Thermostatic Expansion Valve (TEV) Install, Test, Repair

Thermostatic Expansion Valve (TEV) Install, Test, Repair

- POST a QUESTION or COMMENT about refrigeration controls: TEVs, AEVs, & others

TEV installation, testing, troubleshooting & repair guide:

This article describes how to install, test, or diagnose problems with a thermostatic expansion valve used on air conditioners or heat pumps or similar refrigeration equipment. These include improper thermostatic valve installation, wrong sensor bulb location, sticking TEVs, whistling TEVs, hunting TEVs and other problems.

We define and explain other refrigeration equipment metering devices including AEVs (Automatic Expansion Valves), manually adjusted expansion valves, capillary tubes and Low Side or High Side refrigerant float valves.

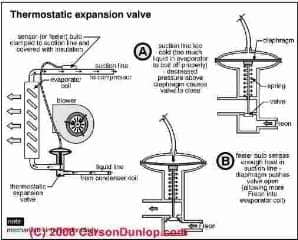

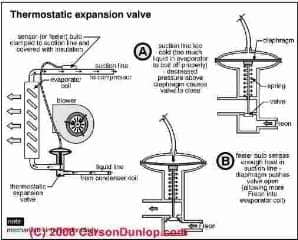

Page top sketch of a thermostatic expansion valve is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Thermostatic Expansion Valve (TEV) Installation, Inspection, Diagnosis & Testing Guide

Thermostatic expansion valves (TEVs) are designed to meter refrigerant into the cooling coil at the proper rate. This design can keep the proper dose of refrigerant entering the cooling coil for maximum air conditioning or heat pump system operating efficiency.

TEVs are similar to automatic expansion valves (AEVs) discussed below, but incorporate the signal from a temperature sensor mounted at the end of the evaporator coil

If you are diagnosing a problem with an air conditioner or heat pump and the TEV appears to be involved, check the TEV installation details against the information we list below.

Article Contents

- THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR

- REFRIGERANT FLOODBACK, LIQUID SLUGGING

- TEV INSTALLATION DETAILS

- TEV SENSOR BULB LOCATION

- TEV SENSOR BULB MISTAKES

- TEV SERVICE ACCESS

- TEV METERING DIAGNOSIS

- EXPANSION VALVE BASIC TESTS

- REFRIGERANT FLOODBACK CAUSES

- SUPERHEAT WRONG due to ADDITIVE

- TEV HUNTING DIAGNOSIS

- TEV STICKING

- TEV WHISTLING

- TEV HEAD TEMPERATURE

- TEV SIZE SELECTION

- TEV INSTALLATION MANUALS & GUIDES

- EEV INSTALLATION MANUALS & GUIDES

TEV Installation Details

The valve fittings and exterior parts must be thoroughly cleaned before soldering or brazing in order to prevent debris from entering the refrigerant system or valve body.

Protect the TEV from heat during soldering or brazing by wrapping the valve body and head with a wet cloth to give 1/4" to 1/2" of thermal protection, and keep the soldering or brazing torch aimed away from the valve itself.

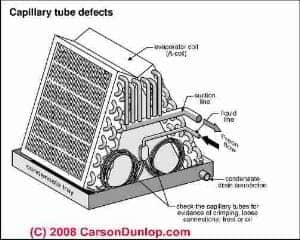

The sketch of CAPILLARY TUBE defects shown above is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education, and report writing tool firm.

[Click to enlarge any image]

Other TEV and cap-tube defects listed below were obtained from an installation guide for TEV's provided by Singer Controls Corp.

As with any soldering or brazing job, don't use excessive solder or flux or the excess may flow into the valve or tubing to prevent proper operation.

TEV / TXV Sensor Bulb Location

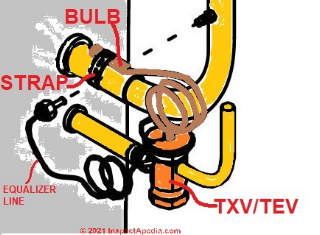

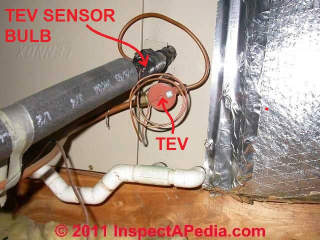

The thermostatic expansion valve sensing bulb that controls the thermostatic expansion valve is clamped to the refrigerant suction line where it monitors the system's temperature.

