Suspended Ceilings

Suspended Ceilings

install, diagnose, repair, insulate, R-Values

- POST a QUESTION or COMMENT about suspended panel ceilings or "drop ceilings" in buildings

Suspended or drop ceilings:

This article discusses interior suspended ceiling or drop ceiling materials, choices, installation, troubleshooting, and the effects on building heating and cooling costs when a drop ceiling is installed.

We describe hazards and problems in suspended ceilings and we include a table of R-values of various suspended ceiling products and designs.

Our page top drop ceiling photograph shows the typical grid system used for supporting a suspended panel ceiling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Suspended Ceilings and Suspended Ceiling Tiles - Properties, Photos

What is a "suspended ceiling" or "drop ceiling"? According to Armstrong Corporation, a manufacturer of suspended ceiling products, [edited and paraphrased]

What is a "suspended ceiling" or "drop ceiling"? According to Armstrong Corporation, a manufacturer of suspended ceiling products, [edited and paraphrased]

Suspended ceilings or drop ceilings are a ceiling suspension system that uses a system of metal members, designed to support a suspended ceiling, typically an acoustical ceiling.

A suspended ceiling may also may be designed to accommodate lighting fixtures or air diffusers.

[Click to enlarge any image]

In simple terms, a grid of metal bars, typically shaped in an inverted Tee form is hung from the building original ceiling or ceiling framing.

The supporting grid is usually spaced two-feet on center to form square openings, or to form two-foot x four-foot rectangular openings into which are "dropped" prefabricated ceiling panels that are offered in a very wide range of designs and materials. [1]

Other suspended ceiling system designs include a "plank look" offered by Armstrong (and perhaps other manufacturers) that is produced in 6" x 48" strips.

Typical suspended ceiling panel thicknesses are 1/2-inch to 2 1/2" except where special products are selected to add greater insulation values. Sound absorption ratings vary by individual product but it is common for an acoustic suspended ceiling panel to claim to absorb up to 50% of noise signals impacting its surface.

The distance between the upper surface of the suspended ceiling grid and the surface of the original ceiling can vary very widely, but in order to install the ceiling panels, manufacturers specify a minimum distance, typically 2" plus the thickness of the panels themselves, or a minimum distance of 2 1/2".[1]

Suspended ceilings or suspended ceiling tiles became popular in North America in the 1960s, and can be made of fiber board or fiberglass, for example. Some have a plastic coating.

Combustible plastics, such as polystyrene, should not be used as ceiling tiles.

Suspended ceiling systems utilize a metal T-bar grid supported by wires from above. You can spot the supporting ceiling grid system in our photo (left) as the bottom edges of the grid are visible between individual suspended ceiling panels.

Advantages of suspended ceiling systems include relatively good acoustic properties, ease of removal to access things above the ceiling, and individual tiles can be replaced readily. On the downside, suspended tiles lower the ceiling at least two to three inches.

Suspended Ceiling / Drop Ceiling Materials, Choices

- Acoustic panels, constructed using wood fibers, fiberglass, possibly other materials.

- Fiberglass & plastic or vinyl coated embossed panel ceiling panels, typically constructed using high density fiberglass panels in thicknesses from 1/2" to 6" (and of varying R-values)

- Metal, or embossed metal ceiling panels, in popular designs resembling antique embossed metal ceiling coverings.

- Plaster panel drop ceilings use suspended panels typically constructed of metal lath. See CEILINGS, PLASTER, LOOSE HAZARDS for a collapse hazard.

- Wood fiber or particleboard ceiling panels

Embossed Metal Drop Ceiling Panels

Metal ceilings were typically tin and most often were installed in kitchens, during the late 1800s and early 1900s.

There are also some metal ceiling lookalike products that are actually drop-in panels, typically 2' x 2' or 2' or larger, that are actually a suspended ceiling system. It's easy to spot a metal panel suspended ceiling by looking more closely for its supporting grid.

