Variable-Speed Zone Circulators

Variable-Speed Zone Circulators

Brands & features of heating circulators that can vary circulating speed

- POST a QUESTION or COMMENT about variable speed heating circulators.

Variable speed heating zone circulators:

This article describes brands & models of forced hot water heating system circulator pumps whose motor speed or circulating speed can be set to varying rates.

We describe both older obsolete variable speed circulator pumps and modern currently-available models including manufacturer brand, model, and circulator pump sources.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Variable Speed Hot Water Heating Circulator Pumps, Motors & Controls

Variable speed heating zone circulators provide an additional level of heating zone control and can be used to solve heating problems amenable to either an increase in circulating water speed (get more heat in a zone) or a decrease in heating zone circulator speed (less heat or continuous, more even heat).

Variable speed heating zone circulators provide an additional level of heating zone control and can be used to solve heating problems amenable to either an increase in circulating water speed (get more heat in a zone) or a decrease in heating zone circulator speed (less heat or continuous, more even heat).

Older Variable Speed Heating Circulator Pumps

At left is a Bell & Gossett UpStart hot water heating zone circulator pump produced - a B&G product no longer distributed. This circulator pump included a variable-speed circulator motor (see that gold knob on the electrical box atop the motor?).

This hot water heating zone circulator used a four-speed motor whose output rate could be set by the consumer or heating service technician.

By changing the circulator motor speed on this pump or on the next model shown below, we could slow or speed the flow rate of hot water through the zone managed by this circulator. The result: this control provided another way to balance heat flow among multiple zones (and circulators) in a building.

This circulator, the Bell & Gossett SLC-25 Upstart Circulator was sold during the 1980's and is not currently available. But B&G offered similar replacements (such as the NRF-22).

At below is a newer but also obsolete product, the B&G NRF-VS variable speed circulator is shown.

Currently-Available Variable-Speed Heating Circulator Pumps & Controls

Taco Variable Speed Circulators

Taco's variable speed circulators include the Taco BumbleBee High-Efficiency Variable-Speed Circulator HEC-2

Quoting from the company's product literature:

The Taco Bumble Bee (model HEC-2) represents the very latest in variable speed wet rotor circulator technology. Its high efficiency ECM motor uses up to 85% less electricity than a standard circulator, and its out-of-the-box settings and 360 ̊ swivel flange makes it a breeze to install.

Most importantly, the Bumble Bee’s Delta-T variable speed technology maximizes the overall efficiency of your heating system. - Taco Catalog q#100-101 retrieved 1/24/2014 [on file] see References at the end of this article

Taco's variable speed heating circulator products also include the

- Taco 00 Series 3-Speed Cartridge Circulators in th following models:

0010

Max. Flow: 31 GPM

Max. Head (ft): 11′

Min. Fluid Temp.: 40˚F (4˚C)

Max. Fluid Temp.: 230°F (110˚C)

Max. Working Pressure: 125 PSI

Connection Sizes: ¾”, 1″, 1¼”, 1½” Flanged

0012

Max. Flow: 45 GPM

Max. Head (ft): 15′

Min. Fluid Temp.: 40˚F (4˚C)

Max. Fluid Temp.: 210°F (98˚C)

Max. Working Pressure: 125 PSI

Connection Sizes: ¾”, 1″, 1¼”, 1½” Flanged

0013

Max. Flow: 30 GPM

Max. Head (ft): 30′

Min. Fluid Temp.: 40˚F (4˚C)

Max. Fluid Temp.: 210°F (98˚C)

Max. Working Pressure: 125 PSI

Connection Sizes: ¾”, 1″, 1¼”, 1½”

0015

Max. Flow: 18 GPM

Max. Head (ft): 17′

Min. Fluid Temp.: 40˚F (4˚C)

Max. Fluid Temp.: 230°F (110˚C)

