEDED?

- ROOF VENTILATION SPECIFICATIONS - home

Suggested citation for this web page

ROOF VENTILATION INTAKE-OUTLET RATIOS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING VENTILATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about attic moisture, condensation & ventilation: what is the proper ratio of soffit intake to ridge outlet venting for roofs?

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. (727) 595-4211 mark@BestTampaInspector.com 11/06 & 12/08

- John Annunziata, P.E. - NY Metro ASHI during informal chapter discussions about roof and attic ventilation options (1986-1996).

- The Smart Vent™ by DCI roof intake venting provides an intake at the lower edge of roof decking for difficult cases. See www.dciproducts.com/html/smartvent.htm

- The AccuVent™ attic ventilation roof baffle produced by Berger permits insulation to extend over the top plate as far forward as possible. See www.bergerbuildingproducts.com/pdfs/AccuVentAtticVent.pdf

- GAF Cobra® and other GAF roof ventilation products: see www.gaf.com/Content/GAF/RES1/roof/RS_whyuse_ventchart.asp?viewer=&module=

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.