Clay Tile Roof Flashing Details

Clay Tile Roof Flashing Details

Clay tile roof flashing in valleys & at walls

- POST a QUESTION or COMMENT about clay tile roof flashing

Flashing details for clay tile roofs:

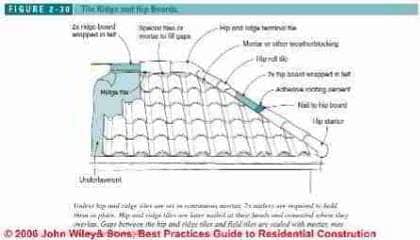

This article describes the special connection methods used seal or close the ridge, hip, and rake sections of clay tile roofs.

Because of the longevity of a tile roof, high-quality flashing materials should be used. The International Residential Code calls for a minimum 26-gauge metal. Galvanized steel should have a minimum of 0.90 ounces of zinc per square foot (G90 sheet metal).

More expensive options include prepainted galvanized steel or 16-ounce sheet copper.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Flashing Requirements on Tile Roofs

This article series discusses best practices in the selection and installation of residential roofing. This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

This article series discusses best practices in the selection and installation of residential roofing. This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

[Click to enlarge any image]

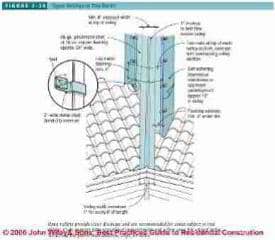

Tile Roof Details Recommended at Openings and Walls

At walls, dormers, chimneys, and other vertical surfaces, extend the flashing up at least 6 inches and counterflash.

Extend the clay tile flashing under the tile a minimum of 6 inches or as specified by the tile manufacturer.

With flat style clay shingles, use step flashing with a minimum 6-inch vertical leg and 5-inch horizontal leg with a hemmed edge.

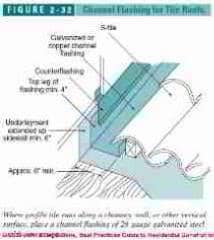

Profile style clay tiles along a wall should receive channel flashing turned up at least one inch on the lower flange (Figure 2-32 shown at left).

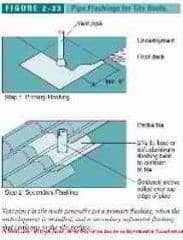

Pipe Flashing Requirements on Tile Roofs

Pipe flashings protruding through a clay tile roof generally get both a primary flashing when the underlayment is installed and a secondary soft-metal underlayment that conforms to the tile.

For profile style clay roofing tiles, this can be 2 1/2 -pound lead or dead-soft aluminum with an 18-inch-wide skirt (Figure 2-33 shown here).

Valley Details for Tile Roofs

According to the International Residential Code (IRC), valley flashing in tile roofs should extend at least 11 inches each way from the valley centerline, and the flashing should have a formed splash diverter at the center at least one inch high.

The code requires a minimum underlayment at the valley of 36-inch-wide Type I No. 30 felt in addition to the underlayment for the general roof areas.

In cold climates (average January temperature of 25°F or less), a self-adhering bituminous underlayment is recommended. Battens, if used, should stop short of the valley metal.

Tiles along the valley edge may be laid first and cut in place along a chalked line. Cut pieces are attached by roofing cement or a code-approved adhesive, or they may use wire ties, tile clips, or batten extenders.

Open Valley Details on Tile Roofs

Open clay tile roof valleys on clay or other tile roofs permit free drainage and are recommended in areas where leaves, pine needles, and other debris are likely to fall on the roof.

[Click to enlarge any image]

The open valley on the New York clay tile roof shown above has been patched more than once.

They are also recommended in areas subject to snow and ice buildup.

Above our photo of an open valley on a clay tile roof demonstrates how a snow guard can block drainage of a roof valley, leading to debris clogging.

[Click to enlarge any image]

The valley flashing for a tile roof should have hemmed edges and be installed with cleats that allow individual sections to expand and contract (Figure 2-34).

Closed Valley Details on Tile Roofs

In this type of valley, the flashing carries the runoff and the tile in the valley is only decorative. These are not recommended where debris from trees may fall on the roof or where the two roof planes joining at the valley have different pitches or length, causing uneven flows.

Our photograph of a closed tile roof valley (above) was taken at a home in Surprise, Arizona, in an area where there were few trees or any other leafy plants.

Foot Traffic Advice for Walking on Clay Tile Roofs

To prevent breakage, walk on tiles with extreme caution.