Max. Working Pressure: 125 PSI

Connection Sizes: ¾”, 1″, 1¼”, 1½” Flanged

- Taco 00 Series Variable Speed Outdoor Reset Circulator

Flow Range: 0-52 GPM

Head Range (ft): 0-35″

HP: 1/40 – 1/6

Min. Fluid Temp.: 40°F (4°C)

Max. Fluid Temp.: 230°F (110°C)

Max. Working Pressure: 125 PSI, 150 PSI - Taco 00 Series Variable Speed Setpoint Circulator

Flow Range: 0-52 GPM

Head Range (ft): 0-35′

HP: 1/40 – 1/6 - Taco 00 Series Variable Speed Solar Control Circulators

Flow Range: 0-31 GPM

Head Range (ft): 0-31′

Min. Fluid Temp.: 40°F (4°C)

Max. Fluid Temp.: 230°F (110°C)

Max. Operating Pressure: 125 PSI - Taco 00 Series Variable Speed/Variable Voltage Circulators -

Max. Fluid Temp.: 40F (4°C)

Max. Fluid Temp.: 230F (110°C)

Max. Working Pressure: 125 PSI (006-008), 150 PSI (009-0014)

Flow Range: 0-52 GPM

Head Range: 0′-35′

HP: 1/40 -1/8

Taco's installation and wiring manuals for these and other Taco products are found

at TACO HVAC components & controls

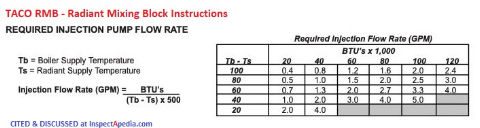

Below: alternative to a variable speed circulator pump itself, for radiant heating systems installers may use the Taco RMB Radiant [Heat] Mixing Block to control flow rate and thus BTU outpout of radiant heat systems.

Specifications for the Taco RMB:

Flow Range: 0-15.5 GPM

Head Range (ft): 0-15′

HP: 1/40, 1/25

Max. Fluid Temp.: 185°F (85°C)

Min. Fluid Temp.: 32°F (0°C)

Max. Working Pressure: 125 PSI

Connection Size: ¾” NPT

Detailed instructions and specifications are

at TACO RMB RADIANT MIXING BLOCK INSTRUCTION MANUAL [PDF] (2015) for radiant heat system control

Grundfos Variable Speed Circulators

Alpha Series pumps by Grundfos also provide variable speed hydronic heating water circulation control. Quoting [with minor adaptations] from product literature from Grundfos, including the UPS15-58FC and the Grundfos Alpha series.

The Alpha Series pumps [above right] (e.g. ALPHA 15-55F - ALPHA 15-55SF/LC) have permanent magnet motors designed for circulating water through domestic hot water systems, heating systems, or cooling and air conditioning systems.

The Alpha pumps can be used in systems with either constant or varying water flow rates. example of a Grundfos ALPHA pump The Alpha pumps incorporate a frequency converter, an integrated differential pressure control, and an electronic processor to automatically adjust pump speed based on the system demand and flow rates.

The AUTOADAPT™ software recognizes changes in the system like opening and closing valves or faucets that can cause a change in the head-flow requirements of the system.

AUTOADAPT™ monitors the motor current versus the pump hydraulic or pressure conditions and automatically adjusts the motor speed to minimize the pumps energy consumption and at the same time maximize your system needs for your comfort level.

The Grundfos MixiMiser™ is the only pump and controller system of its kind. The mixing-reset control automatically calculates and controls water temperatures according to outdoor temperatures in primary and secondary heating systems.

The MixiMizer™ can be installed into a thermostatic or zoning control system for maximum design flexibility.

A fully serviceable check valve is installed into the pump housing to eliminate unwanted, uncontrolled, flow when the pump is not on and will not inhibit water flow when the pump is on. LED indicators located on the terminal box indicate pump performance and help diagnose possible faults without the use of tools.