The thermostatic expansion valve sensing bulb that controls the thermostatic expansion valve is clamped to the refrigerant suction line where it monitors the system's temperature.

Watch out: improper placement of the expansion valve's sensor bulb on the suction line or failure to secure it snugly against the suction line surface can cause TXV problems including hunting, starving, and flooding problems in the refrigeration system.

- TXV Bulb Close to evaporator coil inlet: The TEV should be installed as close as possible to the air conditioning or heat pump evaporator coil inlet.

Danfoss (2005) points out that the expansion valve itself is installed in the liquid refrigerant line ahead of the evaporator coil (cooling coil) and that its sensor bulb is to be fastened to the suction line as close to the evaporator as possible.

Equalization pressure line: For TEVs that use an external pressure equalization feature, the equalizing pressure line must be connected to the suction line (at the cooling coil outlet end) immediately after the temperature sensing bulb that operates the TEV. (Danfoss 2005).

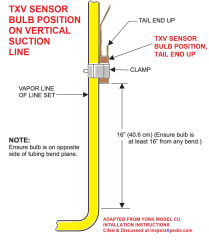

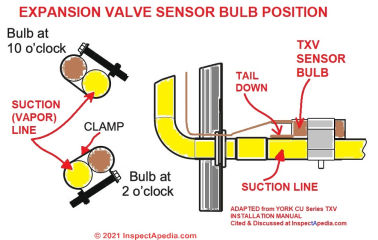

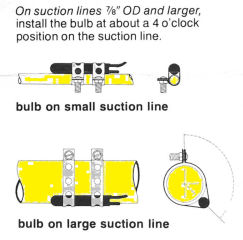

- TXV Bulb position on the suction line - clamp-on locations

As the Singer Corporation illustration above shows, the sensing bulb that controls the thermostatic valve can be clamped on a vertical or on a horizontal section of the refrigerant suction line, but never on a trap or elbow in the suction line where oil and liquid refrigerant can interfere with proper bulb and temperature sensing operation.

On a small refrigerant suction line such as on a residential cooling system or heat pump, the sensing bulb is clamped on top of the suction line at the 12 o'clock position;

If the sensor bulb is located outside of the refrigerated space, additional protection from ambient temperatures is required.

The sensor should not be clamped to the under-side of the suction line.

Extend insulation on either side of the suction line at least one foot on either side of where the bulb is located.

Our photo of a thermostatic expansion valve shows that the sensor bulb was outside of the air handler and was taped under insulation covering the suction line. Our drawing of the TXV or TEV bulb clamped or strapped to the suction line is adapted from ICP's TEV instructions found

at TEV INSTALLATION MANUALS & GUIDES

On larger-diameter suction lines such as on a commercial HVACR system that uses a suction line more than 7/8" in diameter, the thermostatic expansion valve sensor bulb is clamped at the 5-o'clock position or 7-o'clock position on the lower portion of the suction line.

For these larger suction lines, some sources recommend the 4 o'clock or 8 o'clock position, but never on the absolute bottom, at the 6 o'clock position.

Watch out: check the installation instructions provided by the manufacturer of your specific expansion valve, as the manufacturer's recommendations for placement of the bulb on the suction line vary.

For example, Danfoss gives slightly different instructions:

The [temperature sensing] bulb is best mounted on a horizontal suction line tube and in a position corresponding to betweeen 1 o'clock and 4 o'clock. The location depends on the outside diameter of the tube. - Danfoss (2005)

The intent is to place the TEV's sensing bulb close to but above the level of liquid refrigerant in the line. So for larger diameter refrigerant tubing the 2, 3, or 4 o'clock position may be used while on small diameter tubing the 1 o'clock position is used.

The reason we don't clamp the TEV sensor bulb on the bottom of the cooling coil line is that oil traveling along the bottom of that tubing can act as an insulator to prevent the TEV sensor bulb from accurately sensing the temperature of the evaporator coil.

- On vertical suction lines the TXV Sensor bulb is always installed tail-end "up" to be sure that the refrigerant charge remains in the bulb - assuring that the refrigerant reacts quickly to changes in suction line temperature.

- On horizontal suction lines the TXV Sensor bulb is installed tail-end "down" for the same reason - see our illustration above

If multiple TEV's are installed (on a multi-evaporator cooling or heat pump system), each thermostatic expansion valve has to be installed at a refrigerant suction line that will indicate conditions in each individual evaporator, never on a common suction line fed by multiple evaporators.

