Bark Side Up or Down Answer

Bark Side Up or Down Answer

When Should Wood Boards Be Placed Bark Side Up or Bark Side Down?

- POST a QUESTION or COMMENT about wood deck & porch construction: board cupping cause and prevention

Answer to the question: should boards be placed bark side up or bark side down.

Here we summarize advice from both wood experts and deck builders about which way to place deck boards and wood stair treads outdoors.

This article series explains the causes of cupping in wood boards & wood board right side up advice for steps, decks, ramps, concluding which side of boards should face up or down (bark side down or bark side up in some cases) when building a deck or exterior wood stairs.

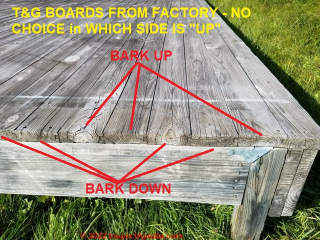

Our page top photo shows a stack of 2x lumber.

From the topmost board in the photo the 5 boards are facing 1-bark up, 2-bark down, 3-bark down, 4-bark up, 5-bark down. These are all flat-sawn boards.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

A Sensible Answer to the Bark Side Up or Down Debate for Deck Board Placement

Confusion about shrinkage, cupping, and twisting in wood in response to moisture changes has plagued both researchers and carpenters since at least the 1940s and probably for centuries.

In large part, this is because there are a number of factors that affect wood behavior as it becomes more wet or more dry including, even, wood boards milled from the same individual tree but cut from different positions in the tree. Wood cupping or twisting is also affected by the wood species and, in our OPINION largely by the actual in-situ conditions to which a wood board is exposed.

For example, wooden deck boards on a deck built right on the ground in a northern climate such as Minnesota are exposed to near constant wet conditions on their under-side and more dry conditions on their upper-side, while a wood deck in a hot dry climate like Arizona and built four feet above ground doesn't see much change in moisture once the boards are nailed or screwed in place.

- Bark side down experts:

for FLATSAWN boards if we want to follow the advice of wood experts cited at the end of this article we'd put the bark side down when setting deck boards or wood stair treads.

The premise of the experts, based on wood cell science is that the board is going to cup "towards the bark side" meaning that side will be concave - as shown in our photo.

Since you want your deck boards to drain well and not retain water on the walking surface, you'd flip this board over - put the bark side DOWN when building a wood deck or an exterior stair tread. You want any arched boards to have the arch pointing "up" and the concave or cupped side "down".

The board above is behaving exactly as wood experts say it should. Flat-sawn boards like this one tend to cup on the bark side, such that the edges of the board curve "up" in this photo and the center of the board cups "down".

But this board, factory milled to be used as a wooden stair tread, has its walking surface milled on the "bark side" - which as you can see is cupped or concave. The result is that this stair tread would tend to hold water, grow algae, and in a freezing climate, form an icy surface - all of which make this step, as factory-prepared, a slip and fall hazard.

This is why wood experts say boards like this should be placed "bark side down".

The technical basis and scientific support for bark side down for deck or stair construction are detailed

at BARK SIDE DOWN ARGUMENT.

Synonyms for "bark side down" board position are "concave" or "upside down arch" or "fruit bowl" position of the board.

Above: nearly all of the boards on Paul Galow's Poughkeepsie, New York on-ground wooden walkway are cupped. The upper surface of these boards is somewhat protected by a wide roof overhang while their underside is just a few inches above the soil.

- Bark side up believers: (are technically mistaken - Ed.)

If we prefer to follow the opinion of many deck builders whose opinion arises from years of field observation, we'd put the bark side up unless the board is already cupped - that is, we like to place deck boards such that the arch shown by the board's growth rings (visible at the board end cuts) tends to be "up".

The bark-side up believers look at the end of the board, notice the "rainbow" like arch of the wood grain, and infer that the "arch" should face "up" so that the board will drain better.

In fact when stacking firewood outdoors, exposed to the weather, the bark-side up people are right - firewood will shed water better outdoors with its bark-side up.

But the deck builders, including our editor [DF], are expressing an opinion, not technical wood science.

That OPINION comes from observing which way most of the deck boards are already cupping at the time of deck construction.

If you install this board as shown in the photo above (bark side up) the board is already cupped and it is going to retain water.

Bark-side-up believers argue that water causes the top of the board to expand more than its underside? Will that cause this board to flatten out? Maybe.