Heating Zone Circulator Pump Speed Selection & Adjustment

Several companies including Bell and Gossett and Taco offer variable-speed hydronic heatingcirculator pumps, such as

Taco 00 Series 3-Speed Cartridge Circulators

Taco 00 Series Variable Speed Circulators in several models (Ourdoor reset, Setpoint, Solar Control, Speed/varibale voltage)

Question: what is the best speed to use for my variable speed circulator pump?

Can you tell me if there are any studies or articles that may guide me to the best speed (RPM) that a circulation pump should have ?

Can you tell me if there are any studies or articles that may guide me to the best speed (RPM) that a circulation pump should have ?

We all know that when an Oil Boiler "kicks" on after a call of heat that the circulation starts however we all also know that the slower (and longer) that water stays in the boiler the faster and hotter the water will heat.

Also, as the boiler reaches a temperature to shut off and the circulation is still on, there must be a best speed to let off heat within the baseboard, radiator, etc. - Anonymous by private email 2018/01/31

Reply: how is the desired circulator speed determined & set?

I too have asked service technicians and manufacturers about the "best" speed for variable-speed circulator pumps and I've gotten answers that were all over the place. I suspect that that the bottom line is that there is some subjectivity in deciding on the circulator speed.

If we need more heat in an area we can send more BTUh through the piping by upping the circulator speed.

Manually-set variable speed circulators are then adjusted to increase the heat output of an individual zone as needed.

Variable-speed self-adjusting hydronic circulators like the Taco Delta T 00® (described in more detail just below) monitor temperature across the zone and adjust the circulator speed to a desired heat delta T setting. That design is particularly useful for radiant heat flooring systems.

You might already realize that in many boiler set-ups, especially in the U.S. the thermostat turns on the circulator and the boiler temperature is what turns the burner on or off. So the circulator will run until the thermostat is satisfied.

The link given below describes a more-sophisticated "Delta-T" circulator from Taco

The instruction sheet for this circulator explains:

Variable speed pumping to maintain a set differential temperature (delta T or ∆T) between two sensors allows for automatic adjustment of the pump’s performance to match the load of the system or zone, eliminate velocity noise in zone valve systems and conserve energy.

Since delta T is directly related to flow rate, the pump’s speed continually adjusts to the required BTU per hour. In almost all applications the design of the system was based on being able to maintain a certain delta T and figured by using the universal hydronics equation of BTU/hr = GPM x 500 x ∆T.

Given that, any time there is a change to the heat load (i.e. warmer day or greater heat loss from a structure) then the GPM should change to match the required BTU/hr.

This is achieved when the variable speed 00-VDT Circulators automatically and continually adjust their GPM output (by varying speed) to match the required BTU/hr output of the system, no matter the changes in heat load, while always maintaining the designed delta T between a supply and return sensor.

The company includes a video on how to read circulator pump performance curves.

- TACO® VARIABLE SPEED DELTA T 00® CARTRIDGE CIRCULATOR (00-VDT) [PDF] (2015) retrieved 2018/01/31, original source: http://www.taco-hvac.com/uploads/FileLibrary/102-359.pdf

Excerpt from product description:

The 00-VDT Variable Speed Circulator adjusts its speed to maintain the differential temperature (based on the RANGE dial setting) between the supply sensor and the return sensor whenever a heat demand is present. This will increase overall comfort and sharply reduce boiler short-cycling.

The 00-VDT will also control velocity noise issues in the system, eliminating the need for a pressure differential bypass valve.

The 00-VDT Variable Speed Circulator adjusts its speed to maintain the differential temperature (based on the RANGE dial setting) between the supply sensor and the return sensor whenever a heat demand is present.

The 00-VDT will also eliminate velocity noise by slowing the actual flow rate through the zone to the minimum required to deliver proper heat. If other zones on the manifold open, the 00-VDT will increase its speed to deliver the required BTU’s, while at the same time maintaining the designed for delta T across the radiant system.