The metal ceiling in our photo (left) is an antique metal ceiling installed in a New York City restaurant. You can see in the left of the photo that a wooden beam was also wrapped in decorative embossed metal.

This link to a different metal ceiling photo shows a typical example of metal ceiling components that are rusting through from leaks above.

Also see ANAGLYPTA CEILINGS & WALLS and LINCRUSTA CEILINGS & WALLS

Insulation R-Values of Suspended Ceilings & Effect on Building Heating & Cooling Costs

While it is generally true that installing a lowered drop ceiling or suspended ceiling might reduce heating and cooling costs in buildings, the actual effects, both gains and losses in building heating and cooling costs, are variable and depend on several factors.

To understand the net impact of a drop ceiling on building energy costs you will need to evaluate:

- The distance between the suspended ceiling and the original ceiling or roof underside above and air movement within that area.

- The R-values of the roof, walls above the ceiling, and of the ceiling itself - some drop-ceiling tiles can be quite thick fiberglass pads that offer varying R-values;

- How the space above the ceiling is used - for example in offices or other buildings the space above the suspended ceiling is often used as a return air plenum, and the presence of certain HVAC equipment in the ceiling cavity that may increase air movement or that may add or remove heat from that space

- Air communication laterally between the ceiling cavity and other building areas - see the blue arrow in our suspended ceiling cavity photograph at above left.

The building occupants and management were unaware that the conditioned space above this suite of offices was subverted by a large opening that connected the building ceiling cavity to an exterior hallway and stairwell. - Presence of additional HVAC equipment or air movement devices that may be installed in the suspended ceiling cavity (red arrow in our photo, above left).

- The care of installation of the suspending grid and whether or not it's leaky,

- The presence of air leaks in and out of the cavity above the drop ceiling from other sources (removed panels, misfit panels, damaged panels)

- Missing suspended ceiling panels

Our OPINION is that the overall R-factor for a suspended ceiling should not be assumed to be simply that of the panels that comprise the ceiling material. The additional factors above will need to be considered. For example, even a single significant air leak can overwhelm the otherwise stated "R-value" for a suspended ceiling.

Table of R-Values or R-Factors for Typical Suspended Ceilings & Ceiling Panels© | ||

|---|---|---|

| Suspended Ceiling Panel Material | Suspended Ceiling Panel Thickness | Estimated R-Value per inch [7] |

| Drywall | 1/2-inch: R 0.2 | 0.45 |

| Fiberboard insulating board | 1/2-inch: R 0.5 | 1.14 |

| Fiberglass, batts, height density | 1/2-inch: R 2.0 | 3.6 - 5 |

| Fiberglass panel, rigid (fiberglass "boards") | 1.2-inch: R 1.125 | 2.5 |

Polystyrene Expanded (EPS) insulation, low-density |

3.6 - 4.7 | |

| Ceilume panels | 0.79 - 0.91 | Engineering judgment (not test data). Ceilume points out that we should be interested in heat flow resistance in both directions (up out of the conditioned space and down into the conditioned space) to accommodate both heating and cooling requirements [10] |

| Ceilite™ foil-faced glass wool insulating panels | R 2.6 - 5.9 | Varies by season and by air space above the suspended ceiling. Combines polystyrene, reflective foil film, and an air space assumed still air [5] |

| Polystyrene board, extruded expanded high-density (XPS) | "up to 4.5" [6] | 4.2 - 5.4 |

| Armstrong mineral fiber ceiling panels ["inert mineral components'] | [8] no R-values claimed in consumer information. | |

| USG Ceiling panels | "up to 1.5" | [9] |

| Owens Corning add-on Sonobatt suspended ceiling insulation | 3 1/2" panel, R-11 |

These are add-on insulating batts and do not include the actual suspended ceiling panel itself. Quoting: "Sonobatts Insulation are easily installed in suspended ceiling systems by simply laying them on top of the ceiling panel and suspension system. Sonobatts should fit tightly together to reduce the amount of heat loss." [11] |

