Septic Drainfield Design Basics

Septic Drainfield Design Basics

Septic Size Requirements Guide

- POST a QUESTION or COMMENT about the design basics of septic drainfield or soakaway bed size or capacity requirements

This article explains the basics of septic drainfield components and design including how to determine the size and design of a septic leachfield or soakaway bed or drainfield. We discuss rules of thumb used to set the size of a conventional septic drainfield.

We discuss septic drainfield trench lengths for various soil perc rates and wastewater flows.

Septic drainfields, also called leach fields, absorption beds, soil absorption systems, soakaway beds, and leaching beds, perform the functions of septic effluent treatment and disposal in onsite wastewater treatment systems, conventionally called "septic systems".

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How large does the septic drainfield need to be?

Article Contents

- SEPTIC TRENCH LINE SPECIFICATIONS

- SEPTIC DRAINFIELD INSPECTION PORTS

- SEPTIC DRAINFIELD DESIGN TYPES

- SEPTIC DRAINFIELD PIPE SIZING

- SEPTIC DRAINFIELD SIZE CODES / REFERENCES

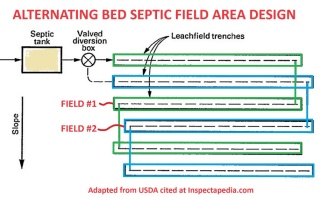

[Click to enlarge any image] Sketch - USDA.

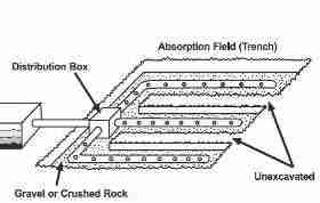

Typically, septic leach fields (synonyms: drainfield, leach bed, soakaway bed, absorption bed), the septic component that disposes of and treats clarified effluent leaving the septic tank, are built by placing perforated effluent distribution pipes in a field or bed of gravel. Effluent runs into those pipes from the septic tank and then is dispersed into the surrounding soil.

A basic question our clients have asked over many years is "How big does my drainfield have to be?" or perhaps "How many feed of leachfield trenches are needed?"

The drainfield is made up of a series of trenches that may be up to 100 feet long and 1 foot to 3 feet in width, separated by six feet or more, depending on local requirements, and sometimes constructed leaving space between the original lines to install replacement leach lines when needed. (Here we are paraphrasing USDA and other sources. - DF)

Drainfield size and location also have to take into account local zoning - setback requirements from property borders, setbacks from streams, wetlands, wells, water supply lines, and other encumbrances.

As you will read below, there is no one "right" septic absorption field size.

Rather, the size needed (in square feet of area, presumably also unencumbered by trees, driveways, buildings, etc.) depends on several variables such as the rate at which the soil can accept liquid (the percolation or "perc" rate), and the expected daily volume of wastewater that will be sent into the septic system.

A site whose soil has a good percolation rate or "perc" of perhaps one inch of percolation in 1-5 minutes might require about 125 feet of drainfield trench for a typical two bedroom home.

But if the same home were built where there was a poor soil percolation rate of 46-60 minutes per inch, 333 linear feet or more might be required for the absorption area.

See our drainfield sizing TABLE 4A.

There are several types of absorption systems however, each having different effluent disposal capacity. The different types of septic absorption field designs are:

- Conventional Septic Leach Fields

- Deep Septic Absorption Trench Systems

- Shallow Trench Systems

- Cut and Fill Septic Systems

- Absorption Bed Systems

- Gravel-less Septic Absorption Systems

- Seepage Pits

Septic Drainfield Basic Specifications

Below we summarize the basics of septic drainfield design, followed by more detailed septic field design specifications for common types of drainfields or soakaway beds.

Below we summarize the basics of septic drainfield design, followed by more detailed septic field design specifications for common types of drainfields or soakaway beds.

[Click to enlarge any image]

This sketch shows a cross section of a typical drainfield trench, and places below the trench the critical biomat as well as other septic field design areas and considerations. (Source: US EPA who in turn obtained the drawing from Ayres Associates)

Where lot space does not permit drainfield trenches such as described, a septic engineer may specify that seepage pits

or galleys are to be installed. These fit in a smaller space since a single pit may be 6' to 8' in diameter.

But the depth to which effluent is

being delivered (4' or more) means that the sewage effluent is unlikely to be fully treated by a biomass. These systems may successfully "dispose" of

effluent but they are probably not adequately "treating" it.

The Biomat: The formation, clogging, and measures to protect and extend the life of the biomat, or organism layer below and around soil absorption system effluent discharge piping is discussed

at BIOMAT FORMATION & SEPTIC LIFE as a subchapter of this text.

- Perforated septic drainfield pipes are

placed in gravel-filled trenches

across the slope line of sloped property (so that all of the effluent doesn't simply rush down to and leak out at the end of the drain line pipe). - Drainfield trench piping slope specifications:

While some experts describe the bottom of these trenches as "level" in practice they are dug to slope slightly, perhaps 1/8" per foot or less.

- Septic drainfield pipe hole or perforation position: up or down?

As you see in the sketches shown here, the septic leaching bed perforated pipe is placed on a bed of gravel and then covered with more gravel. Do not place the pipe at the bottom of the trench before any gravel is placed therein.

We like to place the pipe with perforations at the 5 o'clock and 7 o'clock positions so that we're not simply storing and collecting sludge and effluent in the pipe bottom;

By not placing the perforated septic drainfield pipe with one of its rows of holes facing directly down (at 6 o'clock position) we defer the clogging of the pipe effluent drain openings.

More about "holes up" or "holes down" on footing drains, a different situation, is

at FOOTING DRAINS HOLES DOWN.

Our second drainfield sketch (left, USDA) shows a slightly different view, in this case an isometric cross-section drawing of a septic drainfield trench.

