Drywall / Plasterboard Coefficients of Thermal & Moisture Movement

Drywall / Plasterboard Coefficients of Thermal & Moisture Movement

Data & calculations of the amount of thermal & moisture-related movement in gypsum board

- POST a QUESTION or COMMENT about plasterboard cracks, drywall cracks, gypsum board cracking & movement

Coefficient of thermal or moisture expansion in drywall or plasterboard:

This article cites and explains the thermal coefficient of expansion (or movement) of plasterboard and the coefficient of moisture expansion (or shrinkage) of drywall due to humidity or moisture changes. Drywall cracks in ceilings or walls are often blamed on gypsum board expansion or shrinkage due to temperature and moisture changes.

But plenty of experts think that other building factors such as framing or wood shrinkage or building structural movement are more significant causes of plasterboard cracks.

We cite industry sources, technical research and plasterboard or gypsum board standards for various countries. We include example calculations showing how to convert a movement or coefficient of expansion into a distance or the size of an expected crack or tear as moisture or temperature vary and if other forces are excluded.

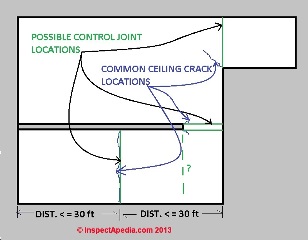

Sketch at page top: common expansion or shrinkage crack risk points in ceiling drywall - where a control joint may be required.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How Much Does Drywall Expand or Shrink in Response to Temperature or Moisture Changes?

Depending on the individual drywall control joint product design and materials (width and plastic vs zinc metal) expansion control joints for plasterboard can handle up to about 4/10" of horizontal movement due to thermal or moisture-related expansion or contraction.

Depending on the individual drywall control joint product design and materials (width and plastic vs zinc metal) expansion control joints for plasterboard can handle up to about 4/10" of horizontal movement due to thermal or moisture-related expansion or contraction.

The required drywall or gypsum board (or plasterboard) control joint width between the abutting drywall panels ranges depending on the specifications of the drywall expansion control strip's manufacturer, typically somewhere between 1/4" and 1" in width.

In the United States, the Gypsum Association (2010) gives an extensive table of drywall properties, including the dimensional stability of drywall, expressed as coefficients of linear expansion. This is for unrestrained gypsum board in the temperature range of 38 °F to 90°F (3.3° to 32°C)

Photo: severe cracking and tearing in a drwyall interior corner. A crack like this one is caused by building movement, not by thermal or moisture changes in the drywall itself.

[Click to enlarge any image]

But in any large expanse of drywall such as along a thirty-foot ceiling or wall expanse, you may see cracks caused by moisture and temperature changes alone if control joints are not installed. Our next photo below illustrates that sort of drywall or plasterboard cracking.

- Temperature effects on drywall expansion: Thermal Coefficient of Linear Expansion of unrestrained drywall (gypsum board or plasterboard) due to temperature variation:

9.3 x 10-6 in/in °F

or for centigrade,

16.7 x 10-6 mm/mm.°C.

What the heck does that mean?

Example: if our gypsum board temperature changes from a low of 40°F up to a high of 90° F that's a 50° swing.

Keeping the math clear, 10-6 = 0.000001 we can write the thermal movement per linear inch over a 50° change as

50° x 9.3 x 10-6 in = (50° x 9.3 x 0.000001) = 0.000465 inches of dimensional change per inch of length - which doesn't look like much.

But for a 30-foot long section of drywall ceiling or wall we can calculate

360 inches x .000465 = or about 0.167 inches of movement - about 2 tenths of an inch - enough to show up on your ruler or possibly to cause a tear or a gypsum board butt-joint ridge formation.

Our drywall ceiling photograph above shows a crack that appeared in a continuous drywall expanse, a ceiling that runs the length of a Poughkeepsie New York home, for 64 1/2 feet in total distance.

- Moisture effects on drywall expansion: The Gypsum association gives the Hygrometric Coefficient of linear expansion of unrestrained gypsum board (drywall or plasterboard) due to moisture level changes as

6.5 x 10-6 in./in/%RH (or also for mm/mm/%RH)

Example: if our gypsum board humidity changes from a typical low and dry building interior of say 10% to a whopping 50% (over a wet or flooded basement, for example but the board is not immersed in water) that's a 40% change in relative humidity or RH for which we calculate the total gypsum board movement (expansion when we are getting wetter or shrinkage when our plasterboard is getting more dry) as

6.5 x 10-6 x 40 x 360 inches of total length = .09 inches of change or about one tenth of an inch - which would produce a very noticeable tear or crack. - Combined forces: if our gypsum board has to endure both the temperature change and the moisture level change we calculated above we've got about

3 tenths of an inch of shrinkage or expansion over 30 feet - a large opening, tear or crack.