TEV Temperature Sensor Bulb Installation Mistakes to Avoid

Most installation guides require that the thermostatic expansion valve has nothing else installed on the refrigerant tubing that extends between the TEV and the evaporator coil, except in commercial installations where a refrigerant distributor may have been installed.

In this instance (use of a TEV with a refrigerant distributor), the TEV should be a unit that provides an external equalizer.

TEV location height:

Do not install the Thermostatic Expansion Valve higher than the liquid refrigerant receiver.

If a TEV is placed too high in a commercial system, refrigerant vapor or flash gas from the receiver may enter the TEV and prevent its proper operation.

TEV Sensor Bulb Mount Connection, Location, Position

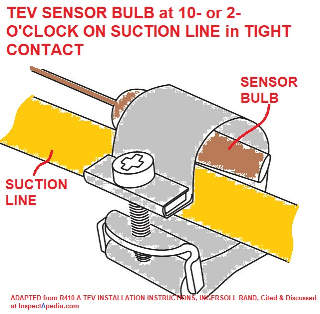

Watch out: a TEV sensor that is too loose or has a poor thermal connection to the suction line can send improper signals to the TEV and can cause liquid refrigerant flood damage to the compressor motor. [2]

If the bulb is not installed parallel to the suction line it may not be in contact along its entire length - it will not sense temperature properly.

If the sensor bulb is installed on a dirty suction line surface it may not have good thermal contact.

Watch out: the TEV's temperature sensing bulb should never be placed at the bottom or under-side of the suction line.

That's becausse there may be refreigerant oil along the bottom of the tubing - a condition that will cause improper reading of the line's temperature, thus causing improper TEV operation.

Watch out: the TEV's temperature sensing bulb must also not be exposed to external sources of heat or cold such as a warm air current. If that exposure is at risk insulation should be added to protect the bulb from that external influence.

Otherwise the sensing bulb, intended to sense the temperature of the superheated suction vapor, will instead be influenced by other temperatures nearby.

Watch out: the TEV temperature sensing bulb must not be installed after a heat exchanger - another location giving improper signals to the TEV

Watch out: the TEV temperature sensing bulb must also not be installed close to compoents of large mass (such as a stop valve onthe refrigerant line) because the large mass will influence nearby refrigerant line temperatures, giving the sensor bulb misleading information and causing it to misinform the TEV itself.

Watch out: don't install TEV temperature sensing bulbs on vertical piping and do not install the sensor bulb on a collection tube or riser or even on a horizontal section of tubing that may be located after an oil pocket location such as at a dip or effectively a plumbing trap formed in the refrigerant line.

Watch out: don't install the TEV sensing bulb after a liquid lock. The bulb must be ahead of any liquid lock on the piping system.

Access Requirements for TEVs

On commercial cooling installations it is also important that the TEV be installed in a location leaving enough access to adjust the device.

Details about TEV adjustment are

at NON-ADJUSTABLE & MANUALLY ADJUSTABLE TEVs

Hunting Thermostatic Expansion Valves - Superheat & the TEV

Hunting Thermostatic Expansion Valves can damage the air conditioning or heat pump compressor: causes and remedies.

Hunting Thermostatic Expansion Valves can damage the air conditioning or heat pump compressor: causes and remedies.

Definition of Hunting at the TEV: Hunting exapansion valves are TEVs that are cycling too frequently between open and closed - a condition that may be detected as rapid changes in suction line pressure by 10-15 psi each time the valve opens or closes.

Two causes of hunting TEVs or TXVs (synonyms we include here as readers use both acronyms for thermostatic expansion valves) are

- improper adjustment of a properly-sized TEV - superheat set too low

- impropr placement of the TEV's sensor bulb on the suction line

TEV Hunting Causd by Superheat Set too Low

If the TEV superheat set too low this can cause rapid-cycling TEVs TXVs and liquid refrigerant flooding the suction line and compressor. Variations in the level of superheat of + or - 0.5°C or less are not considered "hunting" while variations greater than that amount are considered hunting and should be addressedas we explain here.

The superheat must be allowed to change in order for the sensing bulb on the TEV to make corresponding adjustments to the valve opening while it maintains the set superheat.

A low superheat setting can allow the superheat to fall to zero. This condition will cause the valve to close and the superheat will soon rise well above its setting.