- Septic drainfield trench depth specifications:

A typical septic drainfield trench is 18 to 30 inches in depth, with a maximum soil cover over the disposal field of 36"; or per the USDA, 2 feet to 5 feet in depth.

At References or Citations we cite these sources.

In some climates, such as northern Minnesota, we have observed drainfield trenches placed much deeper - unfortunately meaning that while effluent disposal may be protected from freezing, effluent treatment may be marginal. - Septic drainfield trench width specifications:

Typically septic trenches are 8 to 12 inches wide in some applications, or 18" to a maximum of 36" wide in traditional, conventional septic drainfield designs.

Regardless of actual drainfield trench width, for design purposes, each linear foot of drainfield line is considered to provide one square foot of drainage area (by many building code or health department septic design approving authorities). - Septic drainfield trench spacing:

The trenches are dug about 6 feet apart on center (center of pipe to center of next pipe) which allows, in good design, space for a set of replacement trenches to be placed between the original ones when the first set fails. - Septic drainfield trench length:

The maximum length of a trench is typically about 150 feet but we have found installations that were three times that length.

Some writers opine that the maximum septic trench line is 100 feet. A realistic answer is, it depends - on site and soil conditions. - Septic drainfield pipe diameters:

The usual minimum septic drainfield pipe inside diameter is 4". - Septic drainfield gravel (aggregate) specifications:

Typically, washed gravel, 3/4" to 2 1/2" (pretty big) gravel is placed for a depth of 12" under the drain line piping ("septic drain tile" in some references).

The pipe is then covered by additional gravel to a depth of at least 2" over the top of the septic drain line before backfill is added.

Required by septic codes in some jurisdictions, and optionally in others, septic installers place a geotextile over or around the gravel and pipe to reduce clogging by dirt infiltration from the septic trench backfill. - Septic drainfield pipe or drain tile connections:

Modern drainfields constructed using perforated plastic pipe are comprised of pipe sections that are physically connected together: one end of each pipe is expanded to slip over the diameter of its mating section.

Older traditional drainfields made of other perforated piping were constructed by laying perforated pipe end to end, with abutting pipe ends spaced 1/4" apart and protected from backfill soil by a layer of roofing felt.

Summary Table of Typical Disposal Field Specifications |

|

| Drainfield / Soakbed / Seepage Bed Component | Specification |

| Absorption trench (leach line) | |

Maximum Length |

100 Feet |

Maximum earth cover fill thickness (depth) over Trench Top |

36 inches |

| Maximum slope of trench (grade) | 4 inches / 100 feet |

| Minimum slope of trench (grade) | level |

Minimum bottom width of trench |

18 inches |

Minimum spacing between lines, edge to edge |

8 feet |

Minimum usable absorptive material below trench bottom |

12 inches |

Minimum filter material over drain pipes or lines |

12 inches |

Maximum distance from drain line to trench edges |

18 inches |

Notes to the Table Above

Table sources include the Shasta County Department of Environmental Health, Shasta County, CA.

Other Leachfield Construction Specifications

- Base material under & around drainfield piping: stone or equivalent aggregate:

Before drain lines are laid, crushed stone, gravel, slag, or similar filter materials clean in appearance and varying in size from three-quarter inch to two and one-half inches and otherwise acceptable to the Shasta County Director of Environmental Health shall be placed in the trench to the depth and grade required by this paragraph:

The filter material in the leaching field shall conform to the following standards:

Effective size 3/4 inch, uniformity coefficient 3.0, voids 40 percent by volume.

The filter material shall have a cleanness value of at least 70 using test 18 method No. Calif. 227-E method of test for evaluating cleanness of course aggregate.

The gravel shall be placed in the trenches in a manner which will leave the sides and bottom free from deposits of rock dust or cement dust.

"Effective size" for the purpose of these Standards is that size of grain which is larger than 10 percent of the material by weight.

The uniformity coefficient for the purpose of these Standards is that sieve that passes 60 percent of the material divided by sieve size that passes 10 percent of the material.

Drain lines shall be completely encased by filter material to prevent closure of voids with earth backfill. - Shasta County cited below - Filter material over drainfield lines before backfill:

Straw, newspaper, untreated building paper or similar materials shall be placed over filter materials in leach lines or seepage pits prior to backfilling. - Shasta County DEH. - Covering over drainfields:

The site of the initial and replacement disposal fields shall not be covered by asphalt or concrete or subject to vehicular traffic or other activity which would adversely affect the soil. - op. cit.

See: - Drainfield construction in backfill:

Do not construct the drainfield in filled ground. Exceptions, see

These example specifications for a septic disposal field, also referred to as drainfield, leach field, soakbed, soak trenches etc., are based on Shasta County California's septic code cited below.

...

Septic Drainfield Inspection Ports

A high quality septic drainfield or leach bed design includes inspection ports or pipes that permit inspection of the condition of the field. Vertical pipes are placed, usually at the end of each drainfield trench or section or at critical or suspect areas near the drainfield, to permit monitoring of liquid levels in the drainfield trenches.

If a few ports are included outside the drainfield area they will aid distinguishing between a drainfield suffering local effluent saturation from an area groundwater problem that also impedes the drainfield operation.

Some installers trim the inspection ports to ground level, sealing each with a removable cap to permit inspection of the drainfield condition without interfering with mowing.

...

Detailed Specifications for Septic Absorption Field Designs

The following specifications for septic drainfields or leaching beds, of various types, designs, and depths, are adapted and expanded from: New York State Appendix 75-A.8 Subsurface treatment, of New York's Wastewater Treatment Standards for Individual Household Systems.

We also include excerpts and references from other U.S., Canadian, and other authorities at state and provincial levels, and from the US EPA Onsite Wastewater Treatment Systems Manual which is available free from the US EPA and is provided in a linked-to copy at the References or Citations section of this article.

General Information

All effluent from septic tanks or aerobic tanks shall be discharged to a subsurface treatment system. Surface discharge of septic tank or aerobic unit effluent shall not be approved by the Department of Health or a local health department acting as its agent.