Other Citations of Plasterboard Dimensional Stability

For Australia, according to Boral, a producer of plasterboard, under normal temperature and humidity conditions, plasterboard dimensional properties are as follows: - [4][4a]

- Thermal Coefficient of Linear Expansion = 16.2 x 10-6 mm/(mm°C) –at temperature range 4°C to 38°C

- Hygrometric Coefficient of Expansion = 7.2 x 10-6 mm/mm/%RH – at 5% to 90% RH

Other sources use the Boral constants.

Take the HCE for gypsum board of 0.0000072in./% RH; multiply it by 70 (using an integer for the percentage change in relative humidity); multiply it by 0.5 (for the thickness of the board) and you arrive at a figure of 0.00025, or 25 ten-thousandth of an inch.

That is how much a layer of 1/2-inch-thick gypsum board will shrink from front to back when exposed to a decrease in relative humidity of 70 percent — not much of a change and not perceptible to the naked eye.

Here is the math:

.0000072 x 70 x .5 = .00025

Now let's do the same calculation substituting the length [of a 12-foot gypsum board panel] (144 inches) for the thickness:

.0000072 x 70 x 144 =.0725 or a little over a 16th of an inch in 12 feet.

A sixteenth of an inch is a very noticeable crack. - JLC forum discussion t-35269.html

Effects of Restrained (fastened in place) vs Unrestrained Drywall Movement due to Temperature & Moisture

Note: these data are for unrestrained gypsum board panels. In a "real world" application the panels are secured with nails, screws, adhesive, or a combination of these, fastening the plasterboard panels to structural members typically spaced 16" o.c. or 24" o.c. This means that the movement stresses are distributed over fastener points across the panel surface.

One would expect actual movement results to be more constrained than in the unrestrained movement data given above.

Some experts comment that wood (framing lumber) shrinkage and structural movement are more likely to be the dominant forces producing cracks or tears in drywall. I agree - DF. - JLC forum discussion t-35269.html

...

Continue reading at DRYWALL CRACKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- ASBESTOS in DRYWALL

- ASBESTOS-DRYWALL REMEDIATION / REMOVAL

- BESTWALL DRYWALL ASBESTOS

- CELOTEX DRYWALL ASBESTOS

- CERTAINTEED DRYWALL ASBESTOS

- CHINESE DRYWALL HAZARDS

- DOMTAR GYPROC ASBESTOS?

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL CONTROL JOINTS

- DRYWALL CRACK CAUSES & CURES

- DRYWALL FINISH LEVELS

- DRYWALL TYPE IDENTIFICATION STAMPS

- DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL

- DRYWALL GREEN LOW TOXICITY MAGNESIUM OXIDE MgO

- DRYWALL MOLD RESISTANT

- DRYWALL MOLD TESTING

- DRYWALL NAIL POPS

- GYPSUM BOARD GYP ROCK SHEATHING

- GYPSUM BOARD PLASTER LATH SYSTEMS

- IGNIFUGE GYPSUM BOARD ASBESTOS?

- NATIONAL GYPSUM DRYWALL ASBESTOS?

- PICTURE HANGING NAILS to avoid damage/dust

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

- SACKETT BOARD

- SHEATHING, GYPSUM BOARD

Suggested citation for this web page

PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] "Gypsum Joint Ridging and Cracking", (2009), SBCA Tech Notes, Structural Building Components Association, 6300 Enterprise Lane Madison WI 53719, (608) 274-4849, (608) 274-3329 FAX, retrieved 12/11/2013, original source http://support.sbcindustry.com/images/technotes/T-GypsumInstallation09.pdf

- [1a] Paul F. Schofield, Kevin S. Knight, Iona C. Stretrton, "Thermal Expansion of gypsum investigated by neutron powder diffraction", (1996) Manuscript, retrieved 12/11/2013, original source: http://www.minsocam.org/msa/ammin/toc/ Articles_Free/1996/Schofield_p847-851_96.pdf

- [1b] Azree Othman Mydin, "Gypsum Board Thermal Properties Exposed to High Temperature and Fire Condition", (2012), University Sains Malaysia School of Housing Building and Planning, retrieved 12/11/2013, original source: http://www.ce.tuiasi.ro/~bipcons/Archive/325.pdf