Notes to the Ceiling Panel R-Value Table Above

- [5] Ceilite, 4/22 Eastern Service Rd, Stapylton 4207 QLD, Australia, Email: sales@ceilite.com.au, Tel: 1300 663 755

- [6] Silent Source Acoustical Ceilings, 58 Nonotuck Street Northampton, MA 01062 (413) 584-7944 Fax: (413) 584-2377 Email: info@silentsource.com, web search 10/21/2011, original source: silentsource.com/ceilings-ac-suspend-a-

ceil.htmlhttp://www.silentsource.com/ceilings-ac-suspend-a-ceil.html - [7] See table of INSULATION R-VALUES & PROPERTIES

- [8] Armstrong corporation, website search 10/21/2011, see page bottom footnote [1]. The phrase "inert mineral components" may refer to fiberglass. Here is Armstrong's comment about the insulation value "between floors" of their suspended ceilings:

- Most ceilings are installed between floors that are maintained

at the same temperature — making insulation unnecessary.

Basement recreation rooms are at least partly heated by heat

flow through the ceiling from the heated space above. In that

case, attempting to insulate the basement ceiling surface

could actually reduce heat flow. [2]

- [9] U.S. Gypsum, web search 10/22/2011, original source: colorado-ceilings.com/usg-ceiling-tile.html

- [10] Ceilume, 9270 Graton Road Graton, CA 95444, Tel: 800-557-0654 , web search 10/21/2011, original source: ceilume.com/ceiling-tile-insulation.cfm

- [11] Owens Coring World HQ, One Owens Corning Parkway, Toledo OH, USA, 43659, Tel: 1 - 800 - GET - PINK, Website: owenscorning.com

- [12] 2003 IECC, 2006 IECC, 90.1-1999, 90.1-2001, 90.1-2004

Fiberglass Ceiling Tiles, Panels, Insulating Panels: examples & properties

Above: Owens Corning 700 Series fiberglass insulating panels described by the following

- Owens Corning FIBERGLAS 700 SERIES BOARD TYPES 703 & 705 FIBERGLASS INSULATION [PDF]

Excerpt:

Types 703 and 705 Series Insulation Boards are made of inorganic glass fibers with a thermosetting resin binder and formed into semi-rigid or rigid rectangular boards.

Types 703 and 705 are available with factory-applied FRK or poly-encapsulated ASJ Max facings.

Both facings are vapor retarders and provide a neat, finished appearance in mechanical applications.

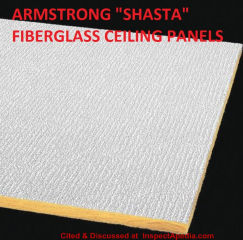

Below: Armstrong Shasta fiberglass ceiling tiles with a plastic surface, typically used in suspended or "drop" ceilings. Sold in 24" x 24" and 24" x 48" dimensions, 5/8" thick.

- Armstrong SHASTA FIBERGLASS CEILING TILES DATA SHEET [PDF] - retrieved 2023/01/28, original source: https://www.armstrongceilings.com/commercial/en/commercial-ceilings-walls/shasta-ceiling-tiles/item/2906.html

- Armstrong SHASTA FIBERGLASS CEILING TILE INSTALLATION INSTRUCTIONS [PDF] Op. Cit.

- Armstrong SHASTA FIBERGLASS CEILING TILE INSTALLATION CLEANING PROCEDURE [PDF] Op. Cit.

- Armstrong SHASTA FIBERGLASS CEILING TILE INSTALLATION SAFETY DATA SHEET [PDF] Op. Cit.

Excerpt:

During the installation be certain that the work site is well ventilated and avoid breathing dust. Avoid contact with skin or eyes. Wear long-sleeve, loose fitting clothes, gloves and eye protection. Cut and trim with knife, razor or hand saw.

Do not cut with power equipment unless either a dust collector is used on the equipment or local exhaust is used and a NIOSH approved respirator is worn to prevent ovrexposure to airborne silica.