Specific information for the various types of septic drainfield design can be found in the separate articles linked to below.- CONVENTIONAL LEACH FIELDS

Typically, septic leach fields (synonyms: drainfield, leach bed, soakaway bed, absorption bed) are built by placing perforated effluent distribution pipes in a field or bed of gravel. - GRAVELLESS SEPTIC SYSTEMS

Because they omit gravel, the soakaway bed or drainfield trench dimensions for no-rock or gravel-less septic systems are different than for conventional drainfields. - DEEP TRENCH SEPTIC SYSTEMS

These are used on sites where a usable layer of soil is overlaid by three to five feet of impermeable soil. - SHALLOW TRENCH SEPTIC SYSTEMS

These systems are used where there is at least two feet but less than four feet of usable soil and/or separation to boundary conditions. - CUT & FILL SEPTIC SYSTEMS

A cut and fill septic system is an absorption trench system installed on sites where impermeable soil overlays a permeable soil. - ABSORPTION BED SEPTIC SYSTEMS

An absorption bed system operates on a principal similar to the absorption trench except that several laterals, rather than just one, are installed in a single excavation. - SEEPAGE PITS

A seepage pit is designed to receive clarified effluent from a septic tank (no large solids), or if the pit receives only graywater waste then it's called a drywell.

Septic Drainfield Pipe Sizing

What is the effect of septic effluent disposal piping diameter on the cost and size of a septic drainfield?

What is the effect of septic effluent disposal piping diameter on the cost and size of a septic drainfield?

OPINION: You might need additional linear feet of septic drainfield trench when using smaller effluent dispersal piping. If so, that will increase the cost of the drainfield much more than the savings from using a smaller diameter pipe.

Also the smaller diameter pipe may be more prone to clogging failures.

Reader Question: Is it OK to use 3" perforated pipe in a septic drainfield?

Moderator Reply:

You could 3-inch triple-perforated drainfield trench pipe but (though I'm no septic engineer) I don't recommend it.

Here I'll describe differences in flow rate between 3-inch and 4-inch pipe in theory, I'll translate that into the implications for a low-pressure gravity flow septic drainfield pipe line, and finally the effect on the ultimate size and cost of the drainfield.

The 3-inch perforated pipe I show here, sold by grainger.com for $8.78/10 ft. length, described by the company as:

This Advanced Drainage Systems® angular, corrugated drainage pipe is heavy-duty construction and ideal for most drainage applications including use in foundation/edge, downspout, culvert, and sub-drainage applications.

NOTICE that there is no mention of its use in a septic drainfield.

The 4-inch perforated pipe intended for use in drainfield sells for about $12.27/ft (Lowes 2021) and is described as:

4 in. x 10 ft. 2 hole triple wall pipe.

Triple wall construction provides superior beam strength

Made from corrosion and abrasion resistant high density polyethylene

Drilled holes make it ideal for leach bed systems

Strong and durable but lightweight

NOTICE that this 4-inch pipe is described as suitable for drainfields.

Watch out: so you might infer that in addition to diameter and hole perforation pattern and location on PVC drain piping, there are strength differences that can make one product better than another for use in a septic drainfield.

Let's look at the underlying theory of changes in a drainfield pipe's ability to distribute septic effluent when you reduce its diameter.

Using a smaller diameter pipe, even by 1 inch dropping from 4" to 3" is a large reduction in the liquid carrying capacity of the system.

IF you could find perforated PVC septic drainfield piping in 3-inch diameter ,the disposal capacity of your drainfield pipes and thus the system would be reduced, per foot of trench length, so you'd need a larger drainfield area (more feet of trench length) to handle the same effluent disposal capacity.

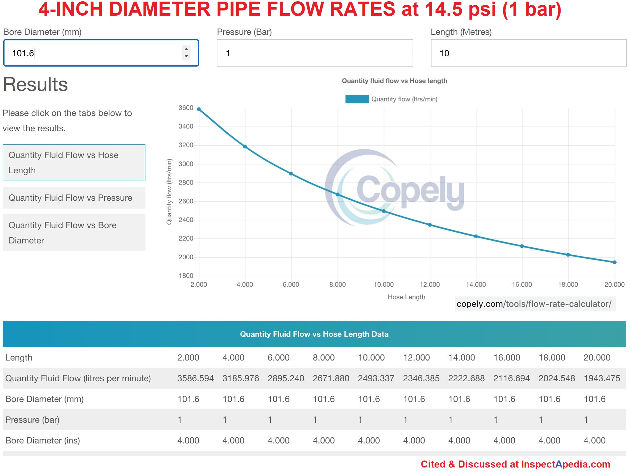

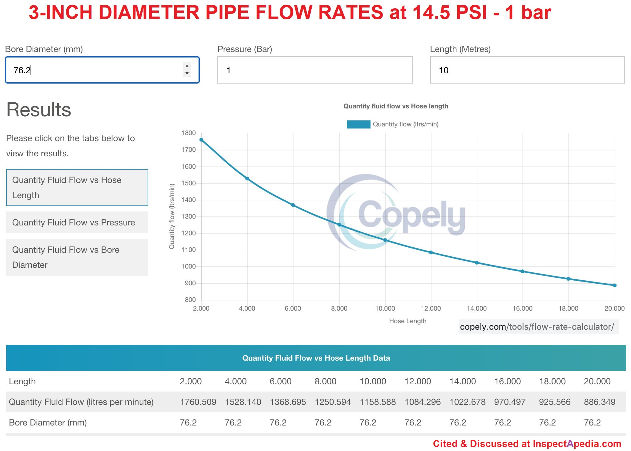

Let's use a nice online pipe flow calculator to compare the flow rates through a 4-inch pipe vs. a 3-inch diameter pipe, keeping pipe length (32.8 ft or 10 meters) and pressure (14.5 psi or 1 bar) the same. I'll show you two curves in successive images posted here.

