Septic Holding Tanks

Septic Holding Tanks

Tight tank, tight septic tank, closed-vault septic systems = septic holding tanks that must be pumped regularly

- POST a QUESTION or COMMENT about using a septic holding tank, applications, code approvals, maintenance

Septic holding tank guide:

This document discusses holding tanks in septic system design applications.

US EPA information has been expanded upon with supplemental documentation, references, and comments.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

What are septic holding tanks, how, where, and why are they used?

Holding Tank Septic Systems use a sealed

tank to hold household waste and wastewater until the tank can be pumped out by a septic pumping company.

Holding Tank Septic Systems use a sealed

tank to hold household waste and wastewater until the tank can be pumped out by a septic pumping company.

Most jurisdictions do not permit septic holding tanks as a permanent wastewater handling method for full-time occupied residences, but holding tanks may be permitted during new home construction and in other special cases.

Our photo shows a worker emptying a septic holding tank in the San Marco area of Venice, Italy, in June 2017. Traditionally Venice's sewer system emptied into the city's canals, and much of it still does, relying on tidal action to keep the canals acceptably clean.

A photo of the septic tank pumper boat or sewage boat is discussed

at PUMPER TRUCKS & VACUUM PUMPS SOURCES / SPECS.

In New York State we've seen holding tank systems in use on small-lot properties located along the Hudson River. Generally such systems will not be acceptable for full time occupied residences as even a large tank of several thousand gallons will require frequent and costly pumping and disposal.

Holding Tank Septic System Regulations for Installation and Use

The use of holding tanks shall not be permitted for new home construction except where occupancy of a home is permitted while the sewage treatment system is under construction.

Tank size shall be based upon five days design flow or 1,000 gallons, whichever is greater and meet the same construction as a septic tank except that the holding tank shall not have an outlet.

Holding tanks are not acceptable for long term use on year-round residences [in most jurisdictions -Ed].

The above sanitary code citation is from: New York State Appendix 75-A.10 OTHER SEPTIC SYSTEMS

Septic Holding Tanks and Septic Hauling Systems

Photo: a septic tank being pumped in Two Harbors, MN. Contact information for the pumping company, David Roeder, Superior Septic Service, and their pumper truck are shown

at PUMPER TRUCKS & VACUUM PUMPS SOURCES / SPECS.

Onsite Wastewater Treatment Systems Special Issues Fact Sheet 4 EPA 625/R-00/008

Description of Septic Holding Tank Systems

A septic holding tank or vault or "tight tank" receives wastewater from a home or commercial establishment and stores it until it is pumped out and hauled to a receiving/processing facility. Although similar to septic tanks, septic vaults have no outlet piping and must be watertight.

The volume can range from 1,000 gallons to 4,000 gallons or more. The vault should be equipped with an audible and visible high-water alarm, which alters the resident to the need for pumping.

Different sizes of vaults and tank trucks can be used; water conservation can reduce costs considerably by reducing the frequency of pumping. A vault can be equipped with a standpipe and a quick disconnect to which the pumping truck can be directly connected for efficient (minimal spillage) emptying of the vault.

Holding tanks can be used for the entire wastewater flow in cases where conventional and typical alternative systems are not feasible. They are often used this way for seasonal homes in sensitive environmental settings. Holding tanks can also be used to collect only a part of the wastewater flow. Usually, they are used to collect the greywater when non-water-carriage toilets are employed in sensitive areas.

This option permits a significant reduction (usually one-third or more) in the number of tank pumpings as compared to the whole wastewater collection option. Another holding tank option is to collect only the blackwater fraction of the wastewater while the graywater is treated in an OWTS.

This option is most popular in estuarine areas where significant nitrogen removal is required because the blackwater may contain from 70 to 90 percent of the total nitrogen load. In this case the reduction in pumping frequency from the whole wastewater option would be about two-thirds.

Over and above these combinations a program to reduce water use can be overlaid. The critical contribution of such a program (see chapter 3) is to reduce the daily volume of wastewater (blackwater, graywater, or combined) produced and the required frequency of holding tank pumping.

Some onsite wastewater recycling can be added to this program in arid regions where gravity feed and belowground watering of non consumable vegetation can be accomplished. However, such a program must meet all local public health requirements.

Applications of Septic Holding Tank Systems

Pump and haul collection is best used when soil absorption fields do not work (for example, where bedrock or ground water levels are near the ground surface) and there is no sewer system.

