Asphalt & SBS Roll Roofing Installation, Defects, Repairs

Asphalt & SBS Roll Roofing Installation, Defects, Repairs

How to buy & install roll roofing on low slope roofs

- POST a QUESTION or COMMENT about roll roofing

Roll roofing installation, inspection, troubleshooting, repairs:

This article describes mineral-granule coated asphalt or SBS (rubber-based) roll roofing roofing materials, choices, installations, inspection, defects, roofing repairs, and product sources.

We include detailed step-by-step instructions for a typical roll roofing installation job.

This article includes a description of severe wear and early failure of a mineral-granule-surfaced roll roofing installation over an older metal roof.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Asphalt Roll Roofing Materials, Choices, Costs, Life Expectancy, Characteristics

Roll roofing is simplest product to install on a small section of low slope

roof is 90-pound roll roofing. This is an inexpensive roofing material often installed (over 15# felt underlayment) by homeowners and do-it-yourself-ers.

Roll roofing is simplest product to install on a small section of low slope

roof is 90-pound roll roofing. This is an inexpensive roofing material often installed (over 15# felt underlayment) by homeowners and do-it-yourself-ers.

"Low Slope" means that these products are installed on roof slopes of 2/12 or more.

Traditional asphalt-based roll roofing consists of a heavy, asphalt-saturated organic or fiberglass felt with a granular surface.

SBS or modified asphalt mineral surfaced roll roofing membranes are based on SBS, a synthetic rubber (styrene butadiene styrene) that gives improved performance over traditional asphalt-saturated felt.

The dimensions and installation procedures for both traditional asphalt roll roofing and SBS roll roofing are similar.

Rolls of roofing are 36 inches wide and weigh 90 pounds. Single-coverage roll roofing typically has a 2-inch lap with exposed nails and is used mainly on utility structures.

[Click to enlarge any image]

Overlapping plies of roll roofing can be applied to provide double, triple, or even a 4-ply roof for longer life, as we'll detail below.

Nails are concealed under the lap joints that are sealed with asphalt lap cement. With two layers of protection, double-coverage roll roofing is acceptable for small roof areas and can be used on roofs as shallow as 1:12.

Photo: Tarco's white 90# mineral-surfaced roll roofing cited below.

In its earliest forms roll roofing consisted of sheets of felt canvas or cloth that were impregnated with asphalt, then rolled flat along a low-slope or even some steeper sloped roofs with the material's long edge parallel to the building eaves.

Modern 90-pound asphalt roll roofing is built of mineral-coated fiberglass-reinforced mat or organic-mat (bituminous impregnated paper) material very similar to asphalt roof shingles, in 36-inch wide material sold in 36-foot long rolls. Roll roofing is coated on both sides with asphalt and its upper or exposed side is protected with mineral granules or with slate granules.

You may find some roofers referring to roll roofing as "90-pound felt" since a 36-foot roll of the material, able to cover about 100 sq. ft. (one roofing "square") traditionally weighed close to ninety pounds. That's not always so - typical rolls of mineral coated fiberglass roll roofing can weigh 72 - 75 pounds depending on the composition of the material.

Roll Roofing Colors

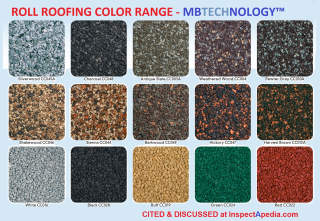

Common roll roofing material colors are white, brown, gray or black.

Some manufacturers such as MB Technology™ (shown above and cited below) provide a wider range of 15 different roll roofing colors like those shown above. MB Technology can also prepare custom roll roofing colors on request.

Other Uses of Roll Roofing

Some roofing specifications such as Owens Corning Oakridge asphalt shingle installation instructions permit use of 50# smooth surface roll roofing as a valley liner for closed-cut asphalt shingle covered roof valleys.

OPINION: that application is fine though other products such as self-adhesive ice-and-water shield products may be preferred by some roofers below closed shingle roof valleys, but in my view you should not use roll roofing as the valley liner for exposed flashing valleys. Use metal flashing in those locations lest the roof valley wear out and leak before the rest of the roof is ready for replacement.

Roll roofing products, both mineral coated and slate granule coated versions, are used in other roofing applications including special purpose underlayments on asphalt shingle roofs, clay and ceramic tile roofs, and others. Below we include a citation for Building Products of Canada Corp. where these uses are described.

Tips For Buying Roll Roofing Materials

Roll roofing is sold in 36-foot long x 36-inch wide rolls of varying thicknesses (typical is 90#) and coatings (un-coated, mineral granule coated white or black), and composition (such as reinforced fiberglass asphalt-base).