- 4" (101.6mm) at 14.5 psi (1 bar) flow = 659 gpm (2493 lpm) using a 32.8 (10 meter) length

- 3" (76.2mm) at 14.5 psi (1 bar) flow = 306 gpm (1158.5 lpm) using a 32.8 (10 meter) length

Source: Flow rate calculator from this U.K. hose and tube developer, Copely Developments Limited, Tel: +44 (0)116 240 1500 https://www.copely.com/tools/flow-rate-calculator/

Astonishing, right? A 1-inch increase in pipe diameter for a liquid such as water or septic effluent, more than doubles the flow rate when we increase the diameter from 3" to 4".

Really? Now does this theory actually describe the reality of a septic drainfield?

Of course not. My calculations, in order to make mathematically sound comparisons of flow rates between pipes of different diameters, assume that the pipes are full of liquid being pushed along at 1 Bar or about 14.5 psi.

In a septic drainfield, liquid is flowing by gravity in a sloped pipe (1/8" to 1/4" per linear foot) and the pipes are not normally ever full of liquid (except when the drainfield has failed and is clogged).

But you can see that there is a significant reduction in the ability of a pipe to carry liquid when you reduce its diameter. The effect of diameter reduction in a gravity-fed septic drainfield system would be quite a bit less than the under-pressure calculations shown above.

Bottom line: it's better to use 4-inch perforated drainfield piping in a gravity-type septic drainfield than to use a 3-inch perforated pipe intended for other uses.

For a residential septic system, I recommend using standard 4-inch diameter perforated PVC pipes designed and intended for septic drainfield use; changing to a smaller diameter would at the very least require re-calculation of the drainfield size and layout by your septic design engineer and you might also run into code-approval issues with your local building or health department.

I think that saving 40 cents per foot of drainfield pipe, might be trivial in comparison with the added cost if your engineer says you will have to dig additional feet of drainfield trench to get adequate effluent disposal by lengthening the trenches to provide sufficient effluent disposal capacity. If you take the question to your septic engineer, do let us know what s/he has to say.

Of course all of these data points would be recalculated if you were using a pressure-dosing septic drainfield design. That's another discussion.

Above our illustration compared 3-inch and 4-inch perforated PVC drain piping and the application or uses of each of those products.

Here is the 4-inch diameter pipe flow rate chart from Copely.

Here is the 3-inch diameter pipe flow rate chart, using the Copely calculator .

Also see WATER SUPPLY PIPE DIAMETER vs FLOW

Septic Absorption (Drainfield) Size Codes & Standards References

- SEPTIC & SEWAGE TREATMENT CODES & REFERENCES - complete set

- [5] Alaska, INSTALLERS MANUAL FOR CONVENTIONAL ONSITE DOMESTIC WASTEWATER TREATMENT AND DISPOSAL SYSTEMS [PDF] Department of Environmental Conservation, Division of Environmental Health Drinking Water and Domestic Wastewater Program, Alaska Department of Environmental Conservation, 1 Aug 2000, Anchorage Offices, 555 Coredova, Anchorage AK 99501, Tel: 907-269-7500. retrieved 17 July 2012, original source: dec.alaska.gov/water/wwdp/onsite/pdf/Certified_Installer%27s_Manual.pdf

Notice: [Quoting]

This document contains information regarding the installation of onsite sewer systems for single-family and duplex residences. It must be used by Certified Installers and homeowners who are subject to 18 AAC 72.

Additional requirements are included in 18 AAC 72. If there is a conflict between the provisions of this manual and 18 AAC 72, 18 AAC 80, or other state regulations, the regulations language controls. AEDC offices.

The regulations cited above for Alaskans can be found at alaska.gov/dec./deh/water/ci.htm - ASSE, PLUMBING DICTIONARY [PDF] 6th Ed., (2007) American Society of Sanitary Engineering, 18927 Hickory Creek Drive, Suite 220, Mokena IL 60448 USA Tel: 708-995-3019, Website: www.asse-plumbing.org

- [2] BOCA "International Private Sewage Disposal Code," 1995, BOCA-708-799-2300, ICBO-310-699-0541, SBCCI 205-591-1853, available from those code associations.

- [3] BOCA, Ontario "Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems," Ontario Reg. 374/81, Part VII of the Environmental Protection Act (Canada), ISBN 0-7743-7303-2, Ministry of the Environment,135 St. Clair Ave. West, Toronto Ontario M4V 1P5 Canada $24. CDN.

- CALIFORNIA Shasta County SEWAGE DISPOSAL STANDARDS, [PDF] Op. Cit. retrieved 2016/11/01 original source: http://www.co.shasta.ca.us/docs/Resource_Management/ehd-forms/sewage_disposal_standards.pdf?sfvrsn=0

Includes additional detailed specifications for the leach field or disposal area including setbacks, proximity to bodies of water, exposure to flooding, percolation rates, seasonal high water table, soil perc test specifications, groundwater monitoring, requirement for height above seasonal high groundwater, soil analysis, prohibition of seepage pits, and other septic system design specifications for septic tank & disposal field specifications. (Excellent detailed specifications.) - [7] CNMI, SOIL PERCOLATION TEST MANUAL [PDF] CNMI Division of Environmental Quality, PO Box 501304, Saipan, MP 96950. The CNMI Division of Environmental Quality, Gualo Rai, Saipan provides an excellent English Language manual guide for soil percolation testing. Original source: www.deq.gov.mp/artdoc/Sec6art108ID255.pdf

- [23] Massey, Howard C., The Plumbers's Handbook, Craftsman Book Company; Rev Sub edition (April 1998), ISBN-13: 978-1572180567 includes septic system design basic sketches and specifications.

