Challenger Electrical Panels

Challenger Electrical Panels

Field Reports of overheating Challenger Electrical Panel bus & breaker components

- POST a QUESTION or COMMENT about Challenger Electrical Panels & circuit breakers

Challenger Electric: electrical panel bus overheats, circuit breaker failures, field reports.

This article includes photographs of overheated Challenger Electric electrical panel components and cites a historical connection between Challenger Electric Company and Federal Pacific Electric. However the specific panel bus and breaker designs are different among those brands.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Challenger Electrical Panel Bus Overheating Field Failure Reports

Challenger Electric panel history, field reports of overheating bus bars & circuit breakers, history, relationship to FPE Stab-Lok equipment.

Challenger Electric panel history, field reports of overheating bus bars & circuit breakers, history, relationship to FPE Stab-Lok equipment.

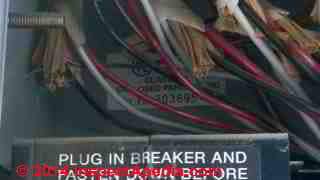

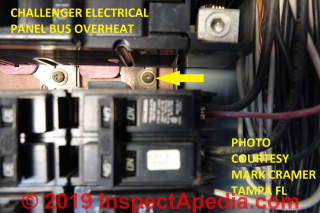

This photo of a discolored, overheated bus in a Challenger electrical panel was provided by Mark Cramer, a Tampa Florida home inspector. (Nov. 2019)

The image illustrates the value of inspecting the electrical panel with care: a casual scan might miss that discolored bus (yellow arrow).

[Click to enlarge any image]

Mr. Cramer adds that currently some insurance companies will not write a homeowners or fire insurance policy on homes served by a Challenger electrical panel.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a home inspector in Tampa Florida, and home inspection educator.

Mr. Cramer served ASHI and the profession in many capacitines including on the ASHI Home Inspection Standards and other committees. He is a contributor to and occasional reviewer of articles at InspectApedia.com. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

Below are additional field reports of overheats and failures in Challenger electrical panels, including a report from Timothy Hemm.

- Timothy Hemm to InspectApedia December 2014

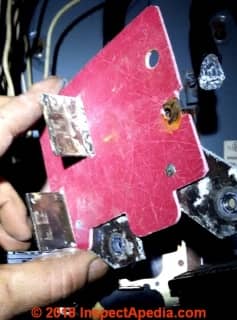

This is the third Challenger panel I have discovered with this damage. Is there a design flaw or could it be attributed to poor installation workmanship?

I asked Douglas Hanson about this, (if there is any repair) & he said the manufacturers are adamant, when the insulation material is damaged there is no repair.

Tim Hemm

Timothy Hemm, CREIA MCI,

ASHI, ICC Certified Inspector, is a professional home inspector in Redlands, California and is a contributor to InspectApedia.com. Mr. Hemm can be contacted at (951)543-3501,

timhemm@yahoo.com or tlhinspector@gmail.com , Website: www.homeinspectioninredlandsca.net

Photo at left provided courtesy of Timothy Hemm.

[Click to enlarge any image]

- Timothy Hemm, CREIA MCI, ASHI, ICC Certified Inspector, is a professional home inspector in Redlands, California and is a contributor to InspectApedia.com. Mr. Hemm can be contacted at (951)543-3501, timhemm@yahoo.com or tlhinspector@gmail.com , Website: www.homeinspectioninredlandsca.net

Reply:

Nice going Timothy. You spotted trouble that in my OPINION most fellows skip.

I agree completely with Doug Hansen and with the panel manufacturers that an electrical panel in which you find evidence of bus overheating and damaged insulating material it is reasonable to conclude that the panel is not safe, not repairable, and should be replaced. In some cases it may be possible to retain the enclosure and install a replacement bus assembly.

See FPE REPLACEMENT PANEL for a discussion of use of the Eaton - Cutler Hammer replacement bus assembly that may be suitable in some applications.

However I emphasize that we do not have the same large body of failure data for Challenger Electric products as we do for FPE Stab-Lok and some other products.

The Challenger Electric Panel photos provided just above and the Challenger circuit breaker photos below were provided by a reader, Lee, who also found evidence of overheating: discolored bus bars (photos above) in Challenger Electric panels and breakers.

I've looked into this very sort of panel damage with some FPE panels , under tutelage of the real expert, Dr. Aronstein. We saw that the bus insulation was sorely compromised by overheating - in some cases when we disassembled the panel the damage behind the components that you could see in-situ was far more severe. We even found blobs of melted plastic on the bottom of the panel.