Exposures to respirable crystalline silica are not detected in industrial hygiene testing on workers installing acoustical ceiling panels for an 8 hour work day and are not expected during the normal use of this product; however, actual levels must be determined by workplace hygiene testing.

Prolonged and repeated exposure to airborne free respirable crystalline silica can result in lung disease (i.e., silicosis) and/or lung cancer.

Panels do not release respirable dust in their installed state and therefore do not present any known health hazards when installed and properly maintained.

Effects on Suspended Ceiling R-Value or R-Factors due to Space Above the Suspended Ceiling Materials

Installing a suspended ceiling can serve to reduce heating or even cooling costs in some buildings by:

- reducing the volume of conditioned space by lowering the ceiling

- providing an insulated surface below the original ceiling (provided insulating suspended panels are installed)

- providing a cavity for the addition of HVAC ducts and registers using the space between the original ceiling and the new suspended ceiling (typical application in offices and other commercial buildings)

But the effectiveness of the suspended ceiling on building energy costs for heating and cooling will be determined by additional factors that we listed earlier in this article. Here we comment on the effects on heating and cooling energy costs of

- Changes in effective ceiling height

- R-values for the original ceiling and upper walls within the space above the suspended ceiling

- Ceiling cavity & building conditions such as leaks or trapped moisture - wet insulation is not only a mold hazard it also loses its insulating R-value.

[Modeling & data collection are in process, CONTACT us to contribute information.]

Energy Code vs Effects of Insulation Installed in Suspended Ceilings

Checking with building suppliers we found at least eight variations on rigid and semi-rigid suspended ceiling insulating panels of varying materials including fiberglass, styrofoam, R-12 OSB-laminated to solid foam, and other products. Do these work? Are they permitted and safe?

Image at left: Barricade™ OSB-foam board laminate providing an R-12 insulation value, sold in 2' x 8' sheets at building suppliers such as Home Depot® stores.

Watch out: foam insulation products (and possibly certain other insulating board products) are not left exposed in buildings due to the fire hazards involved.

In short, it is permitted to install insulation over a suspended ceiling provided that the supporting ceiling grid is listed for that weight and application, but in assessing compliance with the IECC the builder cannot take credit for that insulation.

Really? Why not? Because a suspended ceiling is not sealed against air movement. Insulation installed in a suspended ceiling does, in our OPINION, reduce building heat loss, but because air movement is so critical in actual building energy efficiency, claiming the R-value of insulation added in a suspended ceiling is not allowed in assessing energy code compliance.

In other words, adding building insulation in the logical "middle" of the building rather than at its perimeter surfaces means it is not in contact with air barriers, vapor barriers, etc. so it's effectiveness is compromised by air movement.

In my OPININON the actual compromise or actual air movement probably varies quite a bit depending on the insulation material and ceiling panel materials and the tightness of fit of panels in the ceiling grid.

But picture hundreds of linear feet of suspended ceiling track that are not sealed in any way, combined with air pressure variations between the two sides of the ceiling and you'll get the picture.

Both model energy codes and pertinent ASHRAE standards raise this air infiltration issue. According to the BECRC cited below [and obtained from the public source: www.energycodes.gov], the model energy codes prohibit the insulated suspended ceiling from being part of the building thermal envelope for compliance.

Openings and penetrations in the building envelope shall be sealed with caulking materials or closed with gasketing systems compatible with the construction materials and location.

Joints and seams shall be sealed in the same manner or taped or covered with a moisture-vapor-permeable wrapping material.

Sealing materials spanning joints between construction materials shall allow for expansion and contraction of the construction material. - IECC 2003, Section 802.3.3 and IECC 2006, Section 502.4.3 Sealing the Building Envelope (Commercial)

The roof insulation shall not be installed on a suspended ceiling with removable ceiling panels. - ASHRAE 90.1-1999, Section 5.2.1.4; 90.1-2001, Section 5.5.1.4; 90.1-2004, Section 5.8.1.8 Location of Roof Insulation

The BECRC offers a very helpful interpretation of these energy code statements, from which we quote:

Insulation installed in a suspended ceiling does not meet the infiltration requirements of the International Energy Conservation Code (IECC).