Typical applications are second homes, where annual occupancy may be only a few days to a few months; where a nuisance or public health hazard must be abated; where an isolated building has no running water; in temporary structures or gathering places; or where nutrients must be excluded from ground water to protect environmentally sensitive areas.

Pump and haul collection may also simply be the least expensive alternative in some places.

Pump and haul systems are viable only under a wastewater authority that guarantees service. Pump and haul collection can became prohibitively expensive when homes are occupied all the time or where the distance from the treatment plant to the home is more than a few miles.

Management needs of Septic Holding Tank Systems

Holding tanks should be used only where a proper management program is in place. Construction requirement are essentially the same as for a septic tank in that the onsite testing for tank leakage is vital to a successful design and the alarm system must be dredged for proper functioning before acceptance.

In addition to timely pumping, operation and maintenance requirements should include checking the alarm function, cleaning the activation floats, and comparing volume used vs. volume accumulated in the tank.

The skill requirements at the site are minimal and can be estimated as approximately 1 hour per pumping. There are normally no energy requirements; the residuals are the tank contents, and confined-space entry safety requirements must be followed if tank entry is required.

Risk management issues of Septic Holding Tank Systems

Holding tanks are not subject to upset by flow variation, toxic loads or power outages. They should be insulated and possibly heat-treated in extremely cold climates.

If properly vented through the building sewer, they should not exhibit odor problems, but use in hot climates may require an increase in pumping frequency or a regular addition of lime for mitigation. There is a release of objectionable odors during tank pumping, which can cause some discomfort to residents.

Costs of Septic Holding Tank Systems

More recent cost estimates for holding tank-hauling wastewater disposal indicate that tank installation is about $1 per gallon of capacity (up to 5,000 gallons) while the alarm system is about $400.

Tank pumping is generally in range of 10 to 30 cents per gallon, to which labor, travel and equipment amortization may be added (or these costs may be included in a flat fee). Travel costs will dominate if the round-trip distance to the holding tank, to the disposal site, and back to home base exceeds 50 miles.

The permit costs to discharge the sewage removed from a septic holding tank at an appointed site (treatment plant, land spreading site, or independent treatment facility) is also escalated, multiple pumping from a year-round house can become extremely expensive.

Additional thanks to David Roeder, Superior Septic Service, 524 4th Ave., Two Harbors, MN 55616, USA, Tel: 218 834-6969 for discussion of septic tank pumping procedures, distances, hoses, and levels. May 2017.

Holding Tank Septic System Design References & Product Sources

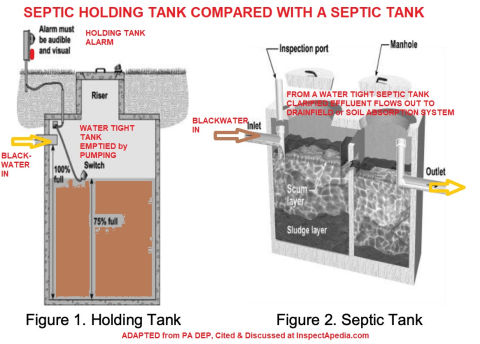

Illustration: the PA DEP illustrates the difference between a holding tank and a septic tank - cited in detail below.

- Anderson, C.D. 1986 Trucked Collection Systems Experience in the Northwest Territories. In Proceedings of Appropriate Wastewater Management Technologies for Rural Areas Under Adverse Conditions. Technical University of Nova Scotia, Halifax, NS.

- Burrows, R., and N. Bouwes. The Cost of Holding Tanks for Domestic Wastewater. Small Scale Waste Management Report. University of Wisconsin, Madison, WI.

- Dix, S.P. Case Study Number 4: Crystal Lakes, Colorado. National Small Wastewater Flows Clearinghouse, West Virginia University, Morgantown, WV.

- Mahoney, W.D., ed.-in-chief. 1989. Means Site Work Cost Data. R.S. Means Co., Kingston, MA.

- Mahoney, W.D., ed.-in-chief. 1990. Means Site Work Cost Data. R.S. Means Co., Kingston, MA.

- Manci, K. No date. Wastewater Treatment Alternatives.Holding Tanks. The Pennsylvania State University, College of Agriculture, Cooperative Extension Service, University Park, PA.

- Mooers, J.D., and D.H. Waller. 1996. Onsite Wastewater Research Program: Phase III. TUNS/Centre for Water Research Study, Halifax, NS.

- National Association of Waste Transporters (NAWT). 1998. Introduction to Proper Onsite Sewage Treatment. National Association of Waste Transporters, Scandia, MN.