- NYS DOH, RESIDENTIAL ONSITE WASTEWATER TREATMENT SYSTEMS HANDBOOK [PDF] (2012) - original source: http://www.ongov.net/health/env/documents/DesignHandbook10_24_2

- [8] OR, SOIL TEST PIT PREPARATION FOR ONSITE SEWAGE EVALUATIONS [PDF] (fact sheet) State of Oregon Department of Environmental Quality, Portland OR, 800 452-4011. PDF document. Original source deq.state.or.us/wq/pubs/factsheets/onsite/testpitprep.pdf

We recommend this excellent document that offers detail about soil perc tests, deep hole tests, safety, and septic design.

Readers of the ORegon DEQ article above should also

see SEPTIC SOIL & PERC TESTS [web article] and for testing an existing septic system, also

see DYE TEST PROCEDURE [ web article] - [22] Pennsylvania State Fact Sheets relating to domestic wastewater treatment systems include

- Pennsylvania State Wastewater Treatment Fact Sheet SW-161, Septic System Failure: Diagnosis and Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-162, The Soil Media and the Percolation Test

- Pennsylvania State Wastewater Treatment Fact Sheet SW-l64, Mound Systems for Wastewater Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-165, Septic Tank-Soil Absorption Systems

- Document Sources used for this web page include but are not limited to: Agricultural Fact Sheet #SW-161 "Septic Tank Pumping," by Paul D. Robillard and Kelli S. Martin. Penn State College of Agriculture - Cooperative Extension, edited and annotated by Dan Friedman (Thanks: to Bob Mackey for proofreading the original source material.)

- [19] USDA Septic Tank/Soil-Absorption Systems: How to Operate & Maintain [ copy on file as /septic/Septic_Operation_USDA.pdf ] - , Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf.

- [1] US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL [online web page copy, free] Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm

- US EPA / Otis, Richard J., Onsite wastewater treatment and disposal systems, published by the US EPA. Although it's more than 20 years old, this book remains a useful reference for septic system designers. U.S. Environmental Protection Agency, Office of Water Program Operations; Office of Research and Development, Municipal Environmental Research Laboratory; (1980)

- US EPA, SEWERS, FORCE MAIN Fact Sheet [PDF] (2000) U.S. Environmental Protection Agency,

Excerpt:

Force mains are pipelines that convey wastewater under pressure from the discharge side of a pump or pneumatic ejector to a discharge point. Pumps or compressors located in a lift station provide the energy for wastewater conveyance in force mains.

- [4] US PHS, Manual of Septic Tank Practice, US Public Health Service's 1959.

- WA DOH, BASIC PRINCIPLES of ONSITE SEWAGE [PDF] (1992) Washington State Department of Health, Office of Water, Washington D.C. USA

Also including as

APPENDIX A: WHY DO COARSE SOILS HAVE LARGER PORE SIZE & LESS SURFACE AREA? & WHY DO FINER SOILS HAVE SMALLER PORE SIZE & MORE SURFACE AREA

and

Cogger, Craig G., APPENDIX B: SEPTIC SYSTEM WASTE TREATMENT in SOIL, (1987) Washington State University Cooperatie Extension, EB1475,

Septic Tank & Drainfield Construction Health-Safety Warnings

Moved to SEPTIC TANK / FIELD INSTALLATION HEALTH HAZARDS

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-01-31 by Tyler - what's the minimum distance you would want to place your drain field from your septic tank

Whats the minimum distance you would want to place your drain field from your septic tank

Moderator Reply:

@Tyler,

Please take a look at the table of clearance distances for various septic system components found here:

SEPTIC TANK & FIELD CLEARANCE DISTANCESYou need to be far enough away to have adequate slope between the two and far enough away to have room for the distribution box and any other connectors.

Typical absolute minimum is five feet.

Beyond that and the minimum clearance distance is that we have already given above on this page, distance is going to be determined by the site and the available space.

Let us know if you still have further questions.

On 2021-12-30 by Helen Burden

How do you install pipe from septic tank to drainfield

On 2021-12-30 by Inspectapedia Com Moderator - How do you install pipe from septic tank to drainfield?

@Helen Burden,

An excavator digs a trench at proper depth and slope to the drainfield area where the plumber or septic installer usually places a D-box or Distribution Box to which the drainfield lines are connected; a solid pipe is laid in the trench between tank and D-box.

On 2021-10-06 by Larry

Building a new house hooking up to existing drain field but I have to pump it to my first d-box can I run my 2”sewer pipe across the drain field to the first d-box

On 2021-10-09 by Inspectapedia Com Moderator - run 2-inch pumped effluent line to D-box

@Larry,

Yes, but take care of the installation sequence and equipment weight so as not to damage the drainfield, and depending on your climate, you could need to deal with freeze risk.

On 2021-08-26 by Susan Bridgit - does the drainfield have to be all in one continuous line?

We are required to have 78 lineal feet of leach line. Can this line be one continuous line or does it have to be divided into a series of trenches?

On 2021-10-09 by Inspectapedia Com Moderator - yes multiple drainfield trenches are permitted

@Susan Bridgit,

It is perfectly permissible to break up the total drainfield trench into more than one sub-line, joined from a D-box or distribution box.

In the Index to Related Articles see our description of SEPTIC D-BOX

On 2021-05-27 by Roger Yates - do all drainfields require a mound?

There is a drainfield that may be built that does not require a mound ?

On 2021-05-28 by danjoefriedman (mod) - No, not all septic systems need to be a mound type

@Roger Yates,

Yes certainly. Mound or raised-bed septic systems are required when there is not enough depth between the top of existing soil and the seasonal high water table below.

if you have adequate depth of good draining soil that is sufficiently above the seasonal high water table in the ground

Then you don't need a mound or raised bed septic.

Reader Question: Can I Backfill the Septic drainfield Trenches with Wet Soil during Field Construction?

I recently installed leaching chambers and before I could backfill the trenches it rained for a couple of hours, is it ok to use the wet backfill to fill the trenches? - B.D.