- source: http://apps.taco-hvac.com/products/water _circulation_pumps__ circulators/wet_rotor_circulators/00_ series/variable_speed_delta_t_00_ circulators/index.html

Reader follow-up:

Thank you for your response .... The Taco pump with the 2 sensors is probably pretty close to what I would look for. If I could use the 2 sensors for keeping the return water temperature 20 degrees less than the supply (so basically the circulation starts when return is less than 20 degrees less than supply).

This would keep the return water temp warmer so the boilers burner is not in a sense at a cold start.

Also, I like you have had answers that basically just don't satisfy me (like "the speed of circulation has nothing to do with how well a boiler makes heat").

I myself would think that HVAC professionals would know for a giving amount of space to heat, a given amount of heat loss based on outside temp AND inside temp, and a given type of system (boiler, copper finned baseboard, radiator, flow rate required, etc) that at least a best guess of what the speed of circulation should be make the boiler effecient when burning and when just holding hot water.

wow, another factor - how much heat is lossed when a boiler is just sitting idle.

Reply:

Thank you for the follow-up. Indeed there are plenty of smart technicians who simply don't communicate clearly. And others who simply don't know. I joke that many techs and even some engineers never even read the instructions on the box - that paper is used to kneel-on while installing parts.

There are clear ratings in BTU output for various types of heating baseboard per linear foot at assumed average water temperature and flow rate.

I think part of the reluctance to give more explicit data is that there are so many variables at an actual installation that the factory assumptions cannot promise to deliver what is described.

Many times I've gone into an attic or crawl area to discover dramatic snafus that had not been noticed by the expert sitting in their office claiming what the heating or cooling system would be delivering. These may be of interest

HEAT LOSS R U & K VALUE CALCULATION

RADIATOR BASEBOARD or CONVECTOR COVERS

On 2021-01-25 by (mod) - What are the recommended flow rates for radiant heat in-floor systems and how is the flow rate adjusted? >

VU

VU

Thank you, that's a great question that I'd re-phrase as: What are the recommended flow rates for radiant heat in-floor systems and how is the flow rate adjusted?

I'm not an expert on the question but I can offer some comments and explanation, and I'll research further and improve this text

In general, radiant heat floor flow rates are much less than those used other hydronic heating systems employing baseboards or radiators.

- Hydronic heat flow rates in GPM: typically between 0 and over 50 GPM

- Radiant floor heat flow rates in GPM: typically between 0.4 GPM and 5.0 GPM [see Taco's RMB table below]

Illustration: the Taco Radiant Heat mixing block used to control flow rate and thus BTU outpout of radiant heat systems.

[Click to enlarge any image]

Water flow rates for Domestic Hot Water Production

Watch out: your question cites minimum and maximum flow rates for tankless water heaters. A tankless water heater is used to produce domestic hot water (for washing and bathign) and is absolutely not intended for use as a building space heater (hyrdonic heating to keep occupants warm). Do not confuse hot water for domestic use with hot water for heating.

Tankless water heater flow rates are indeed specified by the manufacturer, such as your cited

no less than 2 GPM (7.5 L/min) and no more than 4 GPM (15 L/min)

because at too slow a speed the heater might overheat or might not even turn on its heating element (for safety), while at a too high-flow-rate the tankless water heater can not heat the pasiing water hot enough for domestic use (washing and bathing).

Watch out: also if you are using a tankless water heater as your heat source for a building radiant heating system, make sure that the manufacturer agrees that the tankless water heater you have selected is rated and acceptable for that level of usage.

Water Flow rates for Building Heating Systems

Hot water flow rate through any hydronic or radiant heating system will indeed affect the heat output: flowing faster delivers more BTUs per minute to a given length of radiant tubing or baseboard, but I suspect an accurate equation is far more complex than meets the eye. We need both temperature and time of contact to conduct heat out of hot water into and thus out of a radiating device.