When the insulation is on the suspended ceiling, the ceiling is defined as part of the building envelope. This requires that it be air-sealed like any other envelope component.

To meet the energy code, insulate and seal the exterior roof and show compliance with the roof assembly as part of the building envelope component.

The drop-down ceiling can remain as an interior ceiling, but no energy credit will be given for batt insulation draped above the suspended ceiling.

To show compliance for an office space within a warehouse, in which the warehouse is heated only to prevent freezing or is considered an unconditioned space, the office should be treated as a "building within a building."

This means the ceiling of the office space would be part of the "building within a building" envelope and should be insulated and sealed as described above. Interior walls (walls separating the office from the warehouse only) and exterior walls of the office space also will require insulation and sealing. - "Insulating Suspended Ceilings", Building Energy Codes Resource Center, and quoting pertinent energy codes, retrieved 11/25/2013

Key energy code & standard citations include:

- International Code Council , Inc. Falls Church, Virginia. All rights reserved. 2006

- International Energy Conservation Code . 2006 International Energy Conservation Code ;

- ASHRAE 90.1-1999 Reference and link Copyright, 1999, American Society of Heating, Refrigerating and Air-Conditioning Engineers , Atlanta, GA.

- ASHRAE Standard 90.1-1999 . Reproduced with permission. All rights reserved. ;

- ASHRAE 90.1-2001 Reference and link Copyright, 2001, American Society of Heating, Refrigerating and Air-Conditioning Engineers , Atlanta, GA.

- ASHRAE Standard 90.1-2001 . Reproduced with permission. All rights reserved. ;

- ASHRAE 90.1-2004 Reference and link Copyright, 2004, American Society of Heating, Refrigerating and Air-Conditioning Engineers , Atlanta, GA. ASHRAE Standard 90.1-2004 .

Hidden & Visible Hazards in, on, and above Suspended Ceilings

Suspended Ceiling Tiles or Sections - some old contain asbestos?

Often you will find that acoustic ceiling tiles (shown at left - these are not a suspended ceiling product) have been installed on furring strips nailed over an older ceiling that was in poor condition, such as we show in this additional photo where demolition was in process.

However you may come across pre-1986 (date approximate) 2' x 2' or 2' x 4' suspended ceiling panels that might contain asbestos, particularly if acoustic panels were used.

See details about asbestos in ceiling products found

Hidden Hazards in & Above Drop Ceiling or Suspended Ceilings

As we also discuss at WALL FINISHES INTERIOR, water damage is one of the most common problems on interior finishes. Common water sources that show up as ceiling leaks or leak stains include roof leaks, flashing leaks, ice damming, window and skylight leaks, plumbing leaks, leaks from hot water heating systems, and condensation.

The photo [at left] illustrates drop ceiling panels below areas of leaks.

When looking into any damaged suspended ceiling installation and especially where you see ceiling leak stains in a drop ceiling, you want to inspect carefully to determine the following:

- Clues indicating that the ceiling structure may be unsafe, in danger of collapse or unhealthy, due to mold or other contaminants.

Check for the presence of other, perhaps older materials above the suspended ceiling that may themselves present a building hazard or require additional inspection, testing, or cleanup. For example we may find falling asbestos pipe insulation or collapsing asbestos-containing ceiling tiles above the suspended ceiling structure.

We also may find rodents such as mice or bats in these spaces.

See CEILINGS, PLASTER, LOOSE HAZARDS for an example of a dangerous drop ceiling collapse

The photo at above-left illustrates the discovery of asbestos-containing ceiling tiles above a suspended ceiling along with cases of falling tiles and perhaps amateur asbestos material removal.

The photo at below left shows that we found bats infesting the area above the drop ceiling of a public library in upstate New York. At below right we illustrate finding mice in a similar ceiling space.