Roll roofing is sold in 36-foot long x 36-inch wide rolls of varying thicknesses (typical is 90#) and coatings (un-coated, mineral granule coated white or black), and composition (such as reinforced fiberglass asphalt-base).

One roll of roll-roofing, installed as a single-ply roof, will cover one square or about 100 sq.ft. (actually 108 sq.ft.) and sells for about $40. U.S. (2019 prices) at typical building suppliers such as the Home Depot or Lowe's.

For a normal roof covering on a low slope where roll roofing is to be installed, choose a roofing product that is coated with mineral granules for longer roof life.

Calculate how many rolls of roofing you'll need.

- Single-ply roof: (Total roof area in sq.ft.) / 100 = No. of Rolls

- Two-ply roof: (Total roof area in sq.ft.) / 50 = No. of Rolls

- Three-ply roof: (Total roof area in sq.ft.) / 33 = No. of Rolls

- Four-ply roof: (Total roof area in sq.ft.) / 25 = No. of Rolls

To avoid having to return to your building supplier to get what you forgot, at the same time as buying your roll roofing pick up

- the roofing underlayment you'll need, such as 15# or 30# roofing felt ,

- roofing nails and/or sealant

- drip edge

- flashings

Watch out: Our roll roofing material photo above shows that this roll was a bit out of round.

When buying roll roofing avoid rolls that are squashed as they may be difficult to roll out smoothly. Badly squashed rolls of asphalt roll roofing may appear to flatten out if unrolled and left in sunlight for a time before they're installed, but you might later see early roof failure at cracks that form across the width of the material in areas where it was damaged.

When storing your roll roofing prior to use, stand the rolls on end, taking care not to damage the ends or edges of the material. Standing the rolls on end avoids the squashed roll shown in our photo.

Also avoid rolls whose ends are badly damaged as it may make for uneven or raised seams.

Watch out: also to protect the roll roofing from the weather and from damage during storage before it's applied on the roof. Store roll roofing in a dry location until you're ready to install it. Believe it or not, you should not leave the roll roofing out in rain or snow - cover it with a waterproof tarp if it must be left exposed to the weather before installation.

Do not stack pallets of roll roofing more than two pallets high or the weight is likely to damage the rolls on the bottom pallet. The result, as I've seen, is crushed roll edges that do not lie flat and that lead to early roof failure at the roofing seams.

Common Problems on Roll-Roofing Covered Roofs

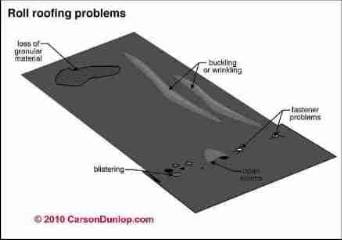

As Carson Dunlop Associates ' sketch (at left) illustrates,

- A common roll roofing problem includes wrinkles or bubbles.

- Granule loss and exposure of "bald spots" or cracking are common signs that roll roofing is at the end of its life

Not quite so common, but we also see misapplications of roll roofing such as:

- Running the roll roofing over a 90-degree angle and up the vertical surface of a parapet wall or chimney as "flashing"

- Running roll roofing with its seams parallel to the building gable ends

Watch out: Because mineral-granule-coated modified bitumen roofing can be mistaken for roll roofing, and vice versa, readers should also

These products look a lot alike but their properties and installation procedures are quite different from one another as is their method of installation.

Above: worn-out, pitted, buckled mineral granule coated roll roofing with failed roofing seams. Surface patching with roof cement is a temporary, unreliable band-aid as you can see from my photo.

Early Roll Roofing Failure When Installed Over Existing Metal Roof

Reader comment: details of failure conditions on a ten-year-old roll roofing installation over metal

Here is a good picture of severely degraded mineral surfaced roll roofing. It was mistakenly and unnecessarily placed on top of a metal panel porch roof, the type fabricated with U-shaped overlapping panels. You can see the lines of the vertical legs of the roof panels clearly in the surface of the roll roofing. These do not require a secondary roof membrane.

Also, mineral surfaced roll roofing requires a smooth and flat surface to ensure property bonding and for full support. This roofing sagged over time, allowing water to pond, and in my opinion, greatly shortened the lifespan.

However, based on permit information and my opinion on the condition, it was ten years old, which is at the end of the anticipated lifespan anyway, according to technical resources (like inspectapedia.com ). But the age was unconfirmed.