And in-floor hydronic radiant heat systems are more-complex than a conventional baseboard or radiator heating system in that we also need to keep the floor temperature from rising anywhere near the surface temperature of a conventional radiator or baseboard, lest we burn the occupants' feet or damage the floor itself.

So radiant floor systems use a mixing system that recirculates the same hot water through the flooring loop, mixing in a bit of hotter water from the boiler under the control of one or more radiant loop thermostatic controllers monitoring the temperature of the return water.

That temperature control is in addition to the aquastat on the boiler itself.

So you can see that regulating flow rate rather than thermostatically-controlled hot water mixing much complicates the question of whether or not we should be concerned with varying the gpm rate of the circluator pump itself.

In fact the terms "GPM" and "Flow Rate" do not even appear in many circulator pump IO manuals.

See the various circulator pump manuals provided at

CIRCULATOR PUMP MANUALS

The simplest approach used by heating system installers or designers is to choose a circulator that, at a given temperature range, can deliver sufficient BTUh of heat to the heated area - which of course varies by area size and heat loss rates and the total amount of radiating equipment.

Taco offers products specifically designed for radiant heating systems such as the company's

TACO RMB RADIANT MIXING BLOCK INSTRUCTION MANUAL [PDF] (2015) TACO, INC., 1160 Cranston Street, Cranston, RI 02920 USA Tel: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8 Canada Tele: 905/564-9422. FAX: 905/564-9436.

Website: http://www.taco-hvac.com

from which the table below is excerpted.

[Click to enlarge any image]

Specifications fodr the Taco RMB discussed here include:

Flow Range: 0-15.5 GPM

Head Range (ft): 0-15′

HP: 1/40, 1/25

Max. Fluid Temp.: 185°F (85°C)

Min. Fluid Temp.: 32°F (0°C)

Max. Working Pressure: 125 PSI

Connection Size: ¾” NPT

Additional Taco radiant heat system conrols are found

at TACO HVAC components & controls

I will review our documentation on radiant heat system installation and controls: there are indeed controls on radiant heat systems that will affect flow and temperature, but to date our focus, and that in the documents I've read and systems I've worked-on has been on getting the right temperature rather than the flow rate in gpm;

I will repeat the question and include a reply in the reader Q&A at

RADIANT HEAT TEMPERATURES

inspectapedia.com/heat/Radiant_Heat_Temperatures.php

If I find enough different material on flow rates for radiant heat I'll spin that off into a new article. Thank you again for asking.

Most hyrdonic heat system circulator pumps do not have an adjustable flow rate, though a group of circulators have a variable speed control, such as the Taco brand - take a look at the conventional hydronic - hot water - heating system flow rates discussed at

CIRCULATORS VARIABLE SPEED

in a section titled

CIRCULATOR PUMP SPEED SELECTION & ADJUSTMENT

We welcome your further questions, comments, suggestions.

Question: banging from zone piping when thermostat stops calling for heat

(Nov 22, 2015) Bob said:

The house warns fine and there is no air in lines. Zones valves open fine to reach temp but when the temperature on the thermostat is turn down it bangs. What is causing this? It does it on all zones.

Reply:

Bob,

You are describing a water hammer problem that usually is traced to a high-speed closing zone valve combined with the velocity of the circulator water.

The solution may be to install an anti water hammer device, to install a slow closing the valve, or to review the circulator speed if you have a variable speed circulator pump.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-12-16 by InspectApedia (Editor)

@Arthur,

Here's an example that can work for you

https://inspectapedia.com/heat/Honeywell-Line-Voltage-Thermostats.pdf

On 2022-12-16 by InspectApedia (Editor)

@Arthur,

In my opinion your suggestion is entirely reasonable. More, if your hydronic heat system is already treated with anti-freeze (as many usually are), the freeze risk while the circulator is off ought not be a concern.