- NY RESIDENTIAL ONSITE WASTEWATER TREATMENT SYSTEMS DESIGN HANDBOOK (2012), New York State Department of Health, Health Education Services, POB 7126, Albany NY 12224 Tel: 518-439-7286 - retrieved 2022/06/22 original source: https://www.health.ny.gov/environmental/water/drinking/wastewater_treatment_systems/docs/design_handbook.pdf

Excerpt:

The use of holding tanks shall not be used for new residential construction regardless of full-time or part-time occupancy, except when temporary occupancy of a dwelling is allowed while the OWTS is under construction or when installation is delayed due to weather conditions (such as freezing temperatures or excessive rain).

Holding tanks are only intended to meet the above noted exception or to correct existing failing OWTS when no other alternative exists.

Holding tanks are not deemed acceptable for long-term use at year-round residences due to high maintenance costs and continuous operation attention.

If considered on a permanent basis due to extreme hardship to replace a failed system and no other options are available, approval may be required by the local code enforcement official (CEO), LHD or other agency having jurisdiction. Tank size shall be based upon a minimum of five (5) days design flow or 1,000 gallons, whichever is greater, and meet the same construction standards as a septic tank except that the holding tank shall not have an outlet.

The holding tank must be designed, installed and maintained in a way that promotes ease of access for pumping and cleanup. Holding tanks should be provided with access to grade. The access should be provided with a cover that is water tight and lockable to prevent inappropriate or unapproved access.

Holding tanks may need to be properly vented through the house vent stack to avoid odor issues and related nuisances.

All holding tanks shall be equipped with an alarm (audible and visual) located in a conspicuous place to indicate when pump out is necessary. The owner should have a contract for service with a NYSDEC permitted septage waste transporter to pump the holding tank as needed.

A solenoid valve on the water service line to the household (upstream of all fixtures and immediately downstream of a hydropneumatic tank, if one exists) should also be considered to avoid holding tank overflows.

Water saving fixtures should be installed and water saving practices should be implemented in any home being

served by a holding tank to minimize pump out maintenance costs. Waste management districts or

RMEs are recommended for areas with numerous holding tanks to provide continuous inspection and

maintenance services.

- Ohio, OUTHOUSES & HOLDING TANKS REGULATIONS, [PDF] Ohio Department of Health, retrieved 2017/10/20, original source: http://www.odh.ohio.gov/

- Pennsylvania, ACT 537: UNDERSTANDING HOLDING TANKS [PDF] Pennsylvania Department of Environmental Protection (DEP) - retrieved 2022/06/22 original source: https://www.harmony-township.org/wp-content/uploads/2017/04/ACT-537-UNDERSTANDING-HOLDING-TANKS.pdf

Excerpts:

As defined in the Department of Environmental Protection (DEP) regulation 25 Pa. Code §73.1, a holding tank is “a tank, whether permanent or temporary, to which sewage is conveyed by a water carrying system.”

Further, it is “a watertight receptacle that receives and retains sewage and is designed and constructed to facilitate ultimate disposal of sewage at another site.”

This section of DEP’s regulations, as well as others, is available on The Pennsylvania Code website. http://www.pacode.com/

Holding tanks (Figure 1) and septic tanks (Figure 2) are very different structures. Again referring to 25 Pa. Code §73.1, a septic tank is “a treatment tank that provides for anaerobic (oxygen-poor conditions) decomposition of sewage prior to its discharge to an absorption area.”

This treatment function is the first of two major differences between a septic tank and a holding tank.

Holding tanks do not treat sewage; they merely store sewage that will be treated at another location.

The second difference is that septic tanks discharge partially treated sewage (called effluent) into the soil for final treatment through an outlet.

Holding tanks have no such outlet. - SEPTIC SYSTEM DESIGN: ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL [PDF] (2002) EPA 625/R-00/008, U.S. EPA, Office of Water Office of Research and Development U.S. Environmental Protection Agency retrieved (new) 2019/09/18 original source: https://www.epa.gov/sites/production/files/2015-06/documents/2004_07_07_septics_septic_2002_osdm_all.pdf

- U.S. Environmental Protection Agency (USEPA). 1984. Final Generic Environmental Impact Statement: Wastewater Management in Rural Lake Areas. U.S. Environmental Protection Agency, Region 5, Chicago, IL.