This in turn can cause the valve to reopen wider than necessary and overshoot the superheat setting. This condition is called hunting. On one of the valve's swings to the wide open position, liquid refrigerant can flood the suction line and allow liquid to enter the compressor, a potentially damaging condition.

In other words, an improper TEV setting can cause rapid opening/closing of the valve resulting in liquid refrigerant flooding the suction line, entering the compressor motor.

Because compressor motor moving parts and valves are designed to compress a gas, and because a liquid (refrigerant) is not particularly compressible, the compressor motor, piston, crank, or more immediately its refrigerant valves are likely to be damaged or destroyed.

It is possible that dirt, debris, or even water in the refrigerant piping system and that enters the TEV could cause this malfunction by freezing the valve's moving parts. - Christopherson [2]

Danfoss (2005) offers this repair procedure to eliminate hunting in the HVACR evaporator: [adpated and paraphrased]

- Increase the level of superheat by turning the expansion valve spindle well to the right (clockwise) until the hunting behaviour stops.

- Next turn the spindle counter-clockwise in small steps until the hunting behavior just begins again.

- From this position turn the TEV adjustment spindle about one full turn clockwise (to the right) [on Danfoss™ T/TE2 TEVs just use 1/4 turn to the right]

The company explains that at this setting adjustment you have stopped hunting in the evaporator and at the same time you are fully using (all of the space in) the evaporator.

TEV Hunting Caused by TEV Sensor Bulb Improperly Placed

These mistakes and their correction are explained at

Refrigerant Floodback - Causes of Liquid Slugging

Watch out: Causes of Refrigerant Floodback in air conditioners, heat pumps, refrigeration equipment. Refrigerant flooding or liquid slugging refers to the return of liquid refrigerant back to an air conditioner or heat pump compressor motor on the low pressure or suction side of the system where only gas is expected.

Watch out: Causes of Refrigerant Floodback in air conditioners, heat pumps, refrigeration equipment. Refrigerant flooding or liquid slugging refers to the return of liquid refrigerant back to an air conditioner or heat pump compressor motor on the low pressure or suction side of the system where only gas is expected.

Watch out: overcharging sufficient to cause liquid slugging can quickly destroy the HVACR compressor motor. The compressor motor's moving parts (piston & cylinder, scroll spirals, or rotary vane pump) expect to be compressing a gas and can't handle liquids. HVAC technicians refer to these conditions as liquid slugging.

Sketch courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Christopherson and the article cited below[2] listed six causes of refrigerant floodback, and we have added some additional sources of floodback or refrigerant liquid slugging - a quick kill for compressor motors.

- Switching the A/C or Heat Pump System OFF then back ON too quickly. Unless sufficient time is given for pressures to equalize on the high and low sides in the system after it has been turned off, there is a risk that liquid refrigerant reaches the suction line and enters the compressor motor.

Watch out: Because the compressor motor is designed only to pump or compress refrigerant in its gas form, sending liquid into the motor can bend a valve or cause other internal damage in the motor, destroying it and thus requiring compressor motor replacement - an expensive repair.

So how long do we have to wait after turning off a running air conditioner or heat pump before we can safely turn it back on again?

In warm months the time required ranges from about fifteen minutes to three hours. Check the IO manual for your specific air conditioner or heat pump system to find what its manufacturer recommends as the minimum tiime OFF before turning the system back on if it has been running.

In winter months: when an air conditioner or heat pump has had all power cut off for hours or longer iIn freezing or very cold weather the system may need to have power on but at the thermostat be left OFF for 24 hours to give the crankcase heater sufficient time to assure that there is no liquid refrigerant in the compressor motor base. - Oversized refrigerant metering device. An over-sized TEV (TXV) dispenses liquid refrigerant into the HVACR low side too rapidly - a problem that may be detected as a "hunting" effect as the valve opens or closes as often as .

Details are at TEV HUNTING DIAGNOSIS

At THERMOSTATIC EXPANSION VALVES we discuss identification, label decoding, and selection of TEVs. - Thermostatic expansion valve (TXV) superheat set too low can cause the hunting effect at the expansion valve that we described above.

At NON-ADJUSTABLE & MANUALLY ADJUSTABLE TEVs we include a description of how to adjust those TXVs that are adjustable.

Also see DEFINITION of SUPERHEAT - Thermostatic expansion valve TXV thermal bulb loose or not thermally tight.