Examples of line voltage thermostats that can work fine - (be sure to choose one that's the same voltage as your circulator pump - you say it's 240V) - are at

https://inspectapedia.com/heat/Thermostats_Line_Voltage.php

LINE VOLTAGE THERMOSTATS

On 2022-12-16 by Arthur

@InspectApedia (Editor), Thanks for the quick response. Unfortunately my installer was me so I have nobody but my self to ask about why the original set up has the pump running continuously. I just followed the set up advice of the heat pump maker. However, they were also the ones suggesting adding the thermostat control to deal with the space “overheating” during the fall/spring shoulder seasons.

The set up I have is in a fairly large shop that I only want to maintain at around 50F from Nov through March when it is fairly cold here. The problem is that because the temperature fluctuates wildly during the shoulder months (Nov and March).

Even at the slow pump speed the place is liable to heat up more than I want during that time (I am a cheap sob so I don’t want to spend money making more heat than I need).

I could play with the storage tank water temp and try to control it that way but it would mean changing it up and down with the weather which is a pain. I have good freeze protection with my heating fluid so am not worried that anything will freeze if the thermostat shuts the pump down.

I will try installing the thermostat and see how it works. I will try to remember post a comment with what I learn once it has been running for a while in case anyone else is dealing with a similar issue. Thanks again for your help.

On 2022-12-15 by InspectApedia (Editor)

@Arthur,

Sure that's perfectly reasonable - a line voltage thermostat (120VAC) can switch your 120VAC pump on and off just in response to room temperature.

But before making this "improvement" I would worry about and discuss with your heating system installer the question of why the original design has the circulator running all the time.

Continuous hydronic heat water circulation is a common practice

- in colder climates like Canada and Norway

- in more moderate climates where specific, individual building construction details raise a worry about frozen heating zone lines (such as where the most-distant corner of the piping passes around the coldest corner of the building)

On 2022-12-15 by Arthur

I have an infloor hydronic heating system run by an air to water heat pump that heats water and circulates it to a storage tank. The storage tank has its own electric heating elements that provide back up heat if/when the heat pump can’t keep the storage tank water at the set temperature (a few weeks in January).

The back up heating elements are controlled by the heat pump so they only run when the heat pump can’t get the storage tank water to the set temperature on its own.

A circulating pump controlled by the heat pump moves heated water from the heat pump to the storage tank. On the floor heating loop side there is a 240 V Grundfos Alpha 2 variable speed circulating pump that takes the heated water from the storage tank to a single heating zone. That pump plugs directly into a wall outlet and is continuously on during the heating season. I can control the flow into the heating loop by adjusting the pump speed.

I would like to control that pump instead using a room temperature thermostat. It was suggested to me that that I should do that by installing a 240V line voltage thermostat in the line powering the pump outlet.

The idea being that I would set the thermostat to my desired room temperature and the thermostat would power the outlet on and off based on that setting. I would then simply leave the circulating pump setting on high and it would automatically turn on when the thermostat supplied power to the outlet and off when the thermostat room temp setting was met and power to the outlet was turned off.

I was told I should use a double pole line voltage thermostat (has a true off setting).

This seems to me like a simple way to get decent room temperature control without having to manually adjust the pump speed. Does this make sense? Can I use a line voltage thermostat typically used for controlling baseboard electric heaters or is there a thermostat more specifically designed for this type of application? Thanks for your help.

On 2022-01-06 by Inspectapedia Com Moderator

@Ray,

Higher speed can deliver more heat to a zone, providing another way to balance heating zones.

These circulator are usually nearly silent. Noise might be a failing bearing.

On 2022-01-06 by Inspectapedia Com Moderator

@Ray,

As stated above on this page:

Variable speed heating zone circulators provide an additional level of heating zone control and can be used to solve heating problems amenable to either an increase in circulating water speed (get more heat in a zone) or a decrease in heating zone circulator speed (less heat or continuous, more even heat).