- [2] "Gypsum Board Typical Mechanical And Physical Properties (GA-235-10)", (2010) Gypsum Association, 6525 Belcrest Road, Suite 480, Hyattsville MD 20782, retrieved 12/11/2013, original source: http://www.gypsum.org/wp/wp-content/uploads/2011/11/GA-235-10.pdf

- [3] Drywall or plasterboard standards: ASTM D3678

- Drywall or plasterboard standards: ASTM C1047

- Drywall or plasterboard standards: ASTM D4216-99

- Drywall or plasterboard standards: Canadian Codes [pending CSA citations]

- ASTM C 473 specifies the maximum deflection in humidified gypsum board for interiors, for ceiling board, and for exterior gypsum soffit board

- Drywall or plasterboard standards: ASTM C840

- Drywall or plasterboard standards: ASTM C844

- Drywall or plasterboard standards: Gypsum Association GA -216

- Drywall or plasterboard standards: Gypsum Association GA -234 (Fire-Resistant Applications)

- Drywall or plasterboard standards: Australian Standard AS2311–1992 for The Painting of Buildings (when painting plasterboard walls & ceilings)

- [4] Boral Plasterboard (Australia), "Boral Plasterboard Installation Manual", August 2007, PB103, Tel: 1800-811 222 (in Australia), Email: tecassist@boral.com.au, Website: www.boral.com.au, ACT: 7 Barrier St, Fyshwick 2609, Tel: 02 6280-4243. Other Boral Plasterboard offices are in New South Wales, Northern Territory, Queensland, South Australia, Tasmania, Victoria, Western Australia, and the company has an export department.

- [4a] Boral, "Plasterboard Specifications", retrieved 12/11/2013, original source: http://www.boral.com.au/plasterboardexport/ plasterboard_specifications.asp

- [5] British Gypsum Co., "Gyproc Control Joint, Products Plasterboard Accessories", Website: www.british-gypsum.com.

- [6] George M. Kutcher, Jr., "Don't Overlook Control Joints in Drywall Construction", National Gypsum Company, Tel: 1-800-NATIONAL, www.nationalgypsum.com, retrieved 12/10/13, original source: http://www.nationalgypsum.com/resources/tech-talk-controljoint.htm

- [7] National Gypsum Company, "Gypsum Board Systems", 12th Ed., (2000), (Gold Bond® brand gypsumboard products), website: http://www.nationalgypsum.com

- [8] George M. Kutcher, Jr., "Don't Overlook Control Joints in Drywall Construction", National Gypsum Company, retrieved 12/10/2013, original soruce: http://www.nationalgypsum.com/resources /tech-talk-controljoint.htm

- [9] "Design Essentials for Controlling Movement Induced Stresses in Building Materials", Winstone Wallboards, Ltd., Winstone Gypsum, Dec. 2009, Winstone Wallboards Ltd

219 Opawa Road PO Box 1983 Christchurch New Zealand Phone: +64-3-332-3159, and Winstone Wallboards Ltd 37 Felix St PO Box 12-256 Penrose Auckland New Zealand, Tel: +64-9-633-0100, Email: gypsum@gib.co.nz, Toll free: 0800 475 475.

Note: per Winstone: for large ceilings, AS/NZS 2589 specifies that all sheet end butt joints are backblocked (to reinforce the joint where such joints are not meeting over a ceiling joist). [This is a reinforcement detail for unsupported butt joints, not a wallboard movement control joint detail. The company's article does recommend that installers insert control joints at the junction of wallboard ceilings at hallways vs large open spaces - Ed. ]- Cracking and Building Movement, Dickinson & Thornton, 2006

- BRANZ Bulletin 418 July 2001 ’Providing for Thermal and Moisture Movement’

- Cracking and Building Movement, Dickinson & Thornton, 2006

- NZS 3602 Timber & Wood Based Products for use in Building

- Wood Processing Newsletter SCION July 2003 Simpson & Turner

- ‘A Field Study of moisture performance of roofs etc.’ Technical Report 127. 1994 Cunningham et al

- ‘Plasterboard Peaking and Cracking under Timber R oof Trusses’ 1999 - Prof H Robert Milner, BE, MEngSc, PhD, FIEAust, AIWSc and CY Adam, BE, MEngSC Monash Engineering Timber Centre, Monash University, Australia

- ‘Walls & Ceilings’ Magazine ‘Drywall Cracking on a Global Scale’ By Greg Campbell March 9, 2001 ix AS/NZS2589 2007 – Gypsum Linings - Application & Finishing