The photo [at above left] illustrates both leak stains into the suspended ceiling and a missing panel, subverting the airflow design of the building HVAC system.

Continuing our examples of hidden hazards above and in drop ceilings:

- the source of the water,

- whether the problem is still active,

- whether there is any concealed damage

- the cost to correct the water problem if needed, e) and the cost to repair the damaged building materials.

- The cost to replace water-damaged ceiling panels

Mold Contamination or Growth Found on Drop Ceiling Panels & Surfaces

Our moldy suspended ceiling tile photo (left) shows a case in which most of the ceiling tiles had become so wet that they had already fallen to the floor.

One moldy ceiling panel remained in this photo - at the bottom of the image.

Our lab tests found extensive Aspergillus sp., some Stachybotrys chartarum, and Rhodotorula and other yeast contamination on these ceiling materials. [Some suspended ceiling products are rated by their producers as "mold resistant"]

Below, the suspended ceiling in this bathroom had become mold contaminated due to the combination of high moisture and inadequate ventilation, not due to leaks from above.

At below left we show two sides of moldy drop-in ceiling panels found in a basement over an area of burst pipe flooding that went unattended for weeks.

In this event the water and moisture originated below the drop ceiling rather than from above - a hot water spill on the basement floor (photo below).

But on removing moldy ceiling materials we also found evidence of older leaks (below).

Advice for mold contaminated ceiling tiles

Where there is a large (more than 30 sq.ft.) reservoir of contiguous indoor mold, such as is shown on our moldy ceiling photo below, there are almost certainly health hazards for building occupants.

But as we discuss

at Q&A on BUILDING INTERIORS: Leaks, Stains, Damage, Repairs, small moldy areas may be of no significant health concern and can be cleaned or removed by most homeowners or a handyman who follow simple basic precautions.

We emphasize in all of our notes on indoor mold inspection and testing that a competent inspection for mold contamination begins outside, and should include the entire structure.

Even drop ceiling tiles that look "clean" might be a hidden mold reservoir if they have been wet. We discuss hard-to-see mold reservoirs in fiberglass insulation products

at INSULATION MOLD CONTAMINATION TEST.

At USING LIGHT TO FIND MOLD we provide a detailed example and procedures for using lighting to find mold on surfaces where mold may be present but where it is not immediately obvious.

Reader Question: Effects of drop ceilings on building energy usage, heat loss, heat gain, air movement, HVAC operation & costs

Do you have any articles on your Web site dealing with drop ceilings while doing an energy audit? - Christopher M. Petersen, West Philadelphia Home Solutions

Reply: Energy & IAQ Impacts & Some Inspection Points for Suspended Ceilings or "Drop Ceilings"

I'm guessing you're asking about the impact of suspended ceilings on building energy costs, heating gains and losses. The topic of how a drop ceiling affects building energy costs and indoor air quality becomes interestingly complicated depending on at least these factors:

- how the space above the ceiling is used - for example in offices or other buildings the space above the suspended ceiling is often used as a return air plenum,

- on the distance between the ceiling upper surface and the building roof,

- on the R-values of the roof, walls above the ceiling, and of the ceiling itself - some drop-ceiling tiles can be quite thick fiberglass pads that offer varying R-values;

- there are also some questions about the care of installation of the suspending grid and whether or not it's leaky,

- removed or damaged drop ceiling panels - I have indeed investigated and even measured airflow changes that happen to confound heating and cooling air flow in offices when occupants remove or partially remove a suspended section to try to tune up their local airflow.

Our photo (above) illustrates the discovery of an unanticipated air pathway between what was thought to be isolated building sections. - leaks into the space above the drop ceiling risk hidden damage, mold contamination, etc.

- debris in the space above the drop or suspended ceiling may be picked up by and distributed by the HVAC system

If you can be a little more specific with questions I'll be glad to do some research and prepare material for you - it'll help us both. Be sure to let me know the total floor to original ceiling height as well as the floor to drop ceiling height- those will be important model parameters.