As far as the noise issue, what Taco model do you have? That may help in figuring out the noise issue. A first step would be to review your owner's manual as there is often a troubleshooting section included.

On 2022-01-05 by Ray

What is the advantage of a multiple speed taco circulator?

Why is my multi speed circulator generating noise to my baseboard?

On 2021-08-09 by inspectapedia.com.moderator

@Dan Clemmensen,

Certainly, among industrial Process Equipment.

On 2021-08-08 by Dan Clemmensen

I wish it do my own system engineering. I wish to control variable-speed circulators using my own control system, so I don't want the circulator using delta-T or delta-P. I just want to tell it what speed to use in either RPM or GPM, suing either an analog voltage or a digital signal.

I might be willing to pay for delta-T, delta-P, and/or GPM measurments output from the circulator to my control system, but I want direct control of the speed. Do such circulators exist?

On 2020-01-06 by danjoefriedman (mod)

Assuming this is a heating application you certainly need a relay to turn the pump on and off at appropriate times.

On 2020-01-06 by Lonny

Can I use a Grundfos Alpha pump with the auto adapt feature without using any kind of pump controller.

On 2016-08-07 by danjoefriedman (mod)

Before rearranging heating zones I'd check for

- an AIRBOUND HEATING SYSTEM

or

- a circulator pump that is not working

On 2016-08-07 by Johnh

My first zone has 60 ft of baseboards plus a toe kick heater it takes a very long time to heat up the space. Should I make it into two zones?

On 2016-02-20 by danjoefriedman (mod)

John, thanks for the excellent question.

My OPINION is that the maximum temperature drop between water leaving the boiler and water returning to it should be 20 degF. Your system is within that range.

A radiant heated floor system uses an automatic temperature control valve to keep the floor from being too hot.

Only if your rooms are not getting enough heat would I change the circulating speed (faster = more heat), and that only after first adjusting the automatic mixing valve that is tempering the water so that your floors are not uncomfortably hot.

On 2016-02-20 by John W. Lasette

our new rinnai radiant flooring heat has 2 grundfos variable heat pumps. the input water temp is 120f and return is at 110f. the pumps have 3 speeds. what would the proper pump speed to do the best job?

...

Continue reading at CIRCULATOR PUMPS & RELAYS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

CIRCULATORS VARIABLE SPEED at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Instruction Manual, Bell & Gossett Series LR Circulators" P86101D, Mayu 2012, Xylem Inc. 8200 N. Austin Avenue Morton Grove, Illinois 60053 Phone: (847) 966-3700 Fax: (847) 965-8379 www.xyleminc.com/brands/bellgossett

- "Installation and Operation Instructions, Raytherm Residential Boilers," courtesy of Raypak®, and technical advisor Wayne Hoffman, personal communication 5/11/2009. Mr. Hoffman is a technical advisor with more than 30 years experience in the heating field. Raypak is a Rheem company that provides hydronic heating boilers for residential, pool, and commercial use. Raypak can be contacted at 866-583-0664 for technical support or for assistance in selecting the proper heating equipment for a specific application. Rheem Corporation is a manufacturer of water heaters and heating equipment including Ruud heating and cooling products.

- Bell & Gossett Air Separators and other heating system components, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379 . Air separators are discussed by B&G at http://www.bellgossett.com/homeowners/BG-airseparator.asp

- Taco air scoops and other heating system components & controls: Taco Inc., 1160 Cranston Street, Cranston, RI 02920 / (401) 942-8000 / Fax (401) 942-2360 Taco (Canada) Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3 / (905) 564-9422 / Fax (905) 564-9436 www.taco-hvac.com

Taco also has some helpful FAQs that are useful in diagnosing circulator problems - see http://www.taco-hvac.com/en/faq.html# - Sparco air purgers, air scoops, and other heating system components & controls:

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.