While I suspect that some of these failures are probably caused by overheating at the breaker to bus connection, which might in turn argue that a breaker is not tripping when it should, we can't conclude the cause for sure from just your photos. They're great but not comprehensive, nor do we know building history, wiring snafus, etc.

In sum to be "professional" we need to a bit reticent about asserting cause when we don't have more data and more forensic analysis.

Bottom line, whether you're seeing a product defect or overheating caused by an installation error, it is reasonable to conclude that the panels you're seeing with this symptom are unsafe and should be replaced.

Interestingly, the failure pattern and location is quite similar to bus overheating damage seen in FPE panels. Doug and I may not see eye to eye on how to discuss that overheat damage, as I think it's caused by a root problem of breakers that don't trip while I think Doug may consider it a separate defect. He's been looking at FPE faults besides the fundamental one (breakers that don't trip in response to overcurrent) for some time.

At https://InspectAPedia.com/fpe/FPE_History.php we report that Challenger was in fact in the ownership path during the history of the demise of FPE. One might reasonably suspect that some engineers, designers, production line employees, and even equipment may have moved from FPE to Challenger at that time.

Thanks again for the photos, I'll be sure to add these to our discussion of Challenger field reports and of course blame you for their origin.

Any chance you can get a hold of one of these panels? If so, clip the wires - don't disturb anything on the bus assembly, and I'll ask that you send it either to me or directly to Dr. Aronstein if he's willing to do some more through forensic work on the panel.

Field Report: Challenger Panel Accepting Eaton CH Type BR Breakers: Overheating

About 2 years ago I sent you an email regarding my Challenger panel that accepts Eaton Cutler Hammer type BR circuit breakers, and wanted to let you know what happened recently.

I was inspecting the panel and found that the piece of bus that feeds the main bus that comes from the main breakers was very discolored.

[Click to enlarge any image]

So I found out that the main breaker is a Zinsco style (model QFP2200) that sits on a mini Zinsco style bus bar.

After my electrician pulled out the old panel I pulled out the breaker and found that the Zinsco bus was fine, and it seemed to me that the main problem with this panel design was the underrated bus connections.

It was a 200a panel. I just had the panel replaced with a Murray.

I wanted to share with you some pictures.. (attached) thank you for your time.. hopefully this will be helpful to people on your website. - Cameron 11/19/2014

Reply:

The discoloration in your photos most likely indicates overheating that could be for any of several reasons. An effect can be corrosion, poor bus connections, and an increased risk that a breaker may not respond properly to an over-current. I'm relieved that you replaced the panel. But with Murray?

Watch out: see MURRAY CIRCUIT BREAKER HAZARDS

Reader follow-up:

I work at home depot in the electrical department and am always referring people to your website. There are so many people in my area with Zinsco and FPE Panels

. I also am amazed at how many people think it is ok to use any brand breaker in any panel, I think that might be another helpful article (if you haven't already done it) on how using the wrong brand although it still fits voids the manufacturer and UL listing and warranty. - C.S. 19 Nov 2014

More Challenger Electrical Panel Field Reports

Photographs of this ca 1980's Challenger electrical panel were provided by a licensed electrician in California who recommended electrical panel replacement as the overheated panel and its circuit breakers were considered unsafe. The electrician noted:

Notice the burning and discoloration on the buss bar on the line and load side of the meter socket

. It also carries on into the distribution side as well on the very same phase.... Not only did the client have over-heating & burning inside his panel, (which may have resulted/caused from the bad utility connection) ,but he also had poor utility connection as well. - private email DF / anon 2016/01/25

We agreed, stating

... electrical panel bus discoloration, if not obvious corrosion, is a reliable indication of over heating. That is an abnormal and unsafe condition as its likely to mean overcurrent have been present without the breakers tripping. I suspect faulty circuit breakers in that case.

Even before condemning the panel based on brand and history data, the overheating is a serious red flag and argues for replacement - something one would reportage advise.

Adding the brand adds emphasis. I've also found signs of overheating on local grounds when the utility company's neutral connection is poor or lost. (LOST NEUTRAL SHOCKS HOMEOWNER ).

However even a loss of power on the utility side of the meter and panel would not (in any way I can see) explain overheating on one leg of the panel main bus nor in the panel itself.

History of Challenger Electrical Panels and Challenger-FPE-Stab-Lok Design circuit breaker products

Excerpting comments posted by Jraef, a moderator in Mike Holt's electrical forum on 11/18/2015, original source: http://forums.mikeholt.com/showthread.php?t=173243 with [Editor's annotations] - Ed.