- US EPA DESIGN MANUAL FOR ONSITE WASTEWATER TREATMENT AND DISPOSAL

- Waller D.H., and A.R. Townshend. 1987. Appropriate Wastewater Management Technologies for Rural Areas Under Adverse Conditions. Special Publication, Technical University of Nova Scotia, Halifax, NS.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-06-22 by InspectApedia-911 (mod) - definition of closed vault septic system

@Anastasia,

Thanks for the helpful question.

Definition of "closed vault septic system" = a septic holding tank that is a water-tight, closed container that stores incoming sewage and wastewater until it can be removed by pumping for transport to a separate sewage disposal or treatment facility.

So yes, a "closed vault septic system" is a closed-septic tank and thus a holding tank that has to be pumped out frequently.

In some texts and countries, people use the word "vault" as a more elegant-sounding synonym for "tank".

That's appropriate in that the general definition of "vault" is a large room or chamber used for storage, especially an underground one. But if you're storing sewage, not money, in an underground chamber that is water-tight and does not discharge any effluent out of the tank to a septic drainfield or other treatment system, then it's a closed septic vault or a septic tight tank.

Synonyms: all of these phrases refer to the same thing:

- "septic holding tank"

- "tight tank"

- "tight septic tank"

- "closed vault septic system"

- "closed vault septic"

- "closed vault septic tank"

Watch out: Holding tank septic systems (discussed above in detail on this page) or closed vault septic systems, are not permitted in most jursdictions for most situations, with a few exceptions such as a restaurant along the Hudson River.

The reason is that "closed vault septic system" is an oxymoron in that it includes the word "system" which implies that the sewage is being treated in some way. But a holding tank does nothing useful except to store sewage and other wastewater.

It does not and can not discharge treated effluent into the local environment.

A conventional septic tank is also water tight and also receives sewage and wastewater from a building or buildings, but in a conventional septic tank, baffles keep solid waste in the tank while permitting clarified effluent to exit the septic tank to flow into a treatment system such as a septic drainfield or mound.

In the septic effluent treatment system, also called a soil absorption system or SAS, soil bacteria further digest pathogens in the wastwater sufficiently that it can then safely flow into surrounding soils or evaporate into air above the drainfield or mound.

On 2022-06-22 by Anastasia

A closed vault septic system is the same as a holding tank that is periodically pumped out?

On 2021-04-07 by (mod) - want to install a holding tank in Ohio

@Joshua A Chapman SR,

Septic tank holding systems are not code approved in most countries and cities so before spending money on that topic you need to check with your local building or plumbing department.

The Cleves website is http://www.cleves.org/

where you will see that officials have done a fantastic job at making it (apparently impossible) to find out how to call, email, or even walk-in to anyone's office: I've had no success finding actual contact information.

Here's "Planning and Zoning" http://www.cleves.org/content/planning-zoning

On 2021-04-07 by Joshua A Chapman SR

Address is 5430 Gieringer Avenue Cleves Ohio a side road that dead ends off East Miami Rvr Road.? Want to put a Modualr cabin something. Their is water on the property and electric would be easy hook up

On 2021-02-19 by (mod) - causes for abnormally-fast fill-up of a closed vault or tight septic tank

@Pam,

Are you sure we're really discussing a septic holding tank? Those are not legal in most jurisdictions.

If it really is a holding tank, then there are two ways the tank may "fill-up"

- water is running in the building - someone might, for example, not have noticed a toilet that's running constantly

- water is leaking into the holding tank from outdoors: from roof runoff, surface runoff, or groundwater leaking into the tank;

If a careful inspection of the tank cover, lid, access ports, shows nothing suspicious, then a more-thorough inspection of the tank sides and bottom should be made when the tank is pumped out.

Watch out: do not try to enter a septic tank to "inspect" it - doing so can be quickly fatal. Special training, equipment, and assistance are needed.

For more-conventional septic tanks:

If "rainwater" is filling your septic tank it's also flooding your drainfield and your septic system cannot work.

You need to divert rainwater or surface runoff away from the septic system and be sure there are no leaks into the tank.

BUT

It's entirely possible thatwhta's actually happening is your septic drainfield is saturated and has failed and is draining backwards into the septic tank.

Finally:

It is normal for a septic tank, in regular use, to be full, all the time, except for a few days to a week right after it has been pumped.