The upper surface of the deck gets hit by the rain, right?

Really? Not necessarily. We also can argue that the under-side of the deck sees less sun and less air movement so the under-side of boards may stay wetter longer than their upper surface. If that's the case, the boards will cup "up" and will drain more poorly.

In sum it seems that carpenters like bark side up but regardless, most people of either camp will agree that moisture differences in practice tend to dominate cupping effects.

The reasons that builders like bark side up, a less technically-supported position are

at BARK SIDE UP ARGUMENT.

- For QUARTERSAWN BOARDS

or boards whose end grain shows that the quartersawn board pattern dominates the board, look at the board by eye and place its already-arched side, if there is one, facing up or "cup down".

These on-ground decks built by our friend Paul Galow (Poughkeepsie NY) are mostly shaded.

These on-ground decks built by our friend Paul Galow (Poughkeepsie NY) are mostly shaded.

That green color you see is algae that, when wet, is the slipperiest substance known.

- The WETTER SIDE of boards

will tend to expand (and arch or cup) more extremely than the more dry side, so we may see different degrees of deck board arching or cupping in decks built close to the ground compared with decks built several feet or more above ground.

High decks have better air circulation both above and below the deck surface and their boards will thus remain more dry than a deck built on or close to the ground surface.

Especially for flat-sawn boards,

Bark-side UP boards on a HIGH DECK

(these are "wrong way up" according to wood experts) will cup in response to rain but because of better air circulation these may cup less than on a low deck.

Bark-side UP boards on a LOW DECK

("wrong way up") will cup in response to rain but their wetter-longer under-side may tend to offset the cupping effect; regardless, the deck will have a shorter life and be more prone to hosting slippery algae, especially if the deck upper surfaces is shaded.

Bark-side DOWN boards on a HIGH DECK

("right way up" according to wood scientists) will arch upwards (cup down) and drain better, giving longer deck life and safer walking surface.

Bark-side DOWN boards on a LOW DECK

("right way up") may arch upwards, somewhat offset by their wetter-longer underside, with a shorter deck life and earlier rot.

Assuring that the deck surface drains adequately (leave gaps, don't butt boards too tightly) reduces both arching and cupping effects as well as reducing related slip trip fall hazards such as slippery algae growth.

See details at SLIPPERY STAIRS, WALKS, ROOFS

[Click to enlarge any image]

This article series illustrates and explains wood cupping, wood warping, summarizes the arguments made by various wood experts as well as experienced builders and carpenters, and cites authoritative sources.

This article series illustrates and explains wood cupping, wood warping, summarizes the arguments made by various wood experts as well as experienced builders and carpenters, and cites authoritative sources.

In 1941, Barkas described wood shrinkage and related cupping.

We think that wood shrinkage affects wood, of course, as its moisture content falls from the high moisture content of green wood, but we also think that these same effects explain wood expansion in response to rainfall or in response to being placed on or close to wet soils.

So Barker's "wood shrinkage" is probably reversed and becomes wood "expansion" if relatively dry boards are nailed or screwed onto a deck and then exposed to wet conditions.

"The shrinkage of wood is not the same in the three directions of the grain.

It is greatest in the tangential (t) direction where the shrinkage per unit change in moisture content dr/dm lies for most woods between 0.2 and 0.4.

In the radial (p) direction dp/dm is usually about half this value,

while in the longitudinal direction ... [shrinkage] is much smaller, amounting to about 1/50th of the tangential.

It is difficult to measure d(lambda) / dm accurately, and in standard tests it is not usually attempted.

These differences in shrinkage may be accounted for by the presence of ray cells in the wood ... " - Barkas (1941) [11]

Bottom Line: Flatsawn Boards Go Bark Down Unless ...

Above we show details of rotting treated wood deck boards on a ground-level wood deck as conditions existed in October 2022. This entry porch on a small cabin in Two Harbors Minnesota was constructed in 2006. Yellow arrows mark the worst areas of rot developing in these deck boards.

Below we show the end of one of the most-rotted boards on this deck.

The on-ground location of this deck is likely to be an important contributor to deck board rot. However let's take a close look at two adjacent boards, one badly rotted, the other in much better condition.

We empasize that as every wood board is unique, the reasons that the right-hand deck board shown below is more-rotted may include more than having been placed bark-side "up" - for example the board may have been less-penetrated by wood preservative, or it may have had a more-soft core at the time it was milled.