Profile tile and lightweight tile are the most vulnerable, and concrete tiles are more fragile when they are freshly manufactured or “green.” If possible, place antennas and other roof-mounted equipment where it is easy to access without crossing many tiles.

When it is necessary to walk on tiles, step only on the head-lap (lower 3 inches) of each tile.

With Mission- or S-tiles, it is best to step across two tiles at once to distribute the weight. When significant rooftop work is required, place plywood over the tile to distribute the load.

Watch out: our own experience is that it is absolutely impossible to walk on many clay tile roofs without damaging them, particularly soft clay such as the roof type used in Latin America (our photo at left).

For these roofs contractors have to remove sufficient clay tiles to provide a walking area. The removed tiles are replaced as the worker is leaving the work area of the roof.

On some other fragile but not totally fragile roofs such as slate roofs, cement tile, cement-asbestos, fiber cement, and hard-fired ceramic clay tile roofs, contractors suspend a ladder over the roof surface, hanging it from the ridge, and cushioning it off of the roof surface using foam or insulation padding, or contractors work from scaffolding. - Ed.

See ROOF INSPECTION SAFETY & LIMITS where we describe roof safety and roof damage issues when inspecting, repairing, or otherwise walking on clay tiles as well as other roof materials such as asphalt, slate, and wood roofs.

Tips for Replacing Broken Roof Tiles - You'll Need These if You Walk on a Tile Roof

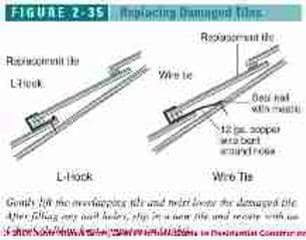

If a roofing tile is cracked, gently lift the overlapping tile and wiggle loose the damaged tile.

Remove the roof tile nail, screw, or clip with a slate ripper or hacksaw blade.

Seal any nail holes with roofing cement and slip a new tile into place, securing the butt end with an L-hook or bent copper wire (as shown in Figure 2-35).

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Clay & Concrete Tile Roof Installation Guides

- Boral Roofing, CONCRETE & CLAY ROOF TILE VALLEY FLASHING INSTALLATION, RIBBED [PDF] (2016) Boral Roofing, Website: www.BoralRoofComponents.com Tel: 1-800-669-TILE, retrieved 2020/02/26, original source: https://www.boralroof.com/wp-content/uploads/boral-resource/Ribbed-Valley-Metal-Installation.pdf

- FRSA, CONCRETE & CLAY

ROOF TILE INSTALLATION MANUAL [PDF] (2001) Florida Roofing, Sheet Metal and Air Conditioning Contractors Association, Inc., retrieved 2020/02/26 original source: https://www.eagleroofing.com/installation_guides/FRSAInstallationManual.pdf

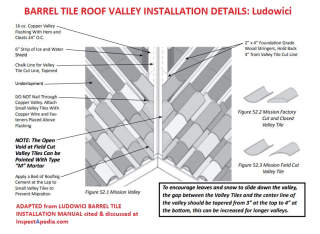

Concrete or Clay tile roof valleys are discussed in Part III - Execution, Section 3.04 as well as in subsequent sections. - Ludowici, BARREL TILE INSTALLATION MANUAL [PDF] (2015) Ludowici Roof Tile, Inc., 4757 Tile Plant Rd. P.O. Box 69 New Lexington, OH 43764 USA, Tel: 1-800-945-8453 Website: www.Ludowici.com retrieved 2020/02.26 original source: https://www.ludowici.com/wp-content/uploads/LRT-435-Ludowici-Barrel-Tile-Installation-Manual-0617-1.pdf

- See CLAY TILE ROOFING - home - for more clay and concrete tile roof installation guides, standards, suppliers, association

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-02-26 - by (mod) -

Anon:

Anon:

Clay and concrete tile roofing guides (documents provided in this article series) discuss open and closed valley designs and underlayments extensively but I don't generally see attention to the cosmetic detail of how the abutting valley tiles are trimmed to fit neatly.

Illustration adapted from Ludowici cited above. [Click to enlarge any image]

Key is a reliance on the valley flashing to avoid roof leaks, leaving the tile abutments at the valley as a cosmetic details

except

as I suggested earlier, that if the valley underlayment is a membrane rather than metal, exposure to sunlight may reduce its life.