- [10] Repair of Gypsum Board Joint Ridging (GA-221-00)

- [11] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [12] "Finishing Drywall Systems", U.S. Gypsum (USG) Corporation [copy on file as USG_Finishing_Drywall_Systems_Ch5.pdf] 2009

- [13] "Sheetrock® All Purpose Joint Compound - Select for professional drywall finishing", Submittal Sheet 09250

- [14] "Quality Drywall Finishing in All Kinds of Weather", USG Folder J-75 (out of print), U.S. Gypsum corporation

- [15] Gypsum Construction Guide, National Gypsum Corporation

- [16] Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- [16a] R.S. Means, The Gypsum Construction Handbook, 6th Ed., [purchase at Amazon] J. Wiley, (2009), ISBN 978-0-87629-258-7, quoting J. Wiley & Sons:

One of the construction industry's longest-running, most relied-on references, The Gypsum Construction Handbook was first published by the U.S. Gypsum Company in 1904. For more than a century and through several editions, the book has become a trusted standard. This new 6th edition is an illustrated, comprehensive, and authoritative guide on all facets of gypsum construction. You'll find the newest product developments, installation methods, fire- and sound-rated construction information, illustrated framing-to-finish application instructions, estimating and planning information, and more. System descriptions – together with full data on products, accessories, tools, equipment, and applications – help plan and estimate projects and ensure compliance with performance criteria. Cost- and time-saving techniques keep the work on budget. New in the sixth edition are chapters on sustainable construction methods and products, building movement, fire resistance, heat transfer, sound transmission, and vapor/moisture control. The Handbook covers both new construction and repair and remodeling and includes: framing drywall and veneer plaster joint treatment and plaster finishing interior cement board ceilings conventional plaster - [16b] Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- [17] Lath & Plaster Systems [copy on file as /interiors/LathPlaster_Nat_Gypsum.pdf ] - , 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- [18] Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster [copy on file as/interiors/Amico_lath-inside.pdf ] - from Amico, a lath and plaster accessory producer.

- [19] Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

[copy on file as/interiors/Plastering_USG.pdf ] -

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

>Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - [20] Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- [21]

Drywall Finishing Council www.dwfc.org, Members: CertainTeed Gypsum • Freeman Products • Georgia Pacific Gypsum LLC • LaFarge North America • Magnum Products •

National Gypsum Company • Panel Rey SA • Rapid Set Cement • Saint-Gobain, Inc • Sherwin-Williams Company • Solid Products, Inc. • Southern Wall Products • Trim-Tex, Inc. • United States Gypsum Company • Westpac Materials

- "Joint Compound Drying Time, the Impact of Environmental Conditions", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2010_03_16_Joint_Compound_Drying.pdf [copy on file as Joint_Compound_Dry_Tmie_DWC.pdf]

- "Jobsite Conditions for Applying Interior Finishing Materials", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2011_09_16_Interior_Job_Condition_Specifications.pdf [copy on file as Drywall_Finish_Conditions_DWC.pdf ]

- DWFC. Interior Job Condition Specifications For The Application of Drywall Joint Compounds,

Drywall Textures, and Paint/Coatings". Drywall Finishing Council, Incorporated. www.dwfc.org - DWFC. Recommended Specification for Preparations of Gypsum Board Surfaces Prior To Texture

Application, Drywall Finishing Council, Incorporated. www.dwfc.org - GA. GA-214, Recommended Levels of Gypsum Board Finish. Gypsum Association, 6525 Belcrest

Road - Suite 480. Hyattsville, MD 20782 www.gypsum.org - National Gypsum Company. ProForm Brand Drywall Finishing Products Construction Guide,

National Gypsum Company, 2001 Rexford Road, Charlotte, NC, 28211, www.nationalgypsum.com

- [22] The Gypsum Association www.gypsum.org Gypsum Construction Handbook H-17 [purchase at Amazon.com] . USG Corporation, 550 West Adams Street, Chicago, IL, 60661, www.usg.com

- [23] Painting and Decorating Contractors of America www.pdca.org Smartwood/Rainforest Alliance www.smartwood.org

- [24] "Joint Compounds", United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124, retrieved 8/16/12, original source: http://www.usg.com/interiors/joint-compounds.html [copy on file as Mud_Types_USG.pdf]

- [25] Gypsum Construction Guide, National Gypsum Corporation

- [26]

- [27] Lath & Plaster Systems, 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- [28] Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster from Amico, a lath and plaster accessory producer.

- [29] Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- [30] Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.