Nevertheless, just above we can see a clear example in which a bark-side down board survived better than her sister who was placed bark-side up.

Below we show another board in this same deck, one with notable cupping that holds water, inviting greater algae growth and possibly rot.

Why do some deck builders disagree with the science of board cupping?

It may be that what deck builders are actually observing is a deck board flattening effect as two opposing forces are at work:

tangential shrinkage wants to make the deck board edges curl upwards towards the bark side and its center to "cup" down.

Thus the experts argue for bark side down, so that the "arch" of the board will be facing up.

while

regardless of whether a board is placed bark-side up or down, the wetter side of the board tends to expand more than its more dry surface, causing the wetter-side of the board to "arch".

So how should you place each wooden deck board or wooden stair tread?

Look at each board.

Don't install a deck board with a significantly concave surface facing up.

In the case of the stair tread shown just above, it has a concave upper surface. If the board is already very cupped "the wrong way" and you install it with the concave surface up, we don't think that frequent wetting is going to be enough to flatten the board or make it arch upwards.

Watch out: Worse, because the air flow and sunlight exposure are much less on the underside of a deck, especially for a deck built close to the ground; in a wet climate the underside of the board on a low deck, say just 1 meter or less above ground, is likely to stay wetter longer than its upper surface.

That means the board's upper surface tends become concave, holding water enough to grow algae and become slippery.

If possible, I'd have left this tread in the photo above in the lumber yard and picked a different one.

Synonyms for "bark side up" board position are "convex" or "arch side up" or "rainbow".

Which way should the bark face when stacking firewood?

Stacking firewood has different considerations from placing wooden deck or stair boards bark-side up or down.

When stacking firewood outdoors, exposed to the weather, we stack firewood with bark-side "UP" so as to better shed-water. If you store firewood exposed to the weather and bark down, the wood tends to hold water longer and may dry less, burn more-poorly, and rot faster.

But when stacking firewood under-shelter (in the wood-shed) you can stack bark up or down according to your preference.

Deck Board Bark Side Up vs Down Research

Photo: for some wood construction like these factory-milled tongue-and-groove 5/4" deck boards used on a stage we build in northern Minnesota, the builder has no choice in which side of the board must be place "up" - the factory-cut T&G allowed only one side of the boards to face upwards.

But the factory paid no attention to which side of these boards was "up" when they were milled. The result is shown above. Some boards have bark-up and others, bark-side down.

This stage is now about twenty years old and has withstood the Minnesota weather very well, but in our OPINION some of the bark-up boards that cupped upwards show a bit worse wear.

- [1] The moisture content in wood varies depending on not only green un-dried lumber versus dried or kiln dried lumber, but also wood species, the ambient environment, and more.

Green lumber that has not been soaked by rain or floating down a river may still have moisture at 30% or above; and wet wood that has been soaked may have 2 1/2 times as much moisture as that same wood species when it has been dried or kiln dried. Free water on or in wood dries quickly but bound water within wood cells takes much longer to dry or requires kiln drying or other measures for its removal. - [2] The fiber saturation point of wood or wood's FSP is defined as the moisture content of that wood when all of the free water has been removed.

Picture the clothes in your clothes washer at the end of a spin cycle. The wet clothing has been squeezed until you couldn't get more water out of it - that clothing is at its fiber saturation point.

And just as FSP varies among wood species, if you've ever done laundry you've noticed that some fabrics retain less water at the end of the washer's spin cycle than others. - [11] Barkas, W. W. "Wood water relationships, VI. The influence of ray cells on the shrinkage of wood." Transactions of the Faraday Society 37 (1941): 535-547.

Excerpting:

The shrinkage of wood is not the same in the three directions of the grain.

It is greatest in the tangential (7) direction where the shrinkage per unit change in moisture content dr/dm lies for most woods between 0-2 and 0.4.

In the radial (p) direction dp/dm is usually about half this value, while in the longitudinal direction ... [shrinkage] is much smaller, amounting to about 1/50th of the tangential" - [9] Boyd, J. D. "Relationship between fibre morphology and shrinkage of wood." Wood Science and Technology 11, no. 1 (1977): 3-22.