See TEV INSTALLATION DETAILS - A sticking or failed thermostatic expansion valve (or one that is improperly adjusted): Liquid slugging might also occur if a refrigerant metering device is not properly restricting refrigerant flow from the high side to the low side of the refrigerant piping system. Liquid refrigerant may not all turn to gas on the low side of the system - if liquid refrigerant enters the compressor motor it is likely to destroy it

See THERMOSTATIC EXPANSION VALVE TEV STICKING REPAIR - Head pressure too high and/or low pressure too low. Perhaps caused by other conditions such as a blocked condensing or evaporator coil or sticking TEV (TXV)

See REFRIGERANT LOW HEAD PRESSURE DIAGNOSIS - Low evaporator air flow: see

COOLING COIL or EVAPORATOR COIL

DAMAGED COOLING COIL,

DIRTY COOLING COIL / EVAPORATOR COIL

FROST BUILD-UP on AIR CONDITIONER COILS - Refrigerant overcharge - An overcharge of refrigerant in the system can result in liquid refrigerant entering the moving parts of the compressor motor where only a gas is expected.

See details at EFFECTS of OVER CHARGING of REFRIGERANT

also see REFRIGERANT CHARGING PROCEDURE - A crankcase heater that is burned out or that is not being turned on when it should by the system controls (which can also destroy a heat pump compressor that is trying to operate in cold temperatures)

- A crimped liquid refrigerant line

- Buried or underground refrigerant line not properly installed - can cause accumulation of refrigerant in the suction line and floodback damage at the compressor.

See REFRIGERANT TUBING UNDERGROUND, BURIED

Thanks to reader TN Goose for finding the cited reference [2] explaining the effects of thermostatic expansion valves on A/C or heat pump compressor failures.

Signs of refrigerant floodback or liquid flooding include

- Condensate visible on the exterior of the compressor motor

- Noises at the air conditioner or heat pump compressor that sound like clanging, rattling, or rocks rattling around in a metal can or like a metallic clattering. Listen to this BUZZ/RATTLE SOUND, - 600KB MP3 file - possible liquid refrigerant slugging sound occurs about 10 seconds into recording - sound recording .mp3 file that might be due to refrigerant floodback

How to Diagnose Problems with Thermostatic Expansion Valves for Refrigerant Metering

Thermostatic Expansion Valve Troubleshooting & Testing after Installation

After installing a TEV the system must be tested for leaks using dry nitrogen;

The system is then evacuated (a vacuum is drawn on the refrigerant coils and piping to remove gases and contaminants),

The system is charged with proper refrigerant type and amount, the system is turned on and allowed to run until it is in stable operating condition, and then the TEV is checked according to the manufacturer's specifications (such as presence of a liquid seal at the valve and that the suction pressure is in the proper range.)

Technical note about TEVs and refrigerant pressure: TEVs do not maintain pressure on the low side of the refrigeration system. The TEV keeps refrigerant flowing into the cooling coil to keep the superheat level as specified across the cooling coil.

Basic Diagnostic Tests for Thermostatic Expansion Valve TEV TXV Operation

Pressure increase TEV bulb warming test: With the air conditioner or heat pump running and in stable state (it has been on for 5 minutes or longer), remove the sensing bulb from its position on a refrigerant tube or coil and gradually warm the bulb. If system pressure increases the TEV probably needs adjustment.

If the TEV is dispensing too much refrigerant you may see condensation on the suction line or right on the compressor motor case. Details are

at TEV STICKING

Watch out: too much refrigerant metered through the TEV can send liquid refrigerant to the compressor motor, causing liquid slugging that can damage or destroy the compressor.

If the TEV is stuck "open" it must be replaced. We discuss refrigerant flooding and six common causes of liquid refrigerant slugging the compressor

at REFRIGERANT FLOODBACK, LIQUID SLUGGING.

If the TEV is "hunting" or short-cycling you will see pressure vacillating up and down about 10-15 psi on the suction side of the system. This may be caused by a defective TEV if it's original equipment, or by an over-sized TEV installed by the guy who was there before you.

Details are at TEV HUNTING DIAGNOSIS

If the TEV is whistling or shrieking refrigerant is low and there's a leak, as we discuss

When re-installing the TEV be sure that it is properly placed at the 4 O'Clock position on the piping as we discuss

Incorrect Super Heat & TXV Malfunctions due to Rust Inhibitor

Comfort Products Corporation has provided the following dealer service bulletin from which we excerpt:

This service bulletin pertains to certain residential split system air conditioner or heat pump units manufactured under these brands: Bryant, Carrier, Payne. Serial Number(s): 4413X - 3814X, 4413E - 3814E. The specific models affected are listed in the document we give below.