Reply:

OPINION-DF: A competent onsite septic field construction inspection by an expert may find additional concerns that need to be addressed to assure a long drainfield life. That said, here are some things to consider:

- Wet soil backfill might be OK:

Provided you are installing the required gravel under and around the drainfield piping, backfilling with wet soil may not be a problem- Other factors put new septic drainfield at risk:

We say "may not be" because of not so much the soil itself, as soil is wet after backfill when it rains, but rather because depending on trench depth and how the operator runs the equipment, driving over some wet soils (depending on soil composition itself), or piling deep amounts of wet soil in a trench may compact the soil more than it would have been compacted if filled dry.- Deep soil backfill over septic means trouble:

Our opinion is that because of its added weight, filling to depths more than 30" might compact soils unnecessarily.- Driving over drainfield during construction means trouble:

But a much more serious concern would be driving the backhoe or other construction equipment over the trenches, makes for a high risk of excessive soil compaction, especially driving the equipment over the trenches.- Soil type for drainfields is important:

So soil that is not clay, and drainfield trenches that are less than 30" deep from top of gravel (over the pipes) to surface, mean you may be ok.

But driving the earth moving equipment around over the drainfield trenches themselves (or in the future driving anything over the drainfield) risks damage to the fields by soil compaction or even crushing and breaking the drainfield piping. Don't do it - backfill with care, driving equipment in the space between the drainfield trenches rather than over them.

On 2021-03-29 by Sarka - what is considered an "abrupt Change in direction" of a leaching (absorption) trench?

Question: Hello what is considered an "abrupt Change in direction" of a leaching (absorption) trench?

On 2021-03-29 by (mod) - Plumbing Code & Definitions of "Abrupt Change" bends & Approved Fittings

@Sarka, great question; IMO a good directional change 1/6 bend or less. However the most common is a 45 degree bend (sometimes misnamed a 90) sanitary wye or tee.

There are similar "abrupt change" or "bend" pertinent to drain piping and to septic system design perhaps best summarized in the UPC or Uniform Plumbing Code:

UPC 706.1 Approved Fittings.

Changes in direction of drainage piping shall be made by the appropriate use of approved fittings and shall be of the angles presented by a one-sixteenth bend, one-eighth bend, or one-sixth bend, or other approved fittings of equivalent sweep.

706.2 Horizontal to Vertical.

Horizontal drainage lines, connecting with a vertical stack, shall enter through 45 degree (0.79 rad) wye branches, 60 degree (1.05 rad) wye branches, combination wye and one-eighth bend branches, sanitary tee or sanitary tapped tee branches, or other approved fittings of equivalent sweep.

706.3 Horizontal to Horizontal.

Horizontal drainage lines connecting with other horizontal drainage lines shall enter through 45 degree (0.79 rad) wye branches, combination wye and one-eighth bend branches, or other approved fittings of equivalent sweep.

706.4 Vertical to Horizontal.

Vertical drainage lines connecting with horizontal drainage lines shall enter through 45 degree (0.79 rad) wye branches, combination wye and one-eighth bend branches, or other approved fittings of equivalent sweep.

Other uses of and warnings about abrupt bends or changes in sanitary drains or septic systems:

Egs:

" Toe of Slope — The base or bottom of a slope at the point where the ground surface abruptly changes to a significantly flatter grade"

Reference:

Kirk, Douglas, "UPC — Change of Direction", June 2016, current source: https://www.linkedin.com/pulse/upc-change-direction-douglas-kirkOn 2021-03-29 by Sarka

thank you for responding and - this question relates specifically to the absorption trench (leaching trench) - the code says:

"They (absorption trenches) need not be perfectly straight but abrupt changes in direction shall be avoided." There is no definition of "abrupt" for this condition. Any thoughts? Thank you!

On 2021-03-29 by (mod) - what constitutes an "abrupt" bend in sewer lines or drainfield effluent piping and what bends are permitted?

@Sarka,

A few considerations:

1. wastewater doesn't flow uphill

(putting it politely) so no drain (solid) or drainfield effluent distribution (perforated) pipe should have a belly or sag - such locations collect waste and lead to clogs

2. changes that are more abrupt than a 45 degree sanitary elbow

or bend in sewer piping - where solids are present - will certainly invite clogging as waste slams into a pipe wall and some of it sticks - both feces and toilet paper; but I suspect that in a drainfield where there should be no large solids the risk is much smaller.

Still we might see a collection of deposits at points of impact (abrupt changes) in effluent distribution if there are small floating solids being released to the drainfield and of course those same solids clog the fields and absorption trenches as well - a good argument for using an effluent filter at the septic tank and a compelling argument for making the septic tank big-enough - see our note about settlement time

in SEPTIC TANK SIZE

and our discussion of "net free area" in the septic tank (that gives enough volume to get enough settlement time)

in SEPTIC TANK LEVELS of SEWAGE

Given that in a properly-working septic system, even unfiltered effluent ought to have only very tiny solids afloat in the effluent, so their impact and accumulation at abrupt bends or changes in the effluent piping is probably less of a worry; safest is to stay with sanitary tee and sanitary bend fittings and to avoid sharp 90s.

Septic & sewer authorities often permit use of sanitary bends such as 45s - e.g. New York'sRESIDENTIAL ONSITE WASTEWATER TREATMENT SYSTEMS HANDBOOK [PDF] (2012) - original source: http://www.ongov.net/health/env/documents/DesignHandbook10_24_2

- you won't see a discussion of abrupt pipe direction change in this book but it's still got good design basics.

Bottom line: best practice in an effluent distribution system is to restrict bends in the effluent piping to 1/16 bends wherever possible, noting that in typical septic codes & standards 45 deg. sanitary elbows are permitted.

And where bends are unavoidable, ask your septic designer if you need to increase the slope or pipe diameter slightly to be sure of adequate flow.