Boral Roofing provides that company's guide to valley installation at

VALLEY FLASHING INSTALLATION, RIBBED [PDF] (2016) Boral Roofing, retrieved 2020/02/26, original source: www.boralroof.com/wp-content/uploads/boral-resource/Ribbed-Valley-Metal-Installation.pdf

Excerpt: A closed or open valley is optional, but should be dictated by site

conditions. A closed valley is created when the roof tiles are cut close to

the center of the valley. An open valley has a 4-8-inch wide open trough

down the center of the Ribbed Valley Metal, created when the roof tiles are

cut 2-4-inches from the center of the valley on each side. In areas subject

to snow or ice damming, open valleys should be cut in a taper to widen

toward the down-slope with a minimum 1/8-inch per foot.

Ludowici roofing, in the company's barrel tile installation manual cited above, describes open tile roof valleys and cites "mission field cut valley tiles" suggesting that the roofer needs a tile saw to make appropriate cuts to bring the diagonal end of the valley tiles sufficiently and uniformly close to the valley center.

The company also notes that the field-cut valley tiles can be pointed with mortar. - Illustration below excerpted and adapted from Ludowici cited above.

On 2020-02-25 18 by Anonymous - closed valley for Boral roof tiles?

is there any step by step installation guidelines of how to install a closed valley (boral tiles)?

Michael

If we can see valley underlayment then it's not a successfully-built "closed valley".

**IF** the valley liner is sufficiently durable, waterproof, wide, and properly installed such that it's not going to be damaged by sun and weather exposure, what remains might be a cosmetic issues.

On 2020-02-22 by Michael

in a closed valley installation should the tiles be aligned at center of the valley? High point of one tile meeting with the high point of the another tile or not?

We have openings at the middle line ( valley) because tiles are not meeting high end with high and low end with low end.

On 2020-01-08 by danjoefriedman (mod) - contractor required to repair flashing not installed according to manufacturer's specifications

Lothar that detail is not provided in any building code that I've seen.

I don't think we can rely on "code compliance" for ever good construction practice detail. The code writers know this, which is why you'll often also see ".... must be installed according to the manufacturer's specifications"

See flashing details for clay tile roofs

at FLASHING, CLAY TILE ROOFS

Arizona provides these

- WORKMANSHIP STANDARDS for LICENSED CONTRACTORS [PDF] Airizona Registrar of Contractors, MAIN OFFICE

1700 W. Washington St. Ste. 105

Phoenix, AZ 85007-2812 USA, Tel:

(602) 542-1525

TDD (602) 542-1588 - original source: https://roc.az.gov/sites/default/files/files/minimum_industry_standards.pdf

There you will see an example of my point, where "

"AT" = acceptable tolerance

"PD" = "Possible Deficiency"

"CR" = Contractor Responsibility

10. PD Improper or inadequate flashing.

AT Flashings should be installed according to manufacturer's recommendations and should be an approved type.

CR Contractor should make necessary repairs.

and Scottsdale provides this little

- CITIZEN'S GUIDE to RE-ROOFING YOUR HOME [PDF] - City of Scottsdale Arizona Government, 3939 N. Drinkwater Blvd.

Scottsdale, AZ 85251

USA Tel: 480-312-3111

TTY: 1-800-367-8939 (Arizona Relay Service), retrieved 2020/01/08 and de-novo 2022/09/26, original source: https://www.scottsdaleaz.gov/Assets/ScottsdaleAZ/Building/Re-RoofingHandout.pdf

You'll see that the flashing detail in your photo is not addressed.

However if you search InspectApedia.com for ROOF VALLEY FLASHING you'll see details about that topic.

On 2020-01-07 by Lothar Martin

how far have valley metals to extend past the roofline in arizona?

I would like to have the protruding valley trimmed back to roof line, but the roofer says that would be against code.

What is the right answer?

This clay tile roof flashing question was posted originally

at ROOF FLASHING, ASPHALT SHINGLE VALLEYS

On 2019-10-04 - by (mod) -

Siu

Please post questions just once on one page - we have many readers to whom we want to respond

https://inspectapedia.com/BestPractices/Best_Roofing_Underlayment.php

On 2019-09-29 by Siu

Mission tile roof with steep slope

Contractor is to re-roof and reset the entire

Question:

Is it ok / effective that the contractor only to remove existing underlayment as needed but will install APOC base (CX-L Crossover Hybrid Roof Underlayment) using plastic cap nails to entire roof field

Thank you

On 2018-07-23 - by (mod) -

Roof.