Ongoing testing and reports from the field indicate that Thermostatic Expansion Valves (TXV) in 1.5, 2 and 2.5 ton indoor coils installed with the above listed condensing units may not maintain the correct SuperHeat (SH) in certain situations.

The end result is a lack of cooling for the homeowner due to high SH and low suction pressures measured at the outdoor unit. Carrier has identified the substance that is causing improper TXV operation by restricting the flow of refrigerant through the system.

Internal and field testing has confirmed that this issue is not caused by the TXV or indoor coil. The TXV metering device is acting as a filter by collecting a substance used in one of the condensing unit’s components.

Through significant research and testing, Carrier found the cause to be an unauthorized change to a rust inhibitor used by a supplier. The previous rust inhibitor has since been re-introduced to correct this issue in new systems being manufactured going forward.

The affected component is used by the majority of HVAC Original Equipment Manufacturers (OEMs) and has impacted much of the industry.

Carrier has thoroughly tested a system additive that has proven to be effective without compromising long term system reliability. This additive will be the solution for systems exhibiting high SH during operation.

- DEALER SERVICE BULLETIN 14-0012 (2014) Title: 1.5, 2, and 2.5 Ton Condensing Units Causing Incorrect Super Heat for TXVs in Residential Split Systems [PDF], Comfort Products Distributingh, Website: https://comfortproducts.com, retrieved 2018/03/12, original source: http://comfortproducts.com/wp-content/uploads/DSB14-0012-additive1.pdf

Whistling Thermostatic Expansion Valves (TEVs)

On refrigeration systems that include a liquid refrigerant receiver and as long as there is adequate level of refrigerant in the system and the TEV is working, the refrigerant charge amount is not absolutely critical.

On refrigeration systems that include a liquid refrigerant receiver and as long as there is adequate level of refrigerant in the system and the TEV is working, the refrigerant charge amount is not absolutely critical.

But on any refrigeration system, receiver or no, if the refrigerant charge gets too low (there is a refrigerant leak somewhere) then refrigerant gas cycles up through the TEV rather than liquid refrigerant.

The result is that the TEV will begin to run "wide open" and it will often make a loud whistling sound. A whistling TEV means low refrigerant.

Relationship between TEVs and Compressor/Condenser motors

When a TEV is installed on refrigeration equipment we need a heavier (more powerful) compressor motor since the compressor has to start against a head pressure.

Why? In a system using a cap tube there is no device that closes down the complete refrigerant piping between the low and high sides of the system, just an orifice that restricts the flow rate.

But where a TEV is installed, the device can close completely, leaving a pressure difference between the high and low sides even when the system has stopped running.

So a hard-starting compressor that is at or near end of life (or has a bad start/run capacitor or is at low voltage) may have a harder time starting against head pressure on a system that uses a thermostatic expansion valve (TEV or AEV) to regulate refrigerant flow.

TEVs and long evaporator coils

On systems that use a long evaporator coil, and equalizer may be used to offset the large pressure drop that occurs across the long evaporator coil. This added feature assures that pressure in the valve and at the end of the condenser are equal so that just superheat (and not the pressure drop) operates the TEV.

TEV Sensor element leak problems

Perhaps the main problem that occurs with TEVs is that the valve stops working due to loss of refrigerant in its sensing device. the Thermostatic Expansion Valve sensor element along with its small diameter tubing is a closed system that contains a refrigerant too - the same refrigerant as that used in the system for which the TEV is designed.

We use the same refrigerant inside the sensor because we want the sensor to respond to temperature changes at the same rate as the refrigerant in the actual system.

That is, we want the pressure exerted by the sensor into the TEV top to be equal to the pressure exerted by the refrigerant inside the valve when both are at the same temperature.

Else the system won't operate properly. But on occasion you may get a leak in the TEV sensor bulb or its tubing - the TEV will stop working.

To test a thermostatic expansion valve (TEV) for a leak, that is for loss of refrigerant from its sensor bulb and tubing, take the bulb off of the cooling coil and just hold it in your hand. The warmth of your hand should be more than enough to cause the sensor to open the TEV and begin refrigerant flowing through the cooling coil.