- 2016/06/10 - Andrew Kester, P.E. 60993 is a forensic and structural engineer practicing in Florida. Also

see CELLOPHANE STRIP ENGINEERS' VIEW

Above: a closer look at the rapidly failed roll roofing installation over what looks like an exposed fastener metal roof panel system. [Click to enlarge any image]

Reply: it's quite likely that this roof needed replacement before the time of its observation at age 10

From the severity of the cracking and crack pattern, I'd bet that those cracks were gross 3-5 years back. Do you think we actually have two effects: linear cracking in the roofing where it bends over the metal roof joints and significant variegated cracking throughout the roofing material.

Would you agree that since this roof, as photographed and reported to be ten years old, has severe variegated cracking worse than we might expect even on a ten year old roof. In turn that might suggest that the cracks were evident 3-5 years ago, had the roof been inspected at that time?

If I'd seen these cracks on a 5 year old roof I'd have said it was failing faster than normal, perhaps because of a combination of bending at the roof panel seams and heat reflected from the metal roof surface over which it was installed?

I know that an engineer should avoid speculation but still, if you thought the text above were reasonable I'll include it.

As the metal roof below this roll roofing failure is clearly not a standing seam roof, I infer it's almost certainly what we call "barn roofing" or more properly, exposed fastener metal roof panel systems consisting of overlapping panels with raised lap joints rather than standing seams.

Those lap joints are usually through-bolted to the structure below; the bolt heads may make additional wear points in any membrane roof later installed over the metal.

Also see METAL ROOF EXPOSED FASTENER SYSTEM

Here is what a typical manufacturer of roll roofing expects to find below an installation of their mineral-granule-surfaced residential roll roofing product:

Install roll roofing directly over clean, dry plywood minimum 15/32” (11.9 mm) decking or approved equal on slopes equal to or greater than 1:12 for the concealed nail method or 2:12 for the exposed nail method. - source: GAF Corporation, "Technical Advisory Bulletin - Options and Application Procedures for Roll Roofing Products", retrieved 2016/06/13, original source: http://www.gaf.com/Residential_Roofing/Residential_Roll_Roofing/Mineral_ Guard/Options_and_Application_Procedures_for_Roll_Roofing_Products_Steep_Slope_Technical_Point_TAB_R_2011_119.pdf

Roof Decks:

For use on new or re-roofing work over well-seasoned, supported wood deck, tightly constructed with maximum 6" (152 mm) wide lumber, having adequate nail holding capacity and smooth surface OR minimum 3/8" (10mm) thick APA–Engineered Wood Association labeled exterior grade plywood/OSB decking.

Be sure that there is no moisture on the surface of the deck or within the deck (which can have an adverse effect on product performance). Nail tin or other metal over gaps or knot holes larger than 1/4" (6.4mm).

Sweep all dirt and debris from roof deck prior to application. - source: GAF Corporation, "Application Instructions for Mineral Guard® Residential Roll Roofing", retrieved 20`6/06/13, original source: http://www.gaf.com/Residential_Roofing / Residential_Roll_Roofing/Mineral_ Guard/Mineral_Guard_Residential_Roll_Roofing_Installation_Instructions.pdf

Reader follow-up:

... what you are suggesting is perfectly reasonable. I also thought the infrared rays reflected from the metal roof probably exacerbated the degradation of the roll roofing. Since I was not there to investigate that section of roof, I am comfortable you using that photograph and your commentary is reasonable.

I will keep sharing these types of dramatic photographs that make for good academic discussion. I have to dig up a few photos where you can see the huge difference in degradation on the same roof based on which slope it is on, i.e., south exposed roofs in Florida are always worse than other slopes.

I am thinking of this one where they had recently removed large solar panels, and the rest of the roof was in bad shape but those areas covered by the panels looked much newer. UV rays and rain, shingles worst enemies!

Portions of this article were adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Continue reading at ROLL ROOFING, ASPHALT & SBS INSTALLATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ROLL ROOFING, ASPHALT & SBS FAQs - questions & answers about roll roofing posted originally at this page

Recommended Articles

- MODIFIED BITUMEN ROOFING

- ROLL ROOFING, ASPHALT & SBS

- ROLL ROOFING, ASPHALT & SBS FAQs

- ROLL ROOFING, ASPHALT & SBS INSTALLATION

- ROOF LEAK DIAGNOSIS & REPAIR - home

- ROOFING INSPECTION & REPAIR - home

- RUBBER ROOF SHINGLES & SLATES

Suggested citation for this web page

ROLL ROOFING, ASPHALT & SBS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about roll roofing installation, life, leaks, repairs..

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- Low Slope Roofing, Manual of, 4th Ed., C.W. Griffin, Richard Fricklas, McGraw-Hill Professional; 4 edition, 2006, ISBN-10: 007145828X, ISBN-13: 978-0071458283

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.