Challenger [Electric] became part of Eaton [Cutler Hammer] years ago, but had bought the rights to the [FPE] Stab-Lok breaker when FPE went bust. Eaton however wanted no part of that legacy, so they had Challenger sell off that product line before the takeover.

They sold it to a company called Providence, [sic, actually "Provident Electric" - Ed.] who later [in 1988] changed their name to American Circuit Breaker Co. (ACBC). They now own the rights to sell that breaker as a "Stab-Lok" replacement breaker.

But the old FPE also had an independent Canadian division, and THAT division had the rights to make and sell the Stab-Lok breakers in Canada and as they later claimed, the US as well. The name of that company changed to Federal Pioneer, then later just Pioneer.

Pioneer was then later bought by Schneider, who of course owns Sq. D too, but Schneider wanted no part of marketing the Stab-Lok breakers in the US. In a huge fight over this, ACBC settled on giving up their production facility in South Carolina that was making the breakers, in deference to Pioneer making them for them in Canada at a guaranteed price.

At the same time Schneider gave up the rights to sell and use the name Stab-Lok in the US and ACBC cannot sell in Canada. The Canadian version is made as grey, the US version is still black. The Canadian grey versions still make it here on the "grey market" (ironically) and are exactly the same beside the color of the plastic.

If you see Stab-Lok breakers that still say Challenger on them, they are old stock, as in pre-1988. Challenger, as a brand name now owned by Eaton, has no official connection to that product any longer.

When Schneider forced ACBC to stop making the Stab-Lok breakers, Connecticut Electric (CE) supposedly bought the old ACBC factory in South Carolina including the molds and machinery used to make the old Stab-Lok breakers (they moved it I think).

But they do not have the rights to the name "Stab-Lok", so you will not see it on their version. In addition, they did not get the rights to the UL listings for them in FPE load centers. So the only thing CE could do is get their versions "Classified" for use in FPE load centers, and because UL had a problem with FPE's listings even when they were FPE, CE got listing under ETL (which some people view as "easier" to get than UL).

Also see FPE STAB-LOK HISTORY where we include details of the history of FPE, Federal Pacific Electric Company, American Circuit Breaker Company [ACBC], Oregan Breakers, INc., Provident Industries, Federal Electric Products (Canada), Pioneer Electric (Canada), Schneider Electric Canada and others.

Field report: Electrical Failures in a Westinghouse - Challenger Electric Panel

Above: corrosion and possible overheating at connectors in a Westinghouse - Challenger electrical panel. [Click to enlarge any image]

Note: shown here are Challenger™ circuit breakers, not Stab-lok™ design circuit breakers, installed in a Westinghouse™ / Challenger™ Electrical panel - Editor.

I have a more urgent situation for a neighbor of mine besides my reputation being on the line it's always a matter of property and lives at stake not being a licensed electrician, plumber,heating guy.

He is too close for comfort as well. It's a Westinghouse(?) panel with Challenger [brand circuit] breakers.

That name jumped out at me. I've heard of it but while on the job I just couldn't remember exactly, no their not stab-locks.

He complained of slowly losing power at receptacles and burning out incandescent bulbs quite too often.

Ok bad grounds, no problem. His utility ground spike clamp was loose from someone doing siding and forgot to remember something safety hazard wise-how stupid. He had normal for a wet basement corrosion on the ground buss bar-why do they not make the screws out of aluminum too I don't know why but we all know 3 dissimilar metals just don't work together nicely in O2.

Is it too much to ask for when being installed by the installer is to put noalox [antixoidant] on most if not all connections?.

He had no black carbon arcing flash burns on any of the lugs,etc..

I further investigated aluminum corrosion in the main breaker leg holes and discolored lug strip on one side. This didn't look right and [that is] the reason i'm contacting you about this.

I did some reading and can't be 100% sure that it is because of the main breaker or one or more breakers that failed to trip on overload over time.

I might have asked you or someone else if over time do breakers become more sensitive or less to trip on overload. It was always something I wondered about. I looked at some breaker time to trip charts and was amazed to see that some don't trip quick enough.

Above: labels on Challenger circuit breakers. The 30A breaker was an example of over-fusing, an un-safe condition.

Anyway I await final advice from you before I put this panel back in service.what I did was clean all lugs with steel wire brush and finely smoothed them all with paper, put noalox on liberally with the same sand paper,did same with main breaker wires, grounds, anything that had a connection together.

Tightened everything very snugly.all breaker grabs are tight too.there were no signs of overheating on wires except at one breaker just the copper looked discolored.no melted insulation or breakers anywhere. I believe I read somewhere that pushing breakers on and off the lugs to establish a clean contact creates scratches that may cause arcing,is this true?