Discussion: CP

I'm asking about a drop ceiling in a more general sense, and in a couple things you hit on in your email. I'm a BPI certified home energy auditor and tomorrow I am doing an audit for a family with a bedroom that has a drop ceiling (it formerly was an office).

I'm specifically wondering about some of the dynamics I may want to be on the lookout for during the blower door test. This particular ceiling has insulated tiles and 3-4 inches of well-installed fiberglass batt insulation above the tiles.

I'm expecting to encounter some leakage through the grids, however, which I know will compromise the performance of the insulation. - C.P.

Reply: DF

With some building data we can use existing tools to build a table of [theoretical] effects on building energy usage and IAQ when a drop ceiling (suspended ceiling tiles) is installed.

Reader Question: do you think this suspended ceiling panel is likely to contain asbestos?

Having looked through your website on asbestos ceiling products I would welcome your view on whether this ceiling tile is likely to contain asbestos. Our building survey did not highlight it as a possibility but it has been suggested by someone that there is a chance it could contain asbestos? - H.T. 9/12/2013

Reply: Six tips for deciding if a ceiling panel is an asbestos hazard

A competent onsite inspection by an expert usually finds additional clues that would permit a more accurate, complete, and authoritative answer than we can give by email alone.

For example an examination of the edges of the ceiling tile can quickly observe that it is fiberglass (if it is) which is not an asbestos product, or observation of markings on the hidden or upper side of the ceiling section may disclose a manufacturer's brand, model or control number, or perhaps a clue about the material age.

You will find additional depth and detail in articles at our website.

That said I offer these comments:

With no other information than your email question and the photo of the exposed side of this suspended ceiling panel, one cannot hazard even a reasonable guess about the risk of an asbestos-containing ceiling in your building. A few additional question can, however help address your concern:

1. How old is the building?

Do we know when the suspended ceiling was installed?

Modern or contemporary drop ceiling or suspended ceiling products are not asbestos-suspect materials. But as we note in our article on suspended ceilings (beginning above

at CEILINGS, DROP or SUSPENDED PANEL), you may come across pre-1986 (date approximate) 2' x 2' or 2' x 4' suspended ceiling panels that might contain asbestos, particularly if acoustic panels were used.

2. Are there asbestos materials above the suspended ceiling,

such as spray-on asbestos fireproofing found in some older buildings. If so, there is an asbestos exposure risk assessment that merits attention.

3. Has anyone exposed the edge or back

of the suspended ceiling panels to make the obvious check for visibly sure non-asbestos materials such as fiberglass?

See ASBESTOS-FREE CEILING TILES

4. Are all of the ceiling panels of the same age and material?

If not additional checks may be in order.

5. What is the condition of the ceiling?

asbestos-suspect materials are potentially much more hazardous if they are friable and are damaged or in poor condition.

6. Is demolition or other work planned that will disturb the ceiling materials?

If so, or if a costly building project of any sort involves the ceiling or its disturbance, it is worth having the materials tested.

In any event, don't panic. As we explain at ASBESTOS IDENTIFICATION IN buildings, The US EPA indicates that not all asbestos-containing products are dangerous.

A health risk exists only when asbestos fibers are released from a product [into the air where they are inhaled for example]. Products that are friable (easily crumbled or made into dust that is easily airborne) are more dangerous than products in which binders immobilize the asbestos fibers.

...

Continue reading at CEILINGS, PLASTER, LOOSE HAZARDS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CEILINGS, DROP or SUSPENDED PANEL FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- ASBESTOS CEILING TILES

- ASBESTOS TESTING LAB LIST if you need to test a ceiling panel for asbestos

- CEILINGS, PLASTER, LOOSE HAZARDS

- CONCEALED SPACE FIRE CODES - as suspended ceilings can form an accessible concealed space in buildings

Suggested citation for this web page

CEILINGS, DROP or SUSPENDED PANEL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.