On 2021-02-19 by Pam - 5000 gallon holding tank pumped out and filled back up in two months with rain water

Hello, 5000 gallon holding tank pumped out and filled back up in two months with rain water. Don't see it leaking out anywhere, no wet spots, so only leaking in? Any idea where could it be leaking at? Thanks

On 2020-06-29 - by (mod) -

Jim

Jim

If I understand the situation, there is a concrete septic tank with concrete lid with an access opening, apparently closed, perhaps over the inlet end, and there is a concrete riser - shown in your photo, with its own lid

In a usable installation, the cover on the tank top itself is removed,

the riser is sealed to the top of the septic tank so groundwater can not leak into the tank and so that the riser doesn't move

the riser has its own secure, child-safe lid.

In that installation your high sewage level alarm is installed and secured in and near the top of the tank and its control wires and alarm signal wires are run up through the riser and probably out along the riser side, well above ground. You'll want a suitable and stable stand to mount the alarm and controls.

Watch out: the tank in your photo may not be designed for nor usable for sewage - and in any event may need a better access for cleaning.

On 2020-06-29 by Jim M

I have a 2000 gallon, never used, concrete holding tank that needs to have a high water alarm installed.

The tank is buried about 3 feet below the ground and has one lid directly on top. There is a second concrete riser on top of that one with another concrete lid. I was told I should drill thru the top of the tank to run the float wire up from inside the tank to the outside.

I was wondering if the top riser had a good seal, do I need the first lid that sits directly on the tank, or could I just use the top lid and run the float wire thru the top riser or lid?

I am hoping to avoid drilling thru the top of the tank and getting inside to run the wire out. Any suggestions would be greatly appreciated?

On 2020-06-14 - by (mod) -

Tom

Your sewage holding tank may be grandfathered "in" as are some at properties right along the Hudson River, and thus permitted but no, in New York, including around Lake George, the building authorities generally won't approve a new installation of a "septic" system that uses only a holding tank. You could face a hurdle when property is to be sold.

If you have sufficient land you can perhaps install a pump-up mound system up-hill and sufficiently back from the lake. I helped install such a system at Lake George - it included a freeze protection system since there is so much rock it's tough to get below the frost line.

You might also ask your building department if they'll approve an advanced mini wastewater treatment system that can operate with a smaller footprint, then get some design advice from a local septic engineer.

On 2020-06-13 by Tomr

I have a 1500 gallon holding tank for a 3 bedroom Home in lake George NY

It does not have an outflow and we have it pumped out

when the Level alarm reaches 3/4 full.

Is this a legal system.

We prefer to do this due to we are close to the lake. We only need to have it pumped out

3x per year due to the home is only part time.

Is this a NYS code approved way of dealing with the sewage

No, Bob, septic tanks are made of

concrete

fiberglass

polyethylene

and used to be made also of steel though IMO that's not a great choice

and have been "home made" using concrete block, a terrible choice

that risks collapse, injury, or worse.

Below I give an example, black polyethylene (plastic) septic tanks from Atlantis, a UK provider atlantistanks.co.uk

More detail is at SEPTIC TANKS, FIBERGLASS / PLASTIC

On 2020-01-12 by Bob Connolly

Do septic tanks come in only concrete ? Is there a better product long term?

Thank you.

On 2019-11-23 - by (mod) -

RL

Generally you can simply calculate compute or estimate the average daily waste water flow into the septic system because they upload will be the same liquid volume. If you search this website for average daily water usage for water usage rates you'll find some tables of typical numbers.

But the actual numbers for your building may be quite different depending on the number of occupants and exactly what they're doing.

On 2019-11-21 by RL Mae

good day..i would like to inquire as to how to compute for the discharge rate of the septic tank so as to come up with at least 1 year siphonage to septage treatment facility?

On 2019-10-03 - by (mod) -

Tammy

First it's not likely that your municipality will approve installing of a holding tank for your home.

Second, you can avoid that cost and instead spend the money on regular pumping of your existing septic tank. IN essence you're using the existing tank as a "holding tank" and having it pumped monthly or more-often.

Regrettably there is no good option other than trying to fix the mound or pump the tank very often.

At $400. per pump out and pumping every few weeks at the least you'll spend in the ballpark of 10,000 before your sewer connection has been installed. Horrible I know.

Monitor at the pump or D-box; by pumping and resting the mound you may be able to stretch out the pump-intervals.

Watch out: even worse: when the septic tank is pumped check with the pumper to assure that effluent is not simply running backwards into and re-filling the tank.

At a properly I've monitored for several years that was an issue; the owners kept pumping the tank and thinking they were gaining something but in a day or two the tank was filled again with surface runoff - so they were not giving their mound or field a rest at all.