I would assume so if they are dry and corroded.a couple of breakers where tripped that I need to check on. I can't get to trace, test or label anything on the panel when the house contents prevent me from doing so-he is a packrat living in a dilapidated house.

He hasn't had a refrigerator for a year or so now. That burned out from lack of maintenance and could have most definitely contributed to the overheated situation..

So my best educated decision would be to either replace the main breaker or break the common trip bar out and keep whatever the double pole breaker is off and maybe replace all the breakers too and get the right size breakers for some.

He had some 30 ampers with 15 amp wiring-my God! The thing too is he said he only like needs one or 2 rooms of power.nowhere else. Not in his basement shop,garage. He needs lighting though I don't know what is what.

I 'm in doubt over my use of noalox and the breakers. I 'm also thinking of splitting up the load evenly with the breakers.what in your expertise should I do do? Also i'm a little confused as to does he have a 300 or 150 amp panel and main?

I know that when it's all plugged in and running that the panel should not hum at all. Hhe last 2 breaker pics have one breaker over heating and the others corroded.

Also I bought this meter and a pair of protected very high volt gloves here for a insanely low price and don't how to use it,would it help with finding out the condition and errors of wiring downstream?

Above: the layout of the Westinghouse Challenger electrical panel.

Any help ASAabsolutelyP would greatly be appreciated please. - Anonymous by private email, Albany, NY 2018/01/29

Continuing: I'm not sure if i need to replace the main only or all breakers including the main.i'm not sure about my fine sandpapering on mostly all connections is ok and that my overuse of noalox everywhere is good either.

The overheated situation i've determined by reading your article on it tells me that a breaker or main is to blame for not tripping, which one? I think I was in a rush to comprehend it all. Also these are challenger breakers.

They might not perform well and this is a Westinghouse panel box. I need to get this old man back into his house again by giving him power first then onto his Lennox pulse furnace situation, i don't know if there is a problem with it or not.hopefully it's not a cracked exchanger. - 2018/02/01

I am also confused about this main is this a 150 or a 300 amp breaker? Also after reading a little bit and watching only a few youtube videos about my megger meter which i only paid $25 for and it's brand new along with high volt gloves.

I either didn't see any or haven't gotten to any that explains about house wiring insulation resistance tests. And if it does i could only do 240v or higher. Not really meeting my needs for residential testing .

Are there testers out there to check house wire insulation health?

I've been boggled in the past when i've gotten stray voltages when i would turn the light switch,etc off.

I don't remember exactly if it was off the hot or neutral but they would range from like say 25 or lower volts. I call it 'bleeding' over. I don't know but i do have some mind boggling questions that would happen to me on the job that I could never figure out. . - 2018/02/02

Reply:

Watch out: working on electrical wiring if you are not trained and qualified has, as you may realize, risks of fire, injury, death by electrocution, and depending on where you live, the lesser hazard of code violations.

Watch out: working on electrical wiring if you are not trained and qualified has, as you may realize, risks of fire, injury, death by electrocution, and depending on where you live, the lesser hazard of code violations.

Image: severe corrosion on the ground / neutral bus in the Westinghouse electrical panel.

Visual Observations of Trouble in the Westinghouse Challenger Electrical Panel

Your panel photos are not sharp enough for me to see the details of your main breaker, but it would be very very unusual to find a 300A breaker in such a panel, nor do your entry mains look nearly big enough for that amperage, nor do we normally find residential panels in that amperage range.

200A is about the largest common residential breaker main size. A close look at the breaker will almost always show the amps rating. There will be labels in the panel giving its specifications too

In your photos I see signs of significant water entry or condensation, wet components, corrosion, and overheating. These conditions alone are sufficient to damage the electrical panel rendering it unreliable and thus unsafe, independent of any innate reliabilty issues with Challenger panels and breakers.

In your notes you also report serious over-fusing, an additional risk of fire or shock.

You also report a history of failures to trip on one or more of the Challenger circuit breakers, though with a panel in this condition we can't know, without independent tests, if the no-trips are due to a product defect or due to moisture and corrosion.

Watch out: Your suggestions of sanding bus connections and using antixoidant on bus, breaker, or wire connections might get some circuits "working" again but these steps are inadquate and unsafe. There remain significant safety concerns:

Watch out: Your suggestions of sanding bus connections and using antixoidant on bus, breaker, or wire connections might get some circuits "working" again but these steps are inadquate and unsafe. There remain significant safety concerns:

- internal moisture and corrosion inside breakers as well as prior overheating can cause circuit breakers to fail to work properly

- sanding on the panel bus might remove a plating that in turn speeds future corrosion

- the moisture source and thus future moisture damage effects have not been fixed

Photo: corrosion at the aluminum service entry wires in this Westinghouse - Challenger electrical panel.