You always want to dry in first on a building before putting on the interior wall finishes - almost any material otherwise you risk water damage to the wall coming through the interior when it rains.

So you need the roof to have been installed and it's best also to have a working gutter system sufficiently that you can keep rain splash from falling off the roof and onto your siding while the work is being done.

On 2018-07-22 by pat

What should be done first? I have a small addition. Installing the roof over the new addition OR doing the outside stucco work?

On 2017-08-01 - by (mod) -

Bruce

Sorry but I'm not sure what you mean by horizontal roof projections.

However you might be able to get the exit venting you need by construction of appropriately located dormers on the roof that are sized and fitted to serve as exit vents.

On 2017-07-31 by Bruce youngman

I need to put in large roof vents to accommodate a full house fan. I have a clay tile roof is there any flashing available to work with horizontal roof protrusions?

On 2017-02-15 - by (mod) - sealant around plumbing vents?

Mike

I would never rely on a sealant to seal vent pipes protruding through a tile roof, as temperature and other weather changes ultimately lead to nasty leaks at the penetration.

I would find, buy, or fabricate appropriate vent stack flashing (that combines metal flashing shaped to fit the tiles and a rubber boot that seals around the vent pipe) that intercepts water and directs it out onto the tiles below the vent.

That said, silicone sealant is durable and bonds well to most clean dry materials.On 2017-02-14 2 by Mike

What sealant do I use around vent pipes on tile roof

...

Continue reading at CLAY TILE ROOF FLASHING LEAKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CLAY TILE ROOF FLASHING

- CLAY TILE ROOF FLASHING LEAKS

- CLAY TILE ROOFING - home

- CLAY TILE ROOF SPECIFICATIONS

- FLASHING on BUILDINGS - home

Suggested citation for this web page

CLAY TILE ROOF FLASHING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Questions & answers or comments about clay tile roof flashing.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ARMA - Asphalt Roofing Manufacturer's Association - Asphalt Roofing Manufacturer's Association - https://www.asphaltroofing.org/

750 National Press Building

529 14th Street, NW

Washington, DC 20045

Tel: 202 / 207-0917 Fax: 202 / 223-9741 - "Design for Long-Lasting Tile Roof Systems", Thomas L.Smith, AIA, CRC, PRofessional Roofing, [ca 1998 Date pending], p. 54

- ASTMASTM - ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, 19428-2959 USA The ASTM standards listed below can be purchased in fulltext directly from http://www.astm.org/

- NRCA - National Roofing Contractors Association - Website: www.nrca.net 10255 W. Higgins Road, Suite 600, Rosemont, IL 60018-5607, Tel: (847) 299-9070 Fax: (847) 299-1183

- UL - Underwriters Laboratories - https://www.ul.com/

2600 N.W. Lake Rd.

Camas, WA 98607-8542

Tel: 1.877.854.3577 / Fax: 1.360.817.6278 E-mail: cec.us@us.ul.com - Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Architectural elements: the technological revolution: Galvanized iron roof plates and corrugated sheets; cast iron facades, columns, door and window caps, ... (American historical catalog collection), Diana S Waite, available used out of Amazon.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Built-Up Roof Systems, Manual C.W. Griffin, Mcgraw-Hill (Tx); 2nd edition (July 1982), ISBN-10: 0070247838, ISBN-13: 978-0070247833

- Concrete Folded Plate Roofs, C. Wilby PhD BSc CEng FICE FIStructE (Author), Butterworth-Heinemann, 1998, ISBN-10: 0340662662, ISBN-13: 978-0340662663

- Concrete Shell Roofs, C. Wilby PhD BSc CEng FICE FIStructE (Author),

- Concrete Dome Roofs (Longman Concrete Design and Construction Series),

- Concrete Roofing Tile, History of the, Batsford, 1959, AISN B000HLLOUC (availble used)

- Copper Roofing, by CDA

- Copper Roofing, Master specifications for copper roofing and sheet metal work in building construction: Institutional, commercial, industrial, I.E. Anderson, 1961 (hard to find)

- Corrugated Iron, Building on the Frontier, Simon Holloway

- Green Roof Plants: A Resource and Planting Guide, Edmund C. Snodgrass, Lucie L. Snodgrass, Timber Press, Incorporated, 2006, ISBN-10: 0881927872, ISBN-13: 978-0881927870. The text covers moisture needs, heat tolerance, hardiness, bloom color, foliage characteristics, and height of 350 species and cultivars.