Abstract:

This is a study on the shrinkage of wood representing the wide range of morphology variation in leaning trees. It involved 13 trees of Eucalyptus regnans, one of Eucalyptus sieberi and four of Pinus radiata, and specimens taken at close intervals around the circumference of each.

Data indicated a systematic modulation, between extremes at upper and lower sides of each stem, in longitudinal growth strains, relative proportions of thin, medium and thick-walled fibres, microfibril angle in the S2 layer of these, and both Klason and acid-soluble lignin content.

Analyses indicated that the microfibril angle in S2 was a prime factor in influencing both longitudinal and volumetric shrinkage reactions; proportion of thick-walled fibres in the tissue, thickness of S2 relative to S1, and variations in lignification also were involved.

Unusually thick-walled fibres were associated with visco-elastic strain recovery effects, which could form a substantial part of dimensional changes apparently attributable to shrinkage. - [8] Clarke, S. H. "The differential shrinkage of wood." Forestry 4, no. 2 (1930): 93-104. .oxfordjournals.org

- [7] Cloutier, Alain, and Yves Fortin. "A model of moisture movement in wood based on water potential and the determination of the effective water conductivity." Wood Science and Technology 27, no. 2 (1993): 95-114. -

Abstract:

A model of isothermal moisture movement in wood during drying using the gradient in water potential as the driving force is proposed. The moisture transport coefficient used in this model is the effective water conductivity.

It is a function of moisture content, temperature, and direction of flow. The boundary desorption curve of the effective water conductivity function is established in the radial and tangential directions of aspen sapwood from nearly saturated to dry conditions at 20, 35, and 50 °C using the instantaneous profile method.

The results show that the effective water conductivity increases exponentially with moisture content and temperature.

The effect of temperature cannot be solely explained by the variation of the viscosity of water.

The variation of the moisture content-water potential relationship with temperature would explain a large part of this effect.

The effective water conductivity was generally higher in the radial direction than in the tangential direction in a ratio varying from 1/1 to 25/1 depending on moisture content and temperature.

The flux-gradient relationship obtained at given moisture contents were found to be linear, confirming the validity of the model for the experimental conditions considered in the present work. - Elaib, Mohamed Tahar, Foue Shel, Mounir Jalleli, Patick Langbour, Kvin Candelier, PHYSICAL PROPERTIES OF FOUR RING-POROUS HARDWOOD SPECIES: INFLUENCE OF WOOD RAYS ON TANGENTIAL AND RADIAL WOOD SHRINKAGE [PDF]

Propiedades físicas de la madera de cuatro especies de latifoliadas de porosidad anular: influencia de los radios sobre las contracciones tangencial y radial, retrieved 2022/09/23, original source:

Abstract:

Some relationships between ray proportions, strength and shrinkage properties and basic density in hardwood species were highlighted. A better understanding of their relationships caused by the variation in moisture content in the hygroscopic domain could be a key factor in determining of wood stability properties and to determine the choice of a specific wood species according to its service life condition.

The objectives of this study were

(i) to determine the physical properties of various ring porous wood species

(ii) and to evaluate the influence of wood rays (according to their proportions and volume) on physical properties of wood and more particularly on the Transverse Anisotropy Ratio for Shrinkage (TARS).

This study focused on four ring-porous hardwood species; Castanea sativa, Quercus canariensis, Quercus petraea and Quercus robur, differing by the presence and abundance of their multiseriate wood rays. Basic densities, tangential shrinkages, radial shrinkages and the TARS of heartwood and sapwood from each wood species were determined.

Wood-rays’ proportions and volume were measured by the image analysis method, and their influence on the last three shrinkages was investigated. A significant correlation between wood ray proportions, wood shrinkage values and basic density was observed.

Excerpt:

Timber twist is caused when wood does not shrink uniformly in all directions when dried. In general, cells get slimmer, but not much shorter, when they lose moisture. Therefore, timber shrinks least in the grain direction and more in radial and tangential directions. Rays act as restraining rods to reduce radial shrinkage, so most shrinkage is developed along tangential direction (Ramage et al. 2017). - Fabian, Thomas Z. "Fire Performance Properties of Solid Wood and Lignocellulose-Plastic Composite Deck Boards." Fire Technology 50, no. 1 (2014): 125-141.

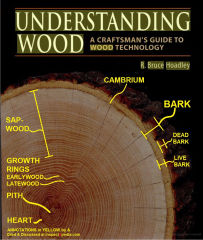

Illustration, adapted from the cover of Hoadley's book cited just below.