Also see our discussion of this abrupt change in sewer piping concern

On 2020-12-26 by john stirmel jr - how far in from the end do they typically come in to install the septic field inspection pipes?

I have a drain field that is 70’ long 3’with of drain tile or dog houses and 6’ apart my question is how far in from the end do they typically come in to install the inspection pipes as mine are buried and I need to find them for inspection to sell my house the frost is a foot and a half so I’m having one hell of a time

On 2020-12-26- by (mod) - installation of new inspection pipes in an existing older septic system

John

installation of inspection pipes in an existing older septic system is a bit unusual in my experience so I don't have a standard answer for you about exactly where those would be installed.For the more it sounds to me as if a contractor is having you do work that they're being paid to perform since the installer would normally be the person required to locate the pipe to which they're planning on making a connection.

It's also unclear exactly why you're having these installed now.

In any event if you need to locate the exact routing of your septic lines that's easily done by using drain tracing equipment. Typically that's a metal flexible snake that's inserted into the lines and that is sensed by a transmitter receiver.

On 2020-09-12 by Nathaniel - any way to bring in top soil (loam, sandy loam, etc.) to achieve the absorption field required?

I am being told that a lot I want to purchase near Charlotte, NC on Lake Norman cannot perc because the soil depth is shallow (as little as 8” in places). I am willing to do a pre-treatment system, but am told that I would need a drain absorption field which cannot be achieved with the shallow soil.

My question is: any way to bring in top soil (loam, sandy loam, etc.) to achieve the absorption field required? Seems like this would be similar to a mound system, but am told I still cannot do that even with pre-treatment.

On 2020-09-12- by (mod) - definitely: it's common to bring in soil to build a septic mound system

Nathaniel

Most likely your local building or health department will accept a raised bed septic or a septic mound system - those involve bringing in soil to build an above-ground effluent treatment system, just as you suggest.

IF your local authorities won't accept a septic mound or similar system ask if they'll accept an aboveground mini wastewater treatment system that is complete - a packaged system that only discharges clean water.

On 2020-09-08 by co8a - septic system depth to avoid freezing in Minnesota

What should be the thickness of the soil above the pipes so that they do not freeze in winter in Minnesota?

...but if the holes are in the pipe for 4 and 8 hours, then a small amount of gray water remains in it. Can the water freeze in cold weather? How can you protect yourself from this, especially in the first year of the construction of the mound systems?

Hello! How to protect a perforated pipe (mound system) from freezing in winter?

On 2020-09-09 - by (mod) -

co8a :

In northern MN the frost line can be 6-8 feet below the surface; I've seen drainfields buried that deep, but unfortunately those drainfields, while they may "dispose" of septic effluent, do not treat it effectively, as there is not much aerobic bacteria (needed for effluent treatment) at that soil depth.

So what septic mounds and other drainfields rely upon in cold climates such as Minnesota are active use. The combination of frequent dosing with warm household water and the heat produced by bacterial action are generally sufficient to help keep a drainfield from freezing.A brand new field might require extra measures such as straw cover at least until there is a protective covering of deep snow.

In normal use the mound septic gets enough warm water as to avoid freezing, but yes, people often insulate a new mound with straw or hay.

On 2020-06-09 by Connie Magistrelli - clearance distance: leach field to structure?

How close to a leach field can something, a structure, be built?

On 2020-06-23 - by (mod) -

Connie

Please see all of the clearance distances given at

CLEARANCE DISTANCES, SEPTIC SYSTEM

and let me know if that leaves you with any questions.

On 2020-04-20 by Howard - distance from septic tank to drainfield

My septic system is 48 years old. How far is the drain tank from the septic tank

On 2020-05-14 - by (mod) -

Howard

Sorry but there is no standard distance.

In the ARTICLE INDEX you'll find articles on how to find the septic tank, distribution box, and drainfield.

On 2020-04-09 by Que - put tar paper over septic drainfield pipes?

When running a drain field wat is the typical layout. Before tuning my pipes. Do I put I think it’s called tar paper down first the my rock or gravel or rock them paper.

On 2020-04-09 - by (mod) -

Que

Typical drainfield layout is parallel trenches, about 5 feet apart.

You would never put tar paper (roofing felt) nor any other impermeable or low-permeable material under or along side nor immediately over the leachfield pipes, though some installers might include a soil barrier synthetic fabric at the top of the drainfield trench under the dream and hope that we'll slow soil penetrating and clogging the piping.

In my OPINION that's not the best thinking. The proper quantity of gravel under, around, and over top of the piping is what's critical along with proper trench size and slope.

Take a look at the basic design specifications above in this article as a start. And then see the rest of the articles in this series to see more details about drainfield construction starting with the article SEPTIC DRAINFIELD SHAPE recommended at the More Reading link below.

On 2020-04-08 by Paul Lloyd - septic design for animal shelter

We are an animal shelter in South East Asia with approx 1000 resident dogs and cats. We have a variety of septic tanks and the overflow is pumped to one location and through filters to our lake. We recently acquired a field adjacent to the shelter approx 160 M x 50 M.

It is flat but approx. 1.3 M lower than our existing land. The plan is to make it in to a drain field and then back fill to the level of our land. The sub soil is good for a meter then clay below. What type of drain field would be best?

On 2020-04-08 - by (mod) -

I cannot be confident of a right design for your drainfield given so little information - an onsite septic engineer would be more-helpful.

But in general, for the location you describe, the best design is one that absolutely assures that the bottom of the drainfield absorption trenches is at least two feet above the seasonal high water table in the area.

In your area with clay just a meter below the surface, you may not have an effective effluent absorption system that actually treats the effluent; you need sufficient soil, above any nearby water table or body of water, to provide time and soil and bacteria to actually treat the septic pathogens in the effluent.

You don't want to end up just leveling the drainfield to the same height as a surrounding area, not to mention sewage that may already be contaminating the nearby lake.