On 2019-10-03 by Tammy Mitchell

I have bad mound. Get sewer in 2 years. How much to install holding tank. Family of 4.

Considering the purchase of older house, says needs new septic. How do i go about finding out what type, and cost of fix b4 purchase?

On 2015-04-19 - by (mod) -

Not in my experience. If there are odors then the eating system is not right. Include an alarm so that you know when pumping is needed. And of course you'll need local building or health department approval.m

On 2015-04-17 by Holding tank pumping

I am looking at putting a septic holding tank at my workshop, as we are near a river, It will be only used for a toilet for 1 person, would it cause to much of a smell if I only get it pumped out once a year?

Thanks

Jim

On 2015-03-04 by nancy

We have an in-ground holding sewage tank with a powerful grinder pump in it. Last year the tank shifted up out of the ground about 4 inches due to the ground heaving with the thaw in the spring. The tank is a 60 gallon fiberglass, cylindrical tank. The shifting has caused the piping to also shift!

Everything is still working normally. The floats function as they should and it pumps when it should.

This is in the basement floor, which is about 6 inches of concrete and then gravel surrounding the tank in the hole.

Is there any way to get this tank reseated into the hole?

I'm concerned it will rise again this year and push out of the ground further, which could be a real mess!!

On 2014-12-21 by keith

I have the permit approved for a dual 1000 tank pump and haul system, it must include the full audio/visual alarm indicator. Have been searching the net for design and requirements for self installation without luck. Can you point me in the right direction?

On 2014-10-27 by Kelly

Hello. We are looking at a vacation home located on a river. The realtor tells us they have an 800 gallon holding tank (not a septic tank). They say the last time it was pumped was March 2012 (it is currently October 2014).

I know they don't use it often, but know they do rent it out throughout the year (when we were there they had 4 people staying at the home). How could this be possible to have a holding tank only 800 gallons and pumped so infrequently. Could it be they are confused and it is a septic system?

Could it be that they are letting it overflow and not properly pumping it? The realtor keeps telling us this is common and no big deal but it makes no sense to me. It seems they are either very confused or releasing sewage illegally. Any thoughts? Am I totally missing a common point. Thank you very much for your thoughts!

On 2014-05-24 - by (mod) -

Just. Sounds ok, though you might ask what was the level found at next pump out. Tha will tell you if you can extend the pump out interval. By the way, some jurisdictions won't allow this system in permanent use.

On 2014-05-24 by Just curious

Hi,I have a holding tank with and alarm,only toilet goes in there and we have it pumped a few times a year 2 bedroom 1 bath. Is this ok?

On 2014-02-09 - by (mod) -

Joan, you need to

1. dig up enough of the holding tank to see where water is entering - if it's entering around the entry pipe (which is common) that's where a new rubber seal or other seal needs to be installed.

If water is entering the holding tank through a lid or cover then it may be possible to seal the cover - but don't glue it down as access is needed for cleaning and inspection; and see point 2 below.

If you don't see an obvious water leak-in point from a little exploration, when the tank is pumped and cleaned, your service company can inspect the tank interior for cracks or damage; it may be possible to repair cracks - you don't say what the tank is made-of.

but

WATCH OUT: NEVER enter a septic tank - it can mean almost instant death by asphyxiation by septic fumes; special equipment and procedures are needed if entry is necessary.

NEVER even LEAN OVER the tank to look inside directly - for the same reason; people are made unconscious and may fall into the tank and die.

An expert uses a combination of flashlight & mirror on a pole for safer and more remote inspection.

See our article titled

How & Why Septic Tank Leaks Cause Septic System Failures

found by searching inspectapedia for that title or just search for SEPTIC TANK LEAKS

Finally, you want to determine where the problem water is coming from and to direct it away from the septic tank.

On 2014-02-01 by Joan davis

water is running in from ground how to repair it?

...

Continue reading at SEPTIC TANK PUMPING SCHEDULE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CESSPOOLS

- DRYWELL DESIGN & USES

- GREYWATER SYSTEMS

- HOLDING TANK SEPTIC SYSTEMS

- SEEPAGE PITS

- SEPTIC TANKS - home

- SEPTIC TANK, HOW TO FIND

- SEPTIC TANK PUMPING PROCEDURE - home

- SEPTIC TANK SAFETY

- SEPTIC TANK SIZE

Suggested citation for this web page

HOLDING TANK SEPTIC SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about using a septic holding tank, applications, code approvals, maintenance.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.