- [5] Hoadley, R. Bruce. Understanding wood: a craftsman's guide to wood technology. Taunton press, 2000.

- [3] Huey, Glen D., "Why Wood Warps", Popular Woodworking Magazine, 12 July 2012, retrieved 7/17/2013 original source http://www.popularwoodworking.com/article/why-wood-warps, reprinting from Woodworking Magazine, Summer 2009.

- [10] Gu, H., A. Zink-Sharp, and J. Sell. "Hypothesis on the role of cell wall structure in differential transverse shrinkage of wood." European Journal of Wood and Wood Products 59, no. 6 (2001): 436-442.

- Laslett, Thomas. TIMBER and TIMBER TREES [PDF] Macmillan, 1894.

- [4] Terrie Noll, The Joint Book, Popular Woodworking Books, Cincinnati OH, www.popularwoodworking.com Quarto Publishing, , Inc., 2002, ISBN 1-55870-633-x

- [39] Lyall, Sarah, "Bark Up or Down? Firewood Splits Norwegians", The New York Times, 20 February 2013, p. A4.

- Mantanis, George, and Charalampos Lykidis. "Weathering test of furfurylated wood decks in a 3-year exposure in Greece."

- Mitchell, Philip H. "Modeling the cupping of lumber." BioResources 11, no. 3 (2016): 6416-6425.

- Ramage, M. H., Burridge, H., Busse-Wicher, M., Fereday, G., Reynolds, T., Shah, D.U., Wu, G., Yu, L., Fleming, P., Densley-Tingley, D., Allwood, J., Dupree, P., Linden, P. F., & Scherman, O. (2017). The wood from the trees: The use of timber in construction. Renewable and Sustainable Energy Reviews, 68, 333-359. doi: 10.1016/j.rser.2016.09.107

- Smith, Paul M., and Michael P. Wolcott. "Opportunities for wood/natural fiber-plastic composites in residential and industrial applications." Forest Products Journal 56, no. 3 (2006): 4-12.

- [6] U.S. D.A. Forest Products Laboratory, "The Wood Handbook",

- White, Robert H., Mark A. Dietenberger, and Nicole M. Stark. "Cone calorimeter tests of wood-based decking materials." (2007).

- [38] Williams, Sam & Mark Knaebe, The BARK SIDE / PITH SIDE DEBATE [PDF] The Finish Line, (A Forest Products Laboratory finishing factsheet), December 1995, U.S. Forest Products Laboratory, retrieved 9/13/12, original source http://www.fpl.fs.fed.us/documnts/finlines/willi95b.pdf

R. Sam Williams and Mark Knaebe are researchers in Wood Surface Chemistry at the USDA Forest Service, Forest Products Laboratory, One Gifford Pinchot Drive, Madison, WI 53705–2398

...

Continue reading at BARK SIDE UP ARGUMENT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BARK SIDE UP or DOWN on DECKS & STEPS?

- BUTT JOINT CURLING in FIBER CEMENT SIDING

- DECK & PORCH CONSTRUCTION - home

- FLOOR DAMAGE DIAGNOSIS

- SLIPPERY STAIRS, WALKS, ROOFS

- WOOD FLOOR DAMAGE

- WOOD FLOOR MOISTURE

Suggested citation for this web page

ANSWER to BARK SIDE UP or DOWN at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- [2] Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - [5] "Are Functional Handrails Within Our Grasp" Jake Pauls, Building Standards, January-February 1991

- [14] Construction Drawings and Details, Rosemary Kilmer

- [17] HUMIDITY CONTROL & TARGETS INDOORS What indoor humidity should we maintain in order to avoid a mold problem?

- [18] Slips, Trips, Missteps and Their Consequences, Second Edition, Gary M. Bakken, H. Harvey Cohen,A. S. Hyde, Jon R. Abele, ISBN-13: 978-1-933264-01-1 or ISBN 10: 1-933264-01-2, available from the publisher, Lawyers ^ Judges Publishing Company,Inc., www.lawyersandjudges.com sales@lawyersandjudges.com

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Paul Galow [Website galowconsulting.com ] - technical consultant on networking, LAN design, applications support. Galow Consulting Services [Website galowconsulting.com ] , 914-204-1749, email: paulgalow@galowconsulting.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.