Watch out: This Westinghouse - Challenger electrical panel and its breakers are all, in my opinion, unsafe, unreliable, and should be replaced in entirety.

Not only is there visible overheating and significant corrosion, possibly some arcing and bus burns, but one cannot have confidence that individual circuit breakers, exposed to corrosion and bus damage and overheating, will then trip properly in response to an overcurrent or short circuit should one occur.

Thus the panel and its breakers are not giving the protection they were intended to provide against fire or electrical shock.

With the electrical panel and breakers replaced and circuit connections to it re-made, you still need to find and correct the source of basement moisture or the new panel risks being similarly damaged and unsafe.

It would help me write up and use the information and also help me to comment to help you further if I could see some sharp photos of

- the whole pane from the front with cover off

- possible sources of water entry or condensation

- each label on the panel face, door, interior sides, main breaker

and I would like to know

- the location of the home, country state/province, city

- the age of the home

- any comments about the home's history of leaks or water entry

Testing the integrity of house wiring insulation?

Your idea of testing house wire insulation integrity is an interesting one. But given the conditions in your photographs and email report, there are more immediate and serious unsafe conditions as we've already cited.

But if you are getting stray voltages, in my view the place to start is with tracing individual circuits to find where there is a wiring error or actual physical damage on that circuit. We should start troubleshooting by first ruling out the most-common trouble sources.

An example I've found is over-tightened BX cable clamps that also were missing their interior plastic guard have resulted ion cutting into the wire and shorting hot to neutral, hot to ground, and neutral to ground. A hot to neutral and hot to ground should trip a breaker. GFCI protection will often detect the third of those problems.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Comment: Challenger Panels = Westinghouse/Cutler-Hammer Panels for some models

I worked for Cutler-Hammer/Eaton as a field engineer (Fixing what others had broken or misapplied.) about the time CH shut Challenger down. The Challenger stuff I had seen in the 70's in Phoenix Arizona was exactly like the Westinghouse/Cutler-Hammer stuff of the same type, just slightly different grey paint.

Alan Bown, IAEI Certified Electrical Inspector, by private email 2019/09/01

Reply:

Thanks for this tip, Alan, it is a field verification that the Challenger electrical panel design appeared under the Westinghouse & Cutler-Hammer labels as well. If you have or come across photos or documentation of product specifications for those products that would be helpful to add here.

Can you give the approximate dates of those observations? - you can post a reply by private email or by posting as a Comment using the Comments Box below.

Daniel

...

Continue reading at FPE FIRES: FAILURE REPORTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CHALLENGER ELECTRIC PANEL FAQs - questions & answers posted originally at this page.

Or see these

Recommended Articles

- CIRCUIT BREAKER FAILURE RATES

- ELECTRICAL INSPECTION, DIAGNOSIS, REPAIR

- FEDERAL PIONEER PANEL SAFETY where Challenger and later ACBC American Circuit Breaker Company "FPE Stab-Lok" breakers are discussed.

- FPE FIRES: FAILURE REPORTS

Suggested citation for this web page

CHALLENGER ELECTRIC PANELS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Dr. Jess Aronstein, electrical engineer, Poughkeepsie, NY, forensic engineering services, independent laboratory testing for various agencies protune@aol.com (independent electrical panel testing, including FPE Stab-Lok® panels, to April 2010)

- David Carrier, electrical engineer, 53 Henmond Blvd., Poughkeepsie, NY 12603 845-430-7527 davidwcarrier@earthlink.net (independent electrical panel testing, including FPE Stab-Lok® panels, beginning 2010)

- Alan Carson, Carson Dunlop Associates, Toronto, Ontario. Mr. Carson is a home inspection professional, educator, researcher, writer, and a principal of Carson Dunlop Associates, a Toronto home inspection and education firm. Mr. Carson is a past president of ASHI, the American Society of Home Inspectors

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator.

- Carl Grasso, Esq., Herzfeld & Rubin, New York, NY. Mr. Grasso is an attorney who managed a plaintiff's class action litigation against Federal Pacific Electric in New Jersey.

- William King, US CPSC Director of Electrical Engineering (Ret).

- Licensed Electricians: FPE FAILURE FIRE PHOTOS includes electricians who have provided cases and photographs of field failures of FPE equipment at this website.

- Homeowners, Home Inspectors, Electricians: FPE FAILURE FIELD REPORTS includes anecdotal field reports provided by a range of contributors including electricians (and some home owners or home inspectors) who have provided cases and photographs of field failures of FPE equipment at this website.

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.