Instead, a raised bed septic or mound system design brings in enough fill to bring the absorption bed to the necessary height.

In the ARTICLE INDEX you'll find links to article describing SEPTIC MOUND SYSTEMS and RAISED BED SEPTIC SYSTEMS

On 2020-03-29 by John Hawkins - distance between drainfields?

What is Min. dist. allowed between drain fields ?

On 2020-03-29 - by (mod) -

John

Are you asking about alternating drainfields on a single building site? You'd have at least 8 ft.

Or are you asking about drainfields on neighboring, independent properties? - see CLEARANCE DISTANCES, SEPTIC SYSTEM https://inspectapedia.com/septic/Septic_Clearance_Distances.php

...

Continue reading at SEPTIC DRAINFIELD SHAPE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see SEPTIC DRAINFIELD SIZE FAQs - reader questions & answers.

Or see these

Recommended Articles

- NEW YORK STATE 75-A.8 SUBSURFACE TREATMENT of EFFLUENT

- SEPTIC DRAINFIELD INSPECTION & TEST - home

- SEPTIC DRAWINGS

- SEPTIC SOIL & PERC TESTS

- SEPTIC SYSTEM DESIGN ALTERNATIVES - home

- SEPTIC SYSTEM DESIGN BASICS

- SEPTIC TANKS - home

- U.K. OFF-GRID SEPTIC REGULATIONS & SEWAGE SYSTEMS

- U.S. SEPTIC AUTHORITIES & DESIGN SPECIFICATIONS - Septic codes & regulations for each US State or Territory

Suggested citation for this web page

SEPTIC DRAINFIELD SIZE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC DRAINFIELDS & DBOXES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about septic drainfield or soakaway bed size or capacity requirements & design.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ASSE, PLUMBING DICTIONARY [PDF] 6th Ed., (2007) American Society of Sanitary Engineering, 18927 Hickory Creek Drive, Suite 220, Mokena IL 60448 USA Tel: 708-995-3019, Website: www.asse-plumbing.org

- NYS DOH, RESIDENTIAL ONSITE WASTEWATER TREATMENT SYSTEMS HANDBOOK [PDF] (2012) - original source: http://www.ongov.net/health/env/documents/DesignHandbook10_24_2

- WA DOH, BASIC PRINCIPLES of ONSITE SEWAGE [PDF] (1992) Washington State Department of Health, Office of Water, Washington D.C. USA

Also including as

APPENDIX A: WHY DO COARSE SOILS HAVE LARGER PORE SIZE & LESS SURFACE AREA? & WHY DO FINER SOILS HAVE SMALLER PORE SIZE & MORE SURFACE AREA

and

Cogger, Craig G., APPENDIX B: SEPTIC SYSTEM WASTE TREATMENT in SOIL, (1987) Washington State University Cooperatie Extension, EB1475, - [1] US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL [online copy, free] Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm Onsite wastewater treatment and disposal systems, Richard J Otis, published by the US EPA. Although it's more than 20 years old, this book remains a useful reference for septic system designers. U.S. Environmental Protection Agency, Office of Water Program Operations; Office of Research and Development, Municipal Environmental Research Laboratory; (1980)

- [2] "International Private Sewage Disposal Code," 1995, BOCA-708-799-2300, ICBO-310-699-0541, SBCCI 205-591-1853, available from those code associations.

- [3] "Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems," Ontario Reg. 374/81, Part VII of the Environmental Protection Act (Canada), ISBN 0-7743-7303-2, Ministry of the Environment,135 St. Clair Ave. West, Toronto Ontario M4V 1P5 Canada $24. CDN.

- [4] Manual of Septic Tank Practice, US Public Health Service's 1959.

- [5] "Installers Manual for Conventional Onsite Domestic Wastewater Treatment and Disposal Systems", Department of Environmental Conservation, Division of Environmental Health Drinking Water and Domestic Wastewater Program, Alaska Department of Environmental Conservation, 1 Aug 2000, Anchorage Offices, 555 Coredova, Anchorage AK 99501, Tel: 907-269-7500. retrieved 17 July 2012, original source: http://dec.alaska.gov/water/wwdp/onsite/pdf/Certified_Installer%27s_Manual.pdf [Copy on file as Alaska_Certified_Installer's_Manual.pdf].

Notice: [Quoting]

This document contains information regarding the installation of onsite sewer systems for single-family and duplex residences. It must be used by Certified Installers and homeowners who are subject to 18 AAC 72. Additional requirements are included in 18 AAC 72. If there is a conflict between the provisions of this manual and 18 AAC 72, 18 AAC 80, or other state regulations, the regulations language controls. AEDC offices.

The regulations cited above for Alaskans can be found at https://dec.alaska.gov/commish/newsroom/23-15-updated-onsite-wastewater-regulations/ - [7] Percolation Testing Manual, CNMI Division of Environmental Quality, PO Box 501304, Saipan, MP 96950

- [8] Test Pit Preparation for Onsite Sewage Evaluations, State of Oregon Department of Environmental Quality, Portland OR, 800 452-4011. PDF document. We recommend this excellent document that offers detail about soil perc tests, deep hole tests, safety, and septic design.

- [9] Wells and Septic System, Alth, Max and Charlet, Rev. by S. Blackwell Duncan, $ 18.95; Tab Books 1992.

- [17] Thanks to reader Michael Roth for technical link editing 6/29/09.

- [19] Septic Tank/Soil-Absorption Systems: How to Operate & Maintain [ copy on file as /septic/Septic_Operation_USDA.pdf ] - , Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf.

- The NSFC Products List has an excellent list of design manuals/modules National Small Flows Clearinghouse (NSFC) now (2019/12/13) hosted at http://www.nesc.wvu.edu/ Tel: 304-293-4191 e-mail info@mail.nesc.wvu.edu. telephone 800-624-8301

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.