- Green Roof Construction and Maintenance, Kelley Luckett, McGraw-Hill Professional, 2009, ISBN-10: 007160880X, ISBN-13: 978-0071608800, quoting: Key questions to ask at each stage of the green building process Tested tips and techniques for successful structural design Construction methods for new and existing buildings Information on insulation, drainage, detailing, irrigation, and plant selection Details on optimal soil formulation Illustrations featuring various stages of construction Best practices for green roof maintenance A survey of environmental benefits, including evapo-transpiration, storm-water management, habitat restoration, and improvement of air quality Tips on the LEED design and certification process Considerations for assessing return on investment Color photographs of successfully installed green roofs Useful checklists, tables, and charts

- Handbook of Building Crafts in Conservation, Jack Bower, Ed., Van Nostrand Reinhold Company, NY 1981 ISBN 0-442-2135-3 Library of Congress Catalog Card Nr. 81-50643.

- Historic Preservation Technology: A Primer, Robert A. Young, Wiley (March 21, 2008) ISBN-10: 0471788368 ISBN-13: 978-0471788362

- Historic Slate Roofs : With How-to Info and Specifications, Tina Skinner (Ed), Schiffer Publishing, 2008, ISBN-10: 0764330012 , ISBN-13: 978-0764330018

- Low Slope Roofing, Manual of, 4th Ed., C.W. Griffin, Richard Fricklas,

McGraw-Hill Professional; 4 edition, 2006, ISBN-10: 007145828X, ISBN-13: 978-0071458283

- Roof failure causes in depth (and specific methods for avoiding them)

- Roof design fundamentals and flourishes, based on voluminous industry research and experience

- New technologies and materials -- using them safely and correctly

- Comprehensive coverage of all major roofing systems pecifications, inspection, and maintenance tools for roofing work

- Metal Roofing, an Illustrated Guide, R.A. Knowlton , [metal shingle roofs],

- Patio Roofs, how to build, Sunset Books

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- Slate Roofs, National Slate Association, 1926, reprinted 1977 by Vermont Structural Slate Co., Inc., Fair Haven, VT 05743, 802-265-4933/34. (We recommend this book if you can find it. It has gone in and out of print on occasion.)

- Roof Tiling & Slating, a Practical Guide, Kevin Taylor, Crowood Press (2008), ISBN 978-1847970237,

If you have never fixed a roof tile or slate before but have wondered how to go about repairing or replacing them, then this is the book for you. Many of the technical books about roof tiling and slating are rather vague and conveniently ignore some of the trickier problems and how they can be resolved. In Roof Tiling and Slating, the author rejects this cautious approach. Kevin Taylor uses both his extensive knowledge of the trade and his ability to explain the subject in easily understandable terms, to demonstrate how to carry out the work safely to a high standard, using tried and tested methods.

This clay roof tile guide considers the various types of tiles, slates, and roofing materials on the market as well as their uses, how to estimate the required quantities, and where to buy them. It also discusses how to check and assess a roof and how to identify and rectify problems; describes how to efficiently "set out" roofs from small, simple jobs to larger and more complicated projects, thus making the work quicker, simpler, and neater; examines the correct and the incorrect ways of installing background materials such as underlay, battens, and valley liners; explains how to install interlocking tiles, plain tiles, and artificial and natural slates; covers both modern and traditional methods and skills, including cutting materials by hand without the assistance of power tools; and provides invaluable guidance on repairs and maintenance issues, and highlights common mistakes and how they can be avoided. The author, Kevin Taylor, works for the National Federation of Roofing Contractors as a technical manager presenting technical advice and providing education and training for young roofers. - The Slate Roof Bible, Joseph Jenkins, www.jenkinsslate.com, 143 Forest Lane, PO Box 607, Grove City, PA 16127 - 866-641-7141 (We recommend this book).

- Slate Roofing in Canada (Studi4es in archaeology, architecture, and history),

- Smart Guide: Roofing: Step-by-Step Projects, Creative Homeowner (Ed), 2004, ISBN-10: 1580111491, ISBN-13: 978-1580111492

- Solar heating, radiative cooling and thermal movement: Their effects on built-up roofing (United States. National Bureau of Standards. Technical note), William C Cullen, Superintendent of Documents, U.S. Govt. Print. Off (1963), ASIN: B0007FTV2Q

- Tile Roofs of Alfred: A Clay Tradition in Alfred NY

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.