Sticking TEV valves

The TEV and also AEVs depend on a little oil or oil mist flowing along with refrigerant to lubricate the interior of the valve. But we suspect that a more common cause of TEV valve sticking is the freezing of a droplet of water at the needle valve, holding it stuck. The valve stops working properly.

We have had field reports of sticking thermostatic expansion valves on some newly-installed residential air conditioners such as the KeepRite® brand discussed at TEV STICKING REPAIR

Sticking TEVs are discussed in detail

at THERMOSTATIC EXPANSION VALVE TEV STICKING REPAIR

To test a thermostatic expansion valve (TEV) for freeze-up, try warming up the valve to see if it starts working again, or let the valve warm up by leaving the system turned off for half an hour or so.

Debris in the refrigeration tubing can also clog and cause sticking of the needle seat in a TEV. If the TEV can be disassembled and cleaned this step may correct that problem but you'll also want to install a new dryer/filter on the system refrigerant piping if there are debris problems in the system.

Capillary Tube problems: see our separate article detailing the inspection, installation, and repair or replacement

Watch out: water or dirt in the refrigerant piping system can cause serious and costly problems in the TEV or cap tube that impact the entire refrigeration system.

TEV Thermostatic Expansion Valve Head Temperature

Because differences in temperature in and around the cooling equipment can affect the TEV's operation, in commercial cooling installations the Thermostatic Expansion Valve has to be placed where its sensor, usually located in the top or "head" of the TEV, will be warmer than the thermal bulb which controls the device.

Otherwise liquid refrigerant may be improperly discharged by the valve.

TEV size selection

Thermostatic expansion valves are rated in tons of refrigeration capacity based on the size of the metering orifice in the device. The TEV (or AEV) must be matched to the capacity of the cooling system (actually the coil) and to the specific refrigerant used, since at any given temperature different refrigerants will exert different pressures in the system.

In fact we can sometimes spot the installation of the wrong TEV on an air conditioner or heat pump system by its behavior: if someone installs an R22 valve on an R12 refrigeration system, the higher pressure of the R22 will hold the TEV always open!

at THERMOSTATIC EXPANSION VALVES we discuss identification, label decoding, and selection of TEVs and there we include installation instructions for TEVs.

HVACR Thermostatic Expansion Valves - TEVs: this air conditioning repair article series explains the function and installation of all types of refrigerant metering devices, beginning with the most-common thermostatic expansion valve or TEV (or thermal expansion valve) that controls release of refrigerant into the evaporator coil of an air conditioning or heat pump system.

Troubleshoot Problems with Thermostatic Expansion Valves

- TEV Thermostatic Expansion Valve problems: see THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR where we also address AEVs, float valves, manual and automatic expansion valves, etc.

- Capillary Tube problems: see our separate article detailing the inspection, installation, and repair or replacement

of CAPILLARY TUBES - Other AC diagnostic articles that may assist:

- At REFRIGERANT HIGH HEAD PRESSURE DIAGNOSIS we explain how a malfunctioning TXV (aka TEV) can cause high HVACR compressor head pressures and system damage.

- At REFRIGERANT FLOODBACK, LIQUID SLUGGING we explain how liquid refrigerant entering a heat pump or air conditioner compressor motor can destroy it and we discuss the recommended time that the system should be LEFT OFF if was switched off while it was running

- At OPERATING DEFECTS we take you through the major air conditioning problem symptoms and how to get the air conditioning system working again.

- At a companion article, LOST COOLING CAPACITY, our focus is on the case in which the air conditioning system seems to be "running" but not enough cool air, or no cool air at all is being delivered to the occupied space.

- We also provide a separate article detailing the inspection, installation, and repair or replacement of CAPILLARY TUBES.

- Also see FROST BUILD-UP on AIR CONDITIONER COILS

- See REFRIGERANT LEAK DETECTION where we describe the effects of dirt and moisture on TEVs and capillary tubes. A quick test for a moisture/ice jammed TEV is to add some heat to see if the device will begin working again.

- REFRIGERANT PRESSURE READINGS & CHARTS - home

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2019-12-17 - by (mod) -

Mark

"noise that sounds like someone is knocking on the water pipes with a wrench" if it's from the heat pump is NOT something to ignore as it sounds as if there is a motor having trouble running, possibly liquid slugging at the compressor - that will destroy it. You need an onsite service tech.

On 2019-12-17 by mark sterling

Question about a 6 month old heat pump. My last compressor went out in May 2019, kept overloading circuit. Local HVAC guy who was one who installed original heat pump 20 years ago recommended new system and air handler to increase and update efficiency. System worked great until Heat Pump changed to heating mode.

So he installed a Trane 18 Seer.. I believe the model is an XI..

System is still operating fine except a couple of times a day there is a noise that sounds like someone is knocking on the water pipes with a wrench. It is most noticeable in early morning hours around 2 AM since the compressor sits on the other side of the wall from my head when sleeping. However, I still hear it once in awhile during the day.

I only lasts till after start up of the Heat Pump.. about 15 seconds or so. The service guy came out and ran all the tests and restarted system a couple of times and could not duplicate problem. He asked me to try to capture the sound with a recording. To help him identify its source.

I fully understand that but not sure how I can do it unless I sit with a recorder outside next to the unit in the cold weather and wait for the sounds.. What do you think is my best solution? I was considering just waiting till it goes out completely but with my luck it will be negative 30 Degrees outdoors. Or it will never go our and I will have to put up with getting woke up every day at 2 AM..

On 2019-09-27 - by (mod) -

Thanks so much for the nice comment micro. We work hard to provide researched unbiased useful information, so I am really grateful when a reader finds our articles useful.

On 2019-09-27 by micronman

great article. thank you

On 2019-04-08 - by (mod) -

Most likely a sticking TEV

On 2019-04-08 by Anonymous

What's the main reason for having ustable pressure reading both in low side and high side..

On 2015-06-22 by Anonymous

awsome

...

Continue reading at THERMOSTATIC EXPANSION VALVE TEV STICKING REPAIR, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CAPILLARY TUBES

- CONTROLS & SWITCHES, A/C - HEAT PUMP

- DEFINITION of SENSIBLE HEAT

- DEFINITION of SUBCOOLING

- DEFINITION of SUPERHEAT

- HVACR OPERATING DEFECTS air conditioning / heat pump problem symptoms & how to get the air conditioning system working

- LOST COOLING CAPACITY - air conditioning "running" but not enough cool air, or no cool air

- PRESSURE CONTROLS & SAFETY SWITCHES - home

- REFRIGERANT FLOODBACK, LIQUID SLUGGING - possible result of a failed thermostatic expansion valve.

- REFRIGERANT LEAK DETECTION effects of dirt and moisture on TEVs and capillary tubes. .

- REFRIGERANT METERING CAPILLARY TUBES

- REFRIGERANT PRESSURE READINGS & CHARTS - home

- THERMOSTATIC EXPANSION VALVES - home

- THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR

- THERMOSTATIC EXPANSION VALVE TEV STICKING REPAIR

Suggested citation for this web page

THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about refrigeration controls: TEVs, AEVs, Capillary Tubes, Float Valves, & Other Refrigerant Controls

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] "Thermostatic Expansion Valve Installation Instructions", Singer Controls Division, Schiller Park IL, 1979 parts brochure

- [2] Christopherson, Norm, "Preventing Premature Compressor Failures, An Ounce of Prevention for Years of Service", web search & reader TN Goose referral, 08/12/2011, original source: http://www.hvacfun.com/a-once-prevent-years-service-comps.htm

- Danfoss Thermostatic Exansion Valves, Type TE / TE2, Danfoss Refrigeration & Air COnditioning Division, Danfoss Ltd., Oxford Rd., Denham, Bucks UB9 4LH, UK, Tel: 0879 241 7041, Email: uk.refrigeration.sales@danfoss.com Website: www.danfoss.co.uk - retrieved 8/31/2014, original source op cit.

- Danfoss Thermostatic Expansion Valves, Fitters Notes, RZ1AH202 → DKRCC.PF.A00.A1.02 / 520H0337, Danfoss A/S (2005),

- Sporlan Thermostatic Expansion Valves Identification [Guide], Bulletin 210-60 (1994), Danfoss Refrigeration & Air COnditioning Division, Danfoss Ltd., Oxford Rd., Denham, Bucks UB9 4LH, UK, Tel: 0879 241 7041, Email: uk.refrigeration.sales@danfoss.com Website: www.danfoss.co.uk - retrieved 8/31/2014, original source op cit.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Complete List of Air Conditioning & Heat Pump Design, Inspection, Repair Books at the InspectAPedia Bookstore.

- Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- Refrigeration and Air Conditioning Technology, 